Corrosion inhibitor and preparing method thereof

A corrosion inhibitor and solvent technology, which is applied in the field of petrochemical industry, can solve the problems of hidden dangers in the use of ethylene oxide, environmental pollution in production and construction, and high toxicity, and achieve safety performance guarantee, good anti-corrosion effect, and good water solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1. Synthesis of the main agent

[0066] Add 574 kg of tung oil and 57.4 kg of water into a stainless steel reaction kettle, raise the temperature to 100°C, and keep it warm for 1 hour, add 684 kg of rosin and 800 kg of water, then raise the temperature to 140°C, and add 660 kg of it dropwise under nitrogen protection. Diethylenetriamine, the dropping time is controlled within 2 hours, and then the temperature is kept at 140-150°C for 3 hours; then the temperature is raised to 180°C for 2 hours, and then heated to 210°C for 5 hours; after the reaction, cool down to Below 50°C, add 334 kg of thiourea and 100 kg of ethanol, and after reflux reaction for 2 hours, add 310 kg of chloroacetic acid and 100 kg of ethanol, and reflux for 4 hours; after the end, add 600 kg of water to obtain a mass concentration of 60 % main agent, recorded as TOROIM-TH-AS.

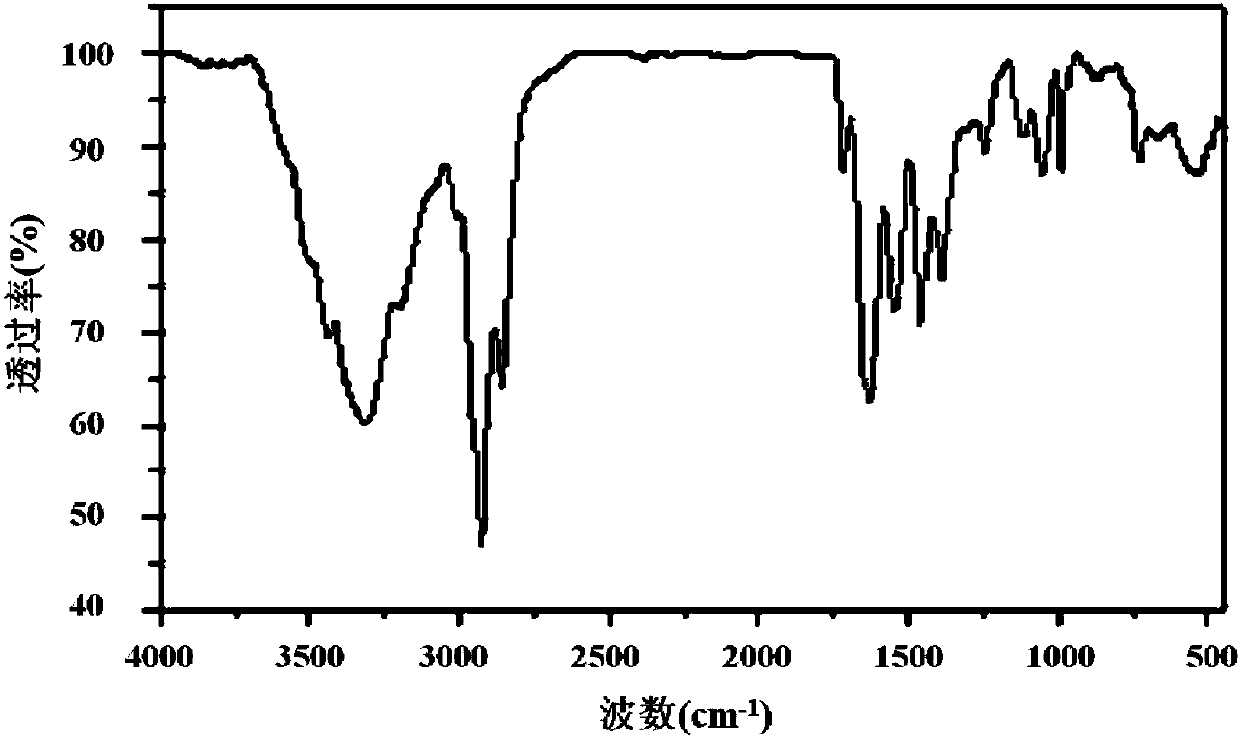

[0067] figure 1 It is the infrared spectrogram of the main agent TOROIM-TH-AS synthesized in this embodiment, as can be s...

Embodiment 2

[0080] TOROIM-TH-AS (60% mass concentration) synthesized in Example 1, triethanolamine phosphate, thiourea, Tween-20, methanol, ethylene glycol and deionized water were mixed and stirred evenly, and the ratio of each component was shown in the table 4. The corrosion inhibitor is prepared, and its code name is TLM-W02.

[0081] Table 4 Composition ratio of corrosion inhibitor TLM-W02

[0082] components

[0083] The conditions completely consistent with those in Example 1 were used to test the protective effects of different corrosion inhibitor TLM-W02 additions on sewage pipelines. The specific test results are shown in Table 5, where the test period is 4 days.

[0084] Table 5 Corrosion rate and corrosion inhibition rate of different corrosion inhibitor TLM-W02 additions

[0085] Corrosion inhibitor dosage (mg / L)

[0086] According to the test results in Table 5, as the addition of corrosion inhibitor TLM-W02 increased from 0 to 100mg / L, the corrosion rat...

Embodiment 3

[0088] TOROIM-TH-AS (60% effective concentration) synthesized in Example 1, triethanolamine phosphate, thiourea, Tween-20, methanol, ethylene glycol, and deionized water were mixed and stirred evenly, and the ratio of each component was shown in Table 6, namely the prepared corrosion inhibitor, its code is marked as TLM-W03.

[0089] Table 6 Composition ratio of corrosion inhibitor TLM-W03

[0090] components

[0091] The protective effect of different corrosion inhibitor TLM-W03 additions on sewage pipelines was tested under the same conditions as in Example 1. The specific test results are shown in Table 7, where the test period is 4 days.

[0092] Table 7 Corrosion rate and corrosion inhibition rate of different corrosion inhibitor TLM-W03 additions

[0093] Corrosion inhibitor dosage (mg / L)

[0094] According to the test results in Table 7, as the addition of corrosion inhibitor TLM-W03 increased from 0 to 100mg / L, the corrosion rate of the sample decr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com