Bridge deck reinforcing structure and method

A technology for strengthening structures and bridge decks, applied in bridge reinforcement, bridges, bridge parts, etc., can solve problems such as improving structural shear bearing capacity, complex surface treatment, and low tensile strength, so as to improve shear bearing capacity and improve Effect of improving shear resistance and bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is further described in conjunction with the following examples.

[0040] See figure 1 , the bridge deck reinforcement structure provided in this embodiment includes reinforcement holes 1 with openings located on the top surface of the bridge deck. A bearing part 11 remains between the bottom of the reinforced hole 1 and the bottom surface of the bridge deck.

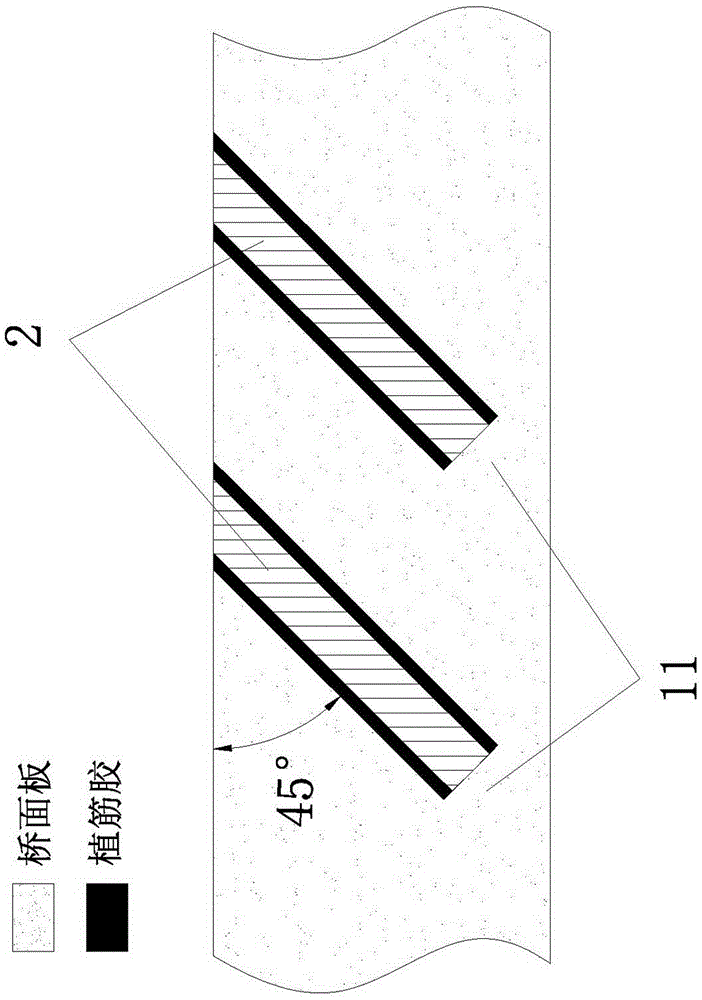

[0041] The axial direction of the reinforcement hole 1 intersects the axial direction of the bridge deck. Preferably, the inclination angle of the reinforcement hole 1 relative to the plane where the bridge deck is located is 45°.

[0042] See figure 2 , the reinforcement hole 1 is provided with an FRP tendon 2, and the FRP reinforcement 2 is bonded to the inner wall of the reinforcement hole 1 through the reinforcement glue. The cross-sectional area of FRP tendon 2 is 1 / 3 of the cross-sectional area of reinforcement hole 1 (see image 3 ).

[0043] The bridge deck strengthening me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com