A fire extinguishing agent for ultralow temperature

A fire extinguishing agent and ultra-low temperature technology, applied in fire prevention equipment, etc., can solve problems such as weak adaptability, slow fire extinguishing speed, and inability to apply to low temperature environments, and achieve the effect of enhanced adaptability and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

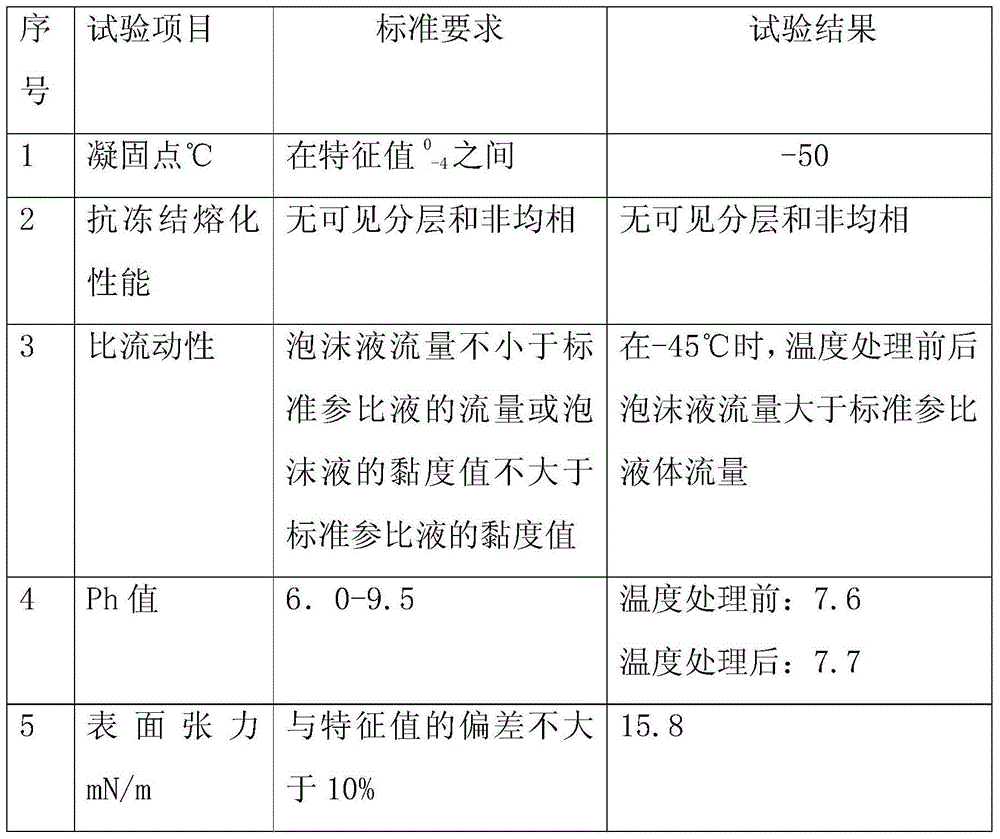

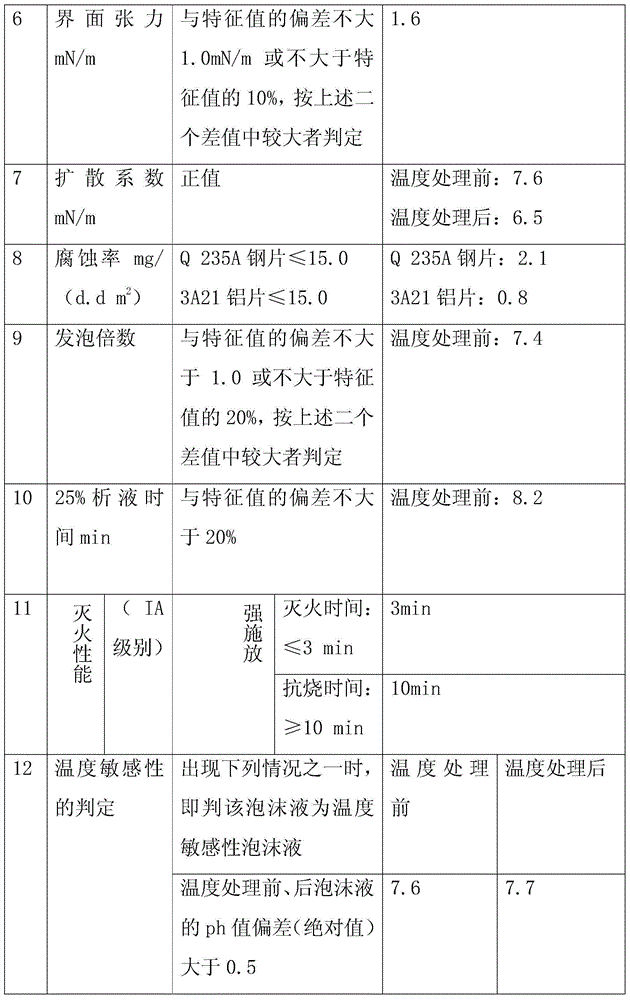

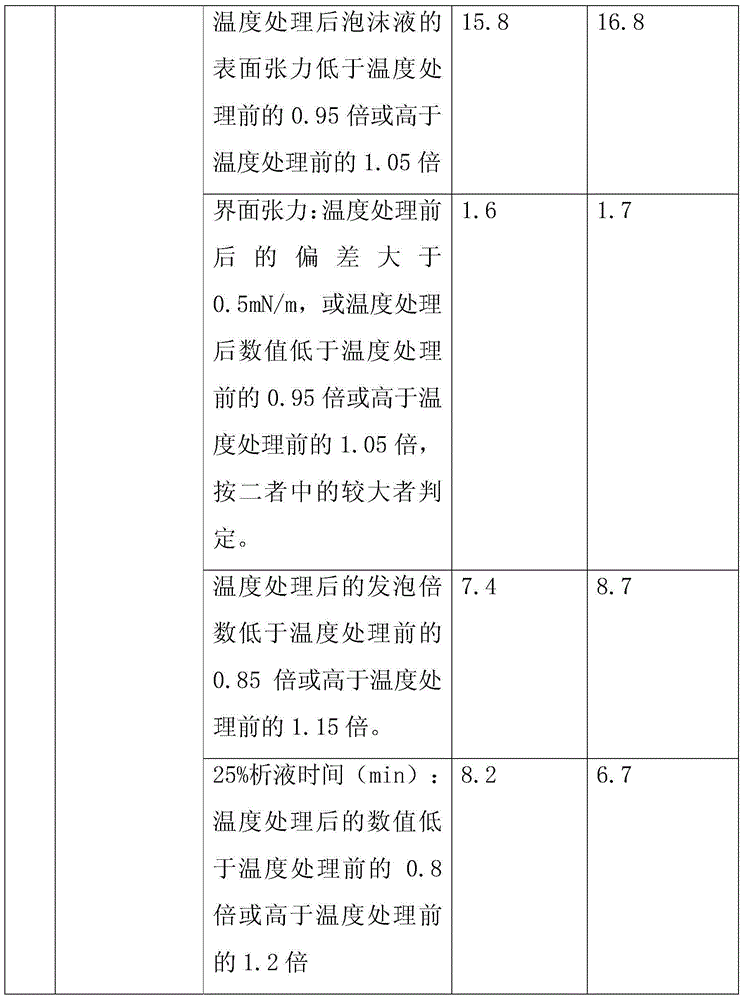

Image

Examples

Embodiment 1

[0012] Weigh 20 grams of perfluorooctyl quaternary ammonium iodide, 20 grams of fluorinated alkyl betaine, 50 grams of decayl betaine, 3 grams of xanthan gum, 50 grams of lauryl imidazoline betaine, and 400 grams of triethanolamine. Phosphate ester, dissolved in 457 grams of water, high-speed shearing and stirring to make it evenly mixed to obtain ultra-low temperature foam fire extinguishing agent, minus 50 ℃ does not freeze.

[0013] The foam fire extinguishing agent is formulated into an aqueous solution with a mass fraction of 6%, which is filled into the MSJ950 water-based fire extinguisher to extinguish 13B gasoline fires. The fire extinguishing agent is sprayed to the oil surface through the fire extinguisher, the dense smoke immediately turns into white water vapor, the fire is controlled within 6 seconds, and there is only a small flame within 8 seconds, and it is completely extinguished within 12 seconds.

Embodiment 2

[0015] Weigh 50 grams of perfluorooctyl quaternary ammonium iodide, 50 grams of fluorinated alkyl betaine, 100 grams of decayl betaine, 8 grams of xanthan gum, 100 grams of lauryl imidazoline betaine, and 600 grams of triethanolamine. Phosphate ester, dissolved in 92 grams of water, high-speed shearing and stirring to make it evenly mixed to obtain ultra-low temperature foam fire extinguishing agent, minus 50 ℃ does not freeze.

[0016] The foam fire extinguishing agent is formulated into an aqueous solution with a mass fraction of 6%, which is filled into the MSJ950 water-based fire extinguisher to extinguish 13B gasoline fires. The fire extinguishing agent is sprayed to the oil surface through the fire extinguisher, the dense smoke immediately turns into white water vapor, the fire is controlled within 6 seconds, and there is only a small flame within 8 seconds, and it is completely extinguished within 12 seconds.

Embodiment 3

[0018] Weigh 35 grams of perfluorooctyl quaternary ammonium iodide, 35 grams of fluorinated alkyl betaine, 75 grams of decayl betaine, 6 grams of xanthan gum, 75 grams of lauryl imidazoline betaine, and 500 grams of triethanolamine. Phosphate ester, dissolved in 274 grams of water, high-speed shearing and stirring to make it evenly mixed to obtain ultra-low temperature foam fire extinguishing agent, minus 50 ℃ does not freeze.

[0019] The foam fire extinguishing agent is formulated into an aqueous solution with a mass fraction of 6%, which is filled into the MSJ950 water-based fire extinguisher to extinguish 13B gasoline fires. The fire extinguishing agent is sprayed to the oil surface through the fire extinguisher, the dense smoke immediately turns into white water vapor, the fire is controlled within 6 seconds, and there is only a small flame within 8 seconds, and it is completely extinguished within 12 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com