Corrosion inhibitor for inhibiting seawater with salinity of 25-40 percent and preparation method of corrosion inhibitor

An anti-corrosion agent, seawater technology, applied in the field of metal protective agents, can solve the problems of toxic side effects, poor environmental friendliness, restrictions and phase-out, etc., to achieve the effects of no toxic side effects, improved adsorption capacity, and increased corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

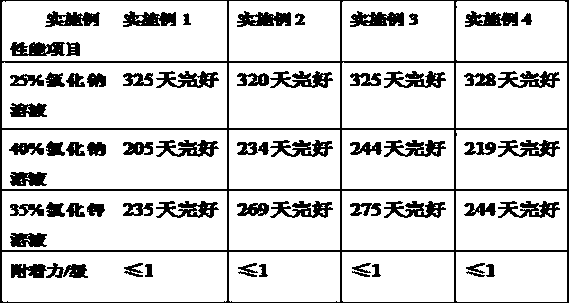

Examples

Embodiment 1

[0015] An anti-corrosion agent for seawater with a salinity of 25% to 40%, its components are composed of the following components by weight percentage: 26 parts of urotropine, 28 parts of sodium molybdate, 19 parts of triethanolamine phosphate, and 3.2 parts of thiosemicarbazide , 15 parts of calcium gluconate, 12 parts of rosin amine polyoxyethylene ether, 18 parts of mineral oil, 35 parts of benzotriazole, 15 parts of haloalkylpyridine, and 25 parts of octacosanol.

[0016] The preparation method of the anti-corrosion agent of above-mentioned 25%~40% salinity sea water, described preparation method comprises the steps:

[0017] (1) Weigh the raw material components according to the weight of the above components;

[0018] (2) Put the above-mentioned raw materials in the reaction kettle, heat and mix evenly, heat to 128°C and stir at high speed for 40~60min.

Embodiment 2

[0020] An anti-corrosion agent for seawater with a salinity of 25% to 40%, its components are composed of the following components by weight percentage: 38 parts of urotropine, 18 parts of sodium molybdate, 15 parts of triethanolamine phosphate, and 0.9 part of thiosemicarbazide , 12 parts of calcium gluconate, 10 parts of rosin amine polyoxyethylene ether, 16 parts of mineral oil, 25 parts of benzotriazole, 12 parts of haloalkylpyridine, and 18 parts of octacosanol.

[0021] The preparation method of the anti-corrosion agent of above-mentioned anti-25%~40% salinity sea water, described preparation method comprises the steps:

[0022] (1) Weigh the raw material components according to the weight of the above components;

[0023] (2) Put the above-mentioned raw materials in the reaction kettle, heat and mix them evenly, heat to 158°C and stir at high speed for 30-60 minutes.

Embodiment 3

[0025] An anti-corrosion agent for seawater with a salinity of 25% to 40%, its components are composed of the following components by weight percentage: 29 parts of urotropine, 19 parts of sodium molybdate, 17 parts of triethanolamine phosphate, and 2.8 parts of thiosemicarbazide , 14 parts of calcium gluconate, 11 parts of rosin amine polyoxyethylene ether, 17 parts of mineral oil, 29 parts of benzotriazole, 13 parts of haloalkylpyridine, and 23 parts of octacosanol.

[0026] The preparation method of the anti-corrosion agent of above-mentioned anti-25%~40% salinity sea water, described preparation method comprises the steps:

[0027] (1) Weigh the raw material components according to the weight of the above components;

[0028] (2) Put the above-mentioned raw materials in the reaction kettle, heat and mix them evenly, heat to 158°C and stir at high speed for 30-60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com