Shield tunnel segment variable thickness steel ring

A shield tunnel segment and variable thickness technology, which is applied in the field of geotechnical engineering, can solve the problem of determining the appropriate thickness of the steel ring without the force characteristics of the tunnel segment, the slipping and peeling of the segment and the steel ring, and the lack of targeted reinforcement and other issues to achieve the effect of reducing construction costs, saving construction costs and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

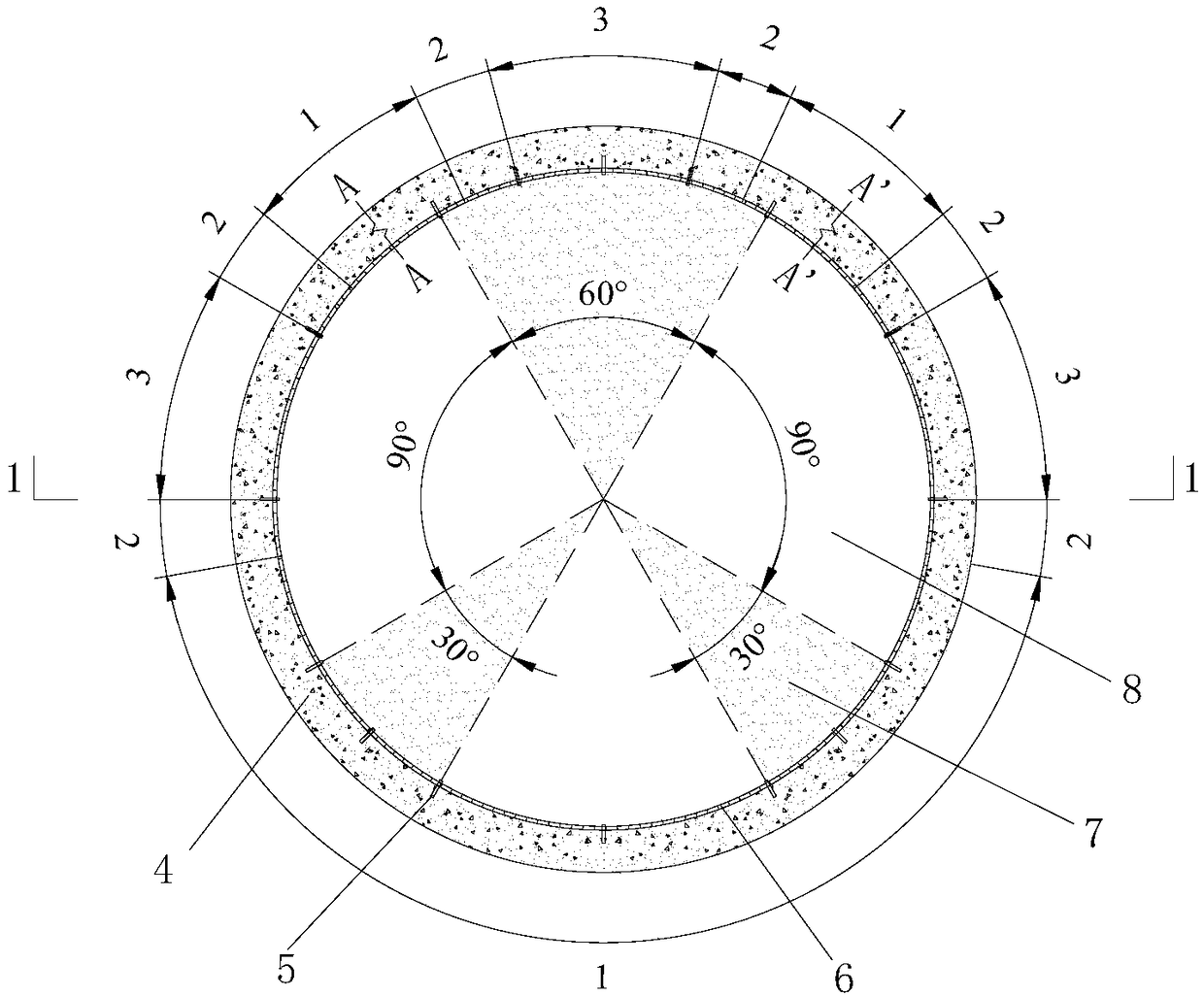

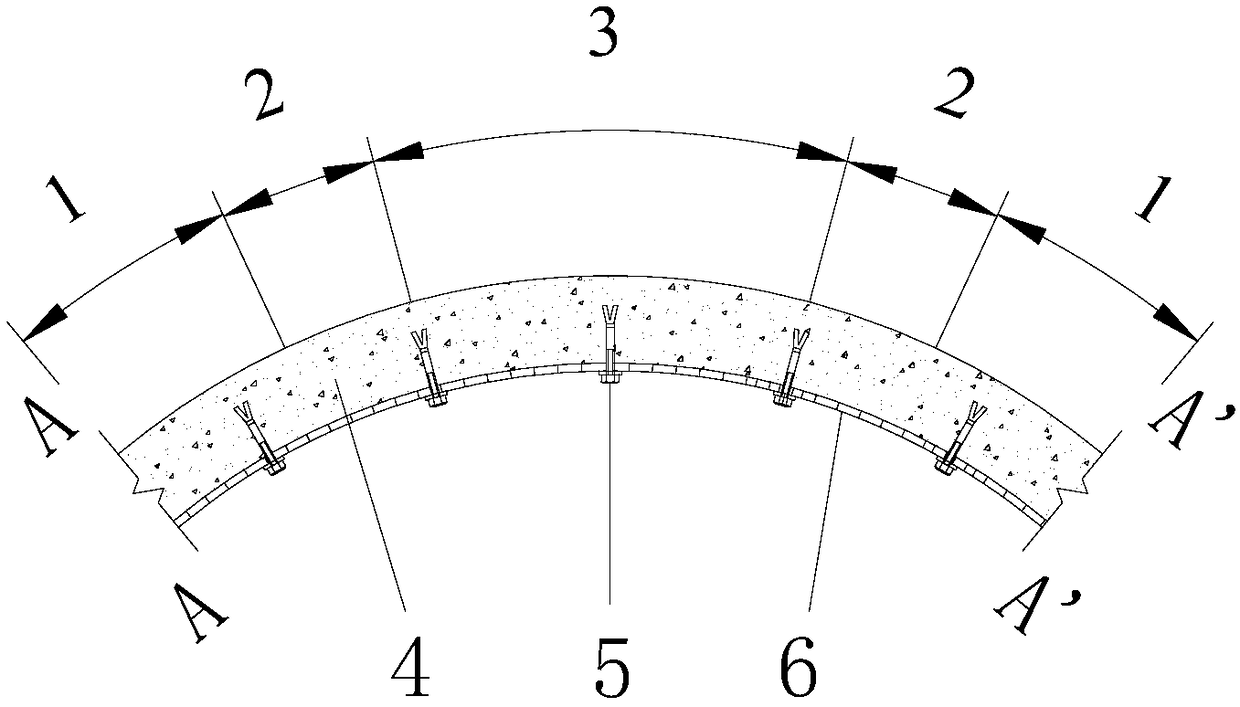

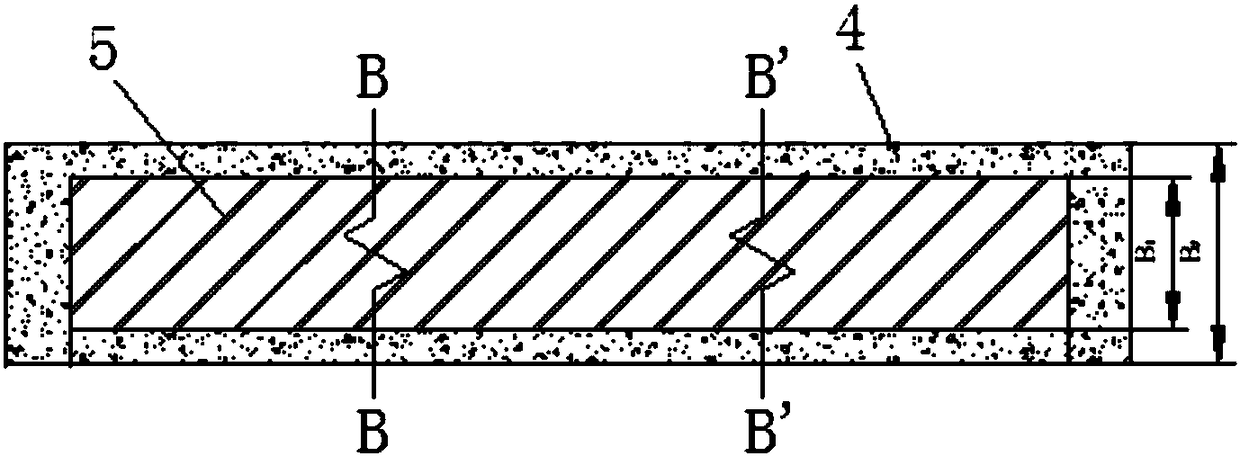

[0027] A steel ring with variable thickness of a shield tunnel segment, which is spliced by steel plates, and its structure is as follows figure 1 As shown in Fig. 1, the urban rail transit shield tunnel in a soft soil layer is reinforced with steel rings of variable thickness. The outer diameter of the tunnel segment 4 is 6.2m, the inner diameter is 5.5m, the thickness of the segment is 350mm, and the width of the segment is B 2 It is 1200mm. Combined with the geological and hydrogeological conditions along the tunnel, the steel ring reinforcement layout is designed. Segment 345°~15°, 60°~90° and 270°~300° are special zone 3, the steel ring thickness of special zone 3 is 30mm; the range of 10° on both sides of special zone 3 is gradient zone 2, and the rest is reinforced The range is normal zone 1. The thickness of the steel ring in common zone 1 is 15mm. Each special area 3 and the gradient area 2 on both sides are made of the same steel plate, with no seam in the midd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com