A multi-layer composite machine for new materials

A composite machine, new material technology, applied in the direction of lamination, lamination device, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

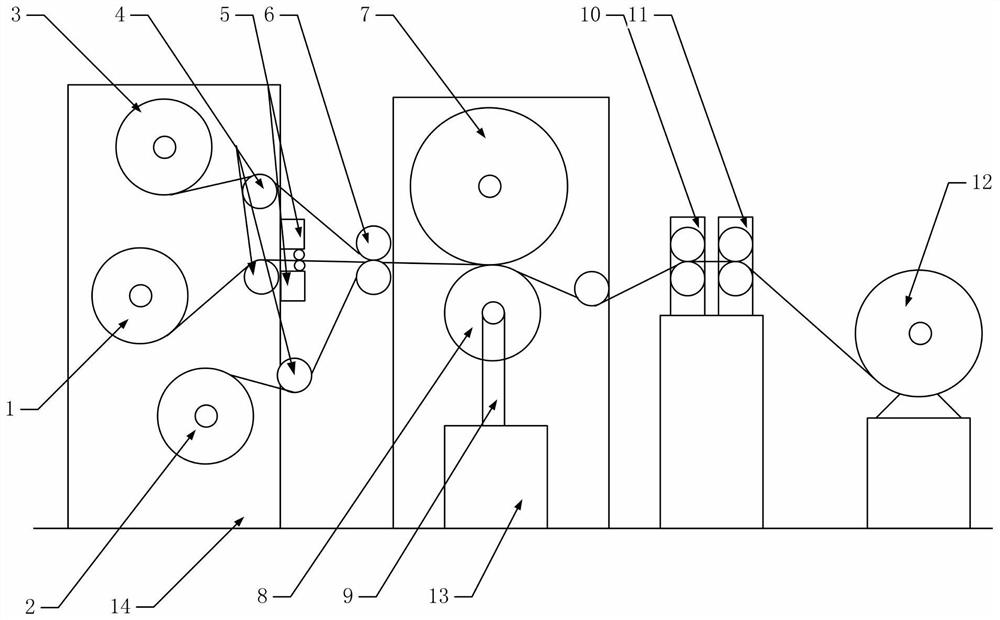

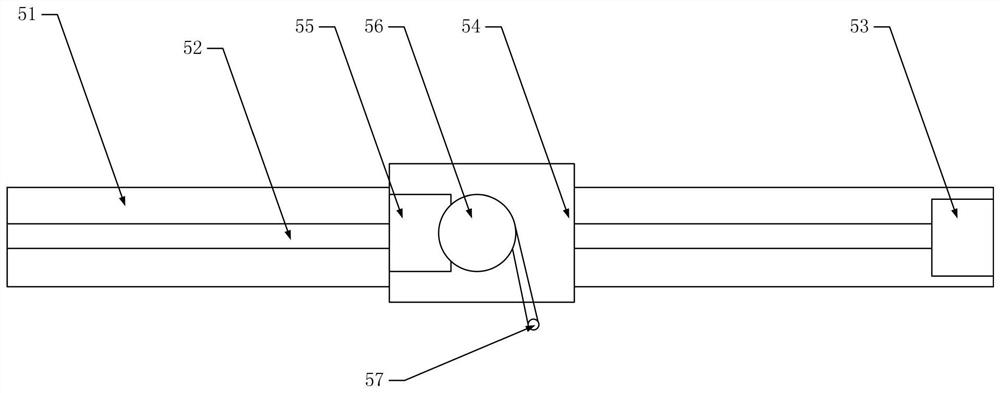

[0022] A special composite machine for multi-layer new materials according to the present invention, such as figure 1 As shown, it includes a first unwinding device 1, a second unwinding device 2, a third unwinding device 3, a tensioning device 4, an electrostatic generator 5, a pre-compositing device 6, a composite steel roller 7, and a pressing steel roller 8 , Linear guide rail 9, guiding device 10, traction device 11, winding device 12, central controller 13, frame 14. The first unwinding device 2, the second unwinding device 3, the tensioning device 4, the electrostatic generator 5, the pre-composite device 6, the composite steel roller 7, the pressing steel roller 8, the linear guide rail 9, the guide device 10, The traction device 11, the winding device 12, and the central controller 13 are fixed on the frame 14, and the first unwinding device 1, the second unwinding device 2, and the third unwinding device 3 are arranged at the front end of the frame 14 , the tensioni...

Embodiment 2

[0027] A multi-layer new material special compound machine, such as figure 1 As shown, the workflow is:

[0028] (1) Load the three raw materials that need to be compounded into the unwinding device. The main raw material, that is, the asymmetric graphene oxide polyimide hollow fiber membrane, is loaded into the first unwinding device, and the first secondary raw material is loaded into the second unwinding device. Rolling device, the second secondary raw material is loaded into the third unwinding device, the secondary raw material objects include but not limited to: metal foil, rubber, non-woven fabric, PE film, special fiber, paper products, film, etc.;

[0029] (2) Adjust the tensioning device so that the three raw materials are in a tensioned state after passing through the tensioning device. Among them, when the main raw material passes through the electrostatic generator, the electrostatic generator works under the control of the central controller, and the wire electro...

Embodiment 3

[0034] Graphene oxide (GO) aqueous suspension was prepared by the modified Hummers method, using flake graphite powder as the starting material, the resulting GO aqueous suspension was sonicated for 30 minutes, and then centrifuged at 8000rpm for 30 minutes to remove incomplete oxidation. of graphite. GO powder was obtained by freeze-drying overnight to prepare asymmetric graphene oxide polyimide hollow fiber membranes, specifically, 0.72 g GO powder was dispersed in 50 mL of methylpyrrolidone gel and stirred vigorously for 10 min, followed by ultrasonic treatment for 1 h , then add 10g of polyimide to the methylpyrrolidone gel and stir vigorously at 75°C, then add 1.5g of polyvinylpyrrolidone to it, then stir at 75°C for 2 hours to form a raw material solution, and put the raw material solution into Vacuum pump, under the action of vacuum pump, carry out vacuum dehydration, cast through the casting manufacturing device of screw strong pressure conveying, melt the raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com