A multi-stage gradient continuous extrusion molding method and equipment for a tea strip pot trough

A technology for extrusion molding and tea processing, which is applied in the field of agricultural machinery, can solve the problems of reducing the molding rate of the pot and groove, difficult mass production, and a large amount of time for installation, and achieves improved molding speed and efficiency, efficient molding, and guarantee. Feasibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings.

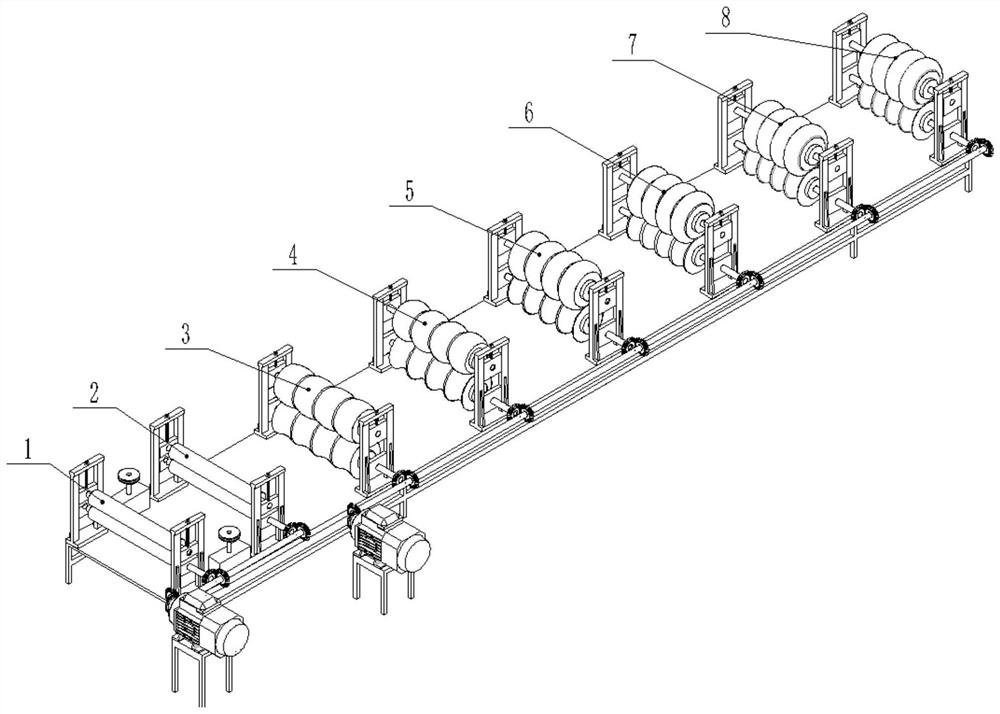

[0037] like figure 1 As shown in the figure, a multi-level gradient continuous extrusion molding method for tea strips and pot grooves includes the following steps in sequence: feeding, leveling, cold rolling and cutting.

[0038] The specific process of feeding is as follows: the strip steel coil is placed in the coil feeding machine, and the strip steel coil is unfolded through the coil feeding machine to facilitate subsequent forming.

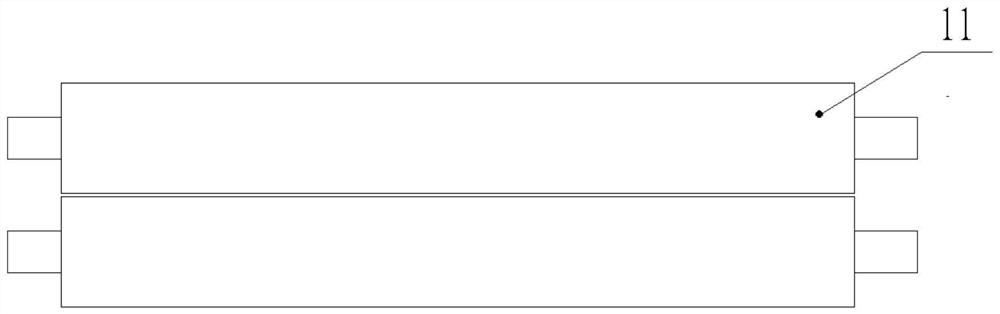

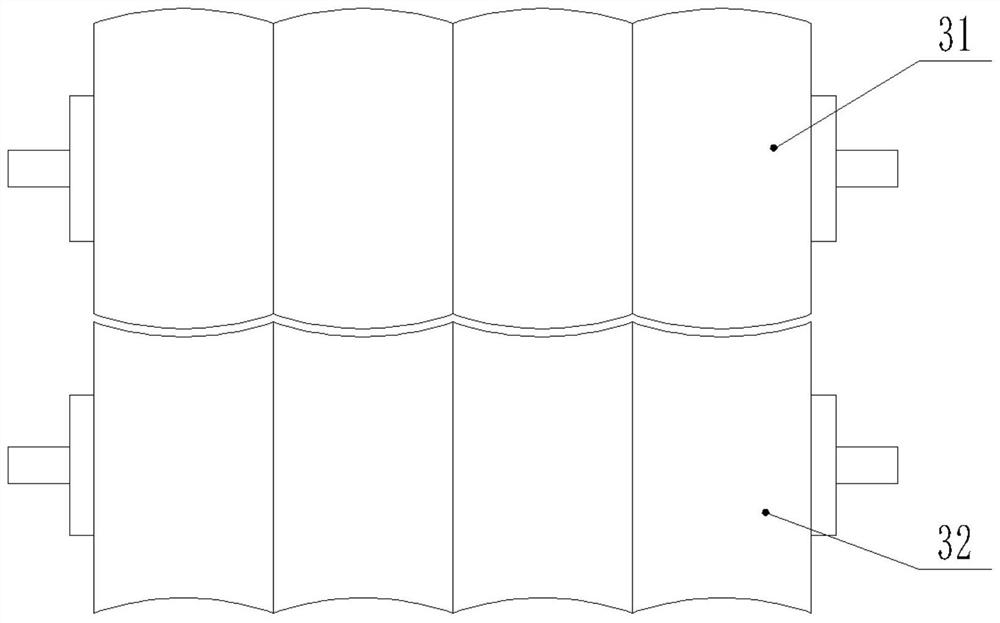

[0039] The specific process of leveling is as follows: make the unfolded strip enter the leveling roller to level the strip and eliminate the deformation of the strip. Among them, the four leveling rollers are divided into two groups with spacing set, each group is composed of two leveling rollers aligned up and down; the gap between the two leveling rollers in each group is provided with limit devices at both ends to prevent strip st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com