Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about "Manganese halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode active material for nonaqueous electrolyte secondary battery and method of producing cathode active material for nonaqueous electrolyte secondary battery

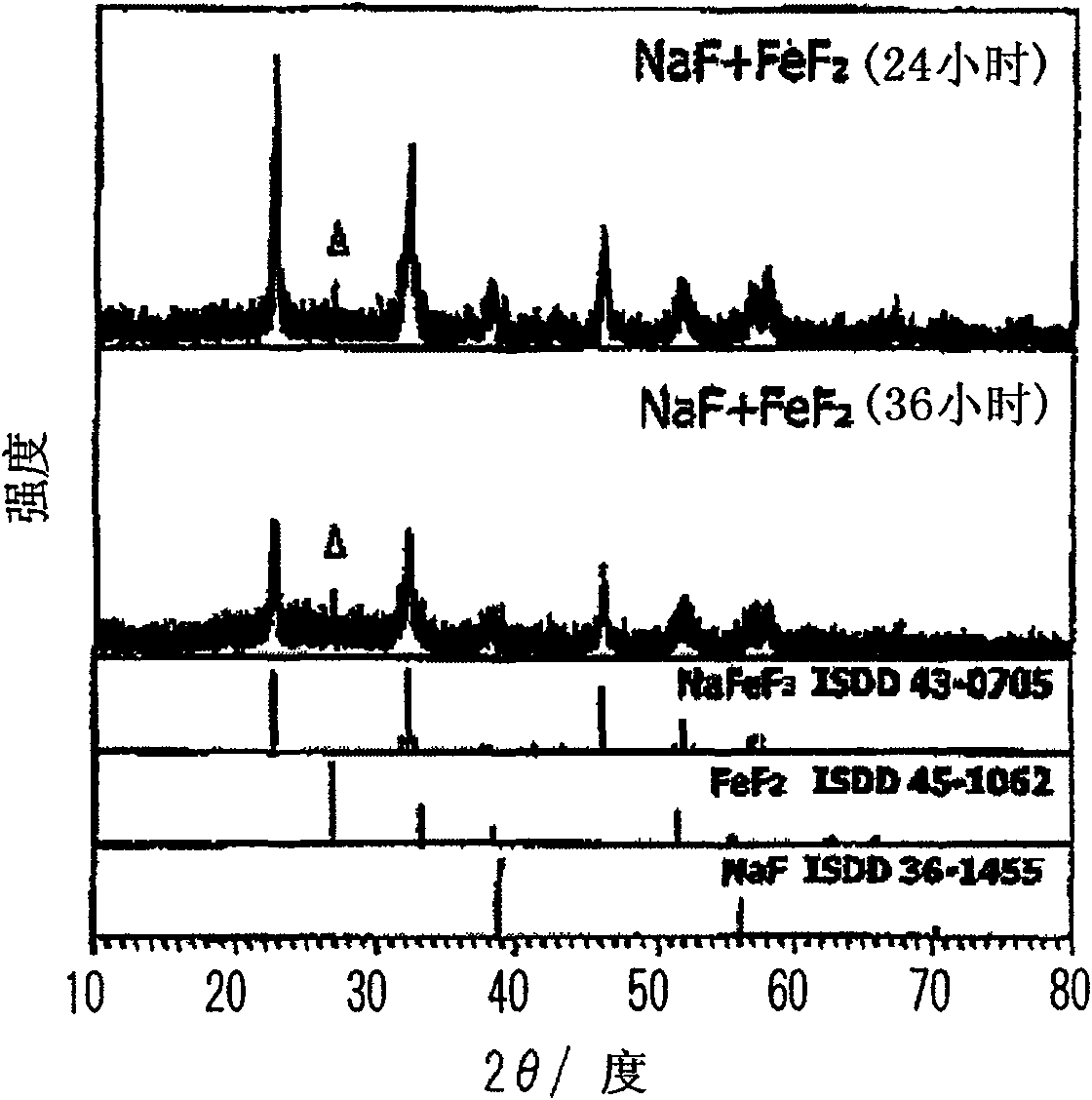

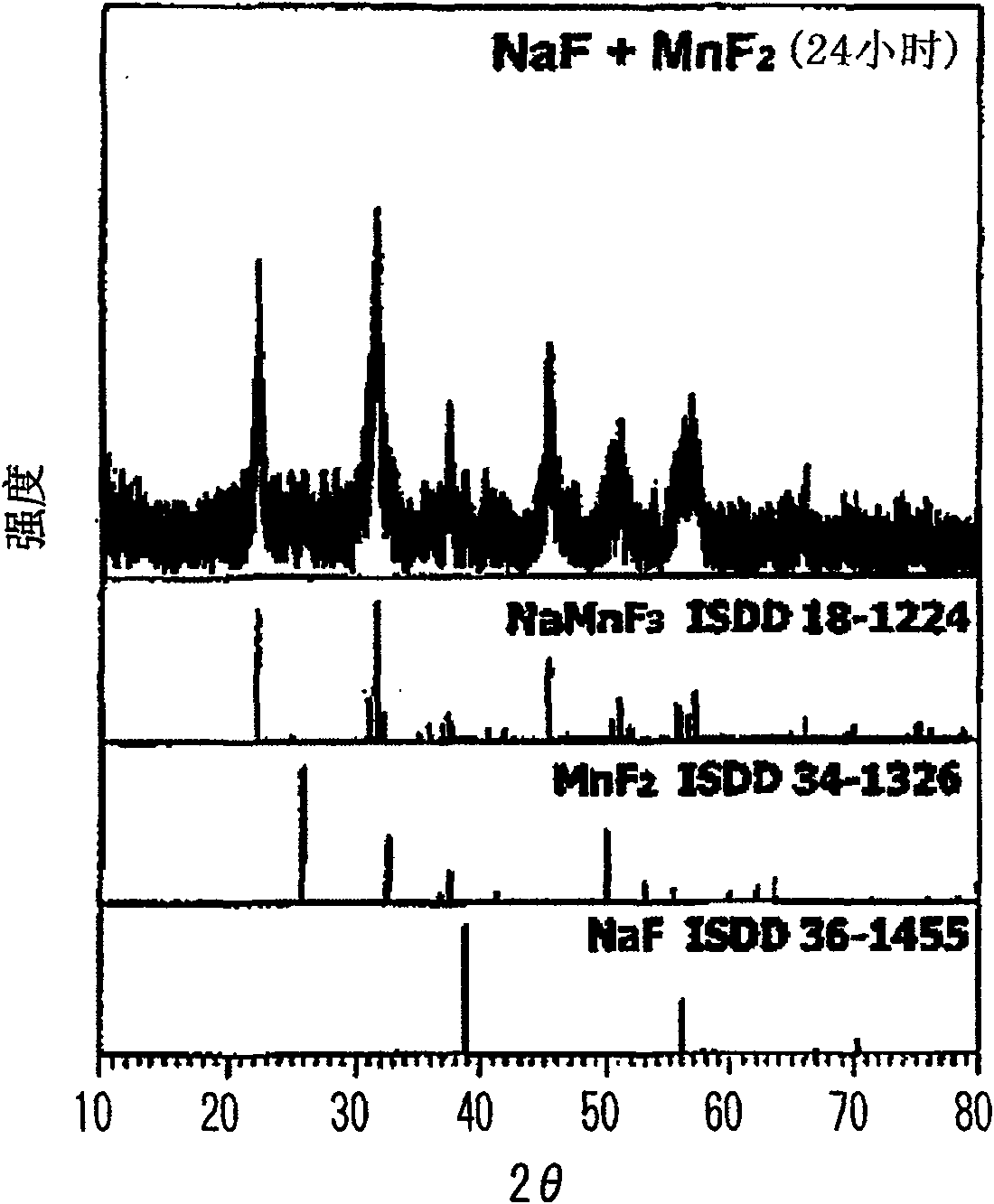

To prepare a fluorinated cathode active material having a guest cation comprising sodium or lithium included therein in a nonaqueous electrolyte secondary battery, an alkali metal fluoride represented by the formula AF and a transition metal fluoride represented by the formula M'F2 are treated by chemical milling to thereby give a fluoride AM'F3. A satellite ball mill is preferably employed in the chemical milling treatment.

Owner:MITSUBISHI HEAVY IND LTD +1

Composite loading nano-titania carrier and its prepn

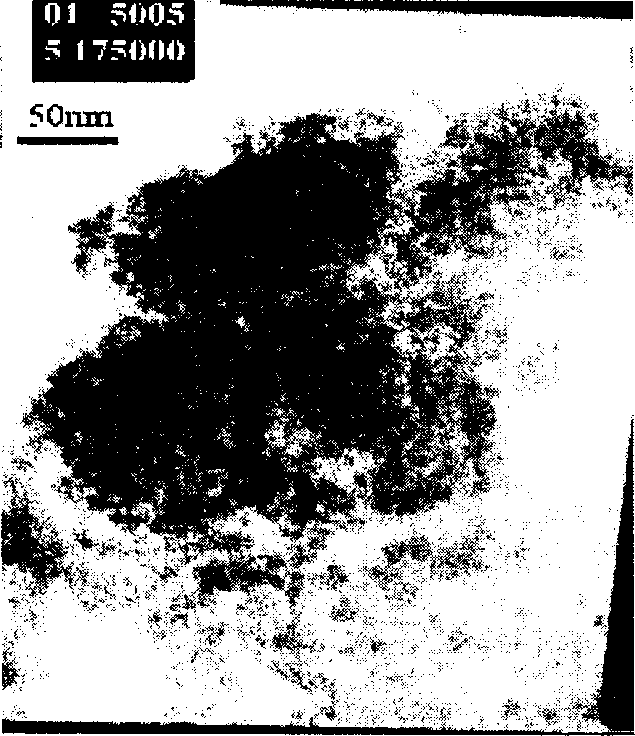

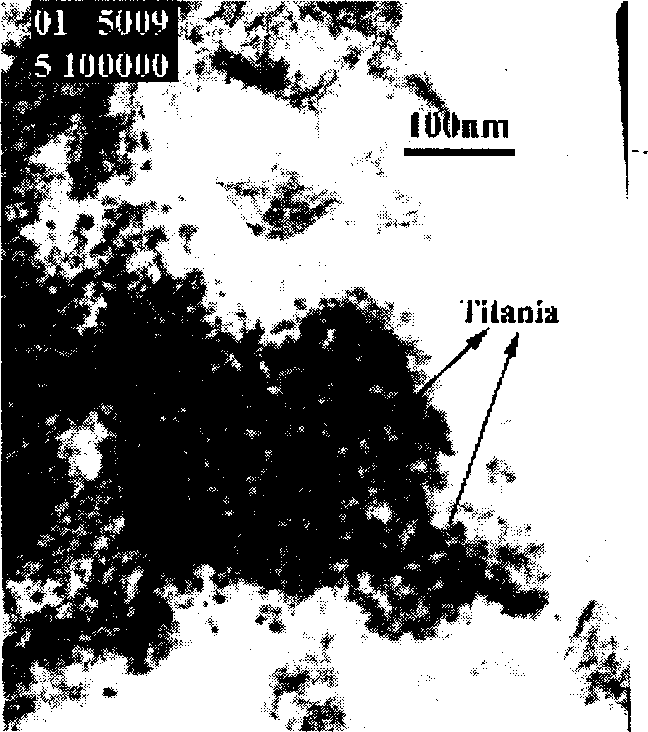

A loading type of nanometer titania composite carrier is constituted by loading 5-20 nm TiO2 in 10-40 wt% onto gamma-Al2O3. Titania sol is first prepared through sol-gel process and then dropped into pseudo-then diaspore pulp of different solution; and the product is finally processed through drying, calcination successively at 200, 300, 400 and 500 deg.c for 2 hr each. The present invention loads nanometer Tio2 onto macroporous Al2O3 to form the composite nanometer carrier. This can utilize the superority of nanometer TiO2 while overcoming the demerits. By means of the micro design, surface acidity regulation of loaded TiO2 and loading active component, the hydrorefining activity of catalyst may be raised effectively.

Owner:NANKAI UNIV

Method for preparing anhydrous manganese chloride under anhydrous reaction conditions

The invention discloses a method for preparing anhydrous manganese chloride under anhydrous reaction conditions, which comprises the following steps: (1) mixing metal manganese powder and solvent alcohol, introducing gas hydrogen chloride into the solvent alcohol in a metering mode to react with the metal manganese powder until the manganese powder is completely dissolved, and filtering to obtain an anhydrous manganese chloride alcohol solution; (2) stirring and distilling under normal pressure in a hydrogen chloride atmosphere to recover the solvent and obtain a manganese chloride crystal alcohol complex; and putting the manganese chloride crystal alcohol complex into a closed dryer, heating in a stirring state, and dealcoholizing under reduced pressure to obtain the anhydrous manganese chloride. The method has the characteristics of simple technique, simple after-treatment, high safety and high product yield, and does not have the basic manganese chloride and manganese peroxide impurities in the conventional preparation method. The anhydrous manganese chloride is obtained under anhydrous conditions, so the method has the advantages of high product yield, high safety and the like, and is simple to operate and suitable for industrial production.

Owner:JIANGXI SILINCO

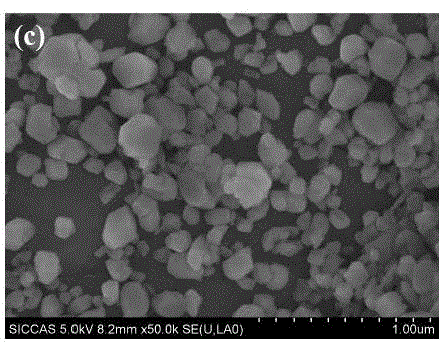

High-performance nano manganous fluoride cathode material and preparation method therefor

The invention relates to a high-performance nano manganous fluoride cathode material and a preparation method therefor. The preparation method comprises the steps of: 1) preparing an alcohol solution where manganese ions and fluorine-containing anion groups are dissolved; 2) carrying out a reaction on the alcohol solution prepared in the step 1) in a reaction kettle at 50-250 DEG C for a specified time, wherein a precipitate is formed in the alcohol solution; and 3) separating the precipitate obtained in the step 2) and washing and drying the precipitate.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

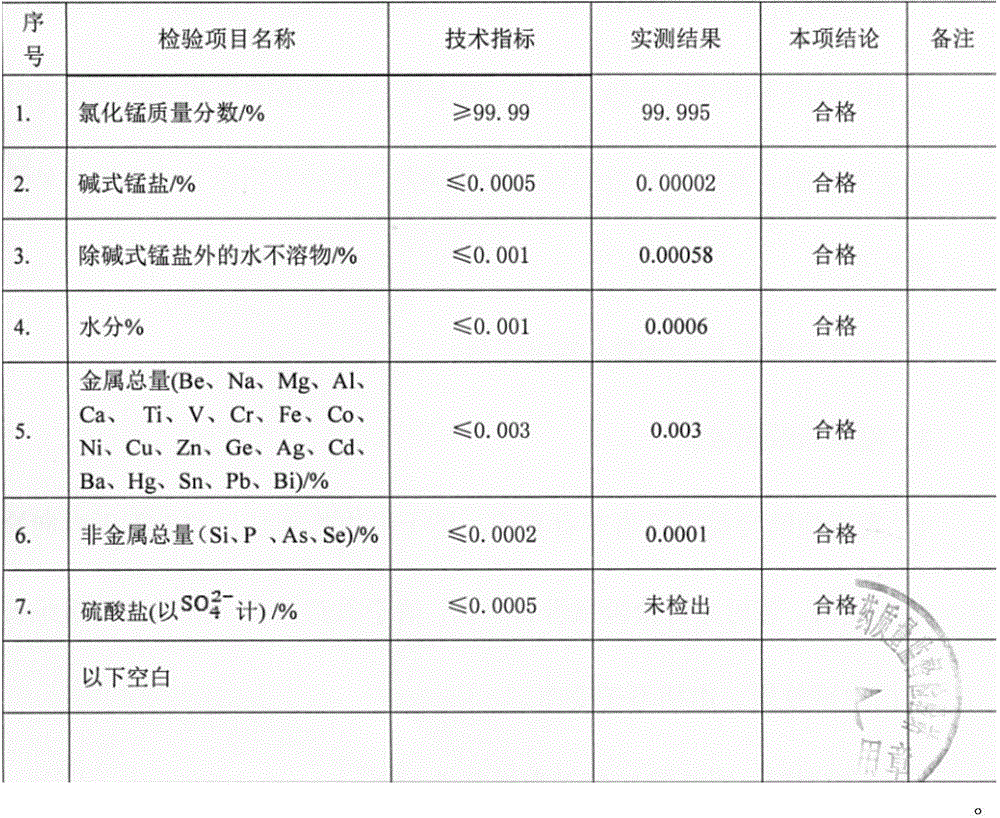

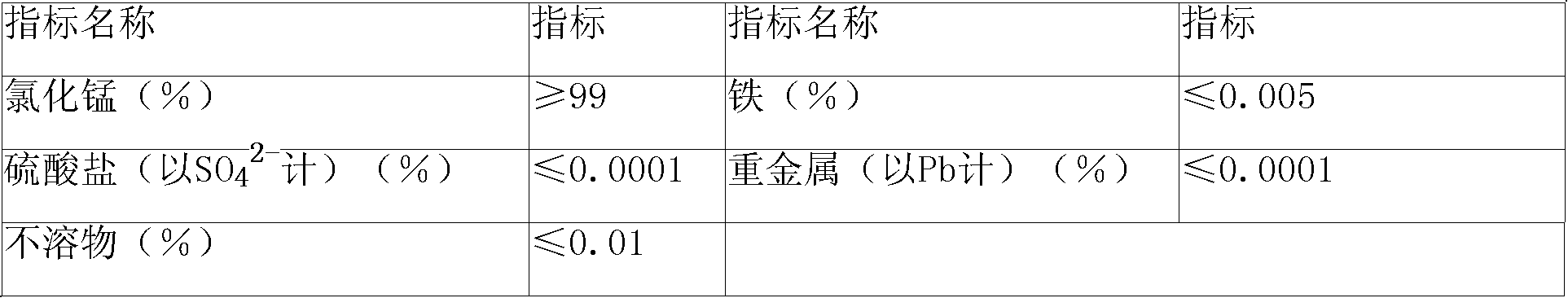

Manufacturing method of ultra-pure battery-grade manganese chloride for battery material

The invention relates to a manufacturing method of ultra-pure battery-grade manganese chloride for a battery material, which comprises the following steps that: manganese chloride solution which is prepared by leaching ordinary manganese carbonate or metal manganese with high impurity content through hydrochloric acid is added with hydrofluoric acid, fluoride, phosphoric acid, phosphate salt or polyphosphoric compound to remove calcium (Ca) and magnesium (Mg), sulfide, polysulfide or sulfuric organic sodium salt is used for removing heavy metal impurities, the pH value of the solution is maintained at 2.5 to 6.0, the solution is filtered after the reaction, filtered liquid enters an iron-removing reactor, the reaction temperature is controlled at 30 to 120 DEG C, the Baume degree is 30 to56 degrees Be, industrial peroxide or hydrogen peroxide is added under the pH value of 2.5 to 6.0 to remove the iron, organic matters can be removed by adding particle or powder active carbon under the temperature of 30 to 120 DEG C, filter liquid after the reaction and filter is pumped into a concentrator to be concentrated, crystallized and dripped at a normal pressure or a negative pressure, so an ultra-pure battery-grade manganese chloride product is obtained. For the manganese chloride product prepared through the method, the content of the manganese chloride product can reach more than 99 percent.

Owner:HUBEI HAOYUAN MATERIAL TECH

Preparation method of ferromanganese component fine adjustable Prussian white mesomorphic material

ActiveCN108821311ALow costReduce energy consumptionIron cyanidesManganese halidesManganateFree cooling

The invention belongs to the technical field of material science and chemical preparation and discloses a preparation method of a ferromanganese component fine adjustable Prussian white mesomorphic material. The preparation method comprises the following steps: dissolving potassium ferrocyanide and a stabilizer into a dilute hydrochloric acid solution and then adding divalent manganate into a mixed solution; after ultrasonic treatment is carried out for 30 minutes, carrying out 80 DEG C hydrothermal treatment for 24 hours; then carrying out natural cooling, washing and centrifugally separatingthe obtained precipitate and drying for 12 hours to obtain a cubic Prussian white mesomorphic nano-composite material. The cubic Prussian white mesomorphic nano-composite material with the characteristics of stable presence at room temperature and uniform size and morphology is synthesized by controlling the doping amount of low-valence manganate; the preparation method has the advantages of simple technology and low cost, and provides certain guidance for shape control synthesis and stability improvement of Prussian white.

Owner:FUJIAN XINSEN CARBON

Method for preparing methanesulfonic acid by recycling byproduct, namely hydrochloric acid

ActiveCN103641748AReduce manufacturing costReduce security risksSulfonic acid preparationManganese halidesWater chlorinationMethyl disulfide

The invention relates to a method for preparing methanesulfonic acid by recycling a byproduct, namely hydrochloric acid. The method is characterized in that a method of hydrogen chloride, chlorine gas, methanesulfonic acid and hydrogen chloride is adopted, and the byproduct, namely the hydrochloric acid is recycled in the preparation process of the methanesulfonic acid to prepare the methanesulfonic acid. The method has the advantages that the byproduct, namely the hydrochloric acid is adopted for preparing chlorine gas and directly reacted with dimethyl disulfide, so that the safety risk and the logistics cost in purchase, transportation and storage of the chlorine gas with severe toxicity can be avoided; the byproduct, namely the hydrochloric acid, which is difficult to sell can be locally digested and utilized, and turned into treasure, so that the byproduct, namely the hydrochloric acid becomes a main raw material for preparing the methanesulfonic acid and the recycling of chlorine element is realized. Simultaneously, leftover manganese dioxide waste after oxidation reaction of potassium permanganate is utilized to prepare manganese chloride, and the manganese chloride can be used for electrolytic manganese, so that the production cost and the safety risk of the methanesulfonic acid are greatly reduced, and two major restricting factors, namely the chlorine gas and the byproduct, namely the hydrochloric acid in the preparation method of the methanesulfonic acid are simultaneously eliminated.

Owner:湖北星火(应城)化工有限公司

Method for recycling chlorine gas from HCl-containing exhaust gas and preparing manganese chloride, and manganese chloride crystals

InactiveCN102674465ASolve the problem of circular enrichmentSolve highManganese halidesLithiumProduct gas

The invention provides a method for recycling chlorine gas from HCl-containing exhaust gas and preparing manganese chloride, and manganese chloride crystals. The method comprises the following steps: 1. introducing HCl-containing exhaust gas into MnO2 pulp to carry out reaction, stopping the reaction when the pH value of the pulp reaches 1-2, wherein the concentration of MnCl2 in the pulp after the reaction is stopped is controlled at 100-300g / L, and meanwhile, the Cl2-containing gas after the reaction is recycled; 2. carrying out solid-liquid separation on the pulp obtained in the step 1 to obtain a first filtrate, adding manganese-containing alkali liquor into the first filtrate for neutralization until the pH value reaches 3-3.5, removing impurities, and filtering to obtain a second filtrate; and 3. crystallizing the second filtrate, and recrystallizing to obtain the MnCl2.4H2O product. The method can be used for preparing the manganese chloride product which satisfies the following condition required by a lithium ion secondary battery: on the basis of MnCl2.4H2O, the purity is higher than 99.71%.

Owner:GUIZHOU REDSTAR DEVING

Technology capable of recycling fluorine and zinc from steelmaking soot

ActiveCN105154681AAchieve recyclingNo emissionsProcess efficiency improvementIron halidesSteelmakingFluoride products

The invention relates to a technology capable of recycling fluorine and zinc from steelmaking soot. Two-segment acid leaching is adopted for enabling zinc, fluorine and iron in the steelmaking soot to be dissolved in a solution, and then a precipitation method is adopted for enabling harmful element fluorine in the solution to be separated from the solution; and defluorination filtering liquid enters a zinc smelting system, and according to the normal technology, electrolytic zinc is produced. Fluorine-contained precipitation is washed, filtered and dried, and then a fluoride product is obtained. after the technological treatment is carried out, the zinc in the steelmaking soot can be recycled in a manner of a product of excellent cathode zinc, the harmful element fluorine is comprehensively utilized in a manner of an auxiliary product, and the environment pollution caused in the long-term stacking and storing or take-out transportation process of the soot in the steelmaking industry can be eliminated.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Hydrometallurgical method for separating and extracting Mn, Fe, Pb and Ag from silver-manganese ore

InactiveCN103468947ABig investmentLong processPhotography auxillary processesProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a hydrometallurgical method for separating and extracting Mn, Fe, Pb and Ag from silver-manganese ore. The method comprises the following steps: leaching silver-manganese concentrate by hydrochloric acid, adjusting the pH value by NH4HCO3 to obtain an ammonium chloride leachate, and leaching residues obtained after the ammonium chloride leaching by a hydrochloric acid solution of calcium chloride to obtain a calcium chloride leachate; electrolyzing the ammonium chloride leachate to prepare iron powder; carrying out a crystallization process of a residual liquid to prepare MnCl2.4H2O, and carrying out thermal decomposition to prepare manganese chloride; and replacing Ag from the calcium chloride leachate by metallic lead to obtain Ag, and replacing by metallic iron or aluminum to obtain Pb. Compared with pyrometallurgy, the method disclosed in the invention has the advantages of saved investment, high recovery rate and substantial economic benefit.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

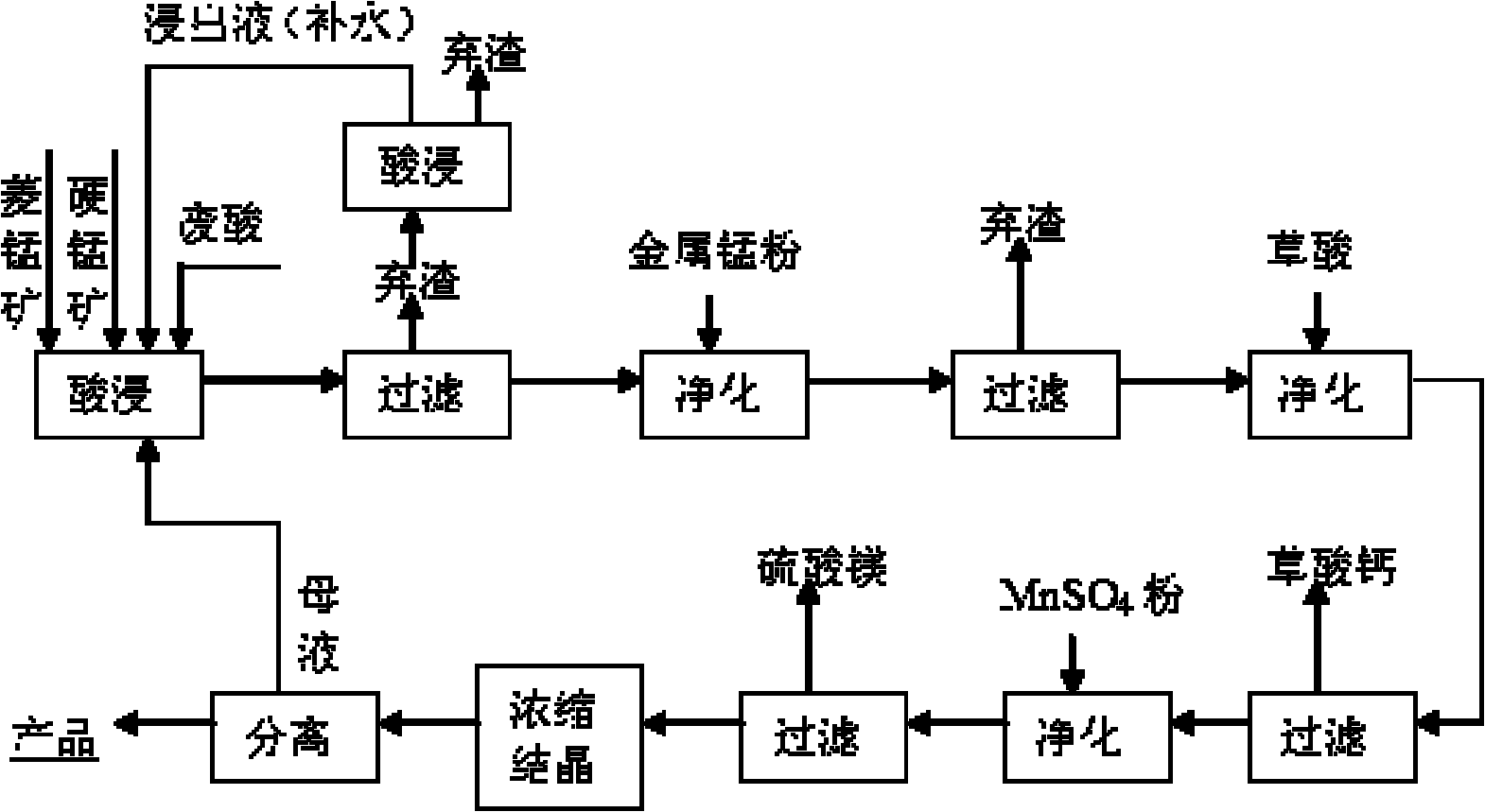

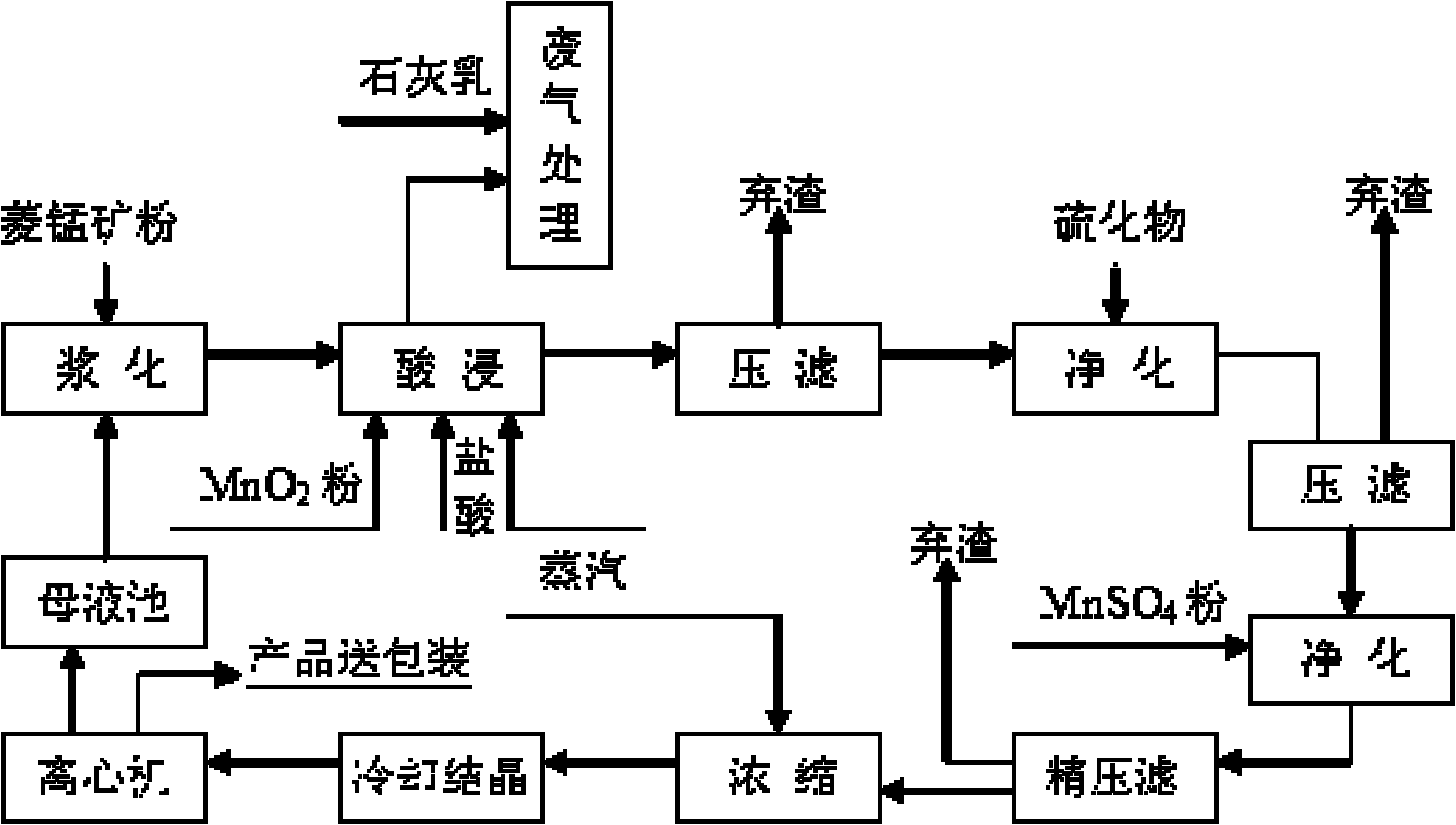

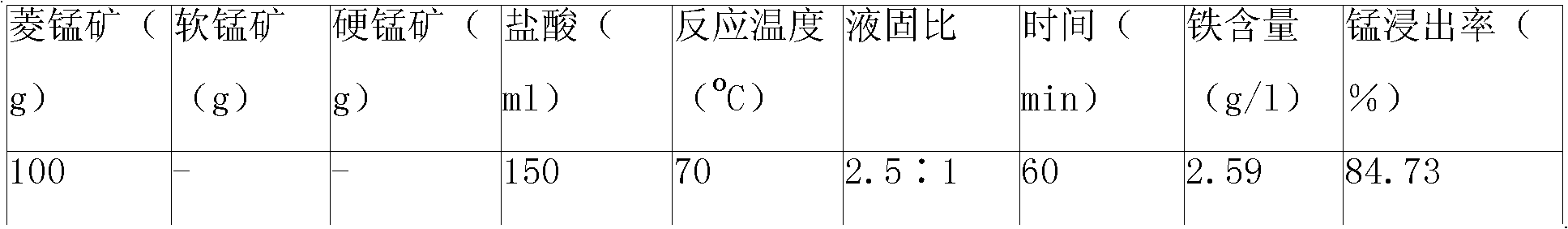

Process for preparing tetrahydrate manganese chloride by leaching out rhodochrosite with waste acid

InactiveCN102050495ATo satisfy the market's needsReduce manufacturing costManganese halidesSlagPsilomelane

The invention discloses a process for preparing tetrahydrate manganese chloride by leaching out rhodochrosite with waste acid. The process comprises the following steps of: adding waste hydrochloric acid to rhodochrosite step by step for leaching, meanwhile, adding pyrolusite or psilomelane which is used as an oxidant; filtering the generated mixed solution, and leaching the filter residue with acid once again; adding metal manganese powder to filter liquor for precipitating, filtering and abandoning slag; adding oxalic acid in the filter liquor for settling, filtering; adding manganese sulfate powder to the filter liquor for precipitating, and filtering; quantitatively adding BaCl2 to the filter liquor, standing still and filtering to remove excessive SO4 <2->; and finally, carrying out concentrating crystallization and centrifugal separation on the filter liquor to obtain a tetrahydrate manganese chloride product. Compared with the prior art, the process has the advantages of simple process flow, convenience of operation, less investment, high efficiency and easy utilization of industrialization. In the invention, low-concentration waste acid is used for leaching the rhodochrosite to produce tetrahydrate manganese chloride, which not only solves the treatment problem of waste acid, but also efficiently utilizes a large quantity of low-grade rhodochrosite resources and realizes the sustainable utilization of resources.

Owner:沈新财

Surface modification method of fluoride luminescent material, and fluoride luminescent material prepared by method

ActiveCN111171815AImprove corrosion resistanceReduce surface defectsEnergy efficient lightingLuminescent compositionsQuantum yieldQuantum efficiency

The invention relates to a surface modification method of a fluoride luminescent material, and the fluoride luminescent material prepared by the method. According to the invention, a matrix material AxMFy:Mn<4+> coated with an inorganic coating layer AxMFy, and an organic solution containing metal phosphate or alkoxy silane or an organic carboxylic acid substance or organic amine, and the obtainedmixed solution is subjected to evaporation drying to obtain the surface-modified fluoride luminescent material co-coated with the organic coating layer-inorganic coating layer; according to the coating method, the corrosion resistance of the fluoride fluorescent powder is remarkably improved, the luminous intensity retention rate and the quantum efficiency retention rate of the modified fluorescent powder reaches 85-95% in a high-temperature and high-humidity environment, and the fluoride fluorescent powder can be widely applied to the field of white light LED backlight source display; afterinorganic coating, the surface defects of the fluorescent powder are reduced, and the luminous intensity and the quantum yield of the fluorescent powder are improved by 5%-15%; after coating with theorganic coating layer, the luminous intensity reducing of the fluorescent powder is less than 3%; and the surface modification method provided by the invention has the advantages that the preparationtemperature is low, the time is short, the process is easy to control, and the surface modification method is suitable for industrial large-scale preparation.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

Method of manufacturing manganese tetrafluoride

A method of manufacturing manganese tetrafluoride comprises reacting a manganese compound and a fluorinating agent at a temperature of 250-350° C. and a pressure of 1.0-10.0 MPs to fluorinate the compound, while constantly or discontinuously crushing or grinding the starting compound and the manganese compound being reacted. According lo the method, since. fluorine is deeply penetrated into the interior of the manganese salt particles, the ratio of conversion to manganese tetrafluoride, MnF4 can he improved.

Owner:SHOWA DENKO KK

Method for producing bivalent manganous salt

InactiveCN107324395AReduce energy consumptionReduce pollutionOrganic compound preparationCarboxylic acid salt preparationManganeseChemical products

The present invention proposes a method for producing divalent manganese salt, which includes the following operations: mixing raw materials containing manganese dioxide, acidic aqueous solution and hydrogen peroxide, controlling the pH value of the reaction mixture to be no greater than 6.4, and generating divalent manganese salt after stirring ; Wherein, the acidic aqueous solution is an aqueous solution containing one or more of sulfuric acid, hydrochloric acid, nitric acid, acetic acid or citric acid. The invention provides a method with low energy consumption and low pollution, which converts manganese dioxide into divalent manganese salt, or removes manganese dioxide as impurities from raw materials. In the present invention, hydrogen peroxide, as a common chemical product, is cheap, produces water and oxygen after the reaction is completed, has no pollution, and does not bring impurities into the solution. According to specific needs, one or more aqueous solutions of sulfuric acid, hydrochloric acid, nitric acid, acetic acid or citric acid can be used to generate different manganese salts, so the product has good adaptability and high purity.

Owner:彭权刚 +2

Preparation method of high-purity anhydrous manganese chloride particles

The invention relates to a preparation method of high-purity anhydrous manganese chloride particles. Synthetic manganese dioxide is adopted as a raw material, and hydrochloric acid is adopted as a leaching agent to react to obtain a manganese chloride solution; and the solution is subjected to impurity removal-crystallization-drying- granulation-drying to obtain uniform manganese chloride particles of which the particle sizes are 0.5-8mm. The preparation technology is simple, reaction conditions are easy to meet, the reaction is also easy to control, and a post-treatment process is simple. The synthetic manganese dioxide which is high in purity and low in impurity content is adopted as a preferred raw material, and the hydrochloric acid is adopted as a reactant, so that the cost is low. High-purity anhydrous manganese chloride particles with uniform particle sizes can be obtained, a product is good in quality, and the anhydrous manganese chloride product can meet the production requirements of some special chemical products and medicines.

Owner:CENT SOUTH UNIV

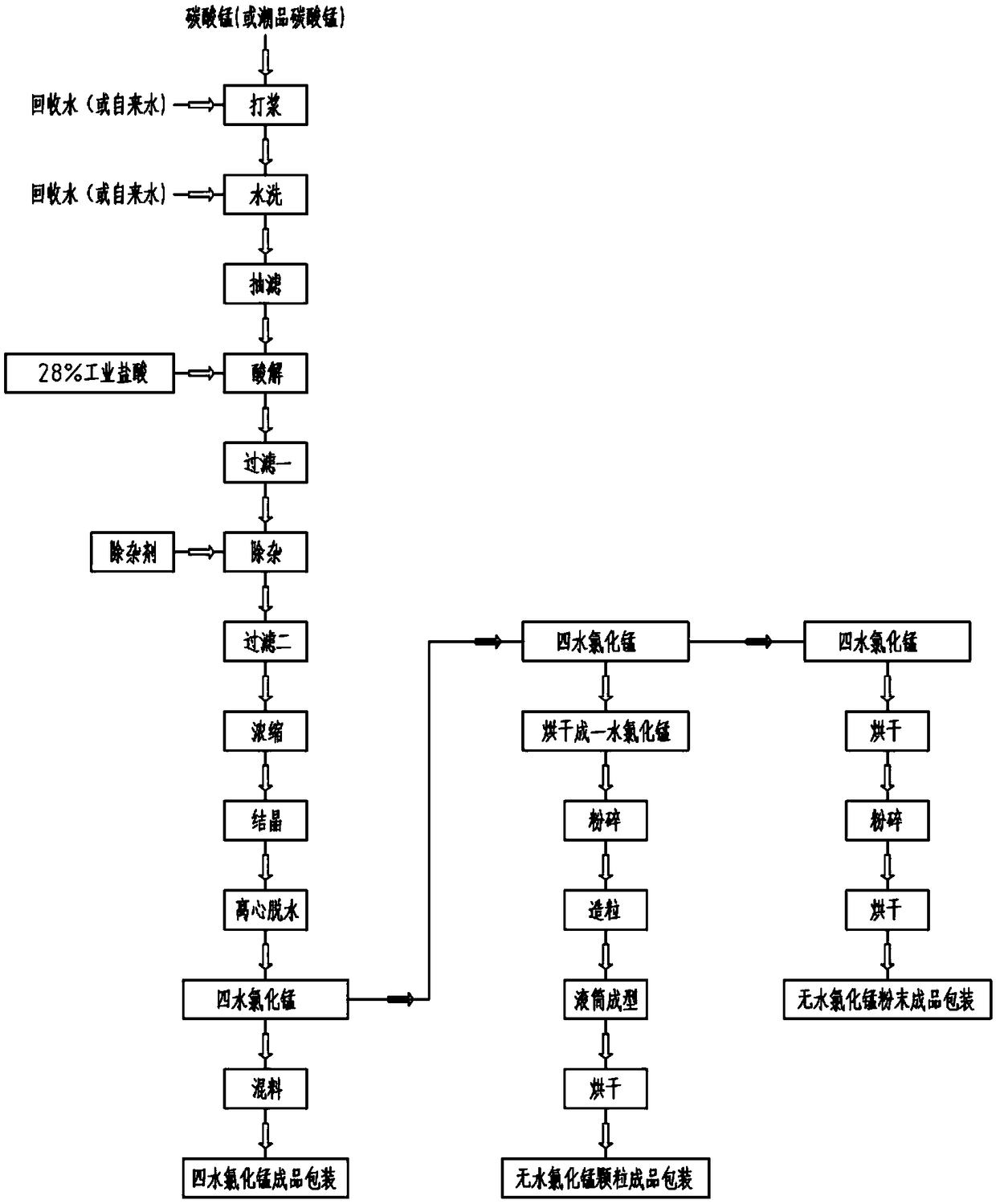

Production technology of manganese chloride

The invention provides improvement of a technology for industrialized production of manganese chloride tetrahydrate and anhydrous manganese chloride, aiming at the problems of a production technologyof manganese chloride in the prior art that a product has more impurities and the form of the obtained product is single, and the production technology is not suitable for the industrialized production.

Owner:HUBEI HAOYUAN MATERIAL TECH

Preparation method of high-purity anhydrous manganese chloride

The invention discloses a preparation method of anhydrous manganese chloride. The method comprises the steps of enabling metal manganese powder to react with hydrochloric acid so as to obtain a manganese chloride solution; removing metal impurities in the manganese chloride solution, then carrying out spray drying on the manganese chloride solution to obtain a solid; dissolving the obtained solid into an alcoholic solvent, filtering, and drying the obtained filtrate by using a spray drying-vacuum rotating disk type drying combination technique to obtain the anhydrous manganese chloride which has the purity of more than or equal to 99.99% and the water content of less than or equal to 0.001%. The obtained anhydrous manganese chloride can meet the application requirements of the special fields such as medicines, high-quality magnesium-manganese alloy, aluminum-manganese alloy, high-purity manganese metal powder catalytic systems and cyclopentadienyl manganese high-efficiency gasoline antiknocks; furthermore, the preparation method of the anhydrous manganese chloride is simple in operation, low in cost and beneficial to industrial production.

Owner:JIANGXI NORMAL UNIV

Method for treating waste manganese mud generated during production of hydroquinone by aniline process

The invention relates to a method for treating waste manganese mud generated during production of hydroquinone by aniline process, wherein the manganese mud contains manganese salt, magnesium salt, iron, silica and a little organic matter; manganese chloride, iron chloride and silica can be extracted from the waste material after treatment; and the waste material and waste residue subjected to the treatment can be used as building materials after being roasted. According to the invention, substances extracted with the method provided by the invention have high purity; the steps are simple; the treated waste materials have no pollution; therefore, the method conforms to the requirements on environmental friendliness.

Owner:湖北开元化工科技股份有限公司

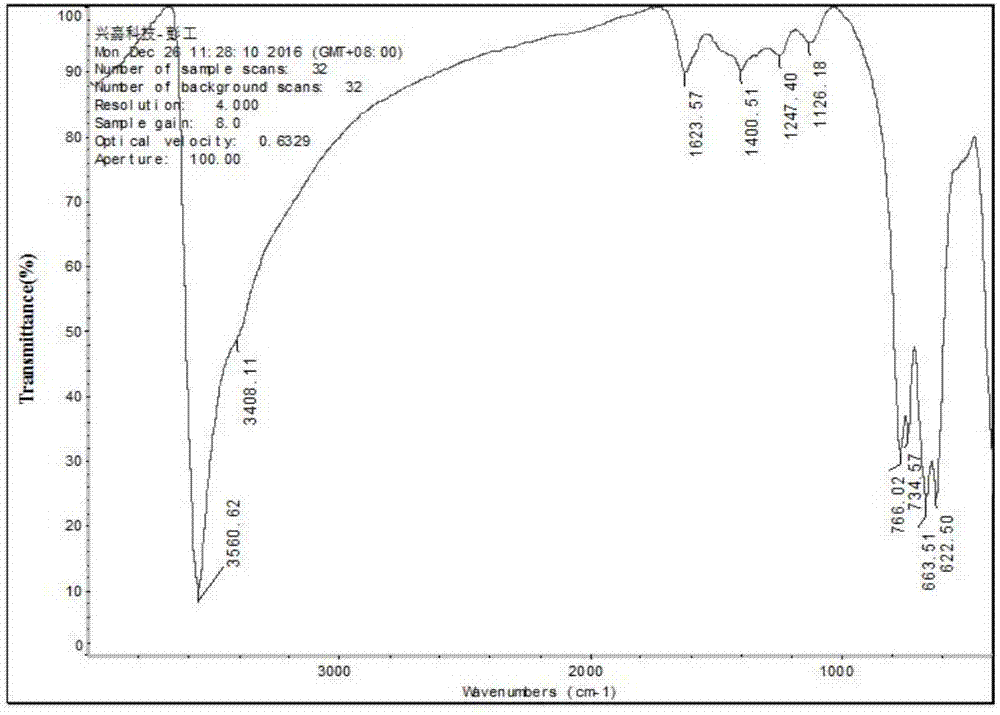

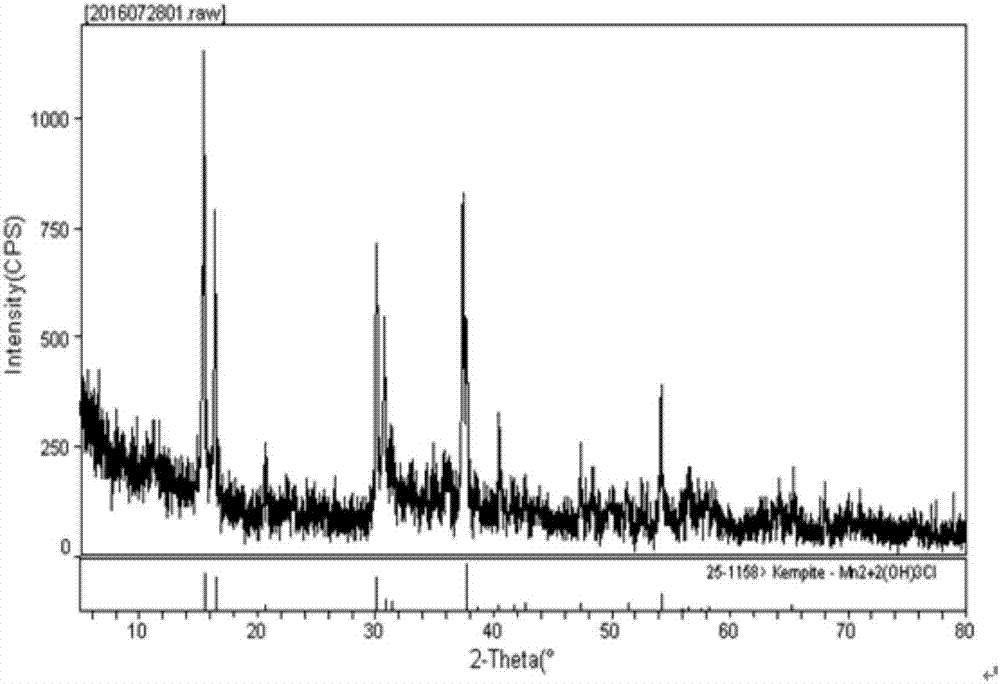

Preparation method of basic manganese chloride

ActiveCN107032409AEasy to handleReduce pollutionAccessory food factorsWorking-up animal fodderReaction temperatureChloride

Disclosed is a preparation method of a basic manganese chloride applicable to animal feeds. The preparation method comprises the following steps of adding ammonium chloride solution into a sealed reaction device, then slowly adding in manganese oxide while stirring, heating the reaction mixture to a reaction temperature for thermostatic reaction, and after reaction is completed, performing discharging, filtering, washing and drying processes to obtain the basic manganese chloride. The prepared basic manganese chloride has the advantages of being in low in damage to nutritious components, high in product bio-availability, low in processing cost, simple in preparation processes and the like.

Owner:XINGJIA BIO ENG CO LTD

Ultrahigh-sensitivity up-conversion nano temperature probe and preparation method thereof

ActiveCN107699226ALarge distance between monitoring emission peaksHigh signal discriminationNanotechnologyTenebresent compositionsFluorescenceGreen-light

The invention provides a novel ultrahigh-sensitivity nano fluorescent temperature probe material KMn<0.8>Yb<0.19>Er<0.01>F<3>. Because the electron-state wave function of Mn<2+> ions and Er<3+> ions of a matrix are overlapped, through an exchange effect, the <4>T<1> energy level of the Mn<2+> ions builds an electron coupling channel for the <2>H<11 / 2> and <4>S<3 / 2> energy levels of the Er<3+> ionswith the <4>F<9 / 2> energy level of the Er<3+> ions. The exchange effect distance is regulated and controlled depending on the temperature, the intensity ratios of green light emitting bands at the positions of 522 nm and 542 nm to the red light emitting bands at a position of 654 nm of the Er<3+> ions are remarkably changed, so that temperature detection suitable for a temperature range in livingbodies is achieved. The monitoring emission peak distance of the up-conversion fluorescent nano temperature probe material is large and reaches 112 nm, the signal discrimination degree is high, the absolute temperature sensitivity is 0.0113K<-1>, the highest relative temperature sensitivity is 5.7%K<-1>, the temperature sensitivity of the up-conversion fluorescent nano temperature probe materialexceeds the temperature sensitivity of other up-conversion fluorescent nano temperature probe materials which are currently studied by far. Therefore, after surface functionalization, the up-conversion fluorescent nano material can be used as a fluorescent nano temperature probe suitable for temperature detection in living bodies.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for producing precipitated barium sulfate and co-producing manganese chloride

ActiveCN104843760AAbundant resourcesSimple geological conditionsCalcium/strontium/barium sulfatesManganese halidesBarium dichlorideSulfate

The invention discloses a method for producing precipitated barium sulfate and co-producing manganese chloride. The method comprises the following steps: A, preparing a barium chloride solution; B, preparing a manganese sulfate solution; C, dipping the manganese sulfate solution prepared by the step B into the barium chloride solution prepared by the step A to perform replacement reaction; D, filtering the product after performing the replacement reaction by the step C, and respectively collecting filtrate and filter cakes; E, performing SO4<2-> decontamination on the filtrate collected by the step D, filtering the decontaminated filtrate, and distilling to obtain manganese chloride; F, rinsing the filter cakes collected by the step D till no chloride ion, baking the rinsed filter cakes in an oven, grinding and sieving to obtain barium sulfate. When precipitated barium sulfate is prepared, simultaneously a byproduct, namely manganese chloride is recovered. The byproduct is high in added value, the utilization rate of the energy is effectively increased, and relatively high economical benefits can be obtained.

Owner:河北日新化工有限公司

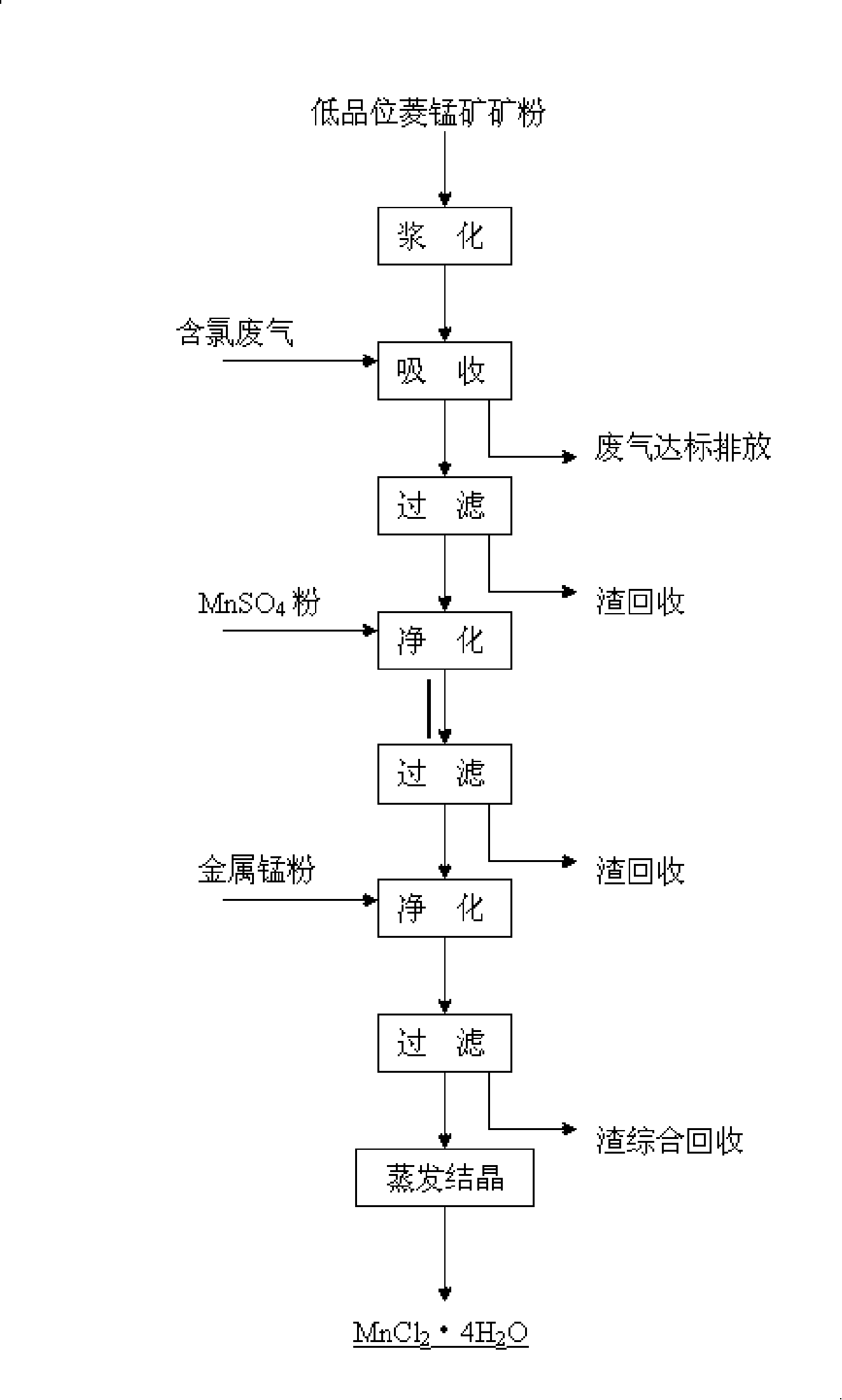

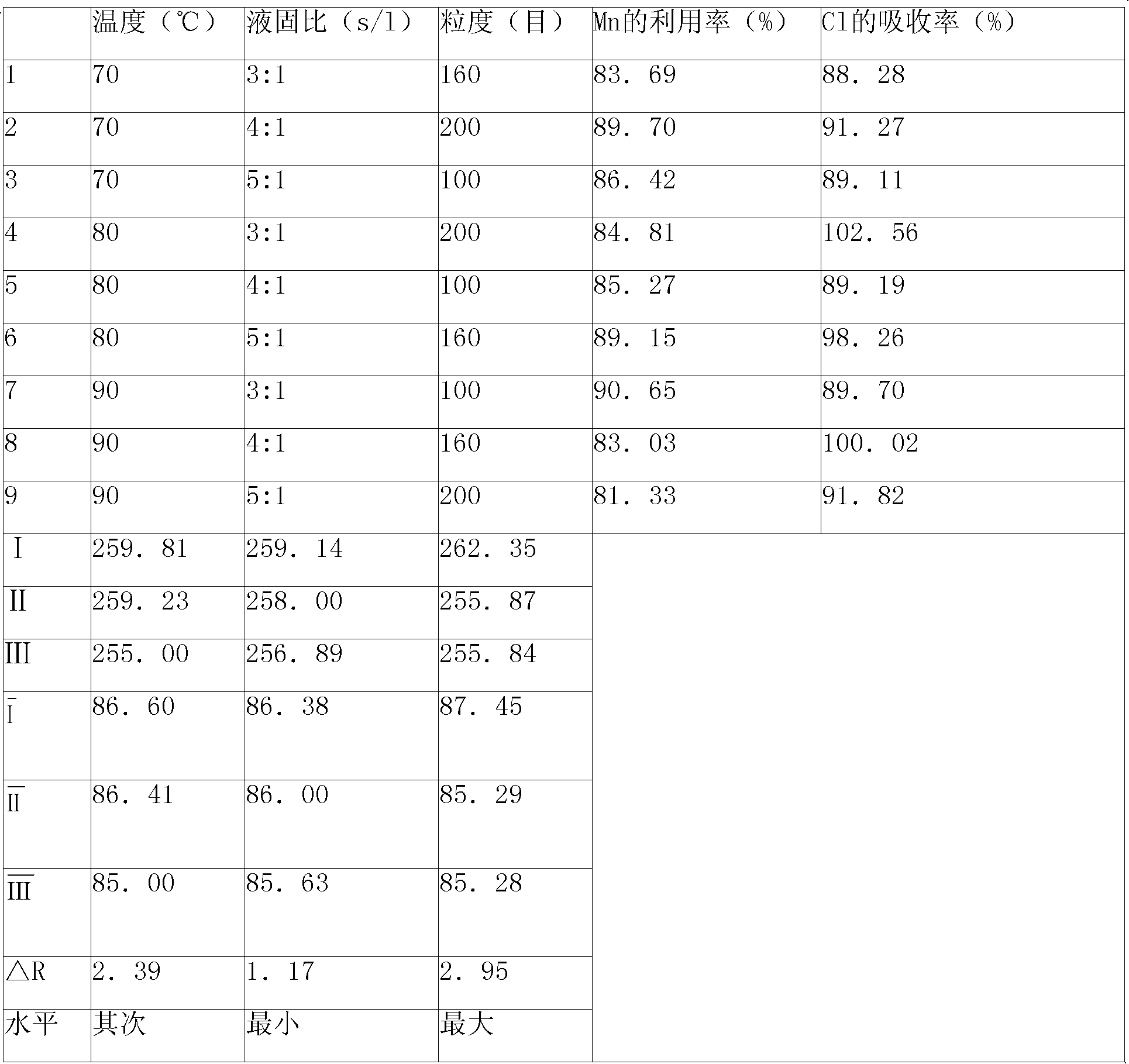

Technique for manufacturing tetrahydrate manganese chloride low ore grade rhodochrosite absorption of chlorine containing waste gas

The invention discloses a process for preparing manganese chloride tetrahydrate by absorbing waste gas containing chlorine by low-taste rhodochrosite. Powder of the low-taste rhodochrosite is prepared to be ore pulp with water; the ore pulp carries out absorption reaction with the waste gas containing the chlorine; the obtained ore pulp is carried out filtration; manganese sulfate powder and metal manganese powder are sequentially added in the filtrate to carry out the purification and the filtration; after the filtrate is evaporated and crystallized, solid MnCl2 4H2O product is obtained. Compared with the prior art, the invention has simple technological process and is convenient to operate. The invention solves the problem of treating the waste gas containing the chlorine, makes full use of the oxidizability without adding oxidant and can also highly effectively use a large amount of low-taste rhodochrosite resource which is difficult to use, which realizes sustainable utilization of resources and reutilization of secondary resources and has good application prospect in industry. By adopting ways of displacement of the metal manganese powder and reduction of the manganese sulfate when purifying and eliminating heavy metals, the invention not only has obvious effect but also reduces secondary pollution to the product and saves process of secondary impurity removal.

Owner:GUIZHOU UNIV

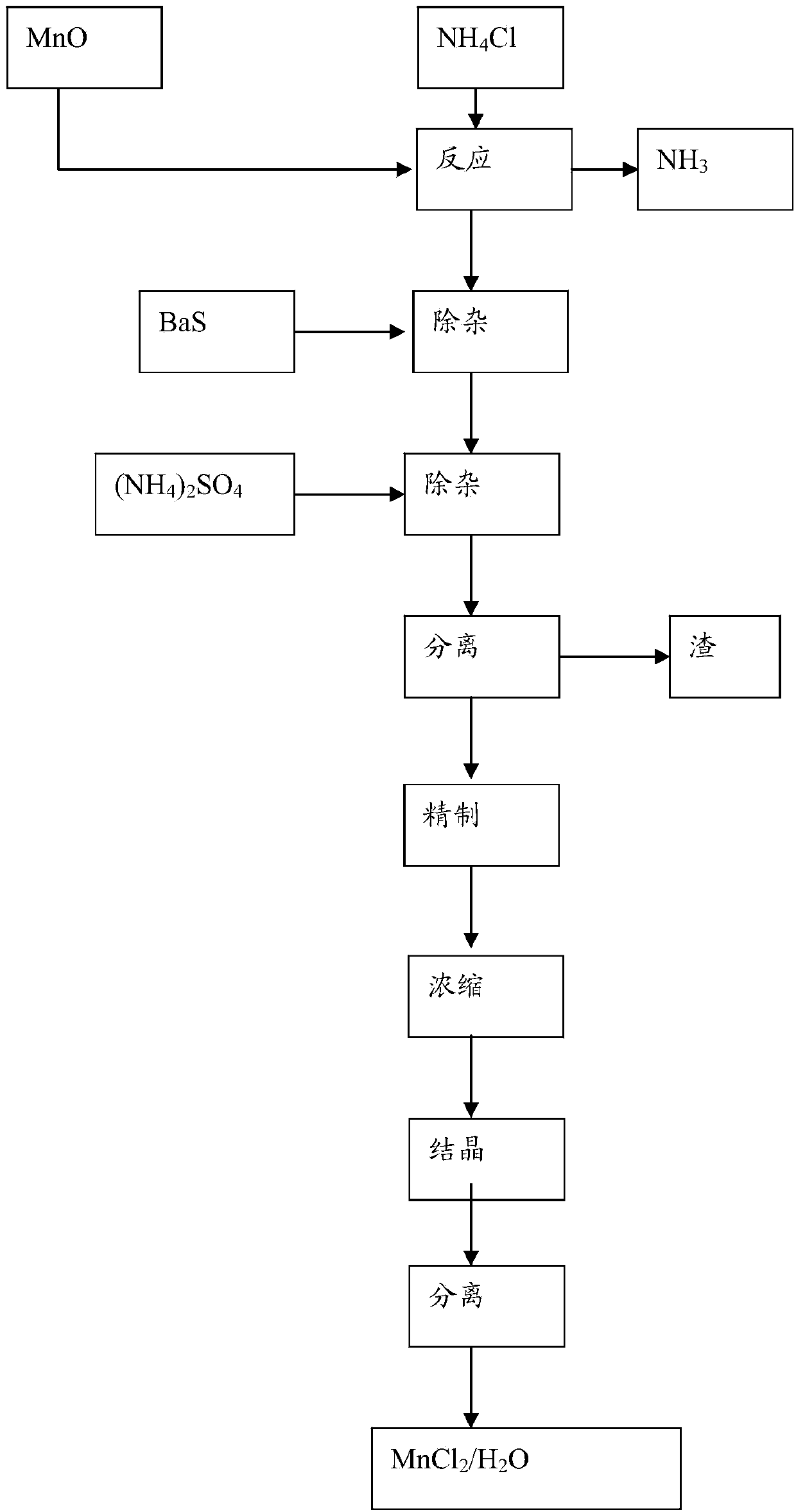

Manganese chloride and preparation method thereof

The invention provides manganese chloride and a preparation method thereof. The preparation method comprises the following steps of: (1) carrying out double-decomposition reaction, namely, mixing manganous oxide and an ammonium chloride solution in the molar ratio of Mn2+ to NH4+ being 1: (2.4-2.8), and then carrying out heating reaction for 2 to 3 hours at 85-90 DEG C; (2) removing impurities; (3) refining, evaporating and crystallizing; (4) obtaining finished products. According to the preparation method, the special manganese chloride product for a ternary anode material is prepared through the double decomposition of the manganous oxide and the ammonium chloride, and the product cost is reduced.

Owner:GUIZHOU REDSTAR DEVING

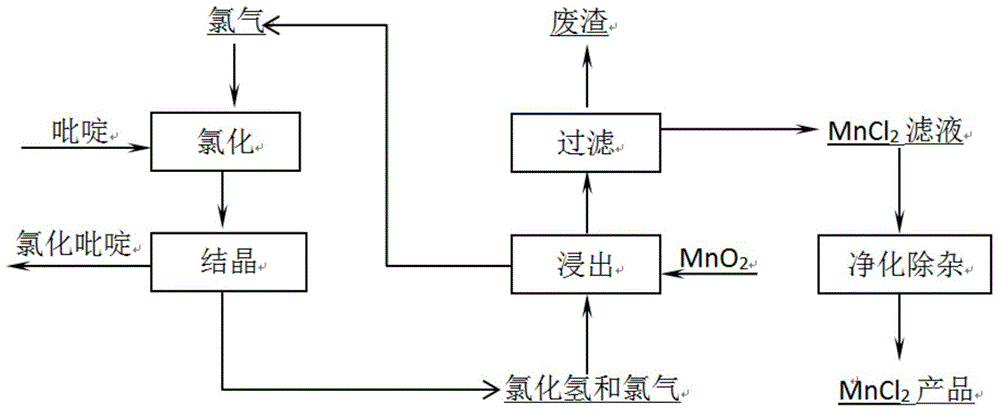

Method for cyclic utilization of chlorine gas and coproduction of manganese chloride in chloride pyridine production process

InactiveCN104860268AIncrease added valueIncrease profitOrganic chemistryPreparation from chloridesSlurryManganese oxide

The invention discloses a method for cyclic utilization of a chlorine gas and simultaneous coproduction of manganese chloride in a chloride pyridine production process. The method comprises the following steps: with pyridine and chlorine gas as raw materials, preparing a chloride pyridine mixture and a mixed gas of the chlorine gas and hydrogen chloride; introducing the mixed gas into slurry of manganese oxide ore, stirring and leaching, and controlling the liquid-to-solid ratio to be (2-9) to 1 in the leaching process; drying the leached chlorine gas and circulating as a raw material for preparing the chloride pyridine; leaching and carrying out solid-liquid separation to obtain a manganese chloride leach liquid; purifying and removing impurities from the leach liquid, evaporating and crystallizing to obtain a manganese chloride product. According to the method, recycling and reusing of the chlorine gas in the pyridine chlorination process can be realized; a high-quality manganese chloride product can be coproduced; the process is economical and efficient; and the method has good industrialization feasibility.

Owner:CENT SOUTH UNIV

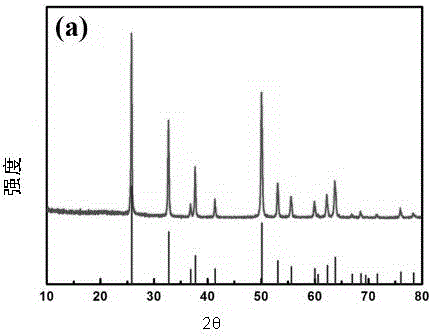

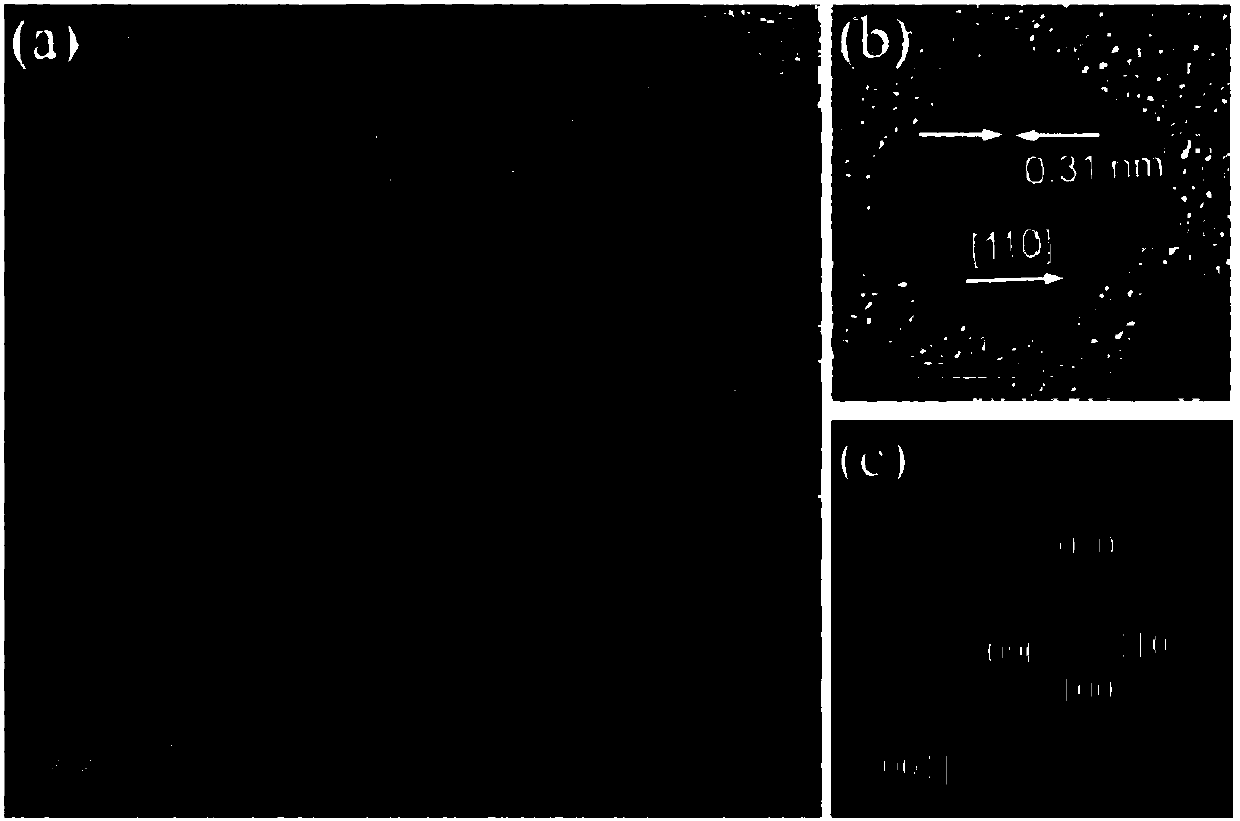

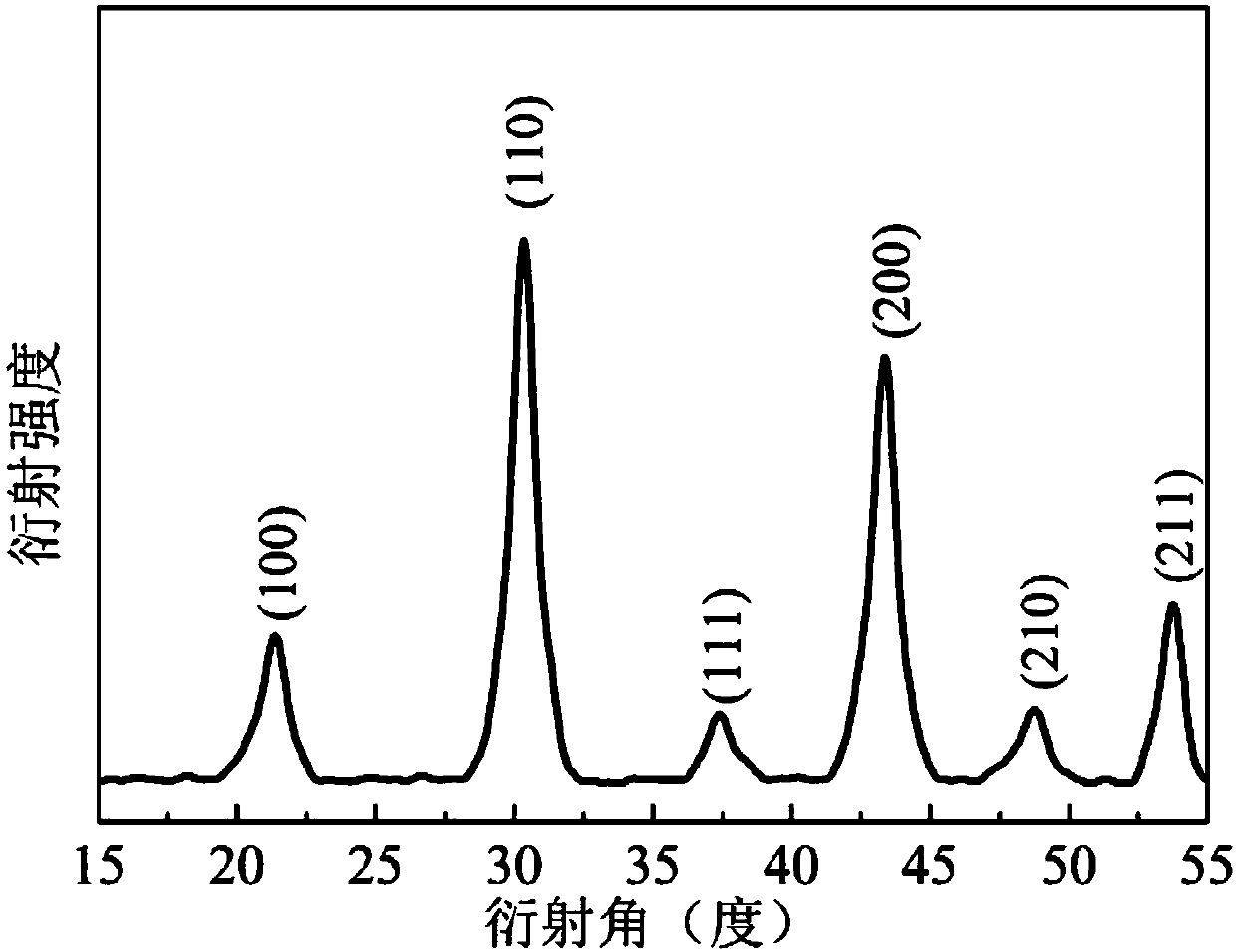

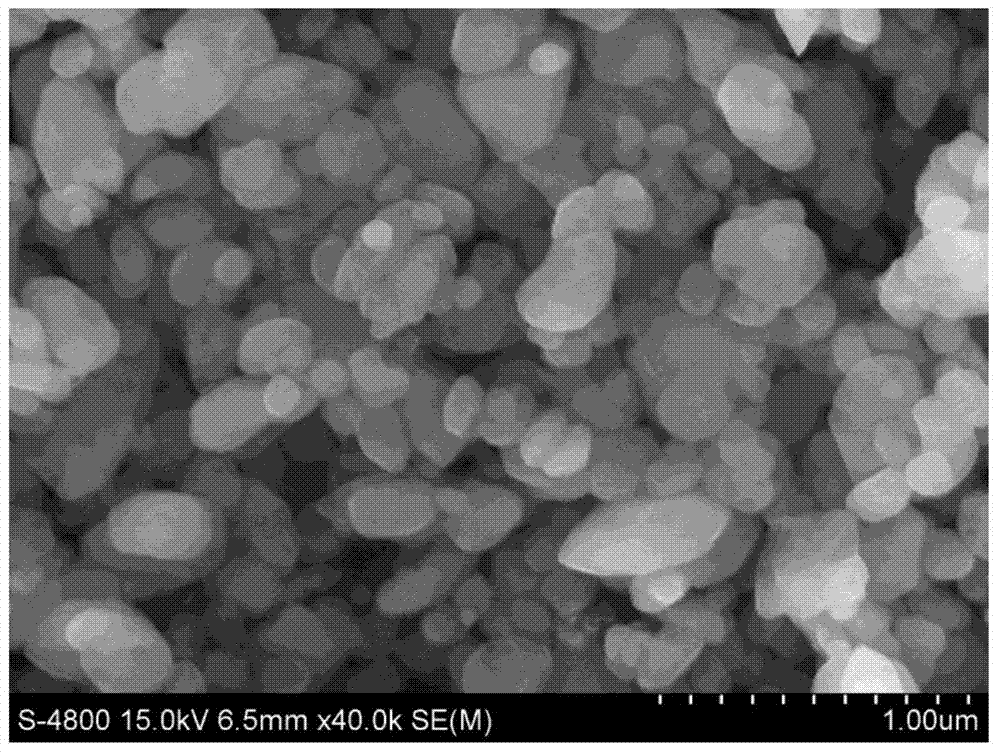

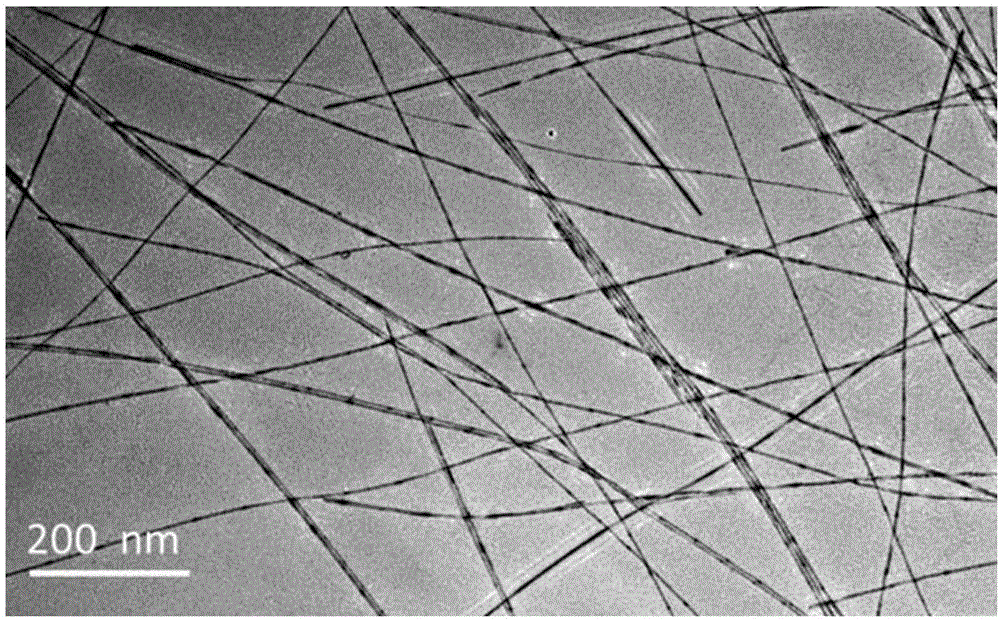

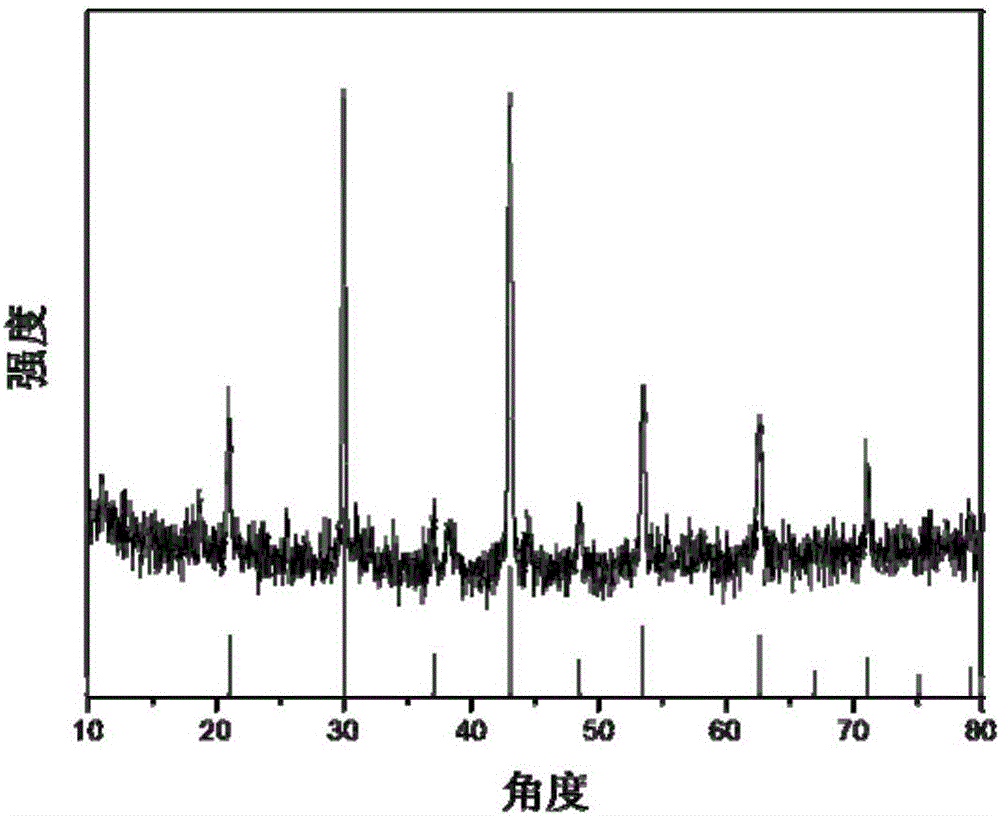

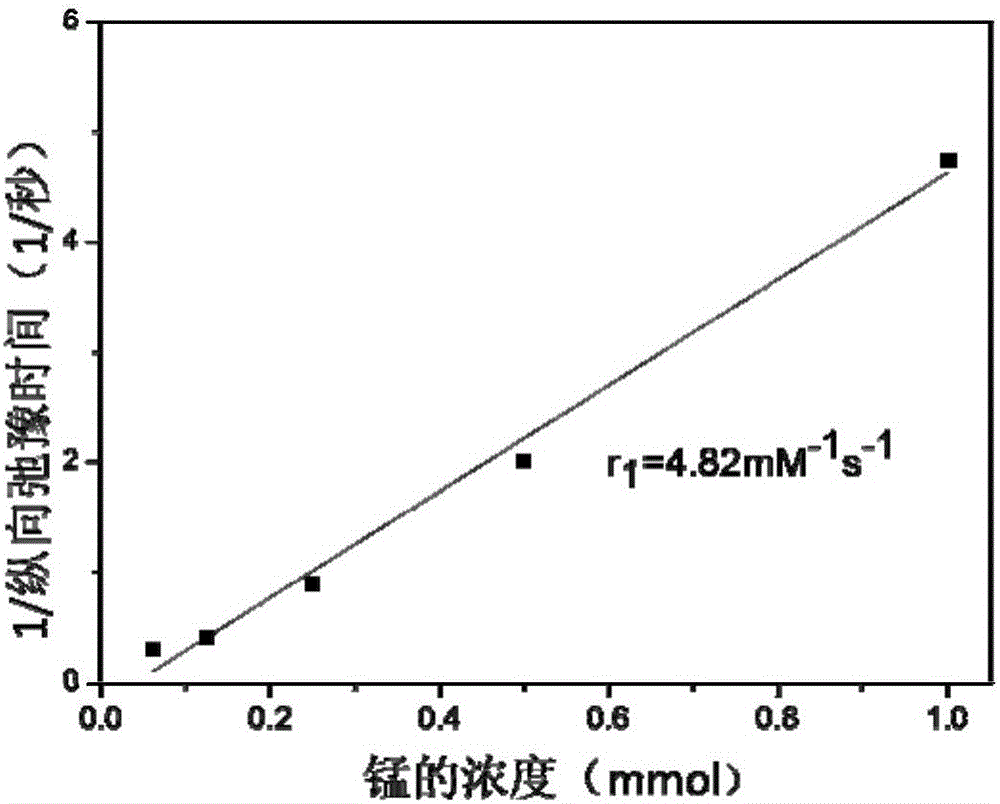

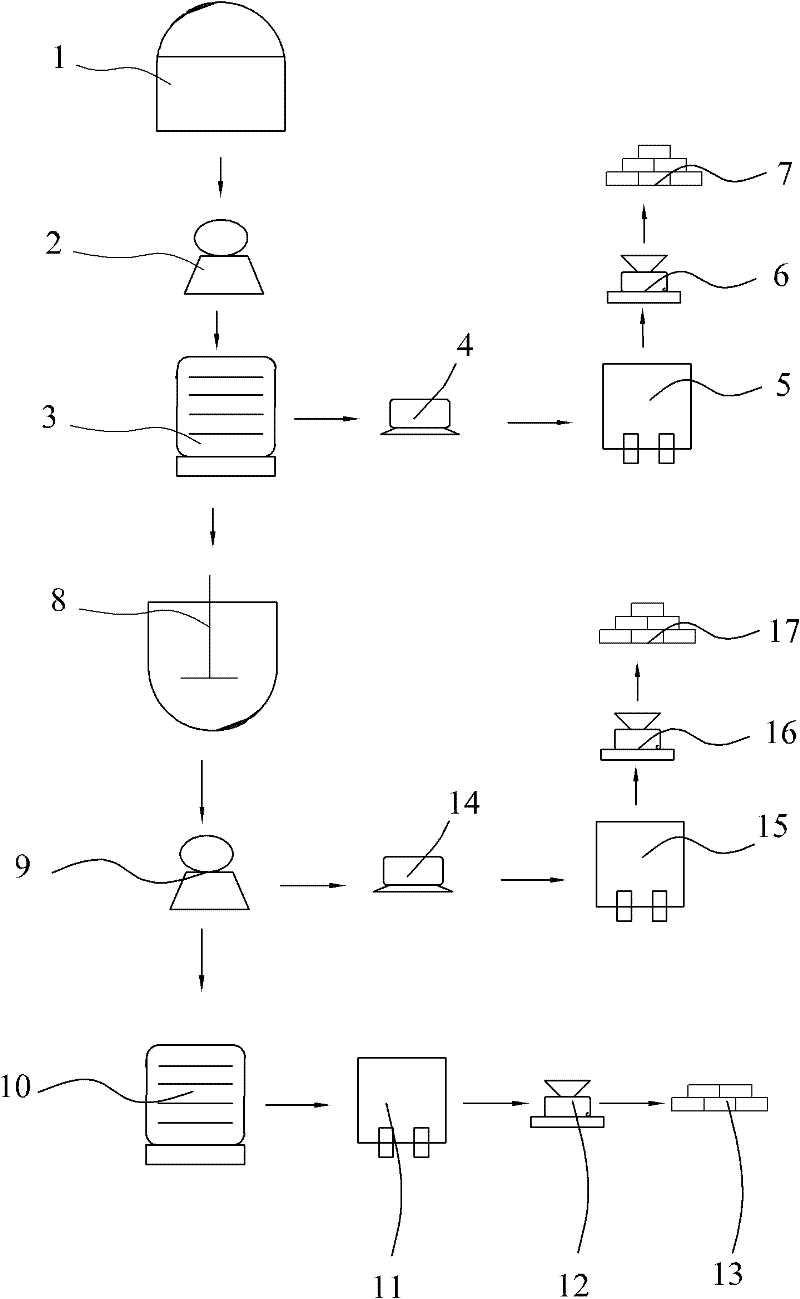

KMnF3 nanowire and preparation method thereof

InactiveCN106745286AUniform shapeThe synthesis method is simpleNanotechnologyManganese halidesNanowirePotassium fluoride

The invention discloses a KMnF3 nanowire and a preparation method thereof,. The KMnF3 nanowire is characterized in that one-dimension oil-soluble KMnF3 nanowire is prepared by mixing manganese oleate, oleic acid, oleylamine and octadecene according to a certain proportion and reacting under a condition of excessive potassium fluoride. According to the invention, the one-dimension oil-soluble KMnF3 nanowire is synthesized by the high-temperature oil phase method for the first time, and water-soluble KMnF3 nanowire is obtained after high molecular surface modification, has a longitudinal molar relaxation rate r1 of 4-6 mM<-1>s<-1>, and is a good T1 magnetic resonance imaging (MRI) contrast agent.

Owner:HEFEI UNIV OF TECH

A method for preparing manganese sulfate, anhydrous manganese chloride and calcium sulfate

InactiveCN102259930ANo secondary pollutionEasy to operateSolid waste disposalCalcium/strontium/barium sulfatesManganese oxideWater of crystallization

The invention provides a method for preparing manganese sulfate, anhydrous manganese chloride and calcium sulfate. Grinding sidellose into coarse powder, and producing titanium dioxide by sulfuric acid method is soaked at 60-80°C for 8-10 hours, and then pumped Filter to obtain a clear filtrate, add manganese hydroxide to remove impurities, and obtain a pure manganese sulfate solution; the pure manganese sulfate solution is distilled under reduced pressure into a saturated solution of manganese sulfate, cooled, and manganese sulfate crystals containing crystal water are precipitated, and then dried and pulverized , to obtain the manganese sulfate crystal product; the pure manganese sulfate solution is reacted with calcium chloride solution under stirring, the reaction product is filtered to obtain calcium sulfate filter cake and manganese chloride filtrate, and the manganese chloride filtrate is distilled under reduced pressure to be manganese perchloride saturated solution, cooled and crystallized to obtain anhydrous manganese chloride crystals, dried and crushed to obtain anhydrous manganese chloride crystal products; the calcium sulfate filter cake was washed, dried and crushed to obtain calcium sulfate dihydrate products.

Owner:王莉

Method for preparing anhydrous manganese chloride

ActiveCN104291381ASimple processSimple post-processingManganese halidesPhysical chemistryManganous chloride

The invention discloses a method for preparing anhydrous manganese chloride. The method comprises the following steps: (1) mixing metal manganese powder and solvent alcohol, dropwise adding fatty acyl chloride to react with the metal manganese powder, thereby obtaining an anhydrous manganese chloride alcohol liquid; and (2) stirring and distilling to recover the solvent at normal pressure, obtaining an anhydrous manganese chloride crystallization alcohol complex, adding the complex into a closed dryer, dealcoholizing under reduced pressure, thereby preparing the anhydrous manganese chloride. The method disclosed by the invention is simple and convenient in process, simple in after-treatment, high in safety and high in product yield, and alkali type manganese chloride and manganese dioxide impurities in the conventional preparation method are avoided. The prepared anhydrous manganese chloride has the advantages of ideal product yield and purity, simplicity in operation and safety, and the product meets the requirements of special chemical products and medical production and is suitable for industrial production.

Owner:JIANGXI SILINCO

Preparation method of manganese chloride tetrahydrate bulk drug

The invention provides a preparation method of a manganese chloride tetrahydrate bulk drug. The preparation method comprises the following steps: mixing manganese monoxide with water to obtain turbid liquid; slowly dropwise adding hydrochloric acid into the turbid liquid to obtain a first reaction liquid; heating the first reaction solution to obtain a second reaction solution; adding food-grade diatomite into the second reaction solution, and stirring to obtain a first mixed solution; filtering the first mixed solution to obtain a first filtrate; adjusting the pH value of the first filtrate; adding manganese powder into the first filtrate, and heating to obtain a third reaction solution; adding the food-grade diatomite into the third reaction solution, and stirring to obtain a second mixed solution; filtering the second mixed solution to obtain a second filtrate; adjusting the pH value of the second filtrate; and purifying the second filtrate to obtain the manganese chloride tetrahydrate bulk drug. The product prepared by the method has very high safety.

Owner:合肥市未来药物开发有限公司

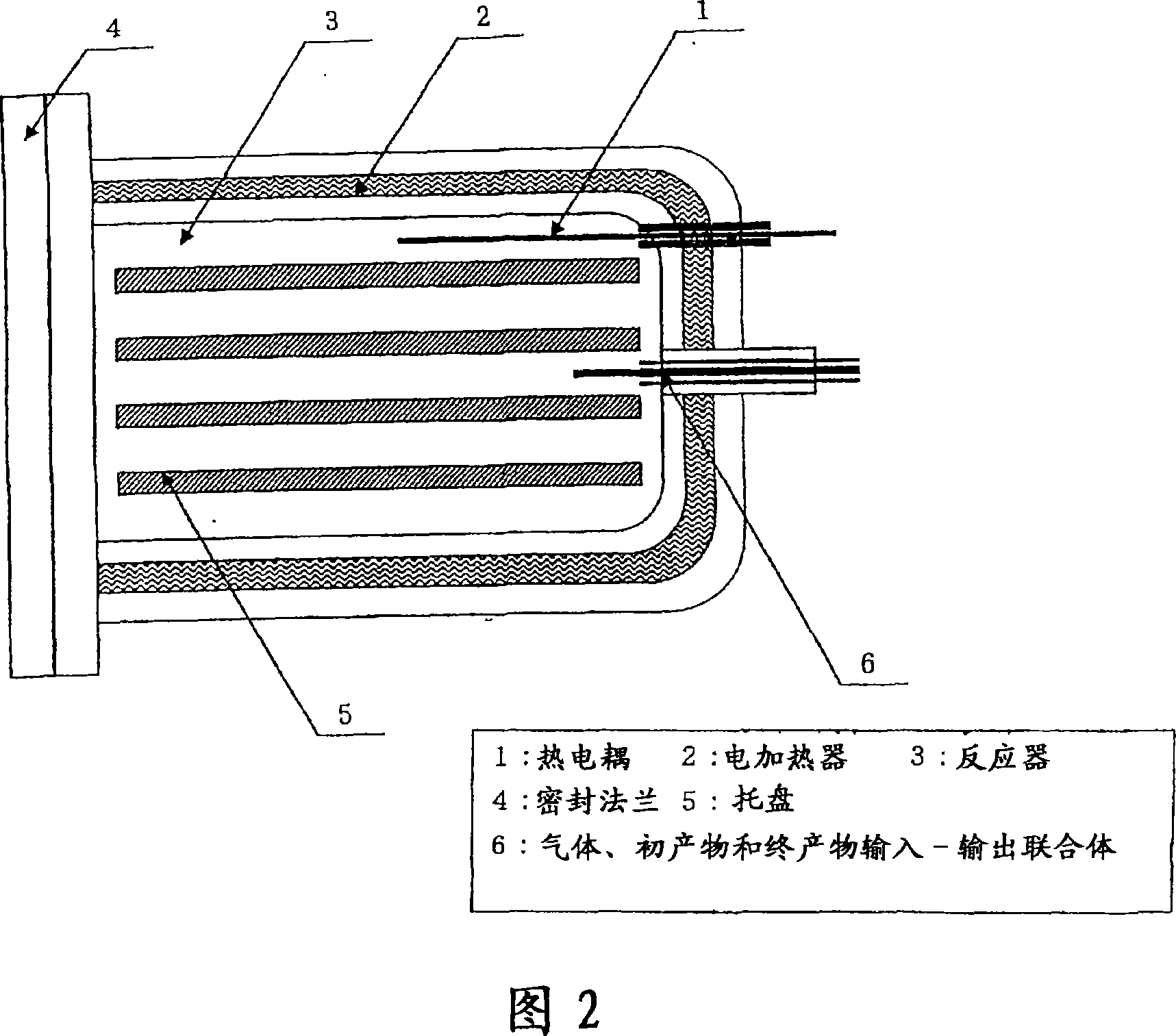

Manganese chloride dehydration method and method for promoting (cyclopentadienyl)manganese compound yield

ActiveCN1970456AReduce moisture contentMeets very low moisture content requirementsMetallocenesManganese halidesManganeseChloride

The invention discloses a dehydrating method to obtain low-water manganese chloride and receiving rate improving method of manganese compound, which comprises the following steps: placing manganese chloride with crystal water in the sealed drier; heating to 150-450 deg.c; extracting into -0.01-0.1Mpa; gasifying the manganese chloride crystal water in the drier; draining along with vacuum; measuring the drained water; putting in the oxonation autoclave through pipe to do oxonation reaction. The invention makes water content of manganese chloride lower than 200ppm, which improves receiving rate of manganese compound by 8-15%.

Owner:宜兴市创新精细化工有限公司

Environment-friendly preparation method of basic manganese chloride

The invention relates to the field of inorganic chemistry, in particular to an environment-friendly preparation method of basic manganese chloride, the method comprises the following steps: adding crystal manganese chloride, powdered manganese hydroxide and a catalyst into an enamel reaction kettle to obtain a precipitate; opening the enamel reaction kettle, and transferring precipitate and mother liquor to a vacuum suction filtration device for suction filtration; after suction filtration, transferring precipitates to a constant-temperature drying box to be dried, wherein the drying temperature is 50-120 DEG C, and mother liquor is pumped into an enamel reaction kettle to be recycled. The method is simple in process, short in reaction time, low in production cost and high in yield, the produced product is free of wastewater pollution discharge, the mother liquor obtained after suction filtration can be recycled, the method is suitable for industrial mass production, wastewater discharge is avoided, and the method is a green and environment-friendly basic manganese chloride synthesis method.

Owner:HUNAN DEBANG BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com