High-toughness hand lay-up epoxy resin composition for wind turbine blades and preparation method thereof

A technology of epoxy resin and hand lay-up molding, which is applied in the field of epoxy resin for hand lay-up molding and its preparation. It can solve the problems of unfavorable human health and non-environmental raw materials, and achieve stable quality, high heat resistance and high compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

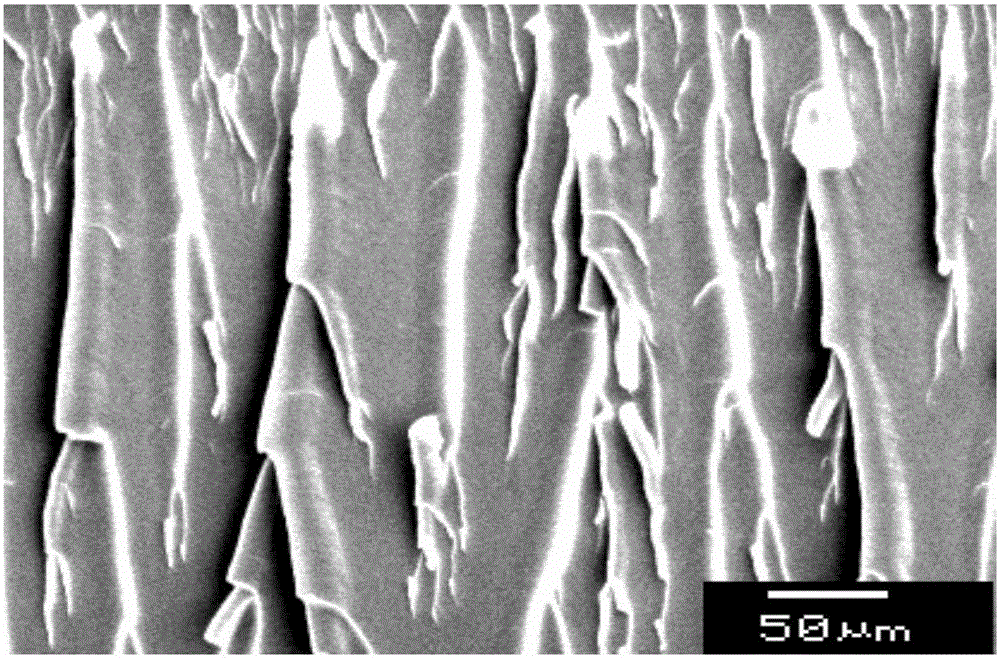

Image

Examples

Embodiment 1

[0038] A method for preparing a high-toughness hand lay-up epoxy resin composition for wind power blades, comprising the following steps:

[0039] (1) Preparation of component A

[0040] Put 80 parts by weight of bisphenol A epoxy resin and 20 parts by weight of epoxy-terminated polyether (epoxy value 0.15) into the reaction kettle, heat to 60°C, stir for 2 hours at a stirring speed of 80r / min, and pump After vacuuming for 50 minutes, stop stirring, continue vacuuming for 5 minutes, cool down, and put the resin into packaging barrel 1;

[0041] (2) Preparation of component B

[0042] Put 30 parts by weight of m-xylylenediamine and 10 parts by weight of isophoronediamine into the reaction kettle, heat up to 100°C, add 30 parts by weight of phenolic resin in 4 batches, and stir for 7 hours at a stirring speed of 80r / min. After the phenolic resin is completely dissolved, cool down to below 50°C, add 13.9 parts by weight of m-xylylenediamine, 16 parts by weight of benzyl alcohol...

Embodiment 2

[0045] A method for preparing a high-toughness hand lay-up epoxy resin composition for wind power blades, comprising the following steps:

[0046] (1) Preparation of component A

[0047] Put 80 parts by weight of bisphenol A epoxy resin and 20 parts by weight of epoxy-terminated polyether (epoxy value 0.1) into the reactor, heat to 50°C, and stir for 1.5 hours at a stirring speed of 100r / min. Stop stirring after evacuating for 60 minutes, continue to evacuate for 30 minutes, cool down, and put the resin into packaging barrel 1;

[0048] (2) Preparation of component B

[0049] Put 20 parts by weight of m-phenylenediamine and 24 parts by weight of isophorone diamine into the reaction kettle, heat up to 110°C, add 26 parts by weight of phenolic resin in two batches, and stir for 3 hours at a stirring speed of 100r / min. After the phenolic resin is completely dissolved, cool down to below 50°C, add 10 parts by weight of m-xylylenediamine, 20 parts by weight of benzyl alcohol and ...

Embodiment 3

[0052] A method for preparing a high-toughness hand lay-up epoxy resin composition for wind power blades, comprising the following steps:

[0053] (1) Preparation of component A

[0054] Put 90 parts by weight of bisphenol A epoxy resin and 10 parts by weight of epoxy-terminated polyether (epoxy value 0.125) into the reaction kettle, heat to 80°C, and stir at a stirring speed of 50r / min for 1.8h. Stop stirring after evacuating for 30 minutes, continue to evacuate for 25 minutes, cool down, and put the resin into packaging barrel 1;

[0055] (2) Preparation of component B

[0056] Put 10 parts by weight of isophoronediamine and 28 parts by weight of m-xylylenediamine into the reactor, heat to 105°C, add 30 parts by weight of phenolic resin in 3 batches, and stir for 6 hours at a stirring speed of 50r / min. After the phenolic resin is completely dissolved, cool down to below 50°C, add 19 parts by weight of m-xylylenediamine, 12 parts by weight of benzyl alcohol and 1 part by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com