Continuous annealing line levelling liquid for steel plant, preparation method and application thereof in steel levelling

A leveling liquid, a steel plant technology, applied in the iron and steel plant continuous annealing line leveling liquid, steel leveling application, preparation field, can solve the problem of leveling liquid not suitable, surface scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described by the following examples, but not as a limitation of the present invention.

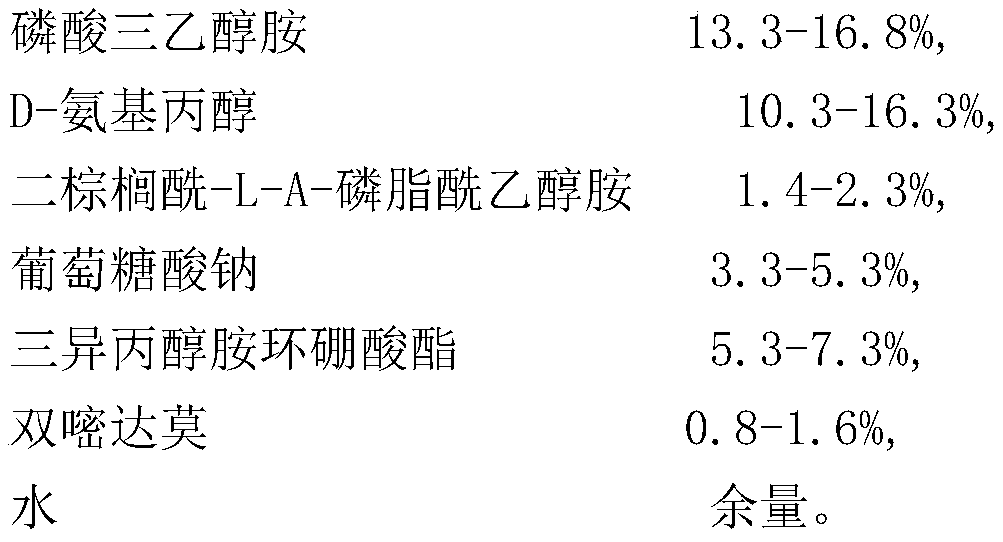

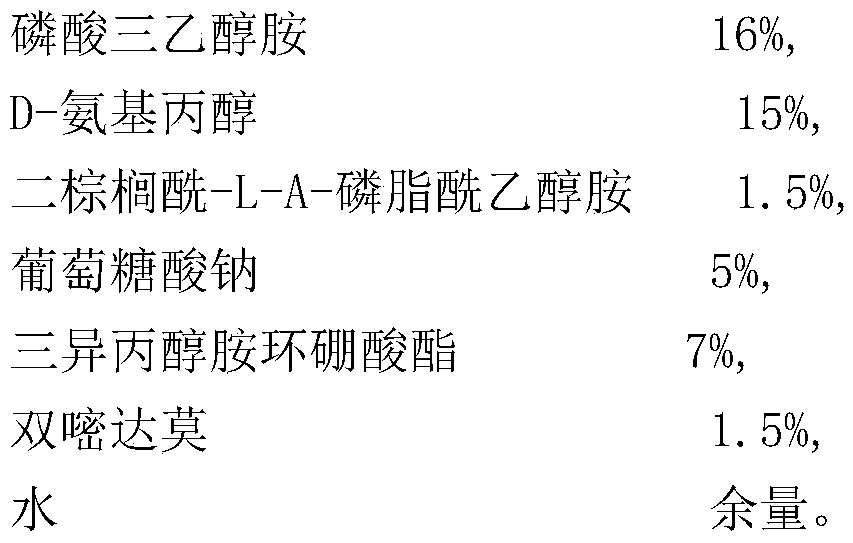

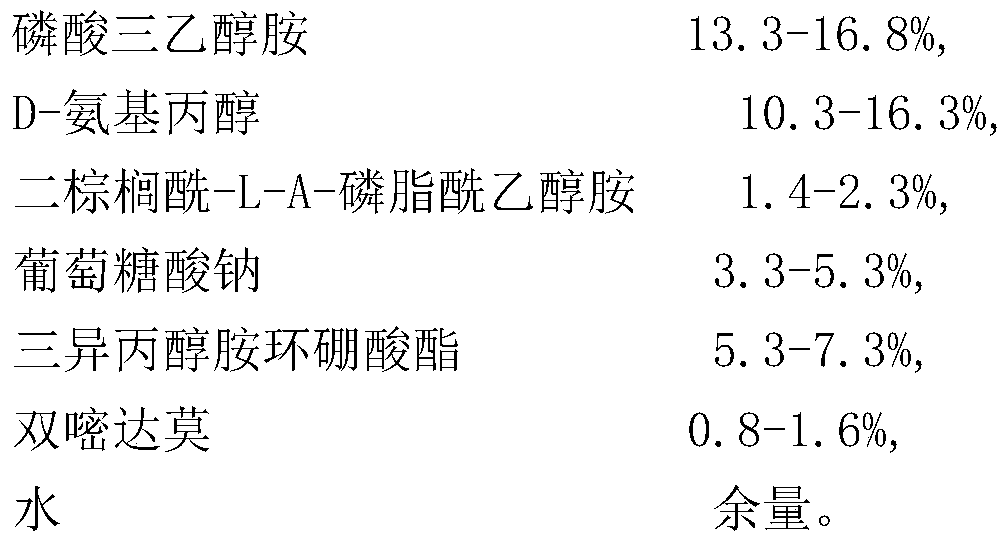

[0018] Table 1 shows the formulations of Examples 1-4 and Comparative Examples 1-2, and the unit is wt%.

[0019] The formula of table 1 embodiment 1-4, comparative example 1-2

[0020]

[0021] Comparative example 1 in table 1 removed dipalmitoyl-L-A-phosphatidylethanolamine on the basis of embodiment 4, and the consumption of phosphate triethanolamine is the total consumption of palmitoyl-L-A-phosphatidylethanolamine and phosphate triethanolamine in embodiment 4 , others are identical with embodiment 4.

[0022] Comparative example 2 in table 1 removes triethanolamine phosphate on the basis of embodiment 4, and the consumption of dipalmitoyl-L-A-phosphatidylethanolamine is the total consumption of palmitoyl-L-A-phosphatidylethanolamine and triethanolamine phosphate in embodiment 4 , others are identical with embodiment 4.

[0023] In Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com