Anti-crack thermal insulation wall and construction process

A technology of thermal insulation wall and construction technology, which is applied in the direction of construction, building structure, and building material processing, etc., and can solve problems such as brush deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 of the present application discloses a crack-resistant thermal insulation wall and a construction process. The anti-crack thermal insulation wall consists of thermal insulation layer and surface layer. The thermal insulation layer is made of polystyrene plastic board, and the surface layer is made of cement, anti-crack agent, and medium sand in a mass ratio of 1:1:5. The anti-cracking agent is a dispersion emulsion of wood fibers.

[0041] The construction technology of the anti-crack thermal insulation wall includes the following steps:

[0042] Brush polyurethane adhesive on the surface of the concrete layer to form an adhesive layer, and paste a polystyrene plastic board on the surface of the adhesive layer; brush fiber mortar on the surface of the polystyrene plastic board, and air dry for 15 minutes at room temperature to form a surface layer.

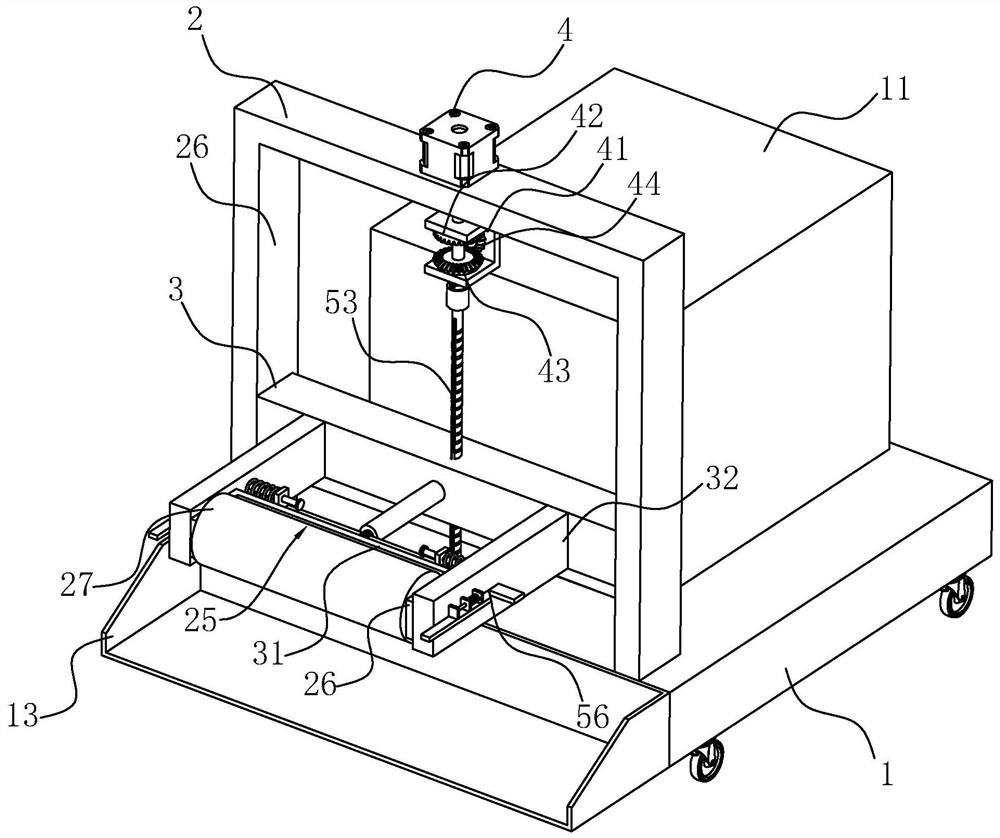

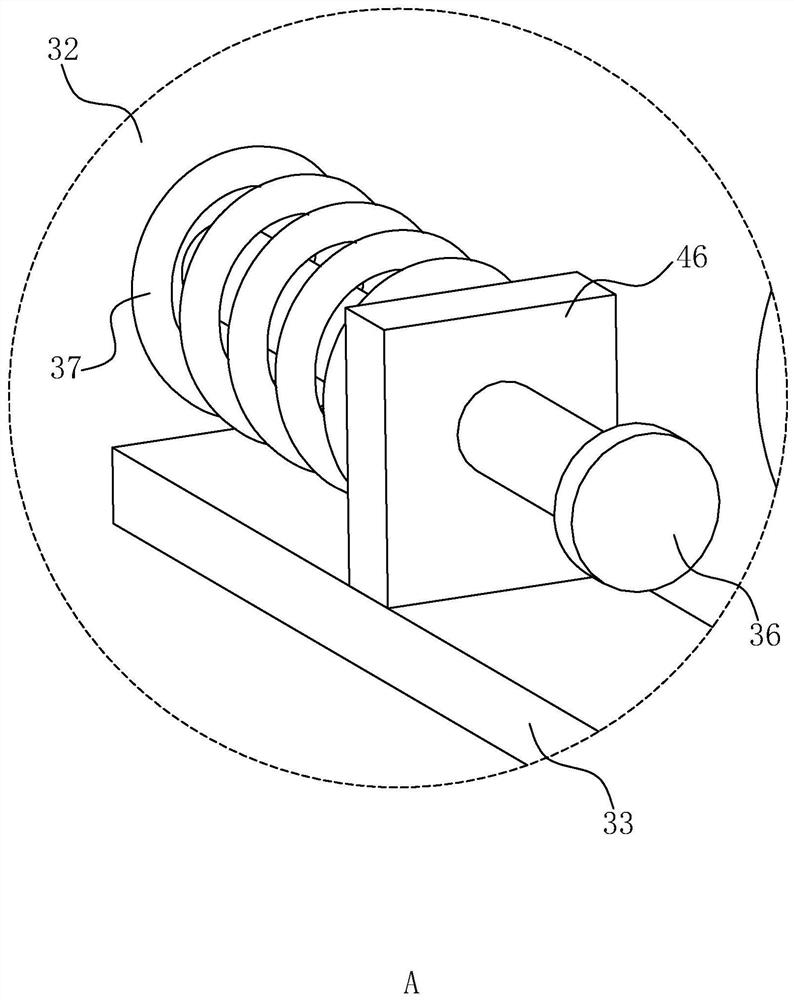

[0043] refer to figure 1 and figure 2, the wall construction device for brushing the adhesive layer and ...

Embodiment 2

[0054] The difference between Example 2 and Example 1 is that the surface layer is made of cement, anti-cracking agent, and medium sand in a mass ratio of 1:4:8. Brush fiber mortar on the surface of the polystyrene plastic board, and air dry for 20 minutes at room temperature.

Embodiment 3

[0056] The difference between Example 3 and Example 1 is that the surface layer is made of cement, anti-cracking agent, and medium sand in a mass ratio of 1:2:6. Brush fiber mortar on the surface of the polystyrene plastic board, and air dry for 18 minutes at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com