Triethanolamine phosphate ricinoleate compound, and total-synthesized water-based anti-wear hydraulic fluid containing same

A technology of triethanolamine phosphate and triethanolamine ester, which is applied in phosphorus organic compounds, lubricating compositions, petroleum industry and other directions, can solve the problems of high toxicity of ethylene glycol, high environmental hazards, and difficult to degrade, and achieve excellent anti-wear and The effect of anti-rust performance, improving environmental adaptability, and reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

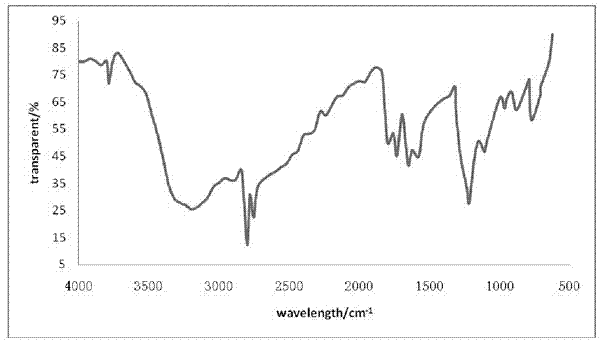

Image

Examples

Embodiment 1

[0028] Embodiment 1 (preparation of ricinoleic acid triethanolamine phosphate)

[0029] (a) Synthesis of triethanolamine ricinoleic acid: first add an appropriate amount of ricinoleic acid into a 250 ml four-neck flask, gradually raise the temperature to 80°C, then add an appropriate amount of triethanolamine in batches, fill with N 2 As protective gas, use toluene as water-carrying agent, start stirring, then gradually raise the temperature to 150°C, react at this temperature for 8 hours, stop heating when no more water evaporates, and naturally cool and discharge the material at room temperature to obtain a yellow oily castor Triethanolamine anesthenic acid liquid.

[0030] (b) Synthesis of ricinoleic acid triethanolamine phosphate: first dissolve the weighed phosphorus pentoxide in an appropriate amount of benzene, then add the self-made above-mentioned ricinoleic triethanolamine into a 250 ml four-neck flask, start stirring, and separate Add the mixed solution of benzene ...

Embodiment 2

[0034] Fully synthetic water-based anti-wear hydraulic fluid formula:

[0035] Ricinoleic Acid Triethanolamine Phosphate 10Kg

[0036] Polyoxypropylene polyoxyethylene block polyether 15 Kg

[0037] Dimethyl sulfoxide 30 Kg

[0038] water 40kg

[0039] Benzotriazole 0.1 Kg

[0040] Water-soluble polyether defoamer 30ppm

[0041] Triazine fungicide 150ppm.

[0042] Preparation:

[0043] a. At room temperature, add distilled water and dimethyl sulfoxide according to the proportion of the formula, turn on the stirring, heat with heat transfer oil, control the temperature at about 40°C, add a viscosity modifier, and stir for 20 minutes;

[0044] B. add embodiment one gained triethanolamine ricinoleate phosphate, benzotriazole, defoamer and bactericide in proportion again;

[0045] c. After adding all the ingredients, keep warm and stir for 20 minutes; filter and repack to get the finished hydraulic fluid.

Embodiment 3

[0047] Fully synthetic water-based anti-wear hydraulic fluid formula:

[0048] Ricinoleic Acid Triethanolamine Phosphate 6Kg

[0049] Polyoxypropylene polyoxyethylene block polyether 10 Kg

[0050]Dimethyl sulfoxide 20 Kg

[0051] water 40 kg

[0052] Benzotriazole 0.05 Kg

[0053] Water-soluble polyether defoamer 30ppm

[0054] Triazine fungicide 150ppm.

[0055] The preparation method is the same as the preparation method described in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com