A kind of multifunctional fully synthetic cutting fluid and preparation method thereof

A fully synthetic, cutting fluid technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of poor lubricating performance and extreme pressure performance of fully synthetic cutting fluids, affecting the health of operators, and weak rust resistance. Environmental friendliness, good cleaning, long cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

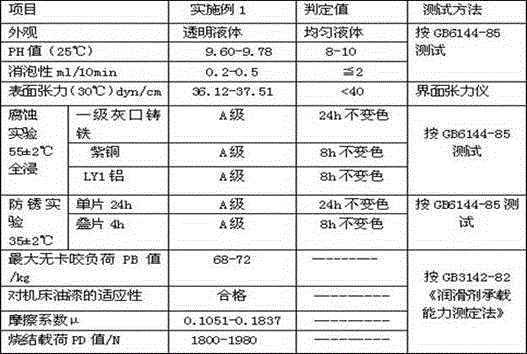

Examples

Embodiment 1

[0038] Example 1. A preparation method of multifunctional fully synthetic cutting fluid, comprising the steps of:

[0039] (1) Prepare modified vegetable oil, phosphate triethanolamine and other reaction components in the reactor.

[0040] The preparation method of the modified vegetable oil is as follows: add 150kg of vegetable oil into a one-ton reactor, slowly heat it to 90-95°C, and then slowly add 100kg of 20% sodium hydroxide solution for saponification. During the saponification process, slowly Add alcohol amine dropwise to disperse. The total amount of alcohol amine is 200kg. Continue to saponify for one hour to obtain a transparent viscous saponified product. Cool down to 70°C, add 50kg of boric acid, react for one hour, and finally 100kg of deionized water. It can be stored for later use.

[0041] The preparation method of phosphate ester: in a one-ton reaction kettle, add alcohol ether and deionized water (ratio 3:1), stir well, then slowly add phosphorus pentoxid...

Embodiment 2

[0045] Example 2. A preparation method of multifunctional fully synthetic cutting fluid, comprising the steps of:

[0046] (1) Prepare modified vegetable oil, phosphate triethanolamine and other reaction components in the reactor.

[0047] The preparation method of the modified vegetable oil is as follows: add 150kg of vegetable oil into a one-ton reactor, slowly heat it to 90-95°C, and then slowly add 100kg of 20% sodium hydroxide solution for saponification. During the saponification process, slowly Add alcohol amine dropwise to disperse. The total amount of alcohol amine is 200kg. Continue to saponify for one hour to obtain a transparent viscous saponified product. Cool down to 70°C, add 50kg of boric acid, react for one hour, and finally 100kg of deionized water. It can be stored for later use.

[0048] The preparation method of phosphate ester: in a one-ton reaction kettle, add alcohol ether and deionized water (ratio 3:1), stir well, then slowly add phosphorus pentoxid...

Embodiment 3

[0052] Example 3. A preparation method of multifunctional fully synthetic cutting fluid, comprising the steps of:

[0053] (1) Prepare modified vegetable oil, phosphate triethanolamine and other reaction components in the reactor.

[0054] The preparation method of the modified vegetable oil is as follows: add 150kg of vegetable oil into a one-ton reactor, slowly heat it to 90-95°C, and then slowly add 100kg of 20% sodium hydroxide solution for saponification. During the saponification process, slowly Add alcohol amine dropwise to disperse. The total amount of alcohol amine is 200kg. Continue to saponify for one hour to obtain a transparent viscous saponified product. Cool down to 70°C, add 50kg of boric acid, react for one hour, and finally 100kg of deionized water. It can be stored for later use.

[0055] The preparation method of phosphate ester: in a one-ton reaction kettle, add alcohol ether and deionized water (ratio 3:1), stir well, then slowly add phosphorus pentoxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com