Round steel replaced cutting platform

A cutting platform and round steel technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of mold being cut by flame, steel plate deformation, etc., and achieve low replacement cost, high production efficiency, and consumables little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

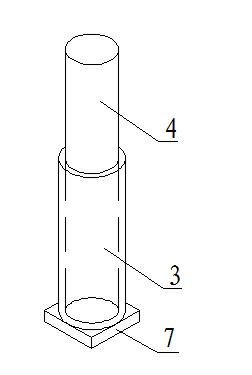

[0022] The structure of the support frame 2 is arranged according to the size of the steel plate to be cut. The support frame 2 is composed of horizontal and vertical support plates 6 that are handed over to each other, and a number of neatly arranged square spaces are formed by the horizontal and vertical support plates 6; the support The frame 2 is provided with a bottom support 5, and the support frame 2 is integrally fixed in the water tank 1 below it; above the intersection point of the horizontal and vertical support plates 6 constituting the support frame 2, a steel pipe set 3 is fixed by welding through a backing plate 7 , the supporting round steel 4 is directly inserted into the steel pipe set 3 .

[0023] The round steel type cutting platform described in this structure can be used to cut steel plates of different thicknesses, and sever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com