Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Achieve room temperature curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-coated film propping agent, preparation method of the pre-coated film propping agent and sand prevention method adopting the pre-coated film propping agent

ActiveCN102660245AImproves breakage resistanceEasy to divertFluid removalDrilling compositionBisphenol FPolyamine

The invention relates to a pre-coated film propping agent, a preparation method of the pre-coated film propping agent and a sand prevention method adopting the pre-coated film propping agent. The pre-coated film propping agent comprises propping agents, one or more pre-coated resins, one or more pre-coating curing agents, a coupling agent and a lubricating agent. The one or more pre-coated resins comprise bisphenol-A epoxy resin, bisphenol-F epoxy resin and / or novolac epoxy resin. The one or more pre-coating curing agents are selected from alicyclic polyamines, aromatic polyamines, modified alicyclic polyamines and / or modified aromatic polyamines. The coupling agent is an organosilane coupling agent.

Owner:BEIJING QISINTAL SCI & TECH +1

Bi-component epoxy zinc rich primer

InactiveCN101407690AReduce zinc dust contentLow costAnti-corrosive paintsEpoxy resin coatingsEpoxyRoom temperature

The invention discloses a dual-component epoxy zinc-rich primer with excellent mechanical performance of a coating layer, low construction cost, high efficiency and prominent anti-corrosion performance. The dual-component epoxy zinc-rich primer comprises A and B components; wherein, the A component comprises the following components by parts by weight: 14 parts of epoxy resin, 54 to 71 parts of zinc powder, 4 to 20 parts of filler, 1 to 3 parts of anti-settlement auxiliary agent and 9 parts of solvent; the B component comprises the following components by weight percentage: 40 percent curing agent and 60 percent solvent; and the mixture ratio by weight of the A component to the B component is 8:1 to 15:1. The dual-component epoxy zinc-rich primer has the advantages of low content of the zinc powder in a paint film, low cost, simple technology and no need of special equipment; the use of the dual-component epoxy zinc-rich primer can realize the curing at room temperature, the paint film has excellent adhesion, flexibility and anti-corrosion effect, the applicable period is long and can achieve 4 hours, the construction is convenient, and the dual-component epoxy zinc-rich primer can be applied in anti-corrosion primers of pipelines, plant facilities, ships, bridges and other steel structures.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION

Polyurethane heat-insulation structural adhesive and manufacturing method for heat-insulation aluminum profile

InactiveCN102079960AGood mechanical propertiesGood wear resistancePolyureas/polyurethane adhesivesToluene di-isocyanateChemistry

The invention discloses a polyurethane heat-insulation structural adhesive, which comprises components A and B, wherein the mass ratio of A to B is (90-110):(70-90); the component A comprises polyether polyol and auxiliaries; on the basis of the mass ratio of the auxiliaries to the polyether polyol, the auxiliaries comprise following components by weight percent: 0.1-0.3% of catalyst, 0.1-0.5% offlatting agent, 0.1-0.5% of de-foaming agent, 0.5-1.5% of chain extender, 0.1-5% of padding, 0.3-5% of plasticizer, 0.1-0.3% of anti-oxygen, and 0.1-0.3% of ultraviolet absorber; and the component B is isocyanate of MDI (methyl diphenylene diisocyanate) or TDI (toluene di-isocyanate). The invention also discloses a method for using the structural adhesive to prepare a heat-insulation aluminum profile. The polyurethane heat-insulation structural adhesive provided by the invention has advantages of excellent mechanical property, fatigue resistance, shock resistance, wear-resisting property, andstability. Room-temperature pouring and room-temperature solidifying processes are realized through the molding production; the pouring period is long; the molding production is not limited by temperature and the shape of aluminum profile; the operation is easily controlled; the rejection rate is low; and the molding production is beneficial to the popularization and application of the pouring type heat-insulation aluminum profile technique.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

Low-surface energy antifouling seagoing ship paint and its prepn

InactiveCN1388196ANon-toxicMeet environmental protection requirementsAntifouling/underwater paintsPaints with biocidesEmulsionOrganic solvent

The antifouling paint is prepared with core-shell type fluorous acrylate emulsion as base material, heavy CaCO3 stuffing, pigment, densifier, dispersant, glycol filming assistant, lubricant, leveling agent, preservative, defoaming agent, deionized water and ammonia water. Its preparation process includes semi-continuous polymerization to synthesize core-shell fluorous emulsion, mixing the emulsion with filming assistant, mixing with other components and filtering. The antifouling paint has low surface energy and indexes meeting the requirement for environment protection, and is soluble in common organic solvent.

Owner:HUBEI UNIV

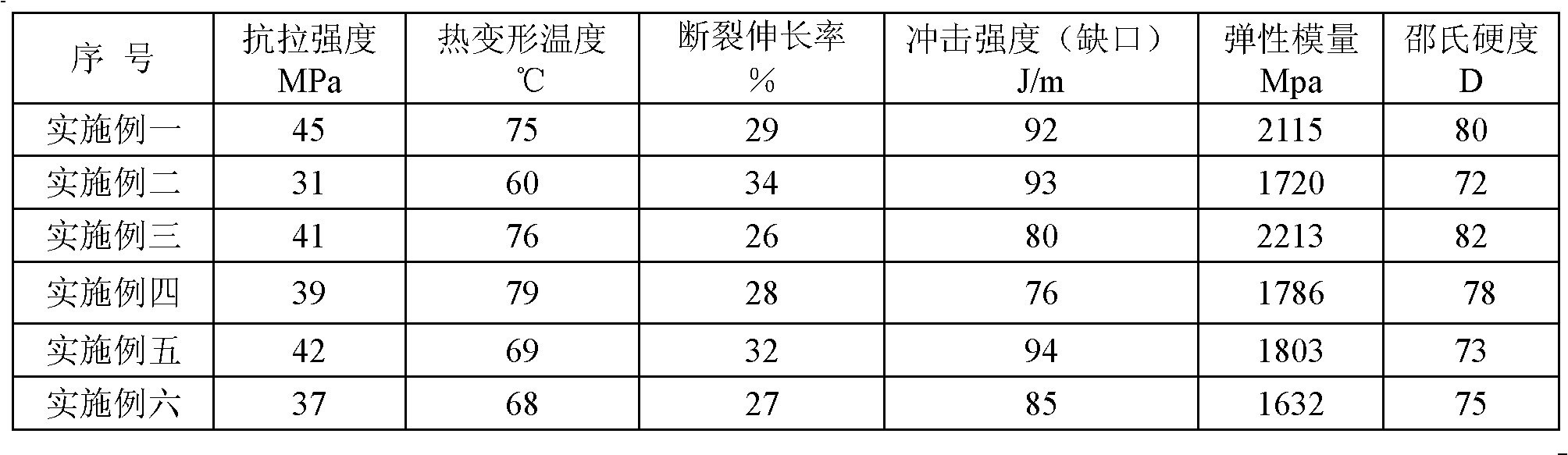

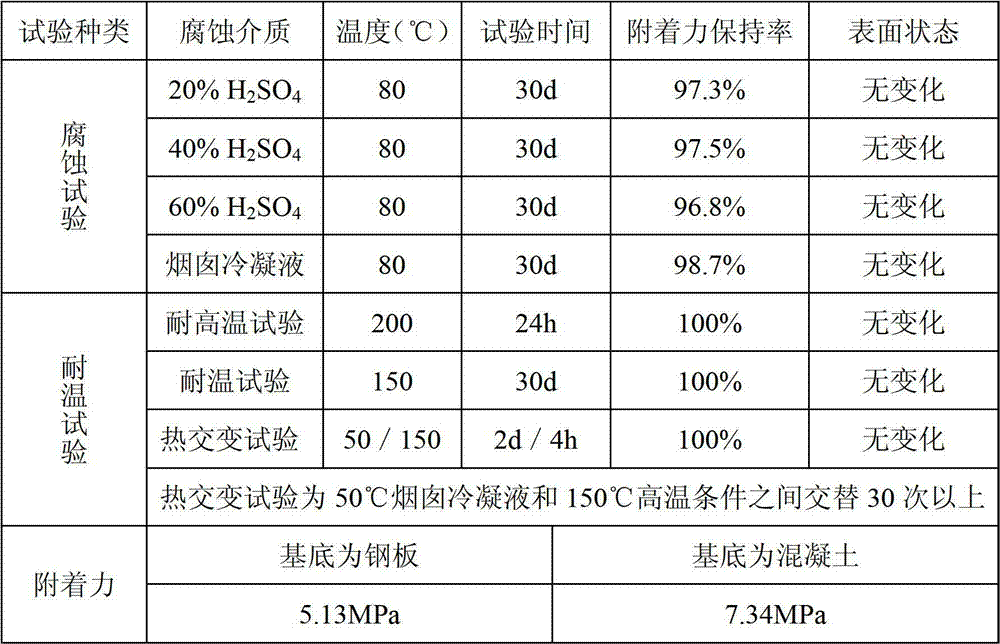

Desulfurization chimney anticorrosive paint and preparation method thereof

InactiveCN102775864AExcellent resistance to stress and strainExcellent resistance to high temperature oxidation degradationAnti-corrosive paintsStrong acidsSolvent

The invention provides a desulfurization chimney anticorrosive paint and a preparation method of the desulfurization chimney anticorrosive paint. The desulfurization chimney anticorrosive paint comprises a first component formed by dissolving, dispersing and mixing fluoroelastomer, a solvent, padding and an assistant according to certain proportion and a second component formed by mixing a solidification agent and the solvent according to certain proportion. The first component and the second component are stirred and mixed according to certain proportion for 10min-30min to conduct painting construction. The desulfurization chimney anticorrosive paint has the advantages of excellent elasticity, adhesive force, strong acid strong base corrosion resistance, thermostability aging performance, high / low temperature change resistance and wear-resisting property, and can meet desulfurization chimney anticorrosive requirements under various operation conditions on the premise of guaranteeing construction quality.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Water-based environment-friendly anti-corrosion composite material and preparation method thereof

InactiveCN110028816ANon-toxicNo pollution in the processAlkali metal silicate coatingsAnti-corrosive paintsWater basedEmulsion

The invention provides a water-based environment-friendly anti-corrosion composite material and a preparation method thereof. The material comprises the following components in percentage by mass: 5-20% of curing agent, 10-40% of anti-corrosion filler, 20-70% of liquid silicate, 0-15% of water-based emulsion and 0.1-2% of material additive. The preparation method comprises the following steps: firstly, preparing a composite filler from a curing agent and an anti-corrosion filler to obtain a solid composition A, then preparing a liquid composition B from liquid silicate, a water-based emulsionand a material additive, and uniformly mixing the solid composition A and the liquid composition B in proportion to obtain the material. A coating is prepared by spraying, brush coating, dip-coating or roller coating, and is cured for 24 hours or more at normal temperature, so that a long-acting anti-corrosion coating can be obtained. The material reduces the content of zinc powder, is excellent in corrosion resistance, and can effectively solve the problem of corrosion of a metal component in a corrosive environment.

Owner:北京中天正源生态科技有限公司

High-tenacity vacuum slow epoxy resin for wind power blade and preparation method thereof

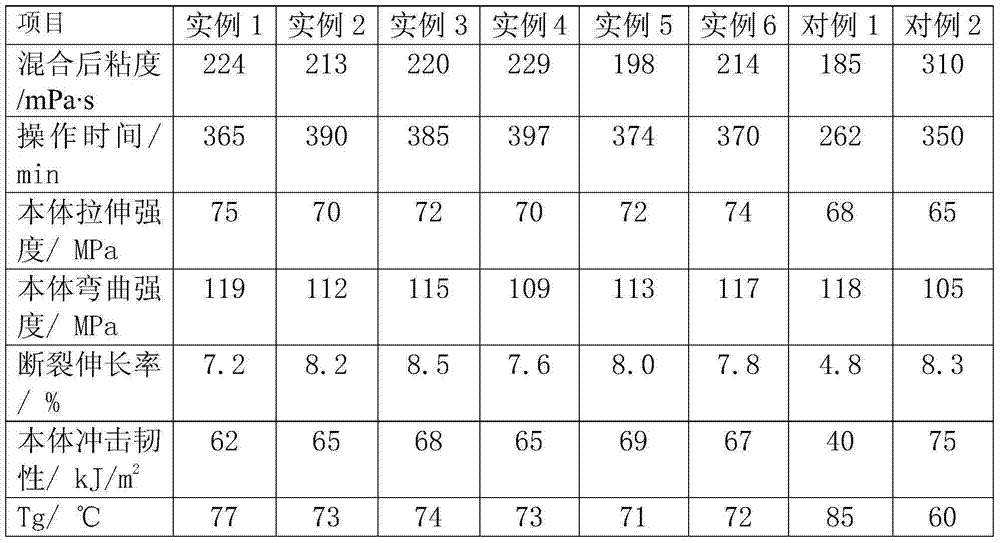

The invention relates to high-tenacity vacuum slow epoxy resin for a wind power blade and a preparation method thereof. The epoxy resin comprises a component A and a component B, wherein the component A comprises epoxy resin, vinyl-terminated epoxy polyether, an activated thinner, a coupling agent and a defoamer; the component B comprises one or a mixture of two of fatty amine, alicyclic amine and aromatic amine. The vinyl-terminated epoxy polyether and the epoxy resin composition in the technical scheme disclosed by the invention have good compatibility, the epoxy resin composition can be toughened after the vinyl-terminated epoxy polyether is compounded with the activated thinner, and the epoxy resin composition is matched with an amine hardener for use, so that normal-temperature cuing of the resin can be achieved, and the gelation time is 365-397 minutes. The obtained epoxy resin product has good mechanical property, and is applicable to a wind power blade product with high demands on the curing degree and the impact property. The vacuum slow epoxy resin is simple in preparation method and applicable to large-scale popularization and application.

Owner:NEW UNITED GROUP

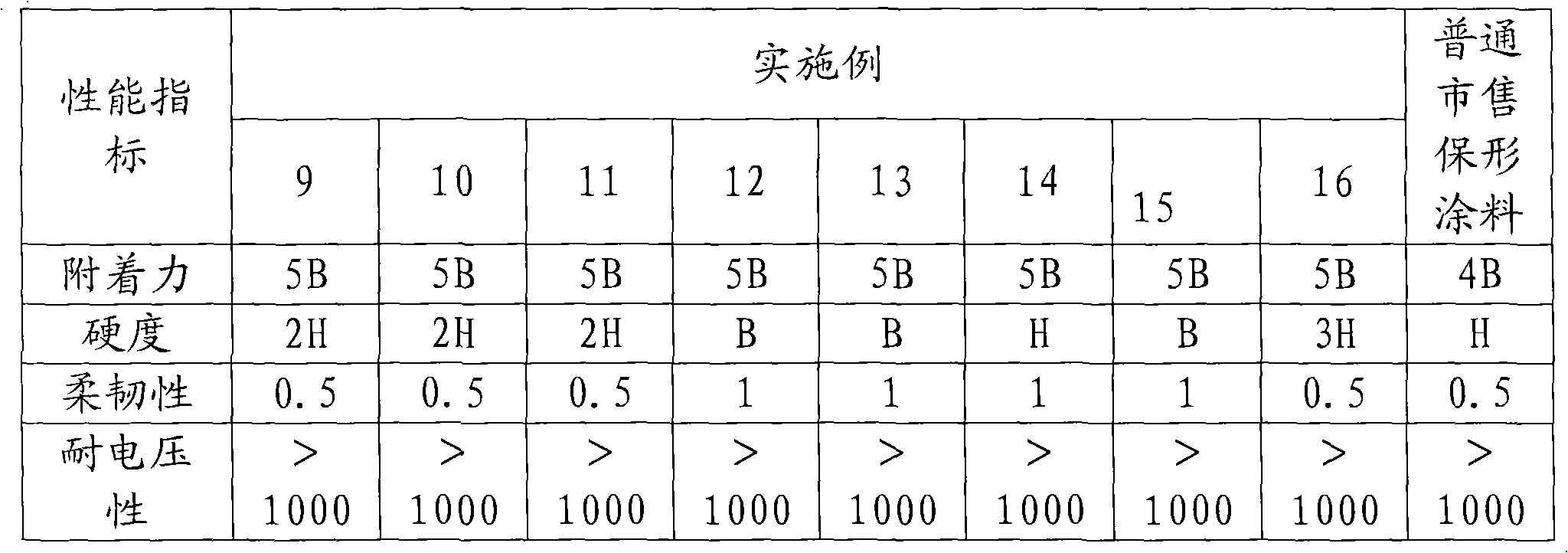

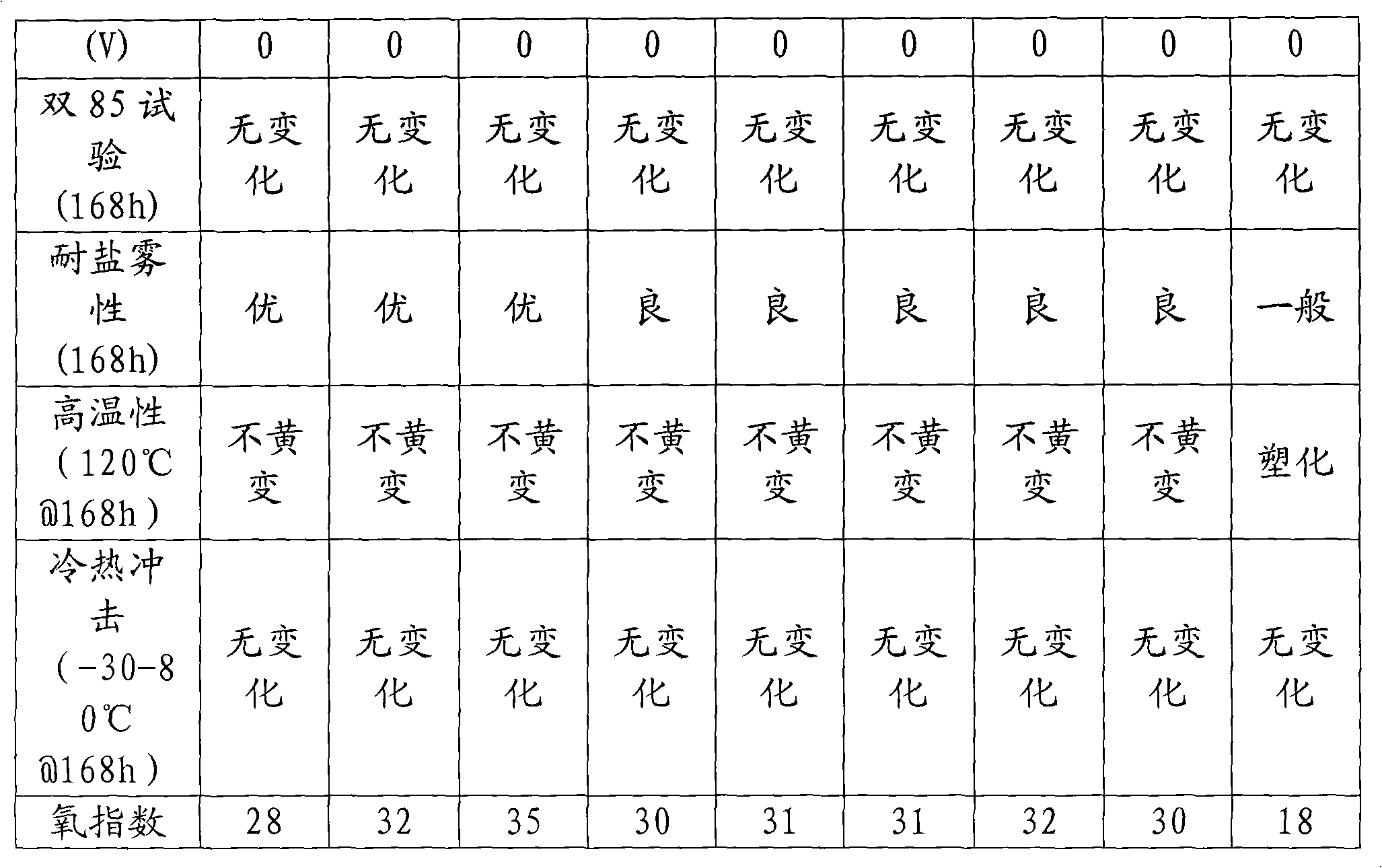

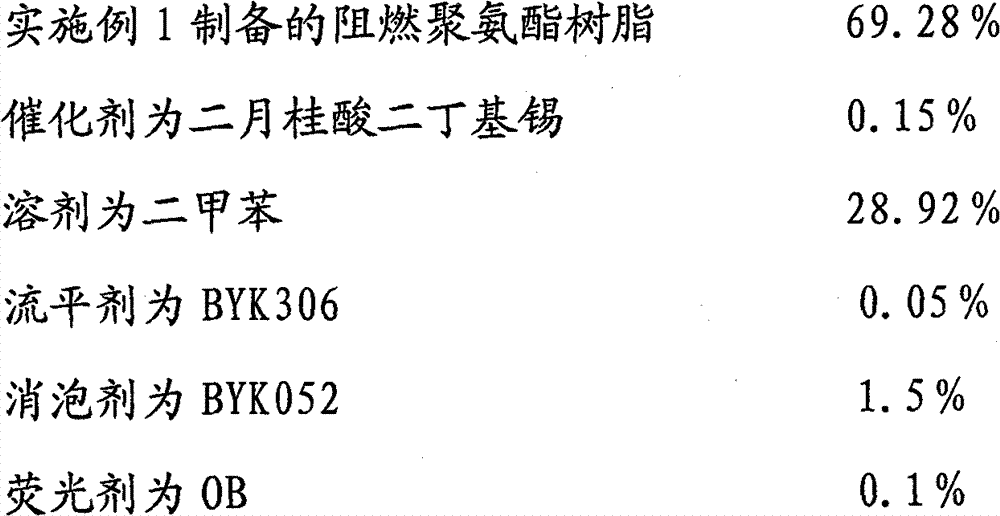

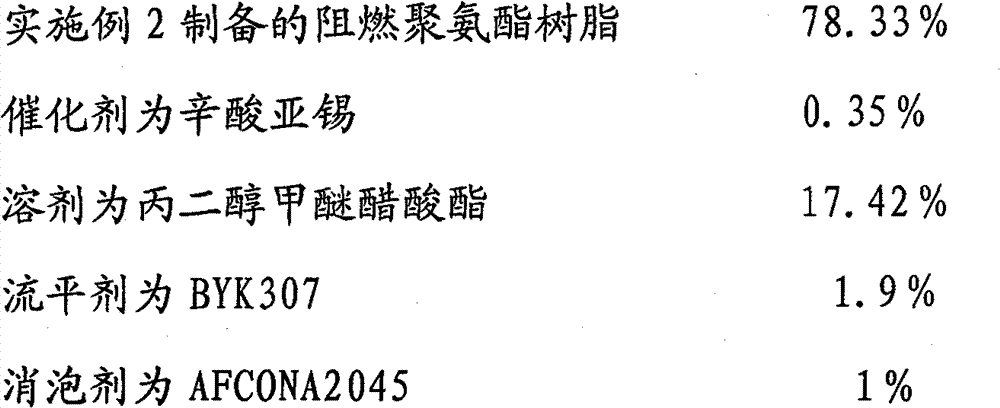

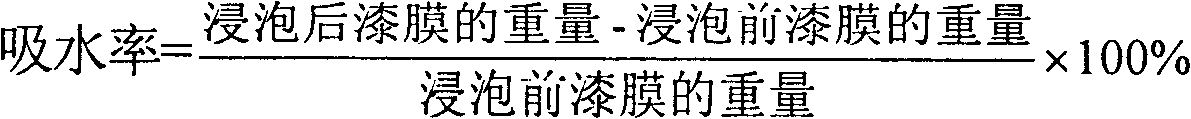

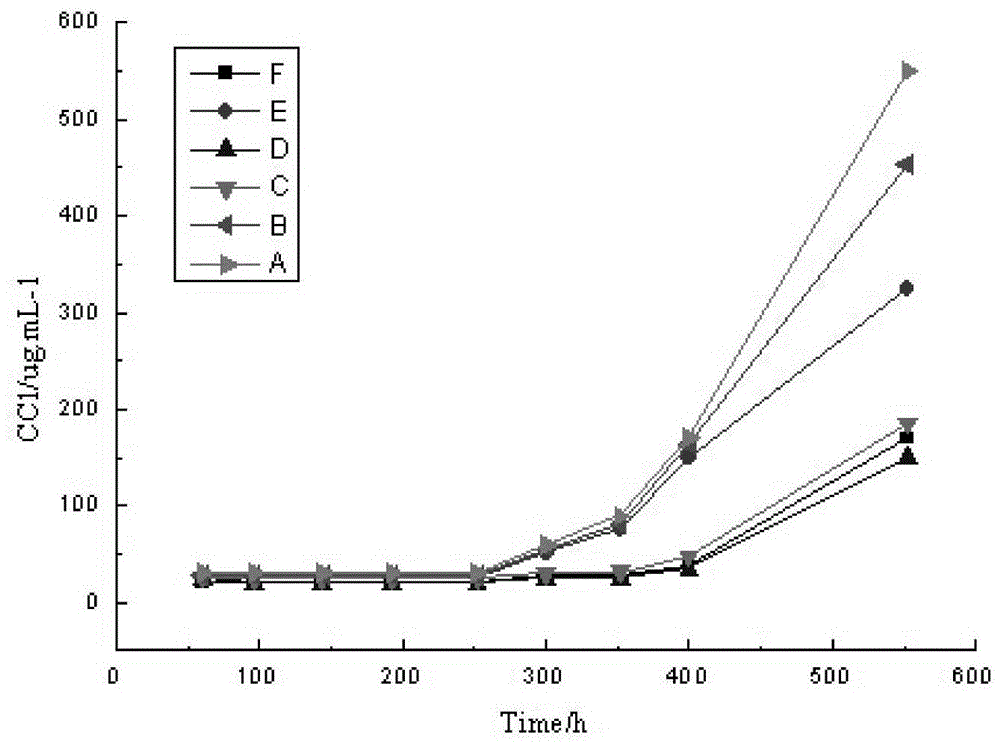

Flame retardant polyurethane resin and preparation method thereof and flame retardant polyurethane conformal coating

InactiveCN102040725ACuring Rate ControlRaw materials are easy to getPolyurea/polyurethane coatingsConformal coatingSolvent

The invention relates to flame retardant polyurethane resin and a preparation method thereof and flame retardant polyurethane conformal coating. The preparation method of the flame retardant polyurethane resin comprises alcoholization of grease and synthetization of the flame retardant polyurethane resin, and the flame retardant polyurethane resin is prepared by the method; and the flame retardant polyurethane conformal coating comprises the following ingredients in percentage by weight: 60-80wt% of flame retardant polyurethane resin, 15-35wt% of solvent; 0.01-2wt% of catalyst, 0-2wt% of leveling agent, 0-1.5wt% of defoaming agent, and 0-1wt% of fluorescent powder.

Owner:YANTAI DARBOND TECH

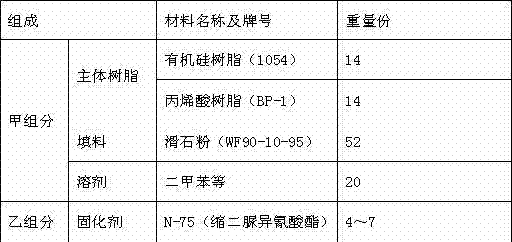

High temperature resistant putty and its preparation method

InactiveCN102898881AImprove heat resistanceImprove cold resistanceFilling pastesAviationAcrylic resin

The invention discloses a high temperature resistant putty and its preparation method. The high temperature resistant putty comprises 100 parts by weight of a component A and 4-7 parts by weight of a component B, wherein the component A and the component B are packaged in a separate manner; the component A comprises 13-16 parts by weight of an organic silicon resin, 13-16 parts by weight of an acrylic resin, 48-55 parts by weight of a filler and 15-25 parts by weight of a solvent; and the component B is a curing agent. Compared with putties in the prior art, the high temperature resistant putty provided by the invention enables a putty film to be good and have a very good static heat insulation property when the putty film tolerates a high temperature of 500DEG C, and is a good filling and repairing material for heat-resistant coats of aviation and spaceflight products. The high temperature resistant putty has been applied to some new-model products, and multi-time target tests prove that the high temperature resistant putty can completely satisfy product design requirements.

Owner:贵州航天风华精密设备有限公司 +1

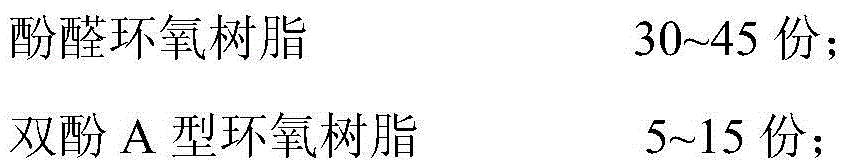

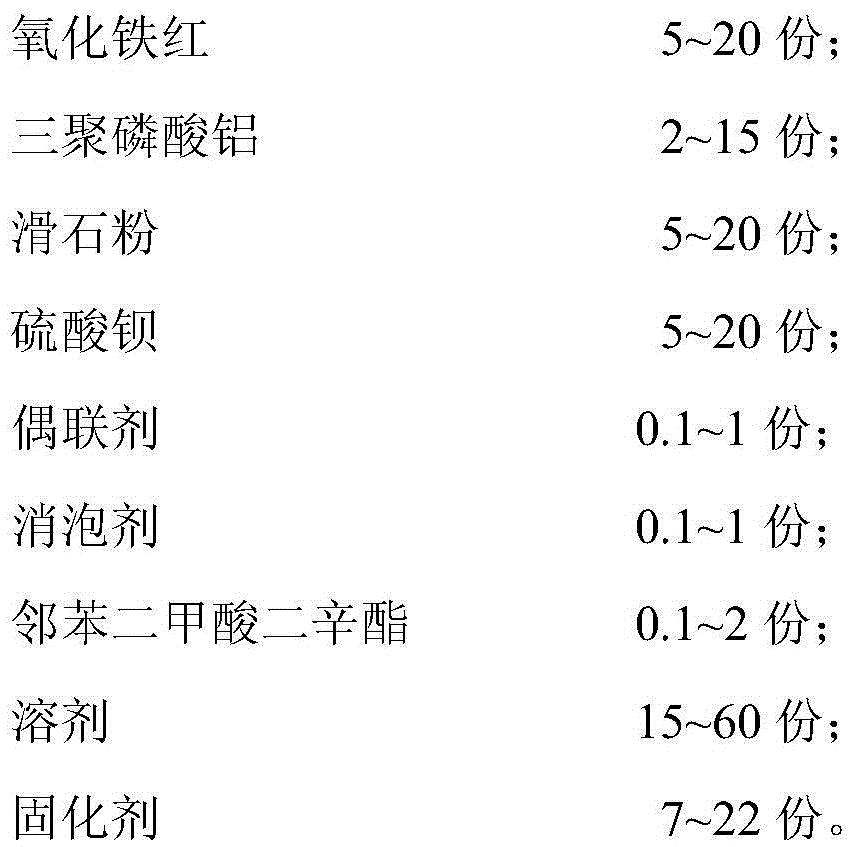

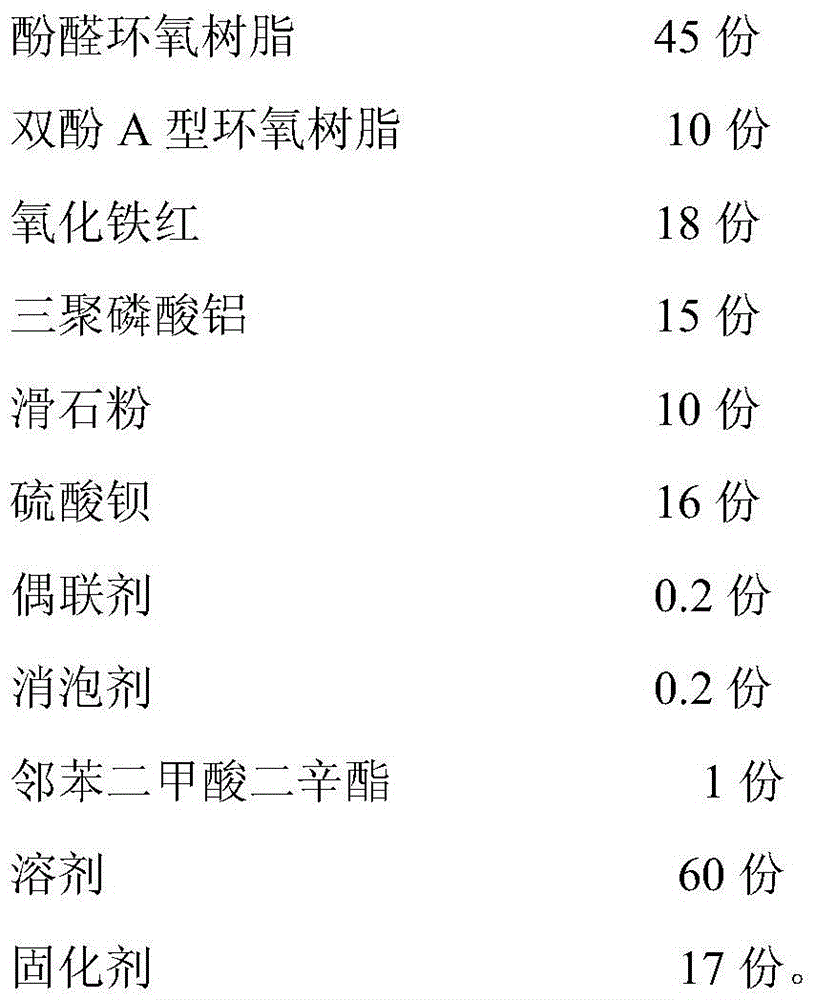

Humidity-heat-resistant long-acting anticorrosion coating

InactiveCN105419569AReduced structural rigidityImprove heat resistanceAnti-corrosive paintsEpoxy resin coatingsSolventPhthalate

The invention discloses a humidity-heat-resistant long-acting anticorrosion coating. The coating is prepared from, by weight, 30-45 parts of novolac epoxy, 5-15 parts of bisphenol A type epoxy resin, 5-20 parts of iron oxide red, 2-15 parts of aluminum triphosphate, 5-20 parts of talcum powder, 5-20 parts of barium sulfate, 0.1-1 part of coupling agent, 0.1-1 part of defoaming agent, 0.1-2 parts of dioctyl phthalate, 15-60 parts of solvent and 7-22 parts of curing agent. The coating is good in acid and base resistance, heat resistance and solvent resistance, convenient to construct and capable of being widely used for long-acting corrosion prevention of metal structural parts in the hygrothermal environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

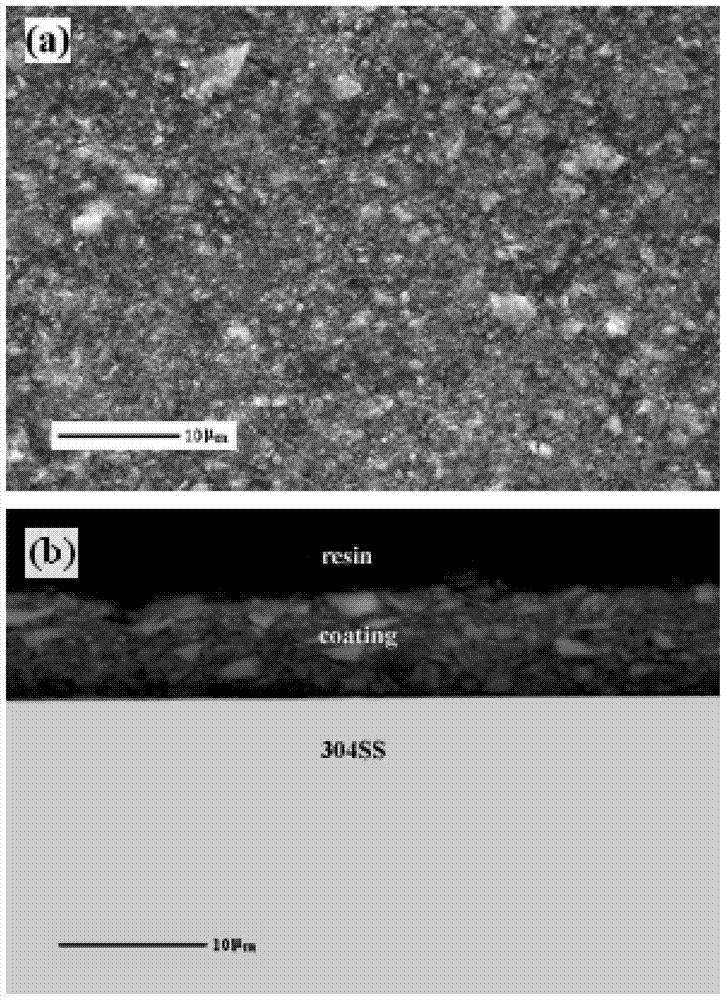

Nano-modified organic silicon coating with high temperature resistance, corrosion resistance and nuclear radiation resistance as well as preparation and application

ActiveCN104804640ASimple preparation processEase of industrial productionAnti-corrosive paintsPolyurea/polyurethane coatingsDip-coatingTemperature resistance

The invention relates to a high-temperature-resistant, corrosion-resistant and nuclear-radiation-resistant protection technology for a metal part, in particular to a nano-modified organic silicon coating with high temperature resistance, corrosion resistance and nuclear radiation resistance as well as a preparation method and an application of the nano-modified organic silicon coating. The nano-modified organic silicon coating comprises components in parts by mass as follows: 50-100 parts of organic silicon resin, 5-60 parts of nano-powder, 5-40 parts of polyurethane resin and 0-50 parts of a diluent. The organic silicon resin, the nano-powder and xylene are proportionally placed in a circular sand mill together with grinding beads and are dispersed for 20-40 min at the rotating speed of 1,500-2,500 rpm to obtain a component A; the component A and a component B are uniformly mixed, with the adoption of a spraying, brushing or dip-coating mode, a coating layer is prepared on the surface of the metal part subjected to surface sand blasting processing, and the coating with high temperature resistance, corrosion resistance and nuclear radiation resistance is obtained after the coating layer is cured at the room temperature. The coating has good nuclear radiation resistance and excellent thermal stability, and the problems of oxidation, corrosion and radiation of the metal part served in the high-temperature, high-humidity, high-salt and nuclear-radiation environments are solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

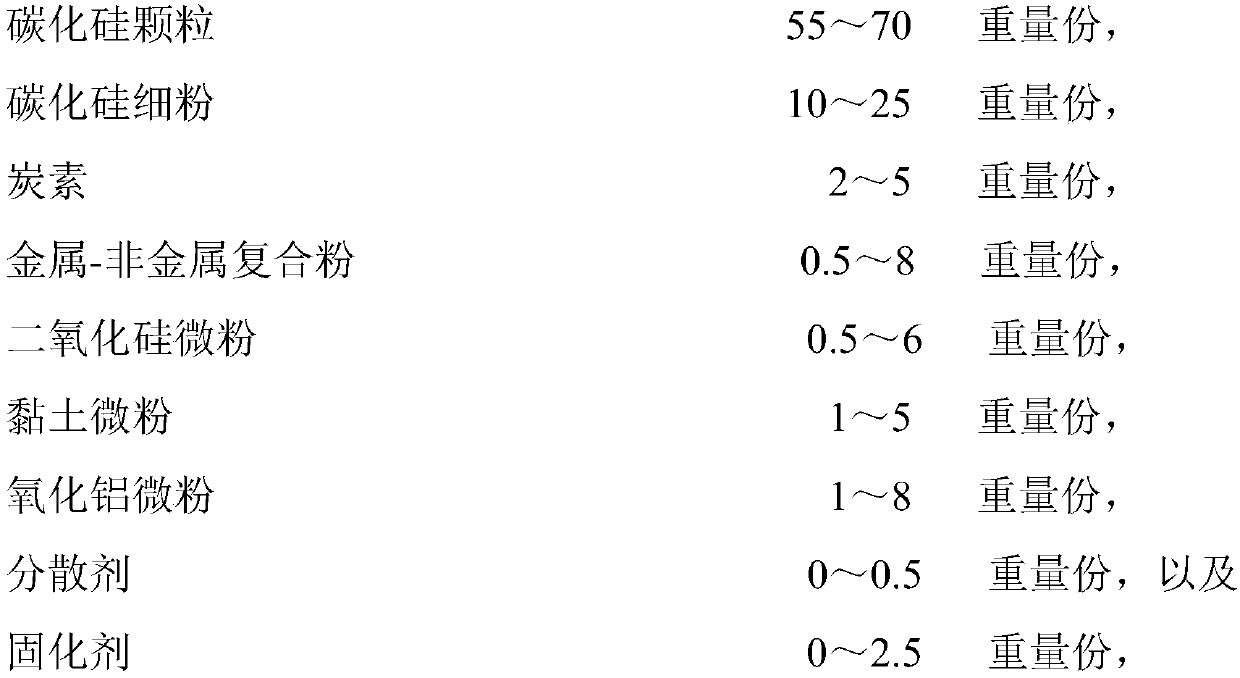

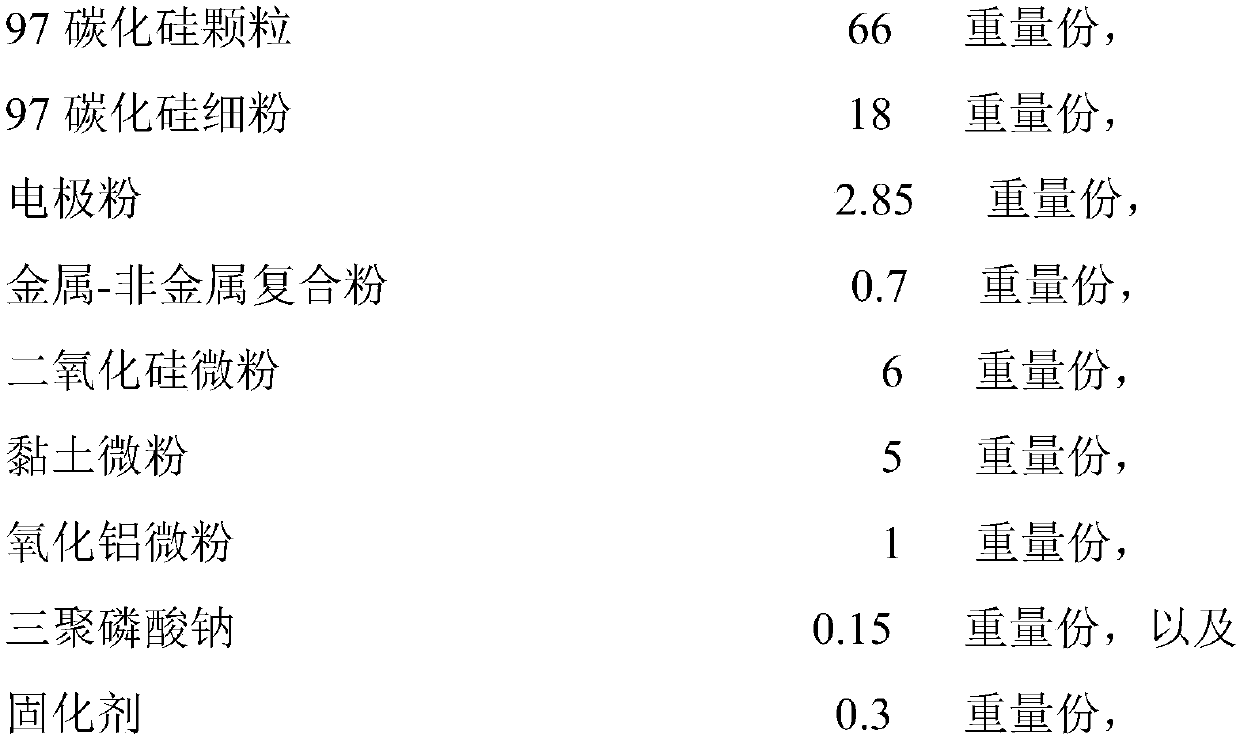

Blast furnace bottom joint filler and preparation method thereof

ActiveCN110627505AHigh thermal conductivity and high strengthImprove liquidityHigh densityResource utilization

The invention discloses a blast furnace bottom joint filler. The joint filler comprises, by weight, 100 parts of dry materials and 10-25 parts of a binder, wherein 100 parts of the dry materials include silicon carbide particles, fine silicon carbide powder, carbon, a metal-nonmetal composite powder, a silicon dioxide micro-powder, a clay micro-powder, an aluminum oxide micro-powder, a dispersantand a curing agent. The invention further discloses a preparation method of the blast furnace bottom joint filler. The blast furnace bottom joint filler has a high heat conductivity coefficient, can effectively transfer heat, has a high strength index and a high density, has no pollution to the environment, is easy to construct, can fully fill joints, can closely combine with a material for filling the area, can be constructed at a high temperature, also can be constructed and solidified at normal temperature, has a small linear change rate and a good thermal shock stability in a use temperature interval, and improves the resource utilization rate by using wastes in other industries.

Owner:CHINA JINGYE ENG +2

Flake zinc powder and nano silica doped epoxy zinc rich primer and preparation method thereof

InactiveCN104710909AImprove corrosion resistanceImprove shielding effectAnti-corrosive paintsEpoxy resin coatingsWaxEpoxy

A flake zinc powder and nano silica doped epoxy zinc rich primer includes a main agent and a curing agent in the weight ratio of 15: 1-19: 1. The main agent comprises the following components by weight: 6-12 parts of epoxy resin, 5 parts of a solvent, 68-80 parts of a spherical zinc powder, 2.6-9 parts of a flake zinc powder, 4 parts of nano silica, 1-1.8 parts of an anti-sedimentation agent, 0.4-1.2 parts of a wetting dispersant and 1-3 parts of polyamide wax. The curing agent composition contains the following components by weight: 90-95 parts of a curing agent and 5-9 parts of a solvent. The preparation method is as below: adding epoxy resin into the solvent, and adding the rest of the main agent, grinding and mixing evenly; evenly mixing the curing agent and solvent into a curing agent composition; preparing the main agent and the curing agent according to the mass ratio of 12: 1-19: 1 for preparation of a coating paint; and drying to reach above 80% of solid in the coating film. Addition of the flake zinc powder and nano silica reduces the pore among the particles in the filler and enhances the corrosion resistance.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

Method for producing environment-friendly pencil

InactiveCN102145616AReduce manufacturing costNo pollutionNon-propelling pencilsCompound aAcetic acid

The invention provides a method for producing an environment-friendly pencil. The method comprises the following specific steps of: (1) cutting paper; (2) sticking a pencil core; (3) placing a paper sheet on which the pencil core is stuck on a glue coating pole coiling machine, continuously dripping special glue on the paper sheet and coiling to form a rough pole pencil, wherein the special glue comprises the following components in percentage by mass: 11 to 11.9 percent of acetic acid resin, 8 to 10 percent of sodium fluosilicate, 0.1 to 0.12 percent of ferrum dioxide, 30 to 40 percent of filler and 40 to 50 percent of water; (4) naturally drying the rough pole pencil for 2 to 4 hours; (5) polishing the dried rough pole pencil, and cutting to ensure the pencil has the specified length and size, namely a polished pole pencil; (6) thermally compounding a plastic sleeve on the polished pole pencil; and (7) sleeving an rubber head. The special glue is used during pole coiling, normal temperature solidification is realized and the solidification time is short, the raw materials are saved and production cost of the pencil is reduced. The prepared pencil is environment-friendly and does not pollute the environment.

Owner:ZHUSHAN WENZHUANGYUAN TECH DEV

Grouting material and preparation method thereof

InactiveCN107384294AGood bonding performance and process performanceGood compatibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryHydroxyl-terminated polybutadiene

The invention discloses a grouting material and a preparation method thereof. The grouting material comprises the following raw materials by weight: 100 parts of hydroxyl terminated polybutadiene, 0.45 part of a cross-linking agent, 30 parts of filler, 0.1-0.5 part of a catalyst and a curing agent. The preparation method includes: firstly sieving filler, taking the siftage and performing drying; then mixing hydroxyl terminated polybutadiene and the cross-linking agent evenly, adding the curing agent, the filler and the catalyst in order, and mixing the substances evenly after each adding; and finally conducting vacuum pumping treatment, thus obtaining the grouting material. The grouting material provided by the invention has good body, bonding performance and technological properties, and can repair the defect space of solid rocket engine charge combustion chamber third interfacial debonding. The system of the grouting material is consistent with the lining and grain, has good compatibility, can improve the aging performance and prolong the service life, has good fluidity, and can realize room temperature curing.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

Pre-coated film propping agent, preparation method of pre-coated film propping agent and sand prevention method adopting pre-coated film propping agent

ActiveCN102660245BImproves breakage resistanceEasy to divertFluid removalDrilling compositionBisphenol FPolyamine

The invention relates to a pre-coated film propping agent, a preparation method of the pre-coated film propping agent and a sand prevention method adopting the pre-coated film propping agent. The pre-coated film propping agent comprises propping agents, one or more pre-coated resins, one or more pre-coating curing agents, a coupling agent and a lubricating agent. The one or more pre-coated resins comprise bisphenol-A epoxy resin, bisphenol-F epoxy resin and / or novolac epoxy resin. The one or more pre-coating curing agents are selected from alicyclic polyamines, aromatic polyamines, modified alicyclic polyamines and / or modified aromatic polyamines. The coupling agent is an organosilane coupling agent.

Owner:BEIJING QISINTAL SCI & TECH +1

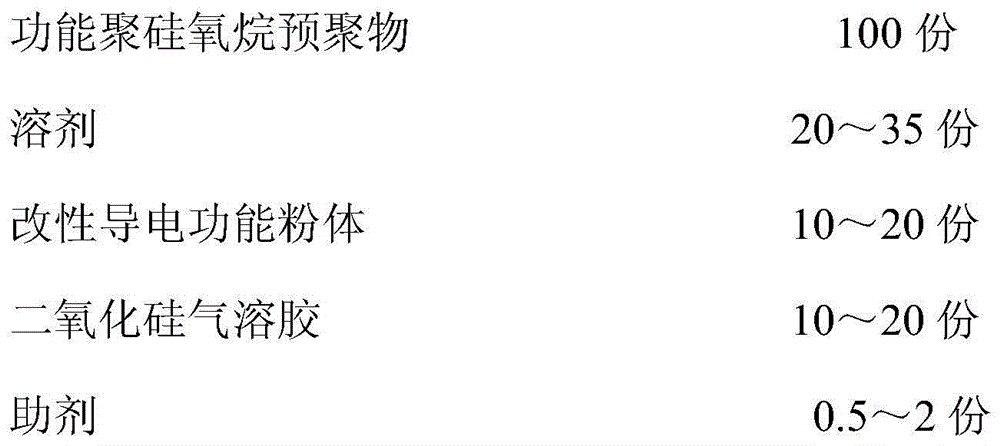

Preparation method of golden yellow ceramic paint for subway stations

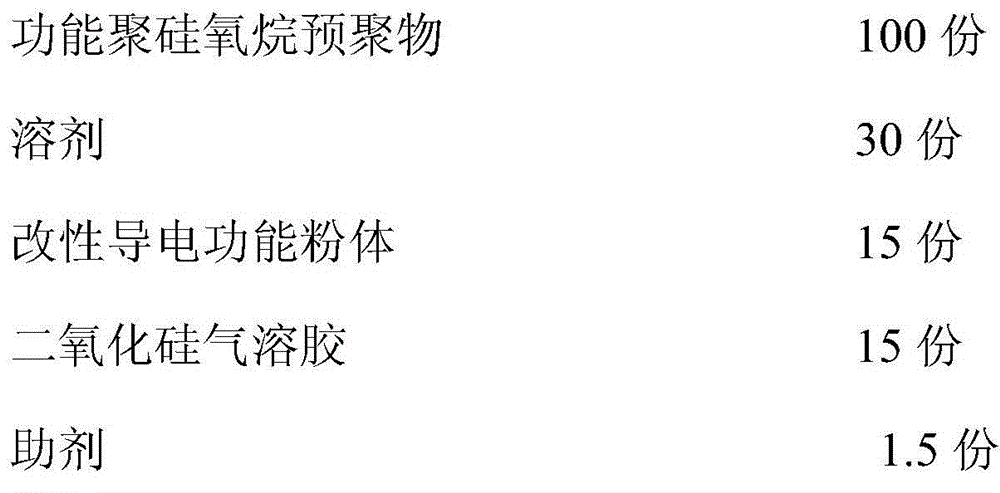

The invention relates to a preparation method of a golden yellow ceramic paint for subway stations. The preparation method comprises the following steps: (1) preparing a functional polysiloxane prepolymer; (2) preparing modified conductive functional power bodies; (3) preparing the golden yellow ceramic paint, under a stirring condition, adding the functional polysiloxane prepolymer, a solvent, the modified conductive functional powder bodies and an addition agent in proportion by weight for mixing, and eliminating bubbles by a supersonic antifoaming method so as to obtain the desired golden ceramic paint for the subway stations. According to the invention, the modified conductive powder bodies are acetified and adsorbed and fixed by carbon black, so that the surface of the carbon black is coated with copper ions; besides, the color of the copper is golden yellow, by an adsorbing and reducing method, not only the electric conductivity of single carbon black can be improved, but also the traditional conductive paint can be enabled to be transformed into golden yellow from single black, as for simple metal addition, the addition level of metal can be reduced, and the high unification of the electric conductivity and the color of the paint is realized.

Owner:刘继伟

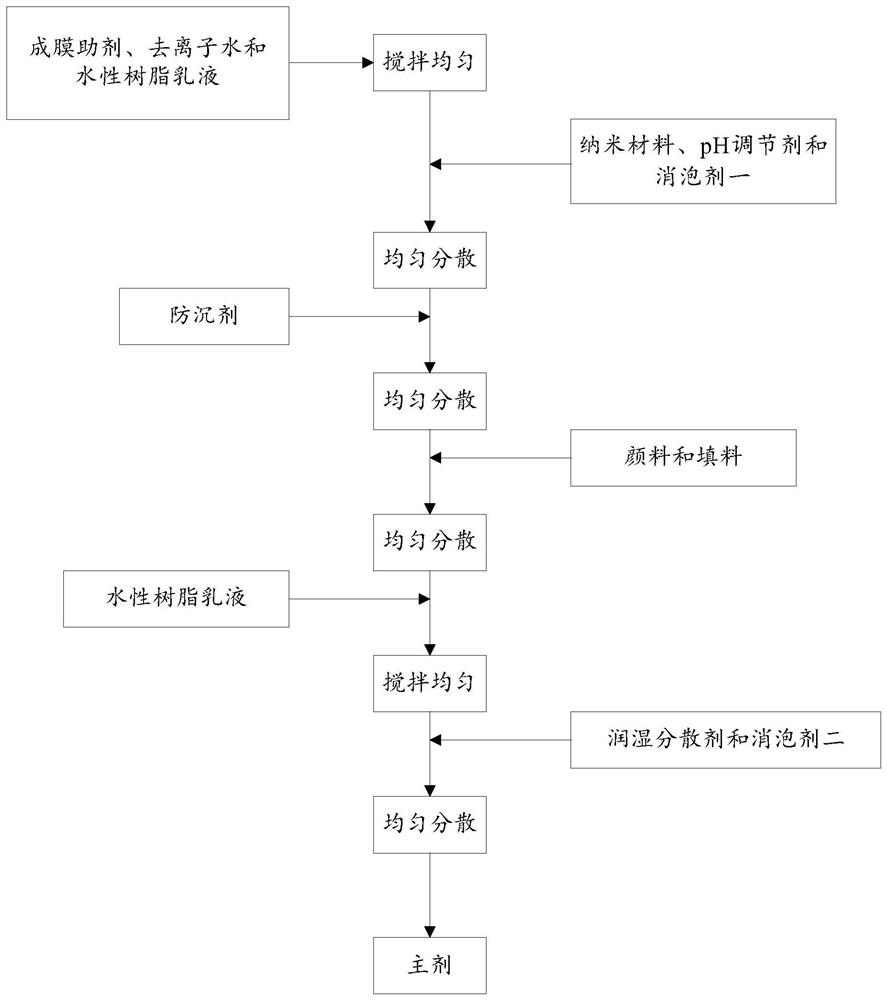

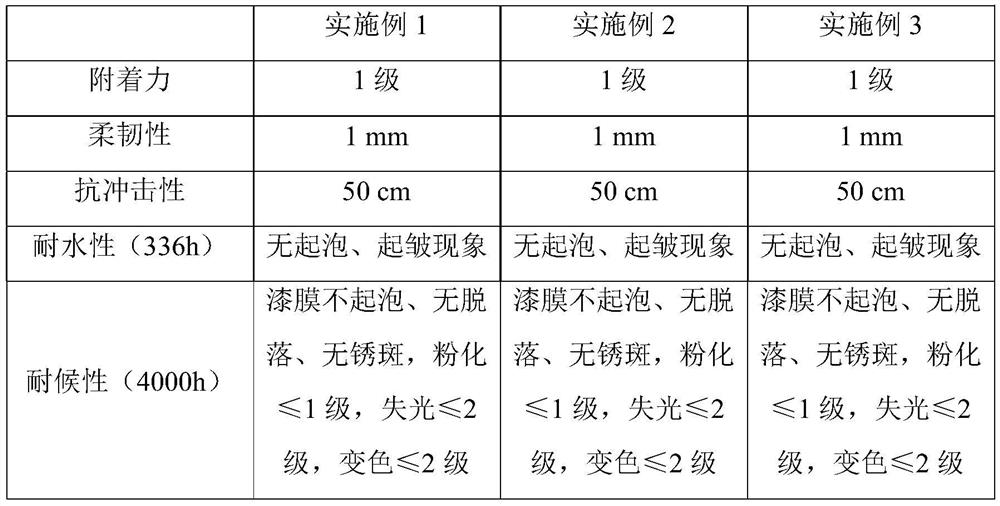

Water-based graphene acrylic acid-polysiloxane coating and preparation method thereof

InactiveCN111777910AAchieve room temperature curingImprove adhesionAnti-corrosive paintsWeather resistanceDefoaming Agents

The invention discloses a water-based graphene acrylic acid-polysiloxane coating and a preparation method thereof. Raw materials of the coating comprise main agents and a curing agent, wherein the main agents include 60 to 60 70 parts by mass of a water-based resin emulsion; 15 to 20 parts by mass of pigment; 10-15 parts by mass of a filler; 0.1 to 1.0 part by mass of a nanometer material; 0.5 to1.0 part by mass of an anti-settling agent, 1.0-1.5 parts of a coalescing agent, 0.1-0.2 part of a pH regulator, 2-4 parts of deionized water, 0.05-0.10 part of a defoaming agent I, 0.5-1 part of a wetting dispersant and 0.1-0.6 part of a defoaming agent II. The curing agent is a water-based curing agent containing an epoxy group and an alkoxy group; wherein the water-based resin emulsion is water-based acrylic acid graft modified polysiloxane resin, and the nano material is surface modified graphene oxide. By applying the technical scheme, the coating can be cured at normal temperature, the energy consumption is reduced, the adhesive force of the prepared coating is enhanced, the water resistance is improved, the weather resistance is excellent, and the mechanical properties such as the flexibility and the impact resistance of the coating are further improved.

Owner:天津中航百慕新材料技术有限公司

Rapid conductive coating for newly changed anode of aluminum electrolysis cell and coating method thereof

InactiveCN104446231AAchieve room temperature curingRapid conductivityPretreated surfacesSpecial surfacesConductive coatingAdhesive

The invention relates to a rapid conductive coating for newly changed anode of an aluminum electrolysis cell and a coating method thereof. The bottom of an aluminum electrolysis newly changed anode is coated by a layer of rapid conductive coating, and the coating comprises the following main formula components: 2-60wt% of an adhesive, 10-60wt% of an additive, 2-20wt% of an enhancer and 2-60wt% of functional particles. According to the rapid conductive coating disclosed by the invention, the initial crystallization temperature of electrolyte in a newly changed anode area can be properly reduced, so that the electrolyte is difficultly condensed on the bottom of the anode. Meanwhile, the coating has the effect of rapidly separating a condensed electrolyte layer at the bottom of the anode from the bottom of the anode, the conductive speed of the newly changed anode is greatly improved, and the aims of saving the energy and improving the efficiency during aluminum electrolysis are achieved.

Owner:CENT SOUTH UNIV

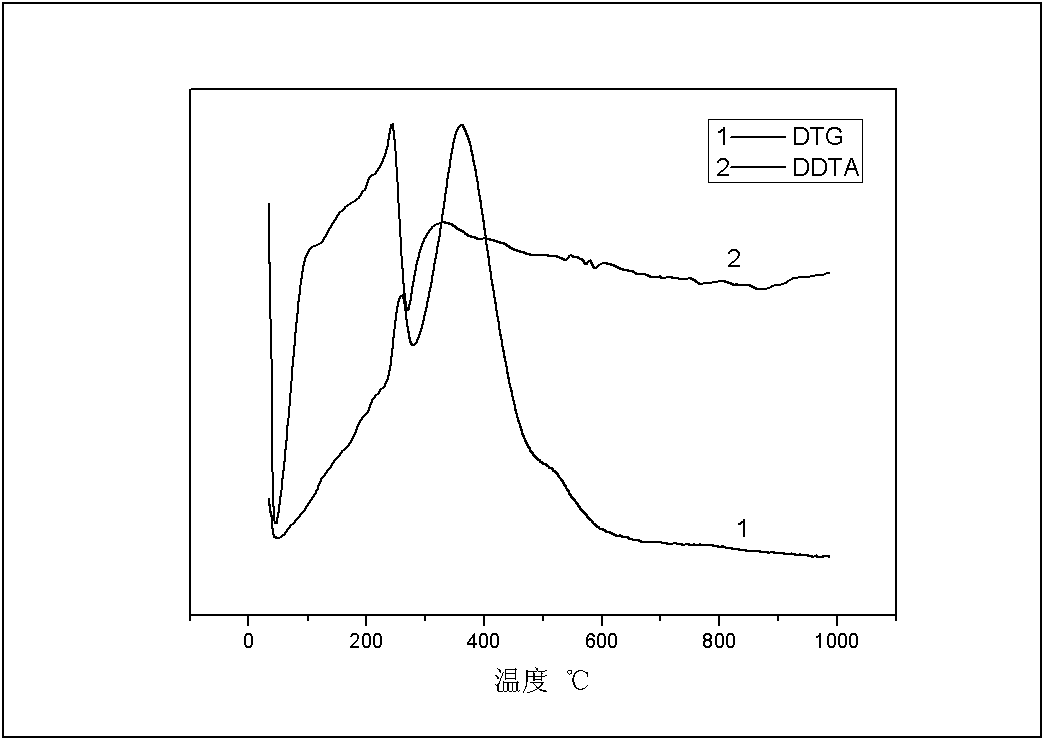

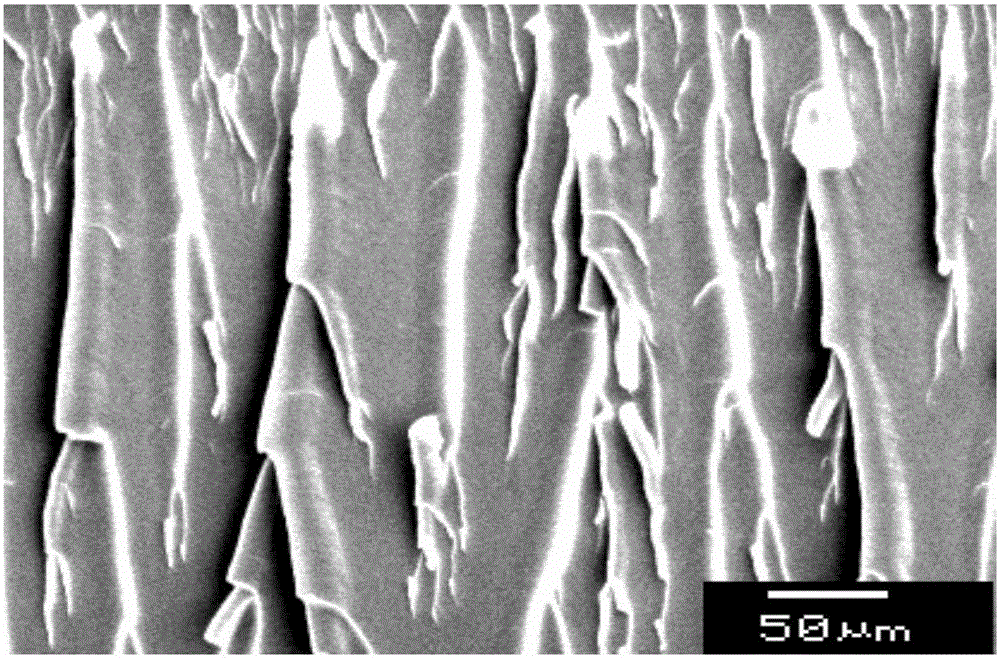

High performance room temperature cured titanium boride cathode coating for aluminium reduction cell

The invention discloses a high performance room temperature cured titanium boride cathode coating for an aluminium reduction cell. The coating is characterized by taking titanium boride powder as a base material, adding phenolic resins, acrylic resins and a curing agent on the basis of the conventional auxiliary material composition, firstly mixing the materials to prepare paste, then applying the paste on the carbon cathode of the aluminium reduction cell, carrying out curing for at least 24 hours at room temperature and then carrying out carbonization according to the optimum carbonization temperature rising system worked out based on variation of mass and energy of the coating paste in the process of high temperature carbonization variation, wherein the phenolic resins and the acrylic resins have the advantages of excellent heat resistance, higher carbon yield and the like. The invention can realize room temperature curing of the TiB2 cathode coating, improve the impact damage resistance capability and toughness of the coating and reduce the resistivity, obtain the TiB2 cathode coating with less deformation and optimum performance and more advantageously promote the popularization and application of the TiB2 cathode coating.

Owner:SOUTHWEAT UNIV OF SCI & TECH

High temperature resistant anti-corrosion anti-nuclear radiation nano-modified organosilicon coating and its preparation and application

ActiveCN104804640BSimple preparation processEase of industrial productionAnti-corrosive paintsPolyurea/polyurethane coatingsSilicone coatingHigh-temperature corrosion

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Water-based high-temperature-resistant coating for high-temperature coating, and preparation method thereof

InactiveCN111218205AGood thermal stabilityImprove stabilityFireproof paintsAnti-corrosive paintsSilane couplingDefoaming Agents

The invention discloses a water-based high-temperature-resistant coating for high-temperature coating, and a preparation method thereof, and belongs to the technical field of water-based coatings. Thecoating is prepared from, by weight, 30-60 parts of a high-temperature-resistant emulsion, 0.05-2 parts of an organic silicon defoaming agent, 0.5-3 parts of an amine neutralizer, 0.3-3 parts of a silane coupling agent, 0.3-3 parts of a phosphate coupling agent, 0.1-2 parts of a base material wetting agent, 1-15 parts of a coalescing agent, 0.5-6 parts of a pigment, 20-40 parts of a filler, 5-25parts of distilled water I, 0.1-4 parts of a thickening agent and 0.1-4 parts of distilled water II. The water-based high-temperature-resistant coating for high-temperature coating has excellent waterresistance and salt spray resistance, can be directly applied to a high-temperature substrate in a coating manner, and can be directly used for treating some high-temperature parts which are in a high-temperature state for a long time due to special reasons without shutdown for cooling.

Owner:山东七维新材料有限公司

Epoxy-acid anhydride coating capable of being cured and used at room temperature and preparation method of coating

InactiveCN110396354ASuit one's needsAchieve room temperature curingRubber derivative coatingsCarboxyl rubber coatingsEngineering plasticAlloy substrate

The invention discloses an epoxy-acid anhydride coating capable of being cured at room temperature and a preparation method of the coating. The formula of the coating comprises the following raw materials in parts by weight: 70-80 parts of epoxy resin, 20-30 parts of episulfide resin, a sulfydryl compound with a sulfydryl mole number of 0.10-0.30 of an epoxy mole number of the epoxy resin, an acidanhydride with an acid anhydride mole number of 0.7-1.0 of a sum of the epoxy mole number of the epoxy resin and the episulfide mole number of the episulfide resin, 20-50 parts of a toughening agent,and 100-300 parts of a solvent. According to the coating provided by the invention, the problem that an epoxy acid anhydride coating needs to be cured at a high temperature is solved, the tensile strength of a room-temperature cured coating layer is greater than 60 MPa, the binding force of the room-temperature cured coating layer on a Ly12 aluminum alloy substrate is greater than 12 MPa, the coating has good adhesive force on materials such as metals and engineering plastics, and the application range of the epoxy-acid anhydride coating is expanded.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

High-toughness hand lay-up epoxy resin composition for wind turbine blades and preparation method thereof

The invention relates to a high-toughness hand lay-up epoxy resin composition for wind turbine blades and a preparation method thereof. The resin is prepared from component A and component B, wherein the component A is prepared from bisphenol A epoxy resin and epoxy terminated polyether elastomer; the component B is prepared from alicyclic amine, aromatic amine, benzyl alcohol, phenolic resin and an amino silane coupling agent; traditional diluent is replaced by the epoxy terminated polyether elastomer in the component A; the alicyclic amine, the aromatic amine and the high-softening-point phenolic resin in the component B can produce condensation reaction to jointly toughen epoxy resin with epoxy terminated polyether; the hand lay-up epoxy resin cure product with higher impact toughness and elongation at break is prepared. The cure product prepared through the method has appropriate operable time, gelation time and curing time, also can be cured in the temperature of 25 + / - 3 DEG C, can meet the manufacture and reinforcement requirements of varieties of large components in different environments, can be widely applied to the field of manufacturing and reinforcing the large compound material components, sports equipment, varieties of moulds and adhesives.

Owner:NEW UNITED GROUP

Preparation method of non-styrene unsaturated polyester resin

The invention relates to a preparation method of non-styrene unsaturated polyester resin. The method comprises the following steps: carrying out condensation reaction on dihydric alcohol, a monohydroxy allyl ether monomer, saturated binary acid or anhydride and unsaturated binary acid or anhydride to obtain an unsaturated polyester polymer; then adding a non-styrene crosslinking monomer and a defoaming additive into the unsaturated polyester polymer to obtain non-styrene unsaturated polyester resin; wherein the crosslinking monomer is one or more of acrylic acid-containing monoester, methacrylic acid-containing monoester, acrylic acid-containing diester and methacrylic acid-containing diester; wherein the defoaming additive is an organic matter containing carboxyl, the molecular weight ofthe defoaming additive is 46-350, and the acid value of the defoaming additive is 160.0 mgKOH / g-1246.0 mgKOH / g. The non-styrene unsaturated polyester resin disclosed by the invention can be cured at normal temperature, basically has no bubbles after being cured, and has excellent cured product performance.

Owner:CHANGZHOU HUARI NEW MATERIAL

Flame retardant polyurethane resin and preparation method thereof and flame retardant polyurethane conformal coating

InactiveCN102040725BCuring Rate ControlRaw materials are easy to getPolyurea/polyurethane coatingsMorpholineConformal coating

The invention relates to flame retardant polyurethane resin and a preparation method thereof and flame retardant polyurethane conformal coating. The preparation method of the flame retardant polyurethane resin comprises alcoholization of grease and synthetization of the flame retardant polyurethane resin, and the flame retardant polyurethane resin is prepared by the method; and the flame retardant polyurethane conformal coating comprises the following ingredients in percentage by weight: 60-80wt% of flame retardant polyurethane resin, 15-35wt% of solvent, one or more mixtures selected from quaternary ammonium salt, morpholine, imidazole derivative and 1,8-aza ring [5, 4, 0]hendecene-7-piperazine derivatives or 0.01-2wt% of a mixture of one or two selected from organic tin catalyst, carboxylic acid salt catalyst, phenylethyl acetate mercury, titanic acid ester catalyst,0-2wt% of leveling agent, 0-1.5wt% of defoaming agent, and 0-1wt% of fluorescent powder.

Owner:YANTAI DARBOND TECH

Nanoclay modified epoxy micaceous iron oxide coating, and its preparing method

ActiveCN100422276CAchieve room temperature curingImprove corrosion resistanceEpoxy resin coatingsAliphatic amineSolvent

This invention is related to coating technology specifically involving a kind of micaceous iron epoxy coating modified by nano clay and its preparation method concretely. The said coating is composed of epoxy resin, micaceous iron oxide, aliphatic amine, intercalating processed clay, phenolic aldehyde modified amide and so on. Its preparation method are as follows: 1) intercalating process of the clay; 2) adding the processed clay into the Epoxy Resin and solvents, mixing for 10~60 minutes; 3) putting micaceous iron oxide into the mixture prepared in 2), dispersing rapidly and uniformly, and then obtaining one composition of the said coating; 4) dissolving the curing agents with solvents to obtain the other composition, then adding the first composition into the second, curing the mixture under 10~120 deg.C conditions for 5 minutes to 15 days. The said coating obtained in this invention has better corrosion and permeability resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A one-component polyurethane coating

InactiveCN103059712BIncrease the degree of cross-linkingHigh impact strengthPolyurea/polyurethane coatingsLinseed oilToluene

Owner:英德市佐桐化学品有限公司

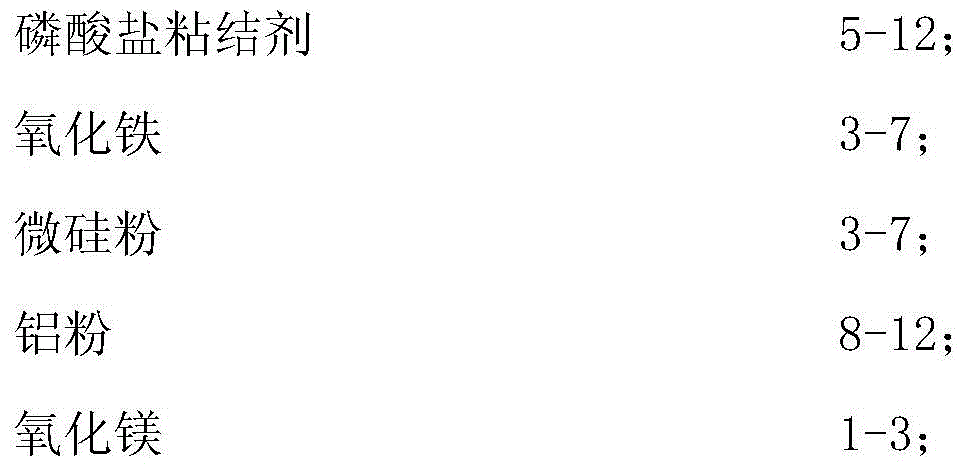

A phosphate-based anti-corrosion coating for steel bars

ActiveCN104404502BConvenient coatingImprove protectionMetallic material coating processesPhosphateThermal insulation

The invention discloses a steel rebar anticorrosive coating material for marine reinforced concrete. The steel rebar anticorrosive coating material is prepared by the following steps: adding aluminium hydroxide into phosphoric acid, heating and carrying out thermal insulation at 70-90 DEG C for 3-5 h so as to obtain a phosphate binder; and using the phosphate binder as a base solution, adding an aldehyde resin modifier, chrome oxide, iron oxide, macro-silicon powder, aluminium powder and magnesium oxide, grinding and uniformly stirring to obtain a phosphate coating. The steel rebar anticorrosive coating material comprises the following ingredients, by weight, 5-12 parts of the phosphate binder, 3-7 parts of iron oxide, 3-7 parts of macro-silicon powder, 8-12 parts of aluminium powder, 1-3 parts of magnesium oxide and 1-3 parts of aldehyde resin. The anticorrosive phosphate based coating material can be cured at normal temperature, and curing time can be adjusted according to requirements. Application of the phosphate coating is popularized. After cured, the coating material has high strength and compact structure and can stably be combined with a concrete structure. By the use of the coating material, a steel rebar can be protected well.

Owner:上海宇砼建筑科技股份有限公司

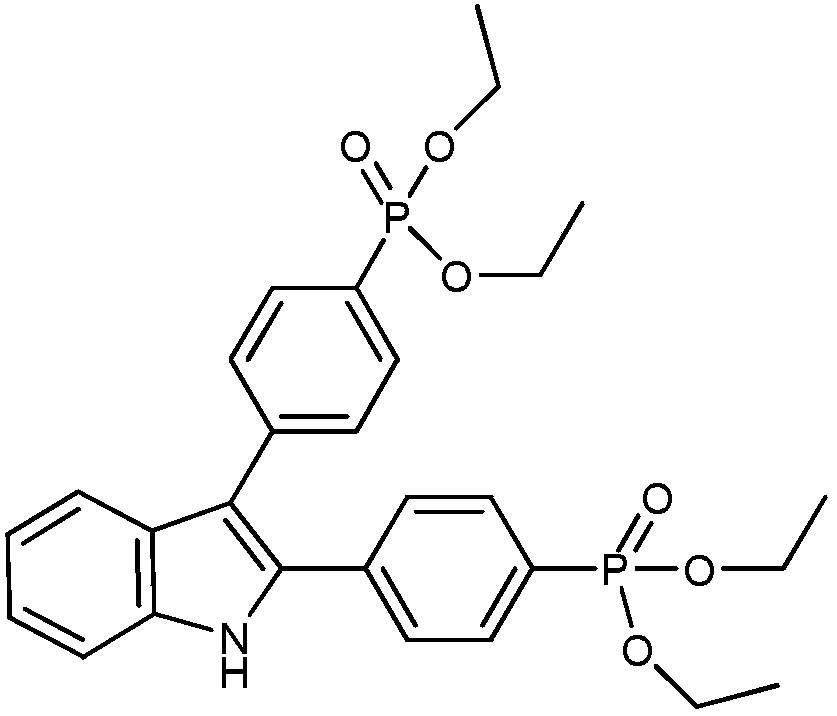

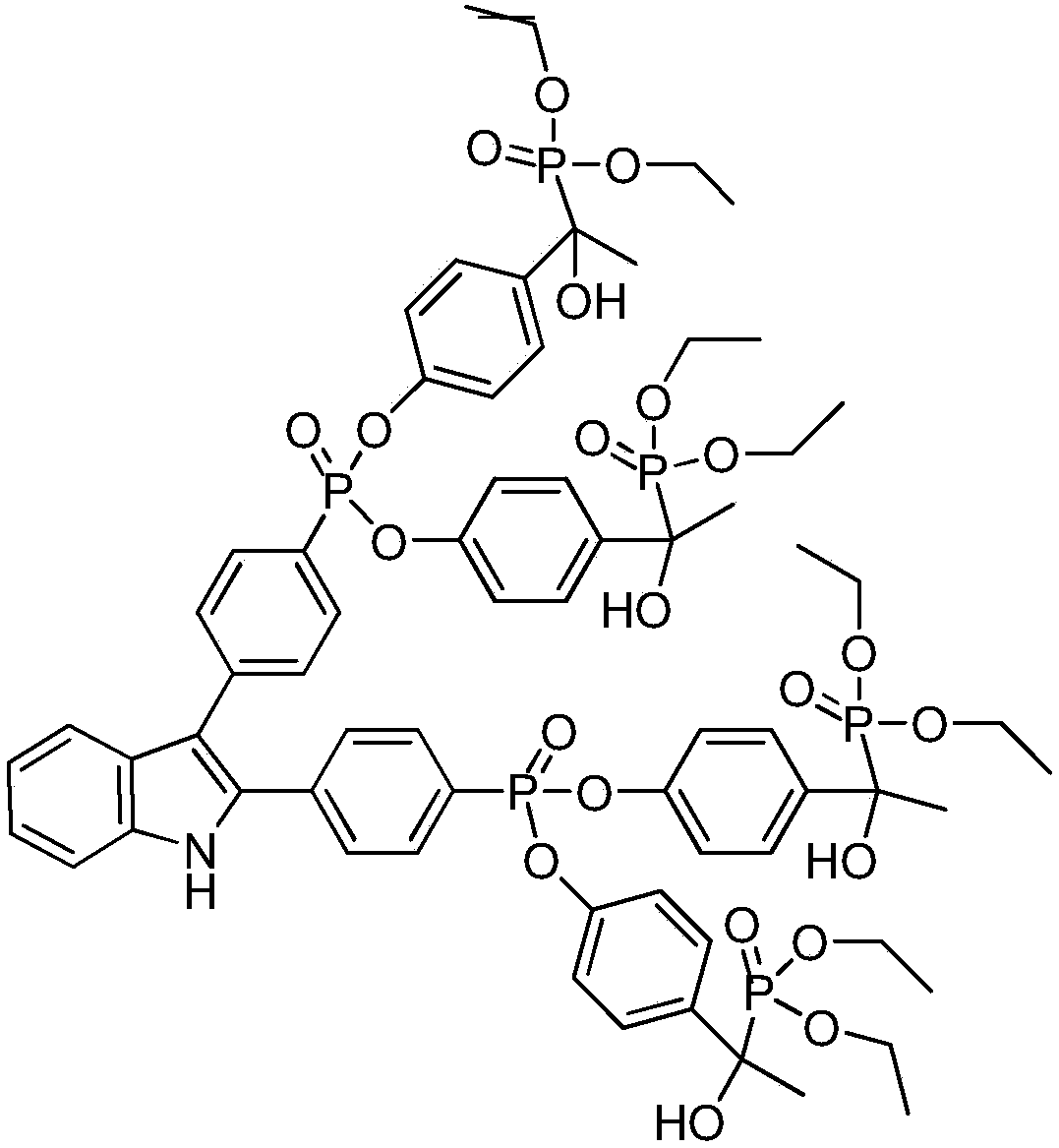

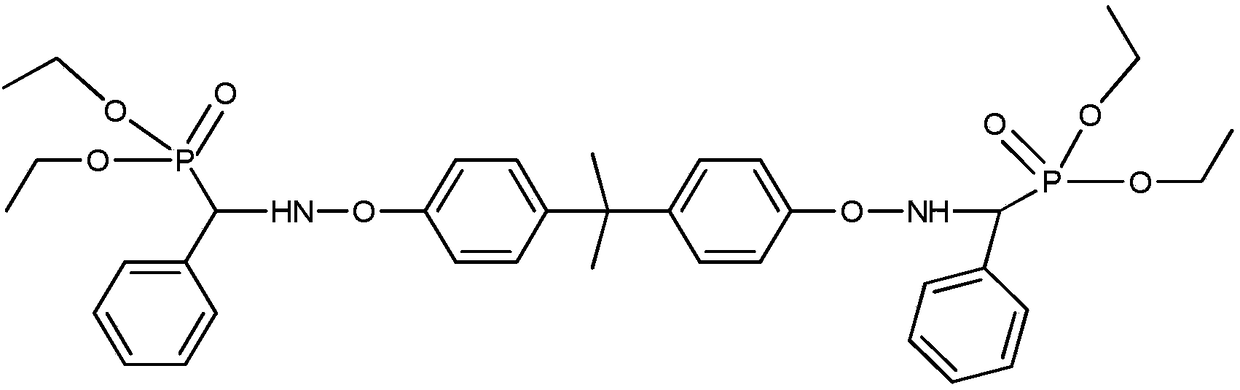

A kind of halogen-free flame-retardant hand lay-up epoxy resin composition and preparation method thereof

The invention relates to a halogen-free flame-retardant hand lay-up epoxy resin composition and a preparation method thereof. According to the technical scheme of the invention, a novel indolyl phosphonate compound is applied to a flame-retardant system for the first time, and the indolyl phosphonate compound has favorable compatibility with an epoxy resin composition and shows a high flame-retardant effect. According to the invention, the epoxy resin cured material has high impact toughness, can be used for manufacturing and reinforcing of various large-size composite components, and can satisfy the hand lay-up process requirements of fiber-reinforced composite materials; and the finished product has the advantages of efficient flame retardancy, corrosion resistance, light weight and the like, can be used instead of a traditional metal product and a plastic board having no flame-retardant characteristic, can be widely used in the fields having high flame-retardant characteristic requirements for materials such as electrotechnics and electronics, aerospace, new energy, rail transportation, sports equipment and the like, and is especially suitable for manufacturing and reinforcing of rail air-conditioning products and wind turbine blades.

Owner:NEW UNITED GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com