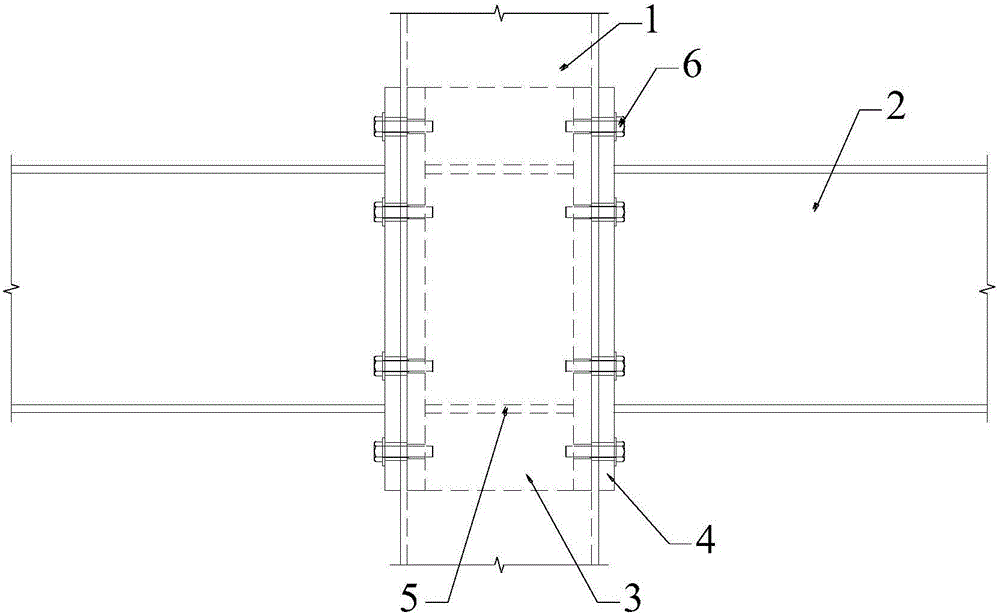

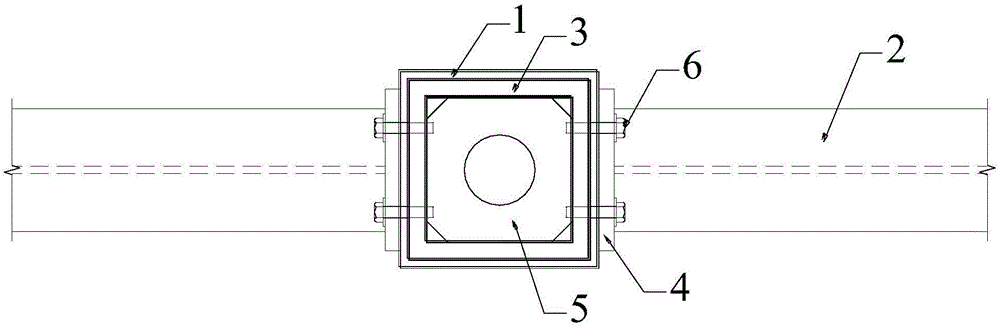

Inner sleeve type unilateral bolt connecting joint of steel tube column and H-shaped steel girder

A unilateral bolt and inner sleeve type technology, which is applied in the direction of construction and building construction, can solve the problem of large deformation of the unilateral bolt wall plate, and achieve the effect of reducing local deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0024] The inner sleeve-type unilateral bolt connection node between the steel pipe column and the H-shaped steel beam of the present invention includes a steel pipe column 1 and an H-shaped steel beam 2, and a steel sleeve 3 is coaxially arranged in the steel pipe column 1, and the steel sleeve 3 corresponds to H The diaphragm 5 at the flange of the shaped steel beam 2, and the end of the H-shaped steel beam 2 are welded with an overhanging end plate 4. The high-strength bolts 6 passing through the overhanging end plate 4; the steel sleeve 3 is provided with tapping bolt holes suitable for the high-strength bolts 6; For the opening of several bolt holes, the steel pipe column 1 is provided with two positioning round holes on the connecting side and the center line of the opposite wall plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com