Ceramic-able room-temperature vulcanized organic silicone sealant capable of retarding flame and inhibiting smoke and preparation method thereof

A room temperature vulcanization and ceramicization technology, which is applied in the direction of adhesives, inorganic adhesives, non-polymer adhesive additives, etc., can solve the problems of glass curtain wall falling off, chemical reaction, and inability to form a firm bonding interface. Achieve the effects of preventing large-scale peeling, low smoke density, and reducing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

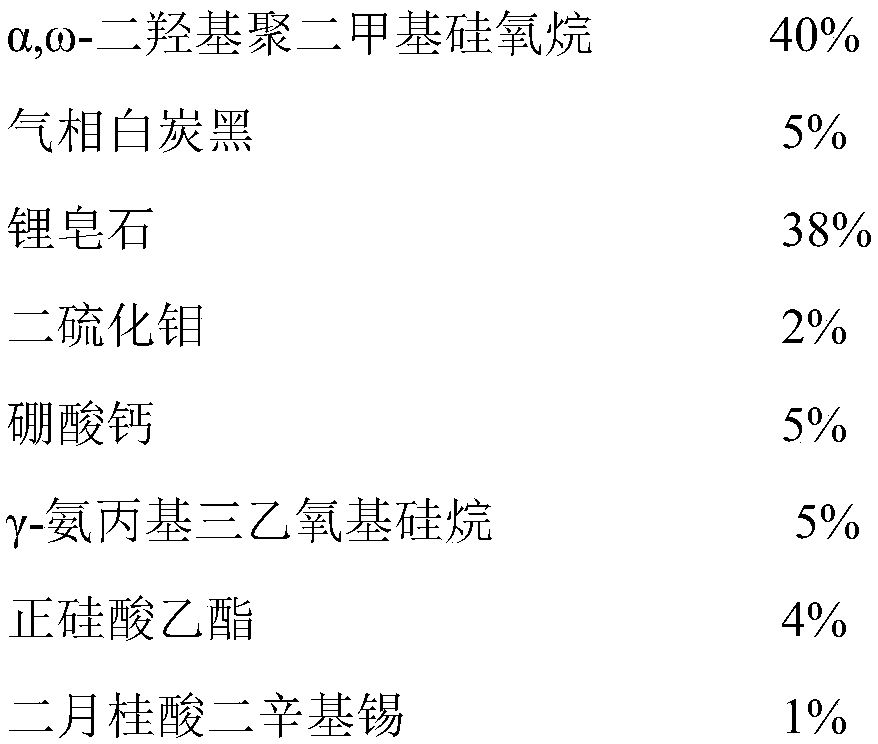

[0038] In terms of mass percentage, the raw material composition ratio of the flame-retardant and smoke-suppressing ceramizable room-temperature-curable sealant is:

[0039]

[0040] During preparation, add calcium borate and hectorite into the crucible, stir at 600°C for 1 hour, and stir at a speed of 50r·min -1 , so that the surface layer of calcium borate is melted, and part of hectorite is adhered to form a ceramic precursor containing silicon-boron covalent bonds. Mix α,ω-dihydroxy polydimethylsiloxane with viscosities of 1500 and 200000mPa·s at 25°C in a mass ratio of 6:1, add them to the kneader, and then add fumed silica, silicon-containing Boron covalent bond ceramic precursor, molybdenum disulfide, set temperature 110°C, vacuum degree 0.05MPa, rotation speed 300r min -1 , blended for 240 minutes, fully dehydrated the raw materials, cooled to 30 ~ 40 ° C to obtain the base material; put the base material into the planetary mixer, and then added ethyl orthosilicate...

Embodiment 2

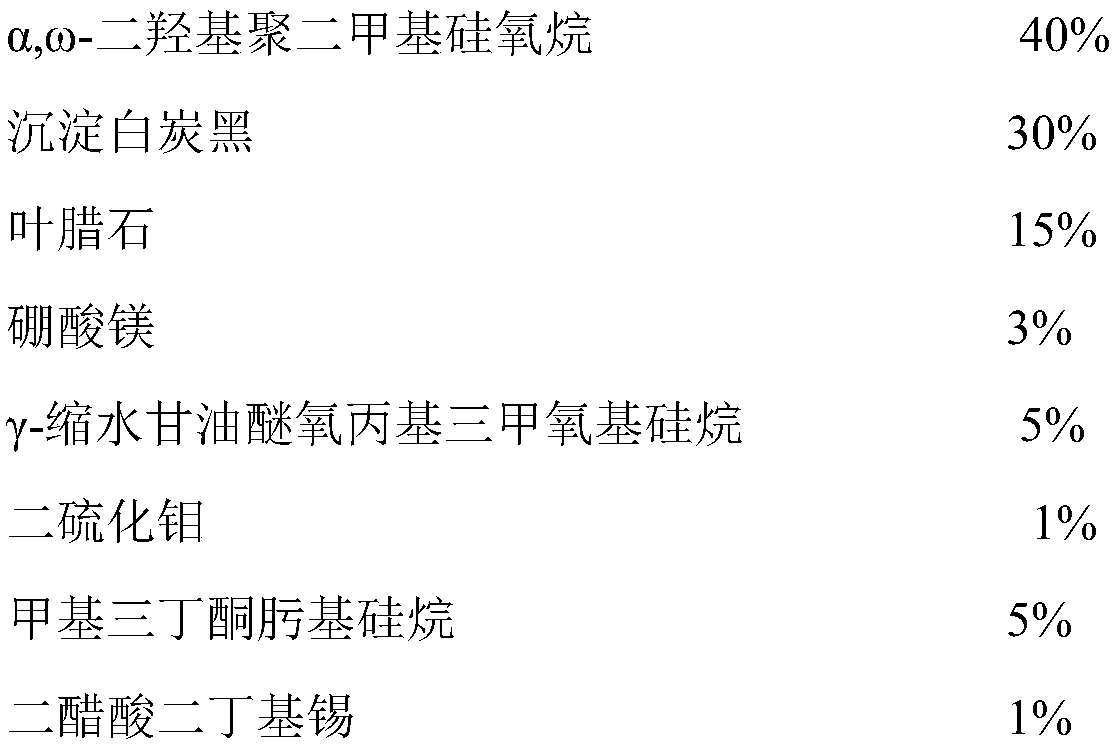

[0042] In terms of mass percentage, the raw material composition ratio of the flame-retardant and smoke-suppressing ceramizable room-temperature-curable sealant is:

[0043]

[0044] During preparation, magnesium borate and pyrophyllite were added to the crucible, stirred at 900°C for 3 hours, and the stirring speed was 80r·min -1 , so that the surface layer of magnesium borate is melted, and part of the pyrophyllite is adhered to form a ceramic precursor containing silicon-boron covalent bonds. Mix α,ω-dihydroxy polydimethylsiloxane with viscosities of 200 and 20000mPa·s at 25°C according to the mass ratio of 4:1, add to the kneader, and then add precipitated white carbon black, containing silicon -Boron covalent bond ceramic precursor, molybdenum disulfide, set temperature 160°C, vacuum degree 0.05MPa, rotation speed 400r min -1 , blended for 180 minutes, fully dehydrated the raw materials, cooled to 30 ~ 40 ° C to obtain the base material; put the base material into the...

Embodiment 3

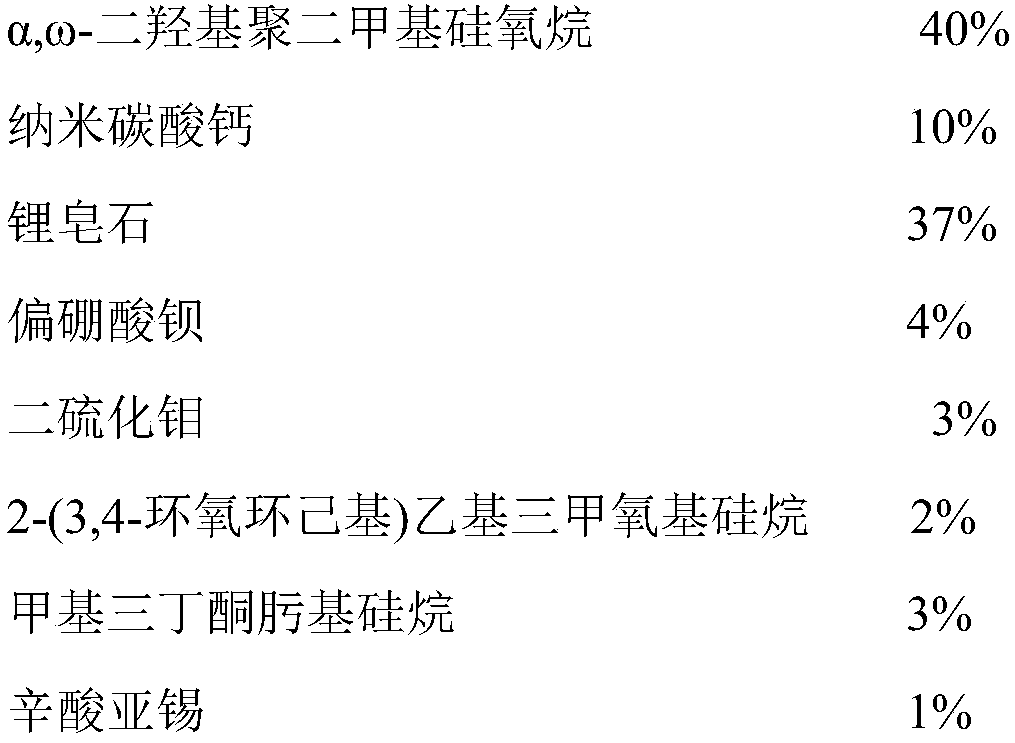

[0046] In terms of mass percentage, the raw material composition ratio of the flame-retardant and smoke-suppressing ceramizable room-temperature-curable sealant is:

[0047]

[0048] During preparation, add barium metaborate and laponite into the crucible, stir at 700°C for 3 hours, and stir at a speed of 80r·min -1 , so that the surface layer of barium metaborate melts and adheres to part of hectorite to form a ceramic precursor containing silicon-boron covalent bonds. Mix α,ω-dihydroxypolydimethylsiloxane with viscosities of 2000 and 100000mPa·s at 25°C in a mass ratio of 5:1, add them to the kneader, and then add nano-calcium carbonate, silicon-containing Boron covalent bond ceramic precursor, molybdenum disulfide, set temperature 160°C, vacuum degree 0.10MPa, rotation speed 400r min -1 , blended for 90 minutes, fully dehydrated the raw materials, cooled to 30-40°C to obtain the base material; put the base material into the planetary mixer, and then added methyl tributy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com