Device and method for nanoimprinting of full wafer

A nano-imprinting and wafer technology, which is applied in the photoplate process, instrument, optics and other directions of the pattern surface, and can solve the problem of small imprinting force and excessive demoulding force, uneven wafer, dirt on the wafer, etc. problems, to achieve the effect of eliminating air bubbles, ensuring the accuracy of the complex, and achieving uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

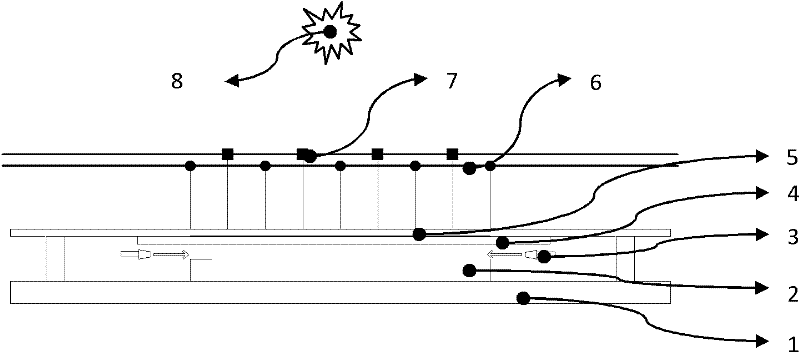

[0044] figure 1 Among them, it includes: a workbench 1, a whole wafer coated with resist 2, a nozzle for demoulding 3, a template 4, an embossing head 5, a pressure pipeline 6, a vacuum pipeline 7 and an ultraviolet light source 8 ; Wherein, the template 4 is fixed on the bottom surface of the embossing head 5, and the lower side of the template 4 is provided with a nozzle 3 for demoulding; the pressure pipeline 6 and the vacuum pipeline 7 are connected to the air inlets on both sides of the embossing head worktable; The entire wafer 2 covered with resist is fixed on the wafer workbench 1 ; the ultraviolet light source 8 is placed on the imprint head 5 .

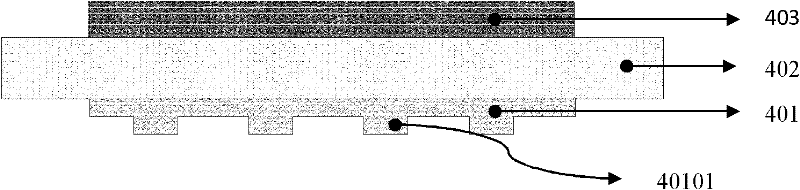

[0045] figure 2 Among them, the template 4 is a transparent flexible mold with a three-layer composite structure, wherein the first layer (lowest layer) is a structural layer 401, the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com