Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Triethanolamine phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

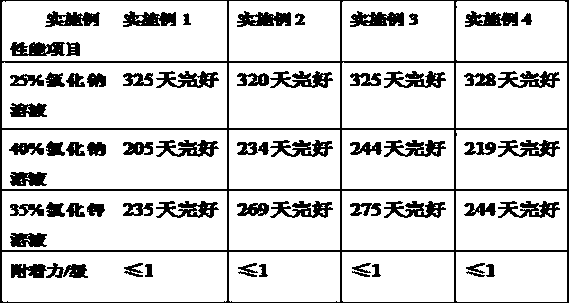

Multifunctional fully-synthetic cutting fluid and preparation method thereof

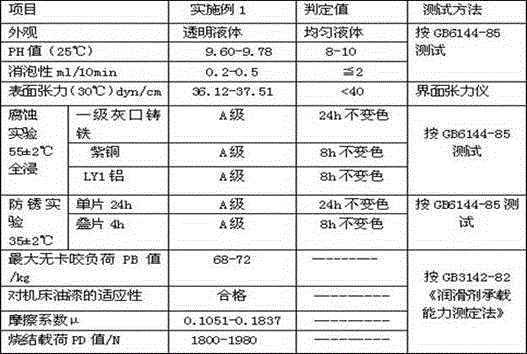

The invention discloses multifunctional fully-synthetic cutting fluid and a preparation method thereof. The multifunctional fully-synthetic cutting fluid is prepared from modified vegetable oil, organic carboxylic acid amide, borate, ethanolamine, a polyether activating agent, a non-ferrous metal corrosion inhibitor, triethanolamine oleate, ethanolamine citrate, triethanolamine phosphate, emulsified silicone oil and the like. According to the multifunctional fully-synthetic cutting fluid and the preparation method thereof, an easily-biodegradable special additive combination is adopted, so that the problem that similar products on the market are generally poor in lubricity and rust resistance is solved; a formula does not contain nitrite, benzene and phenol substances, so that waste liquid is easy to process, the destruction to the environment can not be caused, and the environmental friendliness is good; and the multifunctional fully-synthetic cutting fluid can be applied to medium / heavy-load cutting processing and is applicable to automated production equipment, such as numerically-controlled machine tools, processing centers and the like.

Owner:水泽节(山东)环保科技有限公司

Alcohol-free fountain solution for printing and preparation method thereof

InactiveCN103722928AReduce surface tensionImprove wettabilityPrinting pre-treatmentAlcohol freeSodium metasilicate

The invention discloses an alcohol-free fountain solution for printing and a preparation method thereof. The alcohol-free fountain solution is composed of, by weight, 2-4% of apricot glue, 4-6% of dipropylene glycol methyl ether, 3-5% of sodium metasilicate, 0.5-1% of octadecyl dimethyl benzyl ammonium chloride, 1-3% of cocamidopropyl betaine, 0.5-1% of lauryl dimethyl amine oxide, 1.5-2.5% of lanolin alcohol polyoxyethylene ether, 2-4% of triethanolamine phosphate, 1.5-2.5% of liquid citric acid, 1-2% of zinc nitrate and the rest water. The alcohol-free fountain solution is free of adding of any alcohol, completely free of containing of VOC substances, completely environment friendly and harmless to human body, has the advantages of low surface tension, good wettability and stable chemical performance, is an ideal fountain solution for a high-speed multicolor offset press, can remarkably improve printing effect and quality, is simple in preparation process and low in production cost, and has important economic and social benefit.

Owner:青岛中科菲力工程技术研发有限公司

High-stability low-alkaline liquid accelerator and preparation method thereof

ActiveCN109111145AFast active ingredientLess active ingredientsSodium fluorideO-Phosphorylethanolamine

The invention discloses a high-stability low-alkaline liquid accelerator and a preparation method thereof. The accelerator is prepared from aluminum sulfate, sodium fluoride, a stabilizer and water; the accelerator is prepared from the components in percentage by mass: 45-60% of aluminum sulfate, 8-15% of sodium fluoride, 5-10% of stabilizer and the balance of water; the stabilizer is one or a mixture of multiple of o-phosphorylethanolamine, diethanolamide phosphate, triethanolamine phosphate, triethanolamine borate and boronized diethanolamide phosphate. The high-stability low-alkaline liquidaccelerator has the advantages that production raw materials are easy to obtain, no special requirements on required equipment exists, operation is simple, the long-term storage stability is good, the adaptability to cement types is wide, the mixing amount is less, setting speed is high, the strength is high, and the like.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

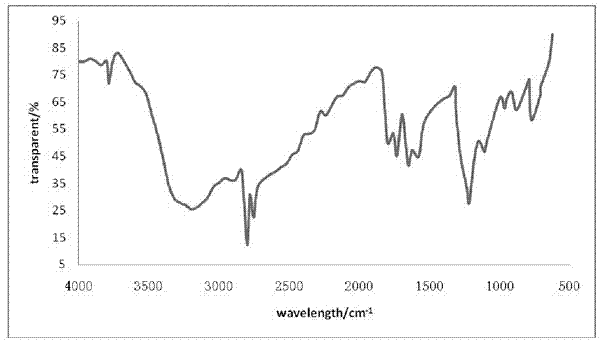

Corrosion inhibitor and preparing method thereof

The invention provides a corrosion inhibitor and a preparing method thereof. The corrosion inhibitor comprises components including, by weight part, 30 to 50 parts of a main agent, 10 to 20 parts of triethanolamine phosphate, 4 to 8 parts of thiourea, 2 to 5 parts of a surface active agent and 17 to 54 parts of a solvent. The main agent comprises a first chemical compound of the formula I structure shown in the specification and a second chemical compound of the formula II structure shown in the specification, and the mass concentration sum of the first chemical compound and the second chemical compound in the main agent is 60%. The corrosion inhibitor can effectively protect an oil and gas field combined station sewage pipeline in the hypersalinity sewage environment containing CO2 and H2S gas, and the beneficial effects of being good in water solubility and compatibility, high in safety, low in filling concentration, excellent in anti-corrosion effect, low in production process needand the like are achieved.

Owner:PETROCHINA CO LTD

Green and environment-friendly water-based hydraulic fluid

The invention provides green and environment-friendly water-based hydraulic fluid. The water-based hydraulic fluid comprises, in weight ratio, 57-65% of deionized water, 25-32% of propylene glycol, 8% of thickening agents (polyethylene glycol), 2% of lubricants (triethylene glycol coupling agents), 0.4% of water-soluble molybdenum extreme-pressure agents and 0.6% of anti-rusting agents (triethanolamine phosphate). The green and environment-friendly water-based hydraulic fluid is non-flammable, a main component of the water-based hydraulic fluid is water, helper components of the water-based hydraulic fluid do not contain nitrite or benzene series toxic compounds and absolutely do not contain toxic substances, and the vast majority of the helper components can be decomposed by microorganisms in a short time. The water-based hydraulic fluid is mainly used in a flammable and explosive production environment, is specially used for a hydraulic system, is applicable to hydraulic equipment for coal mining and petrochemical industries, and replaces current hydraulic oil synthesized with refined mineral oil or polyolefin.

Owner:SHIYAN RUNTE POWER TECH

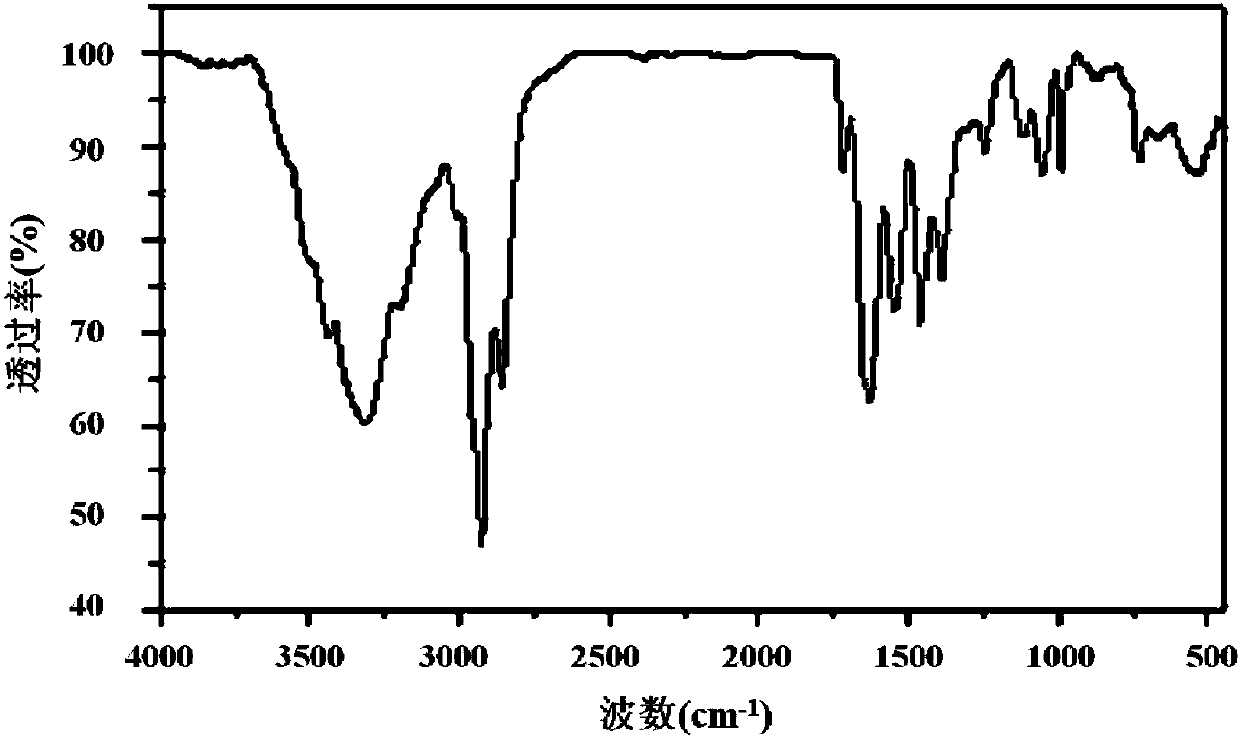

Triethanolamine phosphate ricinoleate compound, and total-synthesized water-based anti-wear hydraulic fluid containing same

ActiveCN102775438AImprove wear resistanceImprove rust resistanceAdditivesPhosphorus organic compoundsWater basedOil production

The invention discloses a triethanolamine phosphate ricinoleate compound and total-synthesized water-based anti-wear hydraulic fluid containing the compound, and belongs to the filed of lubricating oil production. The triethanolamine phosphate ricinoleate has excellent anti-wear and anti-rust properties, and is capable of synchronously satisfying the anti-wear and anti-rust property requirements of the hydraulic fluid. The hydraulic fluid is formed by mixing triethanolamine phosphate ricinoleate, viscosity modifier, dimethyl sulfoxide, water, benzotriazole, de-foaming agent and fungicide, has the following characteristics of energy saving, environmental friendliness, excellent anti-wear and anti-rust properties, and the like, and has high value in promotion and application.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Novel corrosion inhibitor for inhibiting corrosion of steel in tap water or seawater and use method thereof

The invention discloses a novel FX corrosion inhibitor for inhibiting the corrosion of steel in tap water or seawater, which consists of 20%-40% of phosphoric acid triethanolamine, 20%-40% of zinc dihydric phosphate, 20%-40% of sodium tripolyphosphate and 10%-30% of hexamethylene tetramine. When the using concentration of the corrosion inhibitor is 75ppm-250ppm, multiple protective films not onlycan be formed on the surface of the steel in the tap water or seawater, but also has self-repairing capability when being damaged, so that the corrosion inhibitor is especially effective in inhibitingthe corrosion of the steel in the tap water or seawater, and the corrosion inhibiting rate is close to 100%. The corrosion inhibitor has small required dosage, cheap and easily-obtained raw materials, low cost, no toxicity, no pollution, good anti-scaling function, reduced blowdown, and good matching with oxidative bactericides, thus being an efficient water quality treating agent.

Owner:郭良生

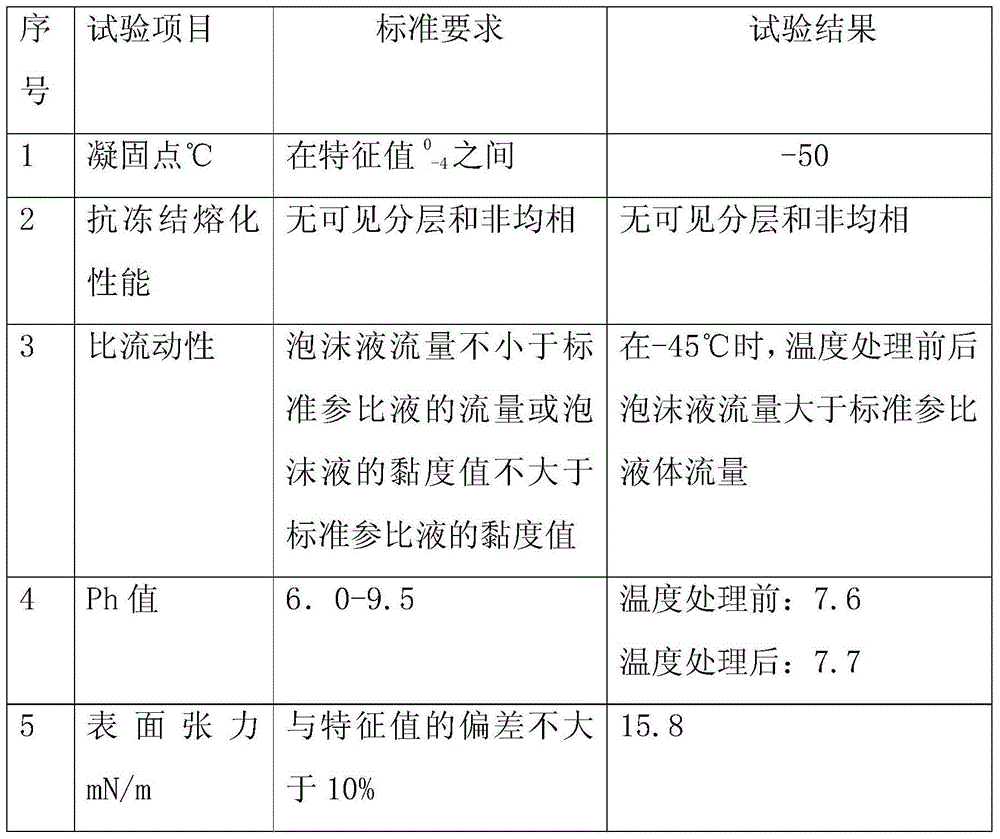

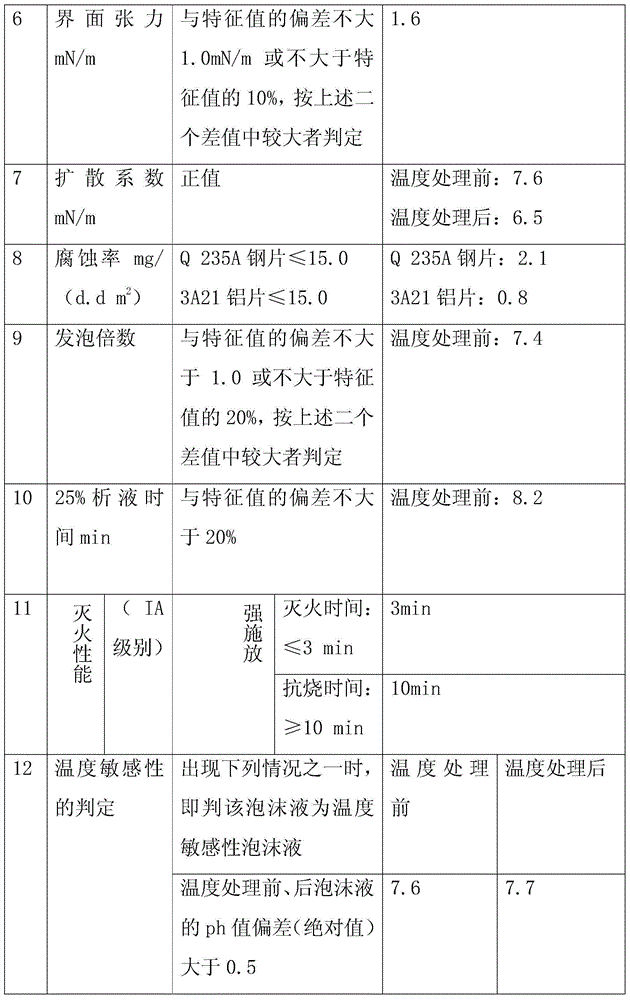

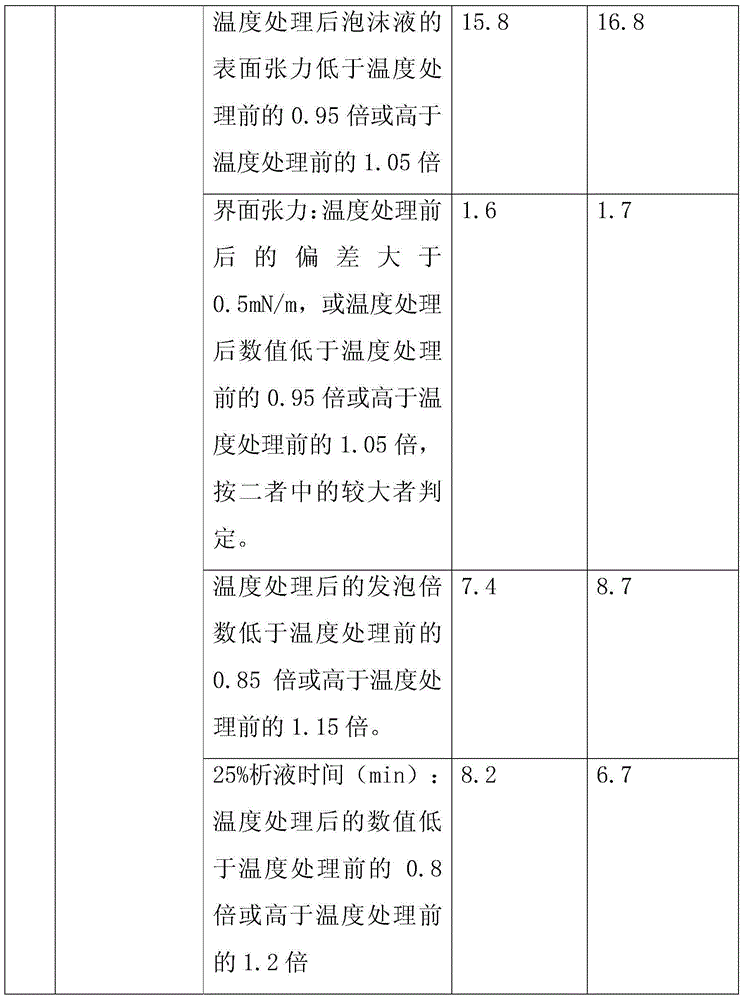

A fire extinguishing agent for ultralow temperature

A fire extinguishing agent for ultralow temperature is disclosed. The fire extinguishing agent comprises following components by mass: 2-5% of perfluoroalkylsulfonyl quaternary ammonium iodide, 2-5% of fluoroalkylbetaine, 5-10% of decylalkylbetaine, 0.3-0.8% of xanthan gum, 5-10% of laurylimidazoline betaine and 40-60% of triethanolamine phosphate, with the balance being water. An application of the fire extinguishing agent for ultralow temperature is further disclosed. The fire extinguishing agent can rapidly extinguish fire and is suitable for ultralow-temperature environments.

Owner:厦门安港消防科技有限公司

Preparation method of colloidal antimony pentoxide

InactiveCN104591278AUniform particle size distributionIncreased dispersionAntimony oxides/hydroxides/oxyacidsEvaporationPhosphoric acid

The invention discloses a preparation method of colloidal antimony pentoxide. The preparation method comprises following steps, step1, triethanolamine is delivered into a beaker filled with water, phosphoric acid is added, and triethanolamine phosphate is obtained via 10min of ultrasonic treatment; step 2, the obtained triethanolamine phosphate is delivered into a three-mouth flask filled with antimonous oxide powder, an obtained mixture is stirred, is heated to 95 to 100 DEG C, and is subjected to constant temperature heating, wherein the three-mouth flask is provided with a magnetic stirring apparatus and a reflux condensing tube; step 3, oxidizing agent hydrogen peroxide is added dropwise using a constant-pressure funnel with full stirring, and after adding, an obtained mixed material is subjected to oxidation refluxing for 30min; and step 4, colloidal antimony pentoxide dry powder is obtained via evaporation, condensation, and drying of an obtained hydrosol. The preparation method is simple; production period is short; energy consumption is low; particle size distribution of the obtained antimony pentoxide colloid particles is uniform; and colloid particle dispersion degree is high.

Owner:QINGDAO WANGYU RUBBER

Tree antifreezing film agent

InactiveCN107047657ANo pollution in the processEffective protectionBiocidePlant growth regulatorsForest industryAcetic acid

The invention relates to a tree antifreezing film agent, relating to the technical field of forestry. The tree antifreezing film agent mainly contains the following raw materials in parts by mass: 10-20 parts of film forming matters, 2-5 parts of paraffin, 1-3 parts of 5-chloro-2-methyl-4-isothiazolin-3-one, 5-8 parts of phenyltriazole sodium, 2-6 parts of tea polyphenol, 3-9 parts of fulvic acid, 10-80 parts of dimethyl sulfoxide, 10-80 parts of ethylene glycol, 2-5 parts of glacial acetic acid, 5-10 parts of fresh ginger, and 2-5 parts of triethanolamine phosphate. The tree antifreezing film agent can effectively protect trees, and is pollution-free and harmless to a human body.

Owner:唐肖近

Use method of tree anti-freezing spraying agent

InactiveCN105104039AReduce freezing damage lossRaise the ratioBiocidePlant growth regulatorsBenzoic acidPolybutylene

The invention provides a use method of a tree anti-freezing spraying agent. The use method includes the use steps of A, diluting the tree anti-freezing spraying agent into 800-volume-fold liquid through water to be sprayed in late autumn and before plant dormancy; B, diluting the tree anti-freezing spraying agent into 600-volume-fold liquid through water to irrigate roots 3-7 days before frosting or cold waves; C, diluting the tree anti-freezing spraying agent into 1000-volume-fold liquid through water to irrigate the roots before and after plant transplanting; D, diluting the tree anti-freezing spraying agent through water by 50-80 volume folds to conduct trunk and branch brushing operation before winter. The steps are required to be conducted at the temperature between 3 DEG C and 8 DEG C. The tree anti-freezing spraying agent comprises 1-hydroxy ethylidene-1,1-diphosphonic acid, tolyl triazole sodium, polybutylene, fulvic acid potassium, benzoic acid, tea polyphenol, phosphoric acid triethanolamine, Chinese mosla herbs, ginger, chrysanthemum and burdock. The use method is simple in ratio, convenient to use, capable of greatly reducing cold injury loss of trees and good in anti-freezing effect.

Owner:王素敏

Rolling oil and preparation process thereof

InactiveCN102391908AGuaranteed smoothnessReduce dosageLubricant compositionMetalworkingPhosphoric acid

The invention belongs to the technical field of rolling oil, and discloses rolling oil used in the process of machining metals and a preparation process for the rolling oil. The rolling oil is technically characterized in that the rolling oil is prepared by stirring phosphoric acid, triethanolamine, a lubricant, a pH value regulator, sodium thiosulfate, Ninol, an antirusting agent, an emulsifier and water. The rolling oil does not contain mineral oil or aromatic hydrocarbon, so the rolling oil is favorable for the health of operators; and when the rolling oil is used for producing steel plates, friction force between rolled workpieces can be reduced effectively. The rolling oil has the characteristics of reducing calendaring loads effectively in the calendaring process, ensuring the glossiness of the rolled workpieces and relieving abrasion between the workpieces.

Owner:王占功

Corrosion inhibitor for inhibiting seawater with salinity of 25-40 percent and preparation method of corrosion inhibitor

InactiveCN104294284AImprove adsorption capacityImprove corrosion resistanceO-Phosphoric AcidHexamethylenetetramine

The invention discloses a corrosion inhibitor for inhibiting seawater with the salinity of 25-40 percent. The corrosion inhibitor comprises the following components in percentage by weight: 26-38 parts of urotropin, 18-28 parts of sodium molybdate, 15-19 parts of phosphoric acid triethanolamine, 0.9-3.2 parts of thiosemicarbazide, 12-15 parts of calcium gluconate, 10-12 parts of rosin amine polyoxylethylene ether, 16-18 parts of mineral oil, 25-35 parts of benzotriazole, 12-15 parts of halogenated alkyl pyridine and 18-25 parts of octacosanol. The corrosion inhibitor can be firmly combined with carbon steel under the action of urotropin, sodium molybdate, rosin amine polyoxylethylene ether, halogenated alkyl pyridine and the mineral oil, so that the adsorption capacity of the corrosion inhibitor to a deck is greatly improved; the corrosion resistance of a metal surface can be enhanced; furthermore, the corrosion inhibitor is environment-friendly and has no toxic or side effect.

Owner:NANJING LISHUI ZHENXING SHIP ACCESSORIES

Preparation method of inorganic oxide pigment and filler loaded with composite corrosion inhibitor

PendingCN113462199AAnti-corrosive paintsPigment treatment with non-polymer organic compoundsTetrazolePhosphoric acid

The invention discloses a preparation method of an inorganic oxide pigment and filler loaded with a composite corrosion inhibitor, and belongs to the technical field of preparation of anticorrosive pigments and fillers. The inorganic oxide pigment and filler loaded with the composite corrosion inhibitor comprises a component A and a component B, wherein the component A is a composite corrosion inhibitor and comprises organic nitrogen azoles (such as diazoles, triazoles, tetrazoles and derivatives thereof), amine phosphate (ethanolamine phosphate, triethanolamine phosphate and the like) and inorganic trivalent cerium and phosphate compounds. The azole compounds have a good corrosion inhibition effect on nonferrous metals such as copper, aluminum, magnesium and alloys thereof, and the compounds such as amine phosphate and phosphate have a good corrosion inhibition effect on iron-based materials such as carbon steel and alloy steel; and the trivalent cerium compounds are used for promoting passivation of the base material. The problems that an existing inorganic pigment filler is poor in compatibility with an organic coating and has no self-repairing effect, and a micro-nano container is complex in preparation process, high in cost and the like are solved.

Owner:BEIJING UNIV OF CHEM TECH

Formula of novel efficient compound anti-freezing fluid

InactiveCN104673215APromote environmental protectionGood corrosion inhibitionHeat-exchange elementsCellulosePhosphoric acid

The invention discloses a formula of a novel efficient compound anti-freezing fluid. The anti-freezing fluid is prepared from the following components in parts by weight: 10-20 parts of diethylene glycol, 0.5-1 part of calcium chloride, 10-15 parts of sodium nitrite, 10-20 parts of ethylene glycol, 1-3 parts of silicate stabilizer, 5-10 parts of triolamine, 2-5 parts of scaling and corrosion inhibitor, 4-5 parts of carboxymethyl cellulose, 2-4 parts of methyl tert-butyl ether, 0.4-0.6 part of triethanolamine phosphate and 10-15 parts of deionized water. The anti-freezing fluid is not frozen at -45 DEG C, foam disappears in less than 3 seconds, carboxylate radical of high polymer, sulfonate radical of poly(sulfonated styrene) as well as ethylene glycol and metal ions carrying positive charge in an aqueous solution generate adsorption effect to form a protective membrane, so that metal is protected from corrosion. The anti-freezing fluid does not contain nitrite or phosphate, has excellent environmentally friendly property, and can be used for sufficiently achieving the excellent corrosion inhibiting effect based on the anti-freezing effect.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Ultra-low temperature foam fire extinguishing agent

InactiveCN106621163ALarge latent heat of evaporationHigh cooling capacity per unit volumeHeat-exchange elementsFire extinguisherDiethylene glycol monobutyl etherFoaming agent

The invention relates to an ultra-low temperature foam fire extinguishing agent. The ultra-low temperature foam fire extinguishing agent comprises the following raw materials in percentage by weight: 3 to 5% of diethylene glycol monobutyl ether, 6-10% of a compound fluorocarbon surfactant, 10-15% of sodium benzoate, 10-15% of a foaming agent, 10-15% of a solubilizing agent, 4 to 6% of trifluoromethane, 6-10% of carbon dioxide, 15-23% of triethanolamine phosphate, and 15-25% of water. The ultra-low temperature foam fire extinguishing agent obtained from the materials in percentage by weight is suitable for low-temperature environment, is environment-friendly, and is stable and effective for a long time.

Owner:ANHUI NEWT FIRE EQUIP

Stainless steel cleaning agent

InactiveCN100529189CImprove cleaning efficiencySimple cleaning processPhosphoric acidCleansing Agents

The stainless steel detergent for washing stainless steel product is prepared with acids, basic salts, surfactant, assistant, stabilizer and water, and through stirring and reaction at normal temperature. Specifically, it consists of sodium carbonate, sodium tripolyphosphate, tartaric acid, citric acid, hydrofluoric acid, nitric acid, phosphoric aicd, JFC, OP-10, triethanolamine, urotropin, trisodium phosphate, acetic acid, alcohol and water in certain weight proportion. It has the features of simple preparation process, environment friendship, high cleaning efficiency, low cleaning cost, etc.

Owner:吴铭鑫

Antirust corrosion-resistant cutting fluid

InactiveCN103602390AExcellent lubricating and anti-wear propertiesImprove cooling effectAdditivesGlycerolPhosphoric acid

A disclosed antirust corrosion-resistant cutting fluid is prepared from the following raw materials in parts by weight: 20-25 parts of 1-hydroxyl-2-acetyl-4-methylbenzene, 10-15 parts of tribasic lead sulfate, 3-9 parts of triethanolamine phosphate, 3-9 parts of an antistatic agent, 2-6 parts of polyaniline waterborne preservative and 8-16 parts of glycerin. Compared with conventional cutting fluids, the efficient extreme pressure-antiwear additive, the cleaning agent, the antirust corrosion-resistant additive and the like are employed for preparation of the antirust corrosion-resistant cutting fluid which has excellent lubrication wear-resistant performance, cleaning cooling property and antirust corrosion-resistant property, and the antirust corrosion-resistant cutting fluid helps to avoid generation of cutting burls, effectively protect cutter, improve processing quality, extremely well take away the heat generated during processing, reduce the processed face temperature, and effectively avoid workpiece crimping and deformation caused by high temperature.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Tree spraying antifreezing agent

InactiveCN105104458AReduce freezing damage lossRaise the ratioBiocidePlant growth regulatorsBenzoic acidPolybutylene

The invention provides a tree spraying antifreezing agent which comprises, by weight parts, 2-5 parts of hydroxyl ethydene phosphoric acid, 5-8 parts of tolyl triazole sodium, 4-8 parts of polybutylene, 3-9 parts of fulvic acid potassium, 5-9 parts of benzoic acid, 2-6 parts of tea polyphenols, 2-5 parts of triethanolamine phosphate and 2-5 parts of cooking liquor of Chinese mosla herb, ginger, chrysanthemum and great burdock achene. The content of ions of Cu, Fe, Mn, Zn and B of the antifreezing agent is not smaller than 100 g / L. The tree spraying antifreezing agent is simple in matching and convenient to use, tree freezing damage can be reduced greatly, and the antifreezing effect is good. Biological enzyme is activated, generation of ice nucleating bacteria is avoided, the ice-forming activity of frozen protein is damaged, and heat is increased. The freezing point value of plant cells is lowered, cellular plasmatic flow is promoted, and the cell activity is improved by 4-8 times. The water retention and drought resistance of plants are improved, the freezing injury is alleviated, the alleviating and recovering effects on the planted subjected to mild and light freezing injury are achieved, the severe damage is invalid, and the plant freezing point value is reduced by 5-8 DEG C.

Owner:王素敏

Anti-rust and stain-free hydraulic fluid

InactiveCN109054937AIncreasing the thicknessHigh strengthLubricant compositionPolyesterHydraulic fluid

The invention provides anti-rust and stain-free hydraulic fluid. The anti-rust and stain-free hydraulic fluid is characterized by being prepared from synthesized sodium sulfonate, base oil, boric acidester, chlorinated paraffin, polyester, nonylphenol polyoxyethylene ether, ricinoleic acid triethanolamine phosphate, polyether, a surfactant, water, a thickening agent, an anti-rust additive, an anti-wear additive and a scale inhibition corrosion inhibitor. The lubricant ash-free extra pressure anti-wear additive is adopted, and the extra anti-rust additive is added, so that the anti-rust protection capacity of the hydraulic fluid in a closed system is effectively enhanced, and the anti-rust, stain-free and anti-wear requirements in a tiny gap are greatly met; in addition, the thickening agent with the high mechanical shearing resistant capacity is adopted, thus, the stability of mechanical shearing is effectively improved, the strength and thickness of an oil film are effectively increased, and the lubricating performance and extreme pressure performance of the hydraulic fluid are greatly improved; besides, the anti-rust and stain-free hydraulic fluid has high lubricating, cooling,cleaning and rust prevention performance, and has anti-corrosion and anti-wear properties, therefore a hydraulic system can transmit working signals reliably, and the service life of the hydraulic fluid can be greatly prolonged.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

Novel anticorrosion cutting fluid

InactiveCN104046470AExcellent lubricating and anti-wear propertiesImprove cooling effectLubricant compositionPhosphoric acidMaterials science

The invention relates to a novel anticorrosion cutting fluid. The anticorrosion cutting fluid is prepared from the following raw materials in parts by weight: 10-16 parts of mixed vegetable oil, 11-18 parts of triethanolamine phosphate, 8-15 parts of waterborne polyaniline anticorrosion agent, 1.4-2.9 parts of tetrachloroethylene, 6.5-11.5 parts of barium acrylate, 1.4-2.7 parts of lubricant, 3-5 parts of mineral oil and 28 parts of water. The cutting fluid disclosed by the invention has the beneficial effects of having excellent lubricating and abrasion-resistant properties, cleaning-cooling properties and antirust and anticorrosion properties, avoiding the generation of the built-up edge and thus effectively protecting a tool.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

Corrosion inhibitor for sulfur-containing wet gas pipeline and preparation method thereof

Owner:PETROCHINA CO LTD

Continuous annealing line levelling liquid for steel plant, preparation method and application thereof in steel levelling

InactiveCN110644011AImprove rust resistanceImprove the lubrication effectPhosphoric acidPhospholipid

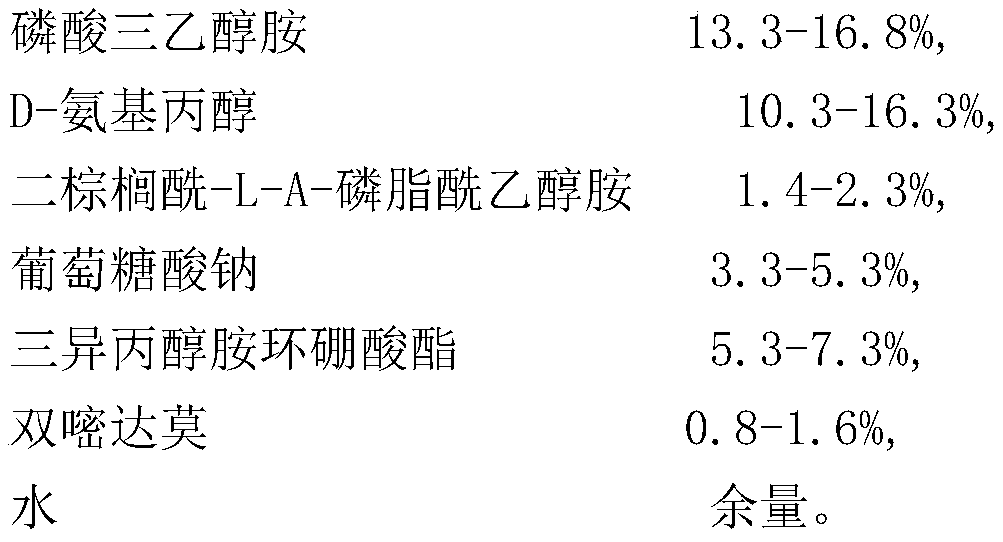

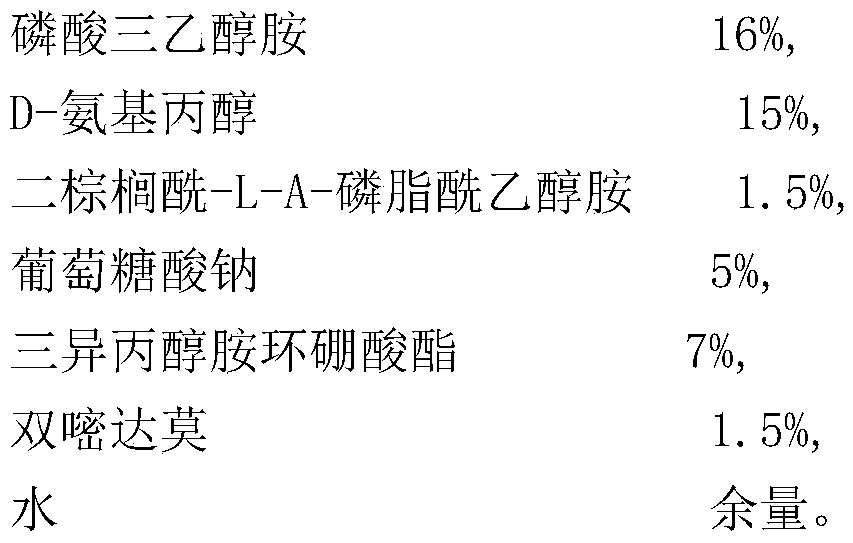

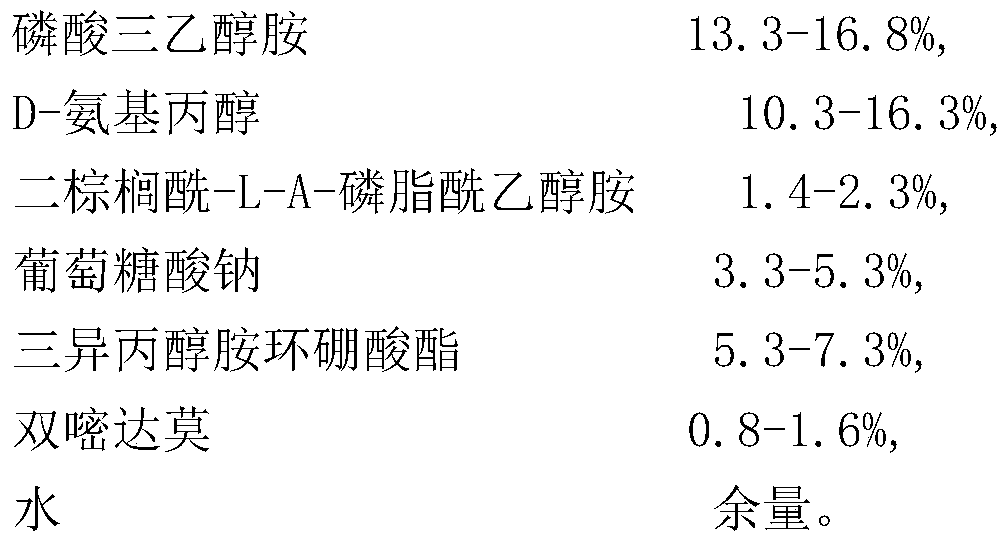

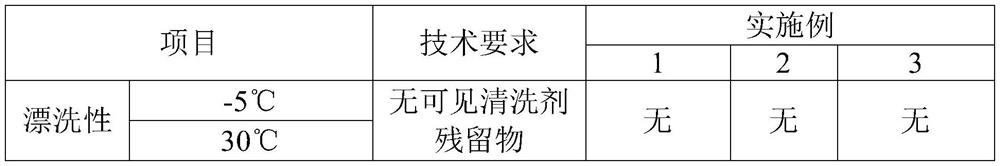

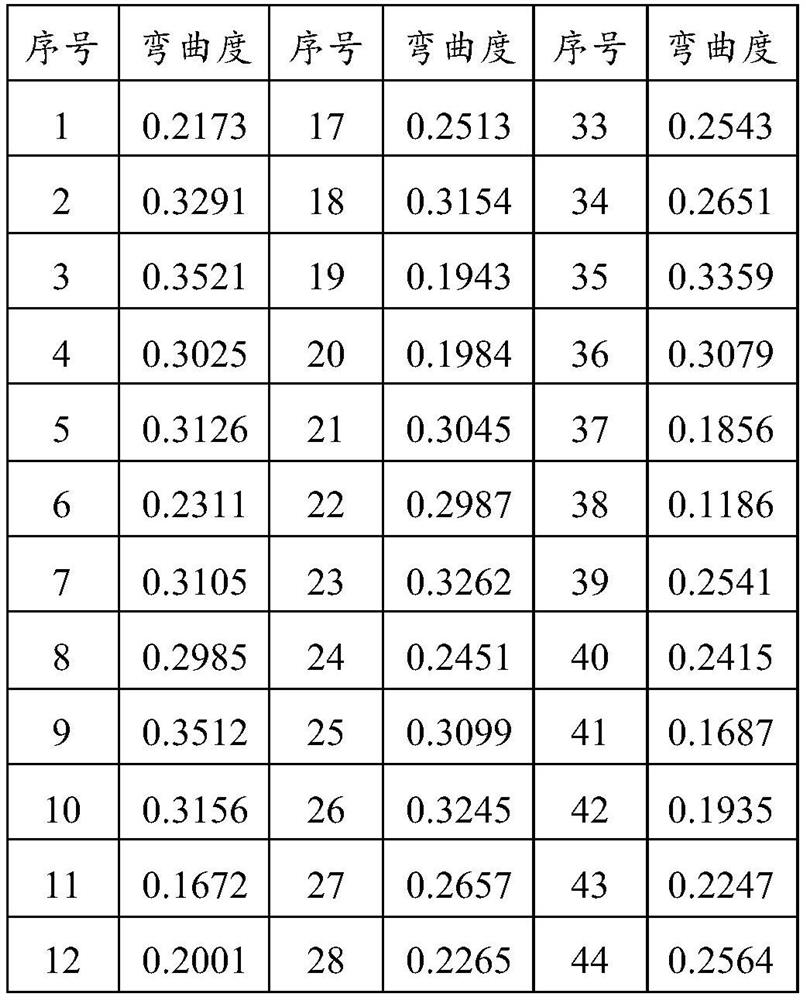

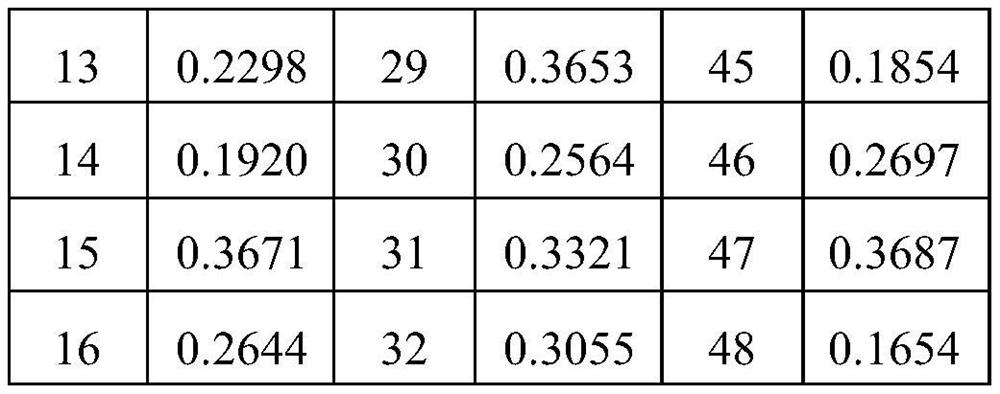

The invention discloses a continuous annealing line levelling liquid for a steel plant. The continuous annealing line levelling liquid for the steel plant is prepared from the following components inpercentage by weight: 13.3%-16.8% of triethanolamine phosphate, 10.3%-16.3% of D-aminopropanol, 1.4%-2.3% of dipalmitoyl-L-A-phosphatidyl ethanolamine, 3.3%-5.3% of sodium gluconate, 5.3%-7.3% of triisopropanolamine cyclic borate, 0.8%-1.6% of dipyridamole, and the balance water. The continuous annealing line levelling liquid for the steel plant is high in anti-rust property and lubricity.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Cleaning agent for condenser and radiator of automobile air conditioner as well as preparation method and application of cleaning agent

PendingCN114292711AWith environmental protection functionHigh degree of cleaning and decontaminationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBenzoic acidPhosphoric Acid Esters

The invention relates to the field of cleaning agents, and discloses a cleaning agent for a condenser and a radiator of an automobile air conditioner as well as a preparation method and application of the cleaning agent, and the cleaning agent is prepared from a composition containing the following components: 20-50 parts by weight of ethanol, 0.1-0.6 part by weight of a composite surfactant and 1.1-15.8 parts by weight of an anti-corrosion additive, wherein the anti-corrosion auxiliary agent is prepared from 0.1 to 0.6 part by weight of methylbenzotriazole, 0.1 to 0.6 part by weight of 6-amino-2-mercaptobenzothiazole, 0.1 to 5 parts by weight of triethanolamine phosphate composition, 0.1 to 0.6 part by weight of oleic acid or oleate, 0.1 to 2 parts by weight of benzoic acid or benzoate, 0.5 to 2 parts by weight of sodium metasilicate hydrate and 0.1 to 5 parts by weight of citric acid or citrate; wherein the composite surfactant is a mixture of perfluoroalkyl betaine and cocamidopropyl betaine, and the composite surfactant is a mixture of perfluoroalkyl betaine and cocamidopropyl betaine. The cleaning agent has the advantages of no toxicity, no residue, quick drying, corrosion resistance and antibacterial property, and can solve the problem of cleaning pollution in the production and manufacturing process of air conditioner condensers and radiators.

Owner:张家港迪克汽车化学品有限公司

A kind of deplating process of panel glass electroplating film layer

The invention provides a stripping process for the electroplating film layer of panel glass, comprising the following steps: A) immersing the panel glass in stripping solution A, stripping the FGAR film layer and ink layer; in terms of mass concentration, stripping solution A The ingredients are as follows: potassium hydroxide 10-12%, tetrahydrofurfuryl alcohol 5-8%, ethylenediaminetetraacetic acid 4-7%, sodium metasilicate pentahydrate 2-5%, hydroxyethylidene diphosphate 4-8%, 6-10% of triethanolamine, 0.1-0.5% of alkyl glycoside, 0.1-0.5% of isooctyl ether phosphate, and the balance is water; B) immersed in stripping solution B to strip the PVD film layer; based on mass fraction , the composition of stripping solution B is as follows: potassium hydroxide 18-25%, sodium gluconate 2-6%, sodium citrate 4-10%, tetrasodium EDTA 2-6%, potassium pyrophosphate 2-8% %, sodium silicate pentahydrate 0.5-2%, triethanolamine 4-10%, glycerol 1-2%, and the balance is water.

Owner:LENS TECH CHANGSHA

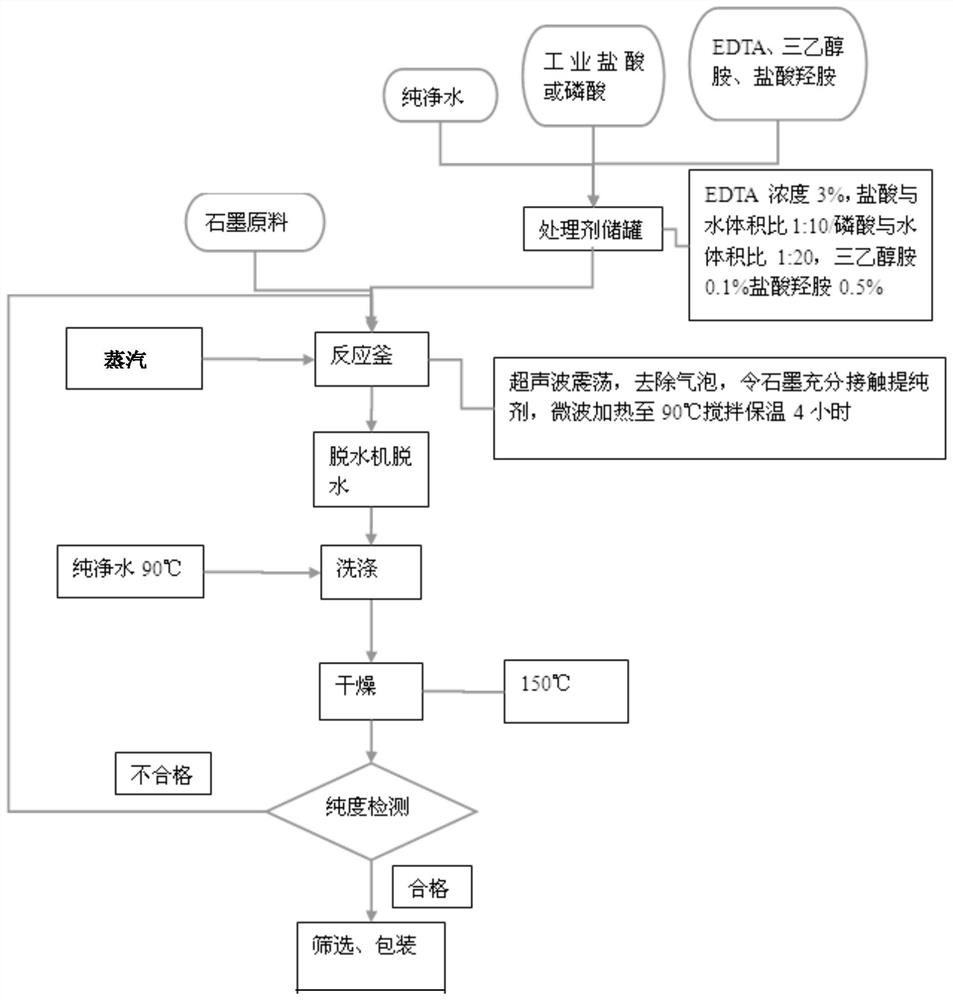

A kind of purification method of high carbon graphite

The invention discloses a method for purifying high-carbon graphite. The method comprises: (1) placing high-carbon graphite with a carbon content between 99-94% in a reaction kettle; (2) preparing a purifying agent: Put purified water, industrial hydrochloric acid or phosphoric acid, EDTA, triethanolamine, and hydroxylamine hydrochloride in the treatment agent storage tank for mixing; (3) Purification: add the purification agent into the reaction kettle, pass in steam at 230°C, and ultrasonically oscillate to remove Bubbles, so that the graphite is fully exposed to the purifying agent, heated by microwave to 85-95°C, stirred and kept for 3-5 hours; (4) dehydration: (5) washing; (6) drying: (7) purity test; and (8) packaging. Experiments have proved that the method of the present invention can effectively stabilize iron in the liquid phase, increase the amount of iron dissolved, thereby promoting the improvement of graphite purity and the reduction of metal ions, and at the same time solves the safety hazards caused by acid mist corrosion in surrounding buildings. Problems, the purification process is more stable, environmentally friendly and safe.

Owner:HEILONGJIANG UNIV OF TECH

A kind of multifunctional fully synthetic cutting fluid and preparation method thereof

The invention discloses multifunctional fully-synthetic cutting fluid and a preparation method thereof. The multifunctional fully-synthetic cutting fluid is prepared from modified vegetable oil, organic carboxylic acid amide, borate, ethanolamine, a polyether activating agent, a non-ferrous metal corrosion inhibitor, triethanolamine oleate, ethanolamine citrate, triethanolamine phosphate, emulsified silicone oil and the like. According to the multifunctional fully-synthetic cutting fluid and the preparation method thereof, an easily-biodegradable special additive combination is adopted, so that the problem that similar products on the market are generally poor in lubricity and rust resistance is solved; a formula does not contain nitrite, benzene and phenol substances, so that waste liquid is easy to process, the destruction to the environment can not be caused, and the environmental friendliness is good; and the multifunctional fully-synthetic cutting fluid can be applied to medium / heavy-load cutting processing and is applicable to automated production equipment, such as numerically-controlled machine tools, processing centers and the like.

Owner:水泽节(山东)环保科技有限公司

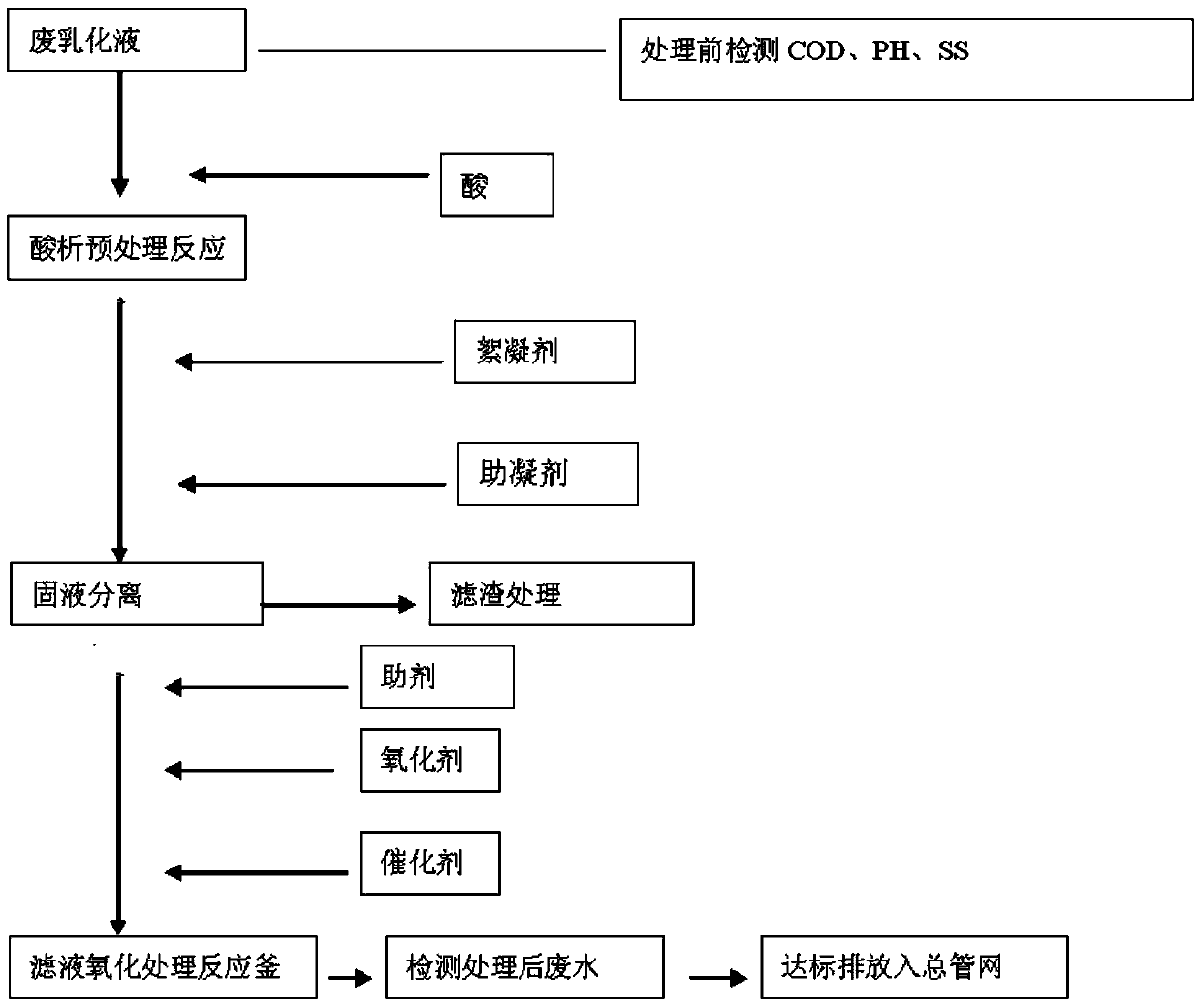

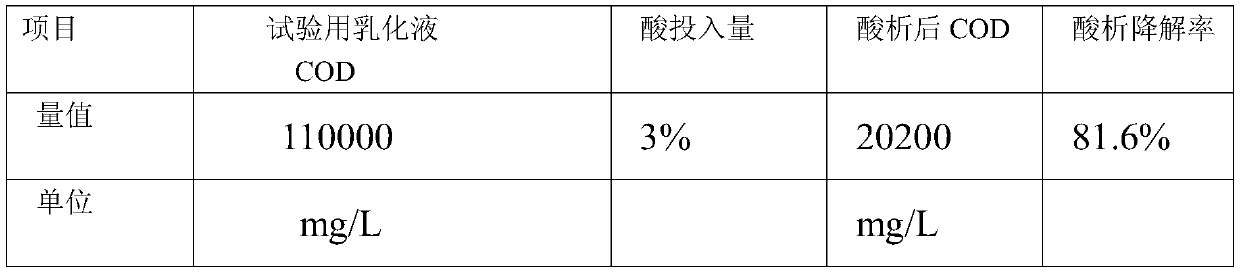

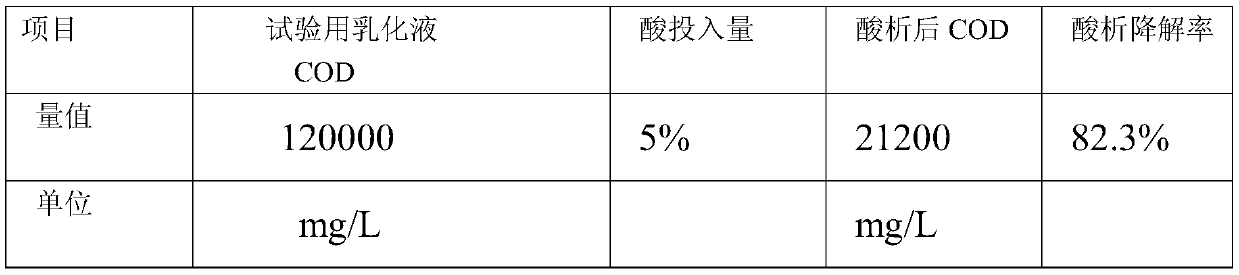

A method of acid analysis-hydrogen peroxide catalytic oxidation treatment of high-concentration waste emulsion

ActiveCN105293756BRich sourcesImprove oxidation efficiencyMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationPhosphoric acid

Owner:丁建林 +2

A kind of high-stability low-alkali liquid quick-setting agent and preparation method thereof

The invention discloses a high-stability low-alkali liquid quick-setting agent and a preparation method thereof. The quick-setting agent is composed of aluminum sulfate, sodium fluoride, a stabilizer and water; the mass percentage of each component is: aluminum sulfate: 45 ‑60%, sodium fluoride: 8‑15%, stabilizer 5‑10%, and the remainder is water; the stabilizer is ethanolamine phosphate, diethanolamine phosphate, triethanolamine phosphate, triethanolamine borate and One or more mixtures of borated diethanolamine phosphates. The production raw materials of the high-stability and low-alkali liquid quick-setting agent provided by the invention are easy to obtain, the required equipment has no special requirements, the operation is simple, the long-term storage stability is good, the adaptability to cement varieties is wide, the dosage is low, and the setting speed is fast And high strength characteristics.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com