Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103 results about "Stainless steel strainer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In plumbing, a sink strainer is a type of perforated metal sieve or mesh strainer used to strain or filter out solid debris in the water system. Different varieties are used in residential premises and for industrial or commercial applications. Such strainer elements are generally made from stainless steel for corrosion resistance.

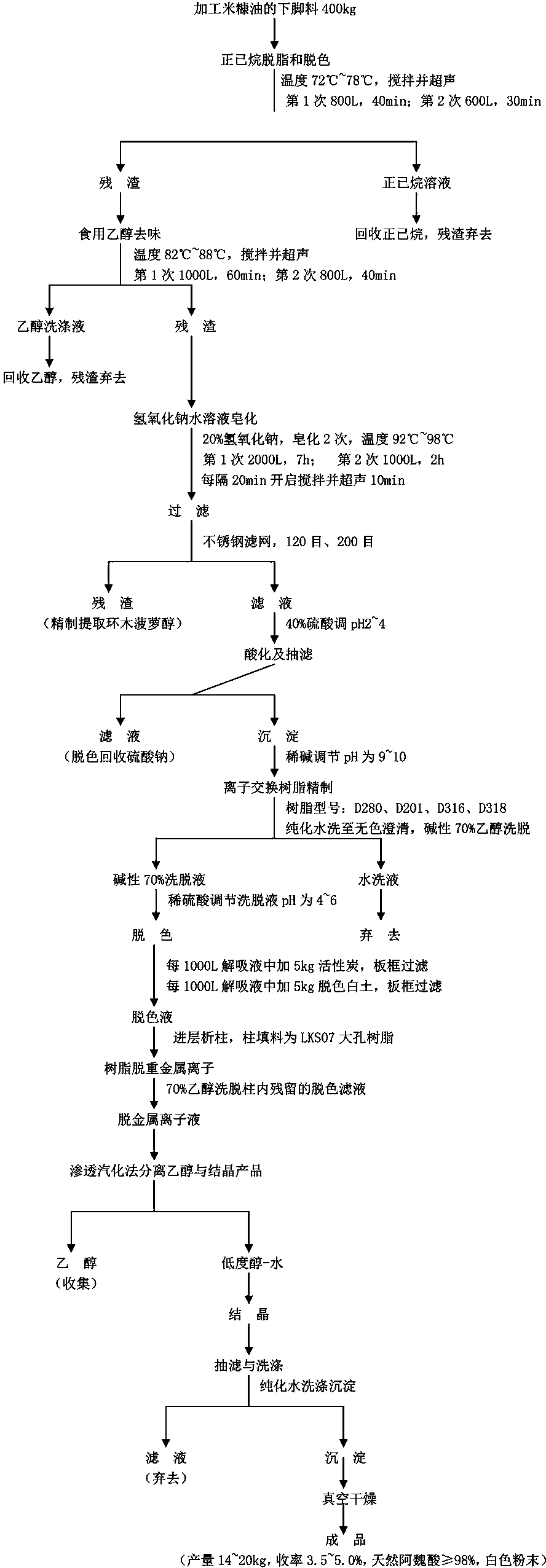

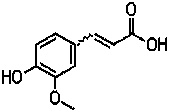

Novel process for extracting not smaller than 98% of natural ferulic acid from rice bran oil processing leftovers

ActiveCN103553903AImprove physiological activityReduce pollutionCarboxylic compound separation/purificationIon exchangeIon-exchange resin

The invention discloses a novel process for extracting not smaller than 98% of natural ferulic acid from rice bran oil processing leftovers. The process comprises the following steps: with the rice bran oil processing leftovers as an extraction raw material, degreasing and decoloring the extraction raw material through n-hexane, and deflavoring through more than 80% of edible alcohol; then, saponifying the extraction raw material twice through a sodium hydroxide aqueous solution with a certain concentration and temperature, naturally filtering the saponification solution through a stainless steel filter screen, regulating the saponification solution through dilute sulfuric acid, and carrying out suction filtration; regulating the pH of precipitate to 9-10 through dilute alkali, refining the precipitate through ion exchange resin, eluting impurities, desorbing through alkaline ethanol, decoloring and filtering; removing harmful metal ions in the filtrate through a resin column; and separating ethanol and a product heavy crystal from effluent through a pervaporation membrane technology, washing, suction filtering and vacuum drying the crystal product to obtain the natural ferulic acid. The process disclosed by the invention can be used for extracting and separating the natural ferulic acid with purity larger than 98% and having a variety of significant physiological activities, thereby not only turning waste into treasure and improving the resource utilization rate, but also being simple in manufacturing process, low in production cost, high in product yield, low in requirements on production equipment and easy to control and realize the production process.

Owner:GUANGXI DAIYUAN VEGETABLE PROD

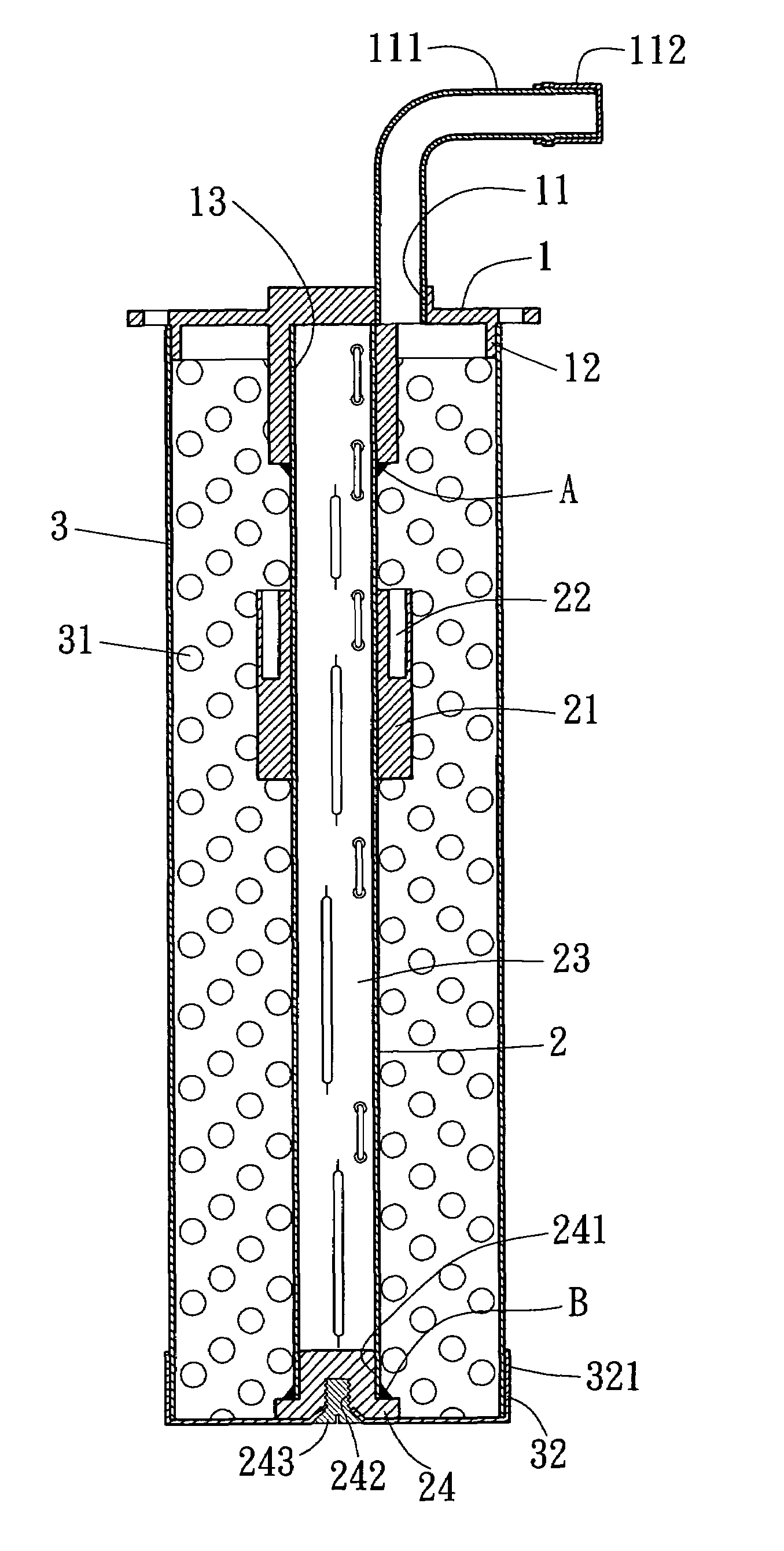

Initial rainwater separation and purification integrated device and using method thereof

PendingCN111732232ARealize automatic separationSmall footprintSewerage structuresGeneral water supply conservationActivated carbonEcological environment

The invention discloses an initial rainwater separation and purification integrated device and a using method thereof, and belongs to the field of ecological environment. A rainwater collection pipeline and a subsequent rainwater treatment pipeline are arranged on the two sides of a double-layer stainless steel filter screen of the device respectively, and a floating ball is placed in a sewage storage tank. The double-layer stainless steel filter screen can intercept solid impurities in rainwater, and meanwhile, a mixture of activated carbon and alkaline substances in the filter screen can play a certain role in purifying the collected rainwater. The storage water level of initial rainwater in the sewage storage tank drives the floating ball to rise, and finally the floating ball blocks asewage inlet of a hose to prevent rainwater from entering in the middle and later periods. The rainwater in the middle and later periods can be further purified or directly discharged into the environment after flowing into the subsequent rainwater treatment pipeline, so that the initial rainwater and the rainwater in the middle and later periods can be automatically separated. The device is simple in structure, can normally work without other external power, reduces the times of manual maintenance, and is suitable for various ways of rainwater recycling.

Owner:CHANGZHOU UNIV

Preparation method of wheat germ instant powder with long shelf life

The invention discloses a preparation method of wheat germ instant powder with long shelf life, which comprises the following steps of: screening and cleaning the wheat germs; performing normal-pressure steam enzyme deactivation on the wheat germs; mixing the wheat germs after the enzyme deactivation with water and soaking; grinding with a colloid mill; performing enzymolysis on the ground wheat germ suspension by use of saccharifying enzyme in combination with cellulase; filtering with a stainless steel filter, and removing large particles in the suspension; performing falling-film vacuum concentration of the filtered wheat germ suspension; adding whey protein and lecithin into the concentrated solution; homogenizing and emulsifying; and performing spray drying to obtain powder. The method disclosed by the invention effectively solves the problems of rough mouthfeel and low brewing property of wheat germs; meanwhile, due to the film forming property of protein, the whey protein and lecithin are reasonably added, the embedding of the wheat germ powder is realized without adding other food additives, and the shelf life of the wheat germ powder is effectively prolonged.

Owner:JIANGNAN UNIV

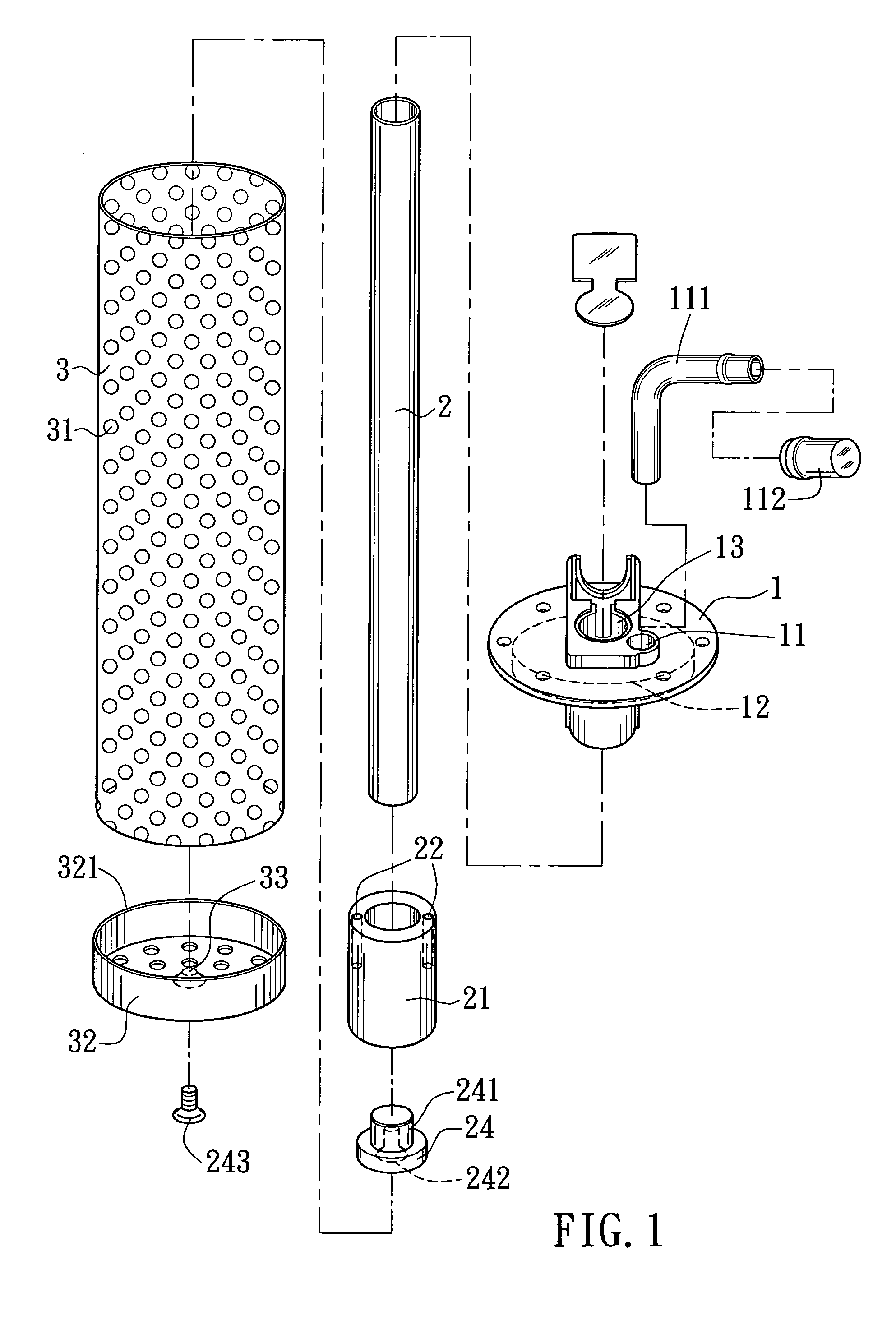

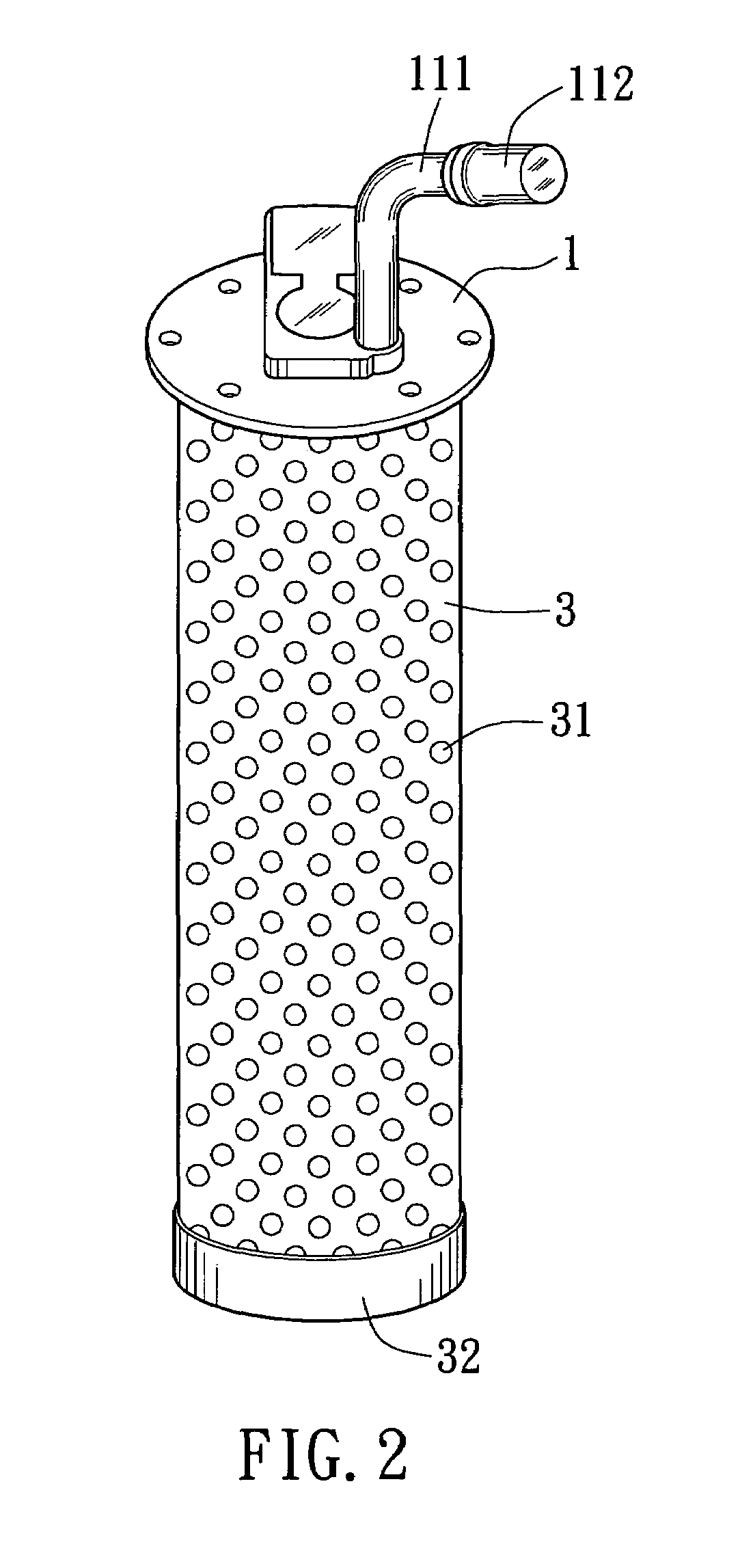

Vehicle cesspool lever sensor

InactiveUS6983655B2Easy to useEasy to implementMachines/enginesLubrication indication devicesPulp and paper industryLiquid level sensor

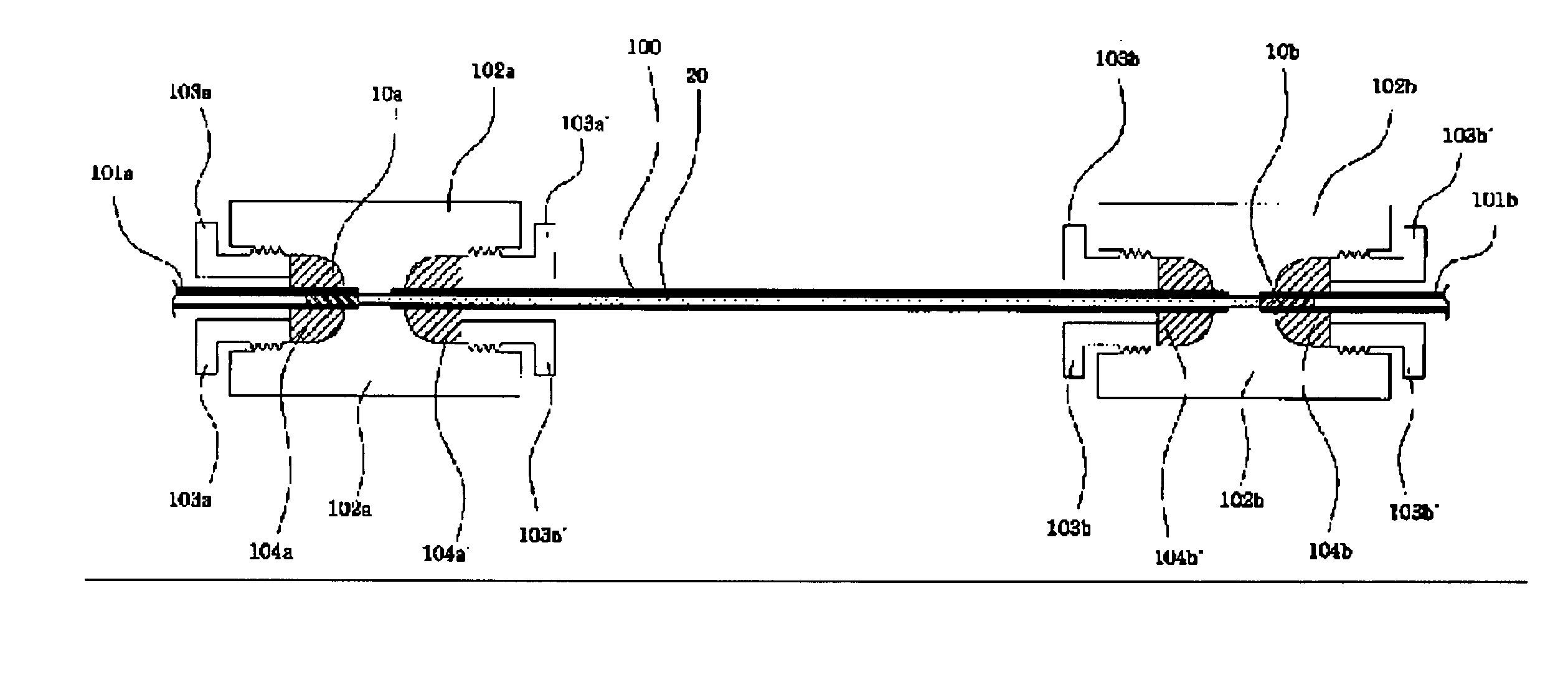

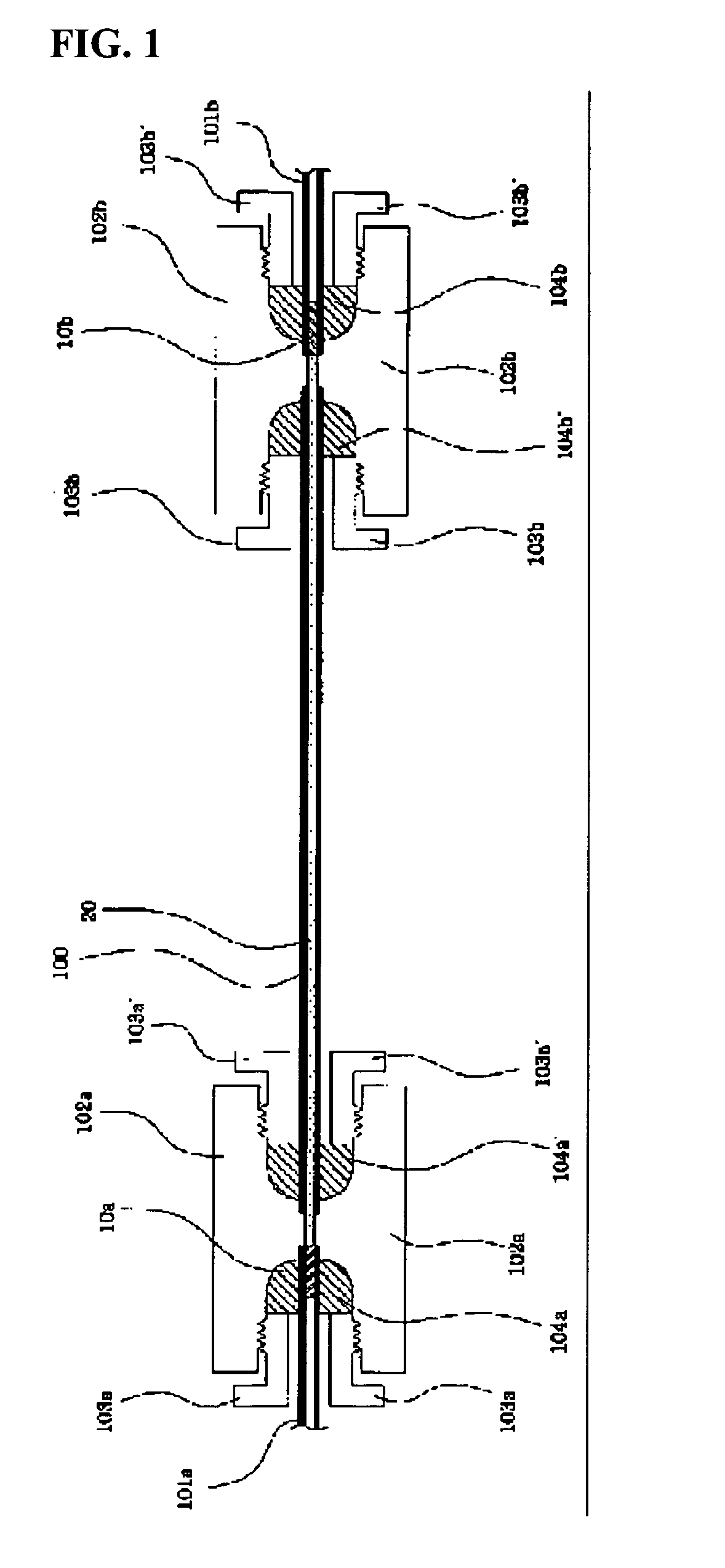

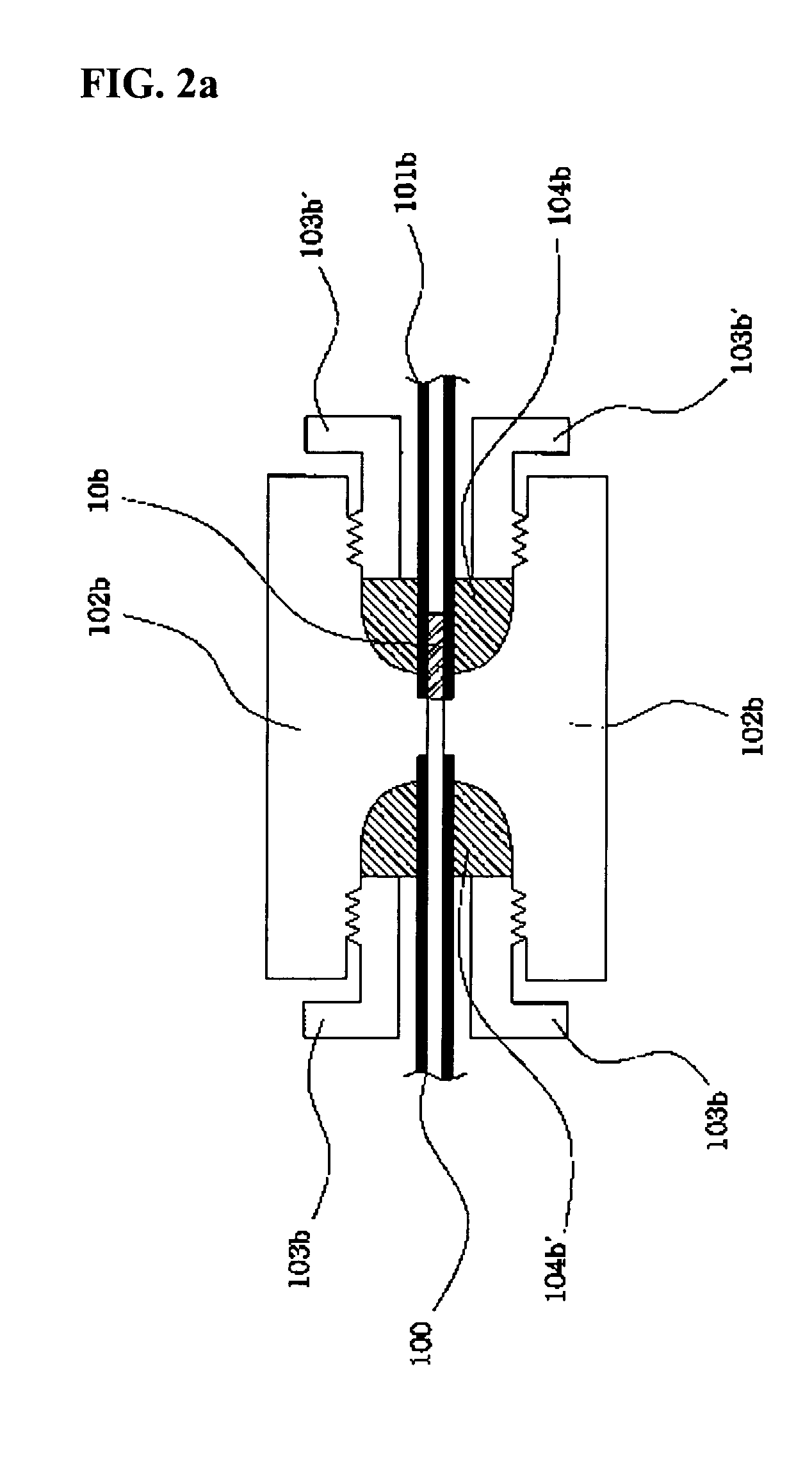

A vehicle cesspool level sensor includes a mounting base, a stainless steel detection tube welded to the bottom side of the mounting base to hold a detection circuit on the inside, an end cap welded to the bottom end of the stainless steel detection tube, a float axially movably mounted the detection tube and movable, the float having two magnets symmetrically disposed at two sides and adapted to induce the detection circuit, a stainless steel strainer fastened with the top end to an endless locating flange at the bottom side of the mounting base, and a strainer cover capped on the bottom end of the stainless steel strainer and fastened to the end cap with a screw.

Owner:LIANG CHIA HUNG +1

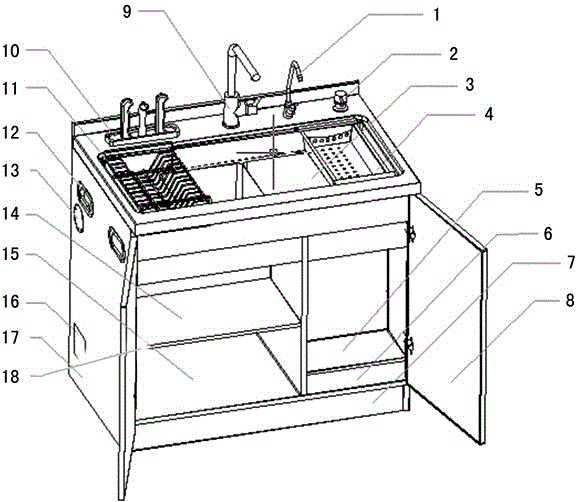

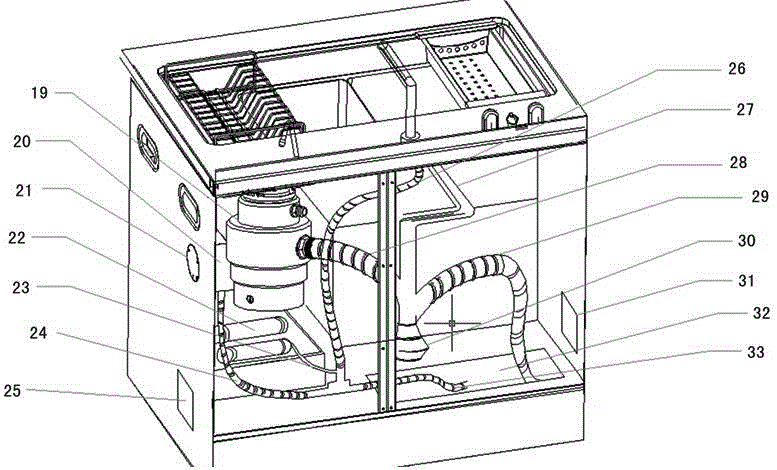

Integrated sink

The invention relates to an integrated sink, wherein a stainless steel strainer and a stainless steel bowl drain rack are placed inside a multi-layered stainless steel sink; a stainless steel purified water faucet, a stainless steel soap dispenser, a stainless steel hot and cold water faucet and a stainless steel kitchen knife rack are mounted on the front edge of the multi-layered stainless steel sink; three accommodating spaces, a skirting, a stainless steel door plate, a stainless steel side plate and a movable shelf form the frame of the stainless steel sink; an instant electric water heater is mounted adjacent to the stainless steel side plate; a purified water inlet pipe is connected onto a five-layered filter element; the five-layered filter element is arranged in a water purifier drawer formed by a detachable cover plate and a stainless steel small drawer; and the depth of the sink is 250mm. The integrated sink has the advantages that the problems as deformation, mildewing and decaying of the conventional sink is fundamentally solved; the non-cabinet function matching products become more attractive; the sinking of the table top due to cracking is avoided; and the available space of the cabinet is enlarged. The integrated sink has comprehensive functions and novel style.

Owner:NANJING OLO HOUSEHOLD CO LTD

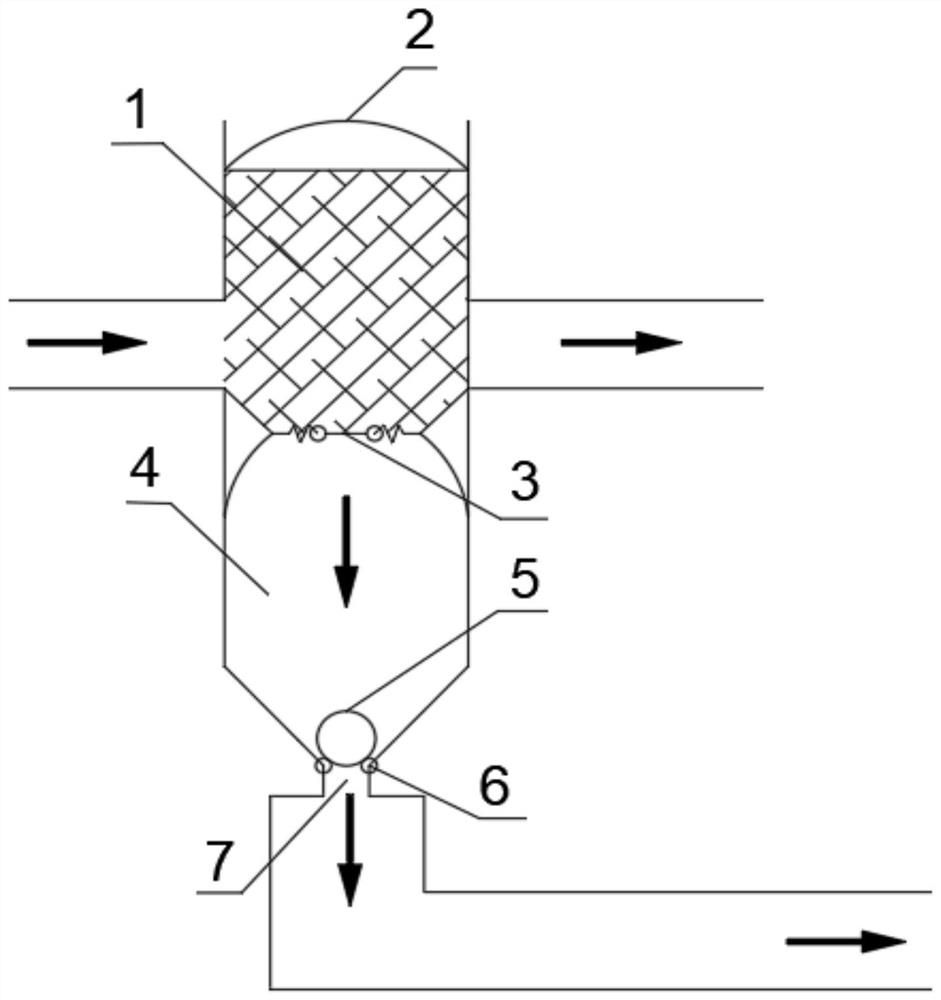

Dust flameless releasing device

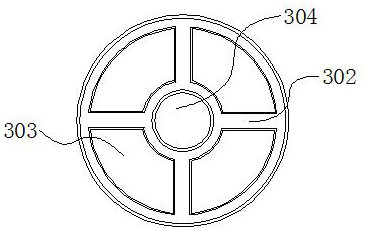

PendingCN107314140AReduce weightReal-time monitoringEqualizing valvesFire rescueThermodynamicsSS - Stainless steel

The invention relates to a dust flameless releasing device. The dust flameless releasing device comprises an explosion venting plate and an explosion venting cavity. The explosion venting cavity is provided with an inlet and an outlet. The explosion venting plate is connected to the inlet of the explosion venting cavity. A flame retarding layer is arranged at the outlet position of the explosion venting cavity, and a filter net made of stainless steel materials is adopted in the flame retarding layer. A fan shape can be seen from the side face of the outlet of the explosion venting cavity. The stainless steel filter net is adopted as a flame retarding material of the flame retarding layer, the circulation rate is increased, the weight of the flame retarding layer is reduced, and cost is reduced. The flame retarding layer is designed into the fan-shaped structure, the releasing area is increased, and mounting and dismounting are convenient.

Owner:江苏爵格工业集团有限公司

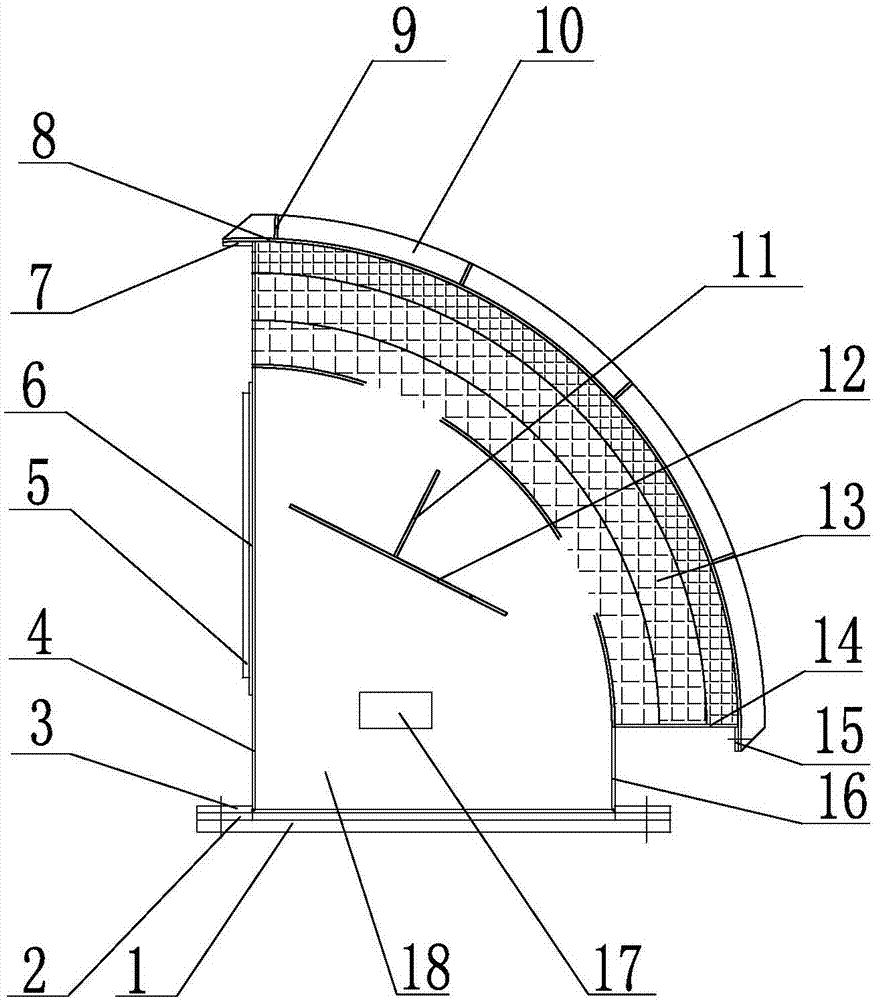

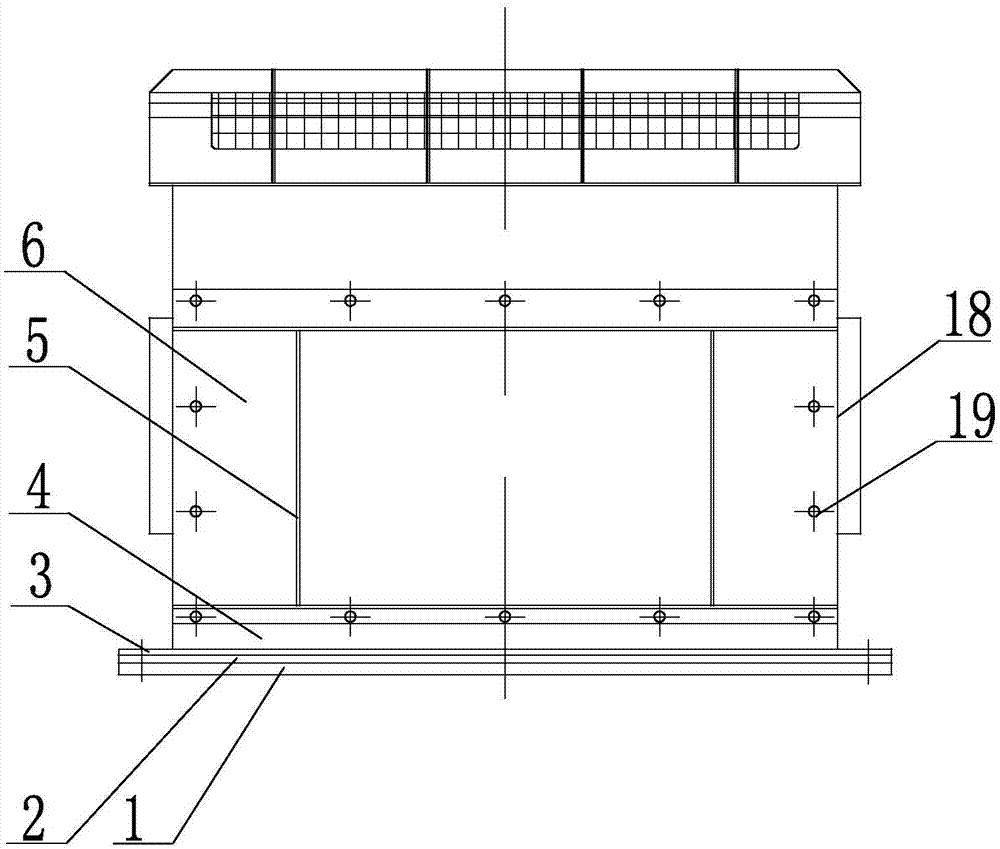

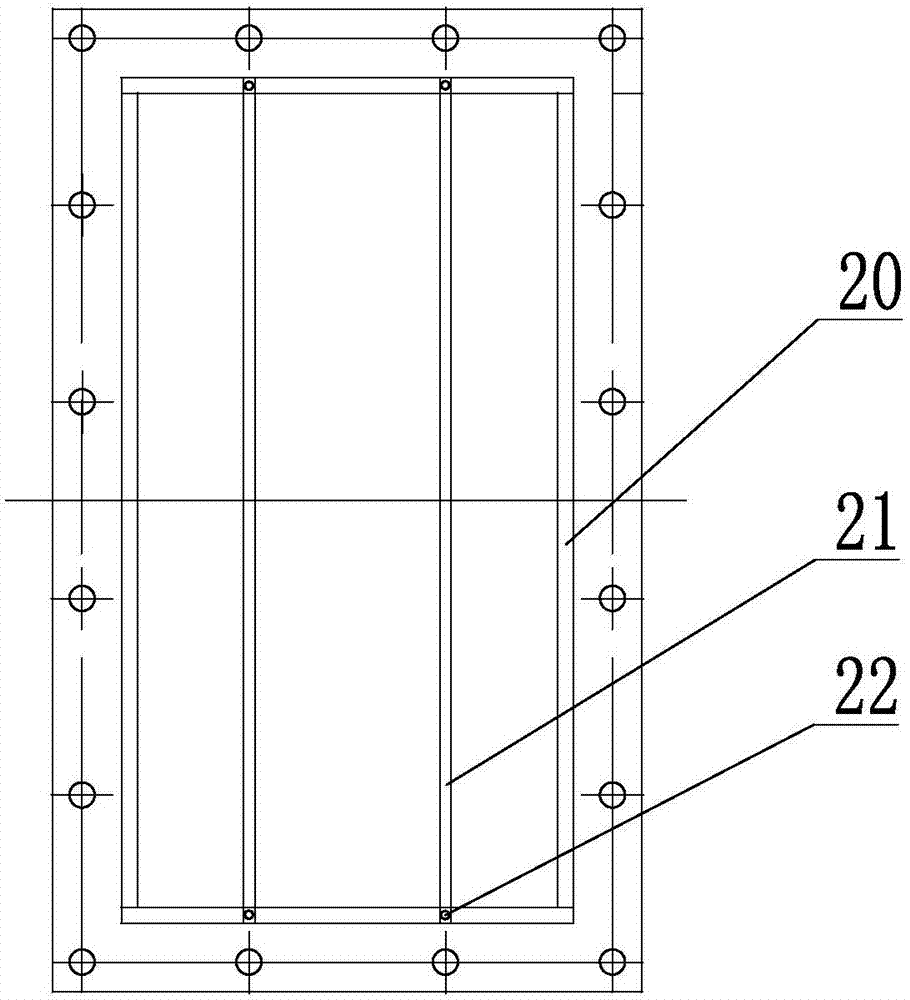

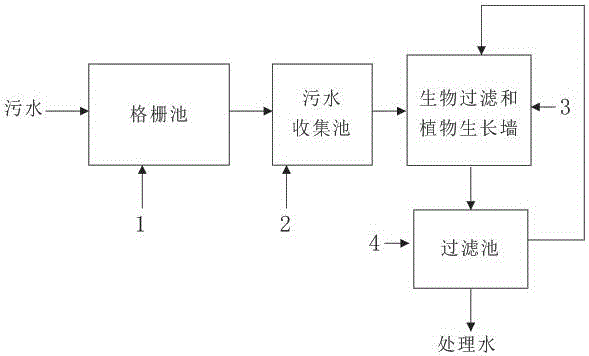

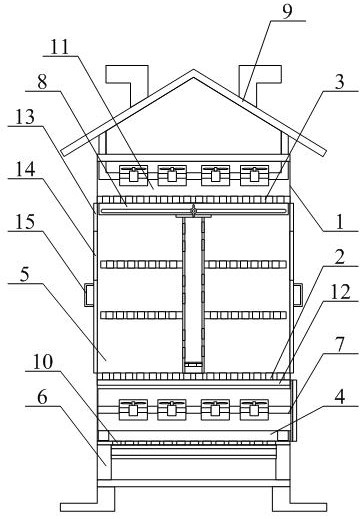

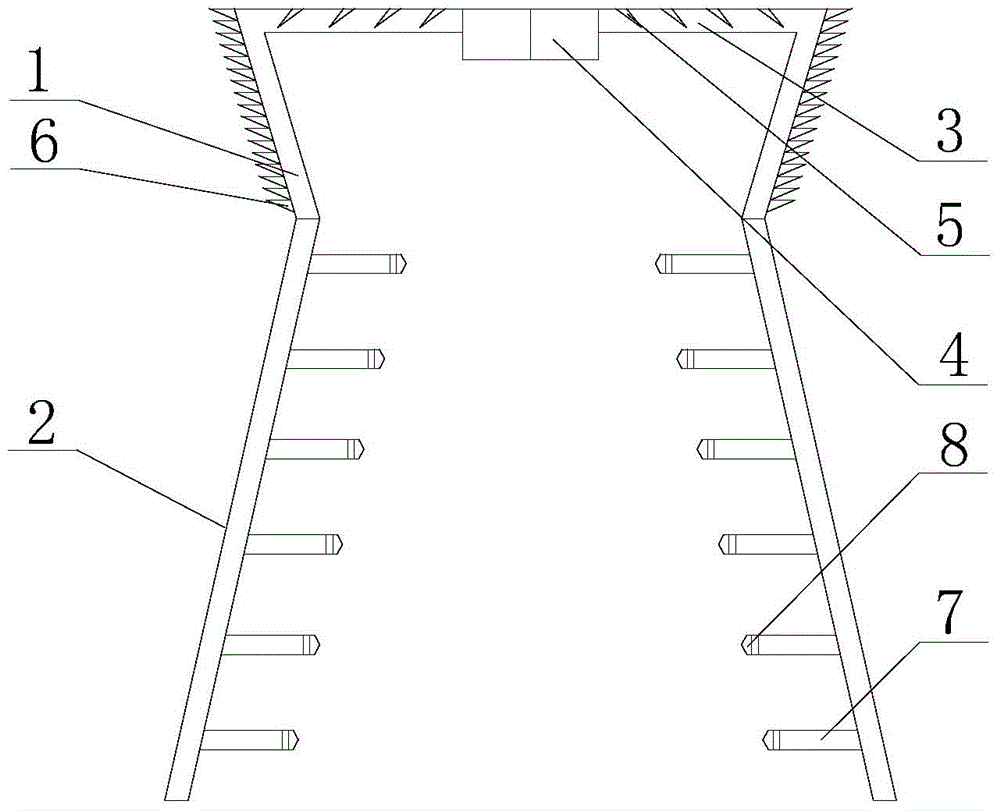

Biological filter wall system

ActiveCN105800771AOvercome the disadvantages of too short residence timeEfficient purification functionTreatment using aerobic processesWatering devicesFiltrationBiological filter

The invention relates to a vertical biological filter wall, in particular to the domestic sewage treatment and plant cultivation technology combining a vertical biological filter device with a plant wall.The biological filter wall comprises a stainless steel frame, a filter wall body, the plant wall, a water spray pipeline, a sunshade, a visor and a filter pond.Stainless steel wire meshes are welded to the four vertical faces of the stainless steel frame.The filter wall comprises a stainless steel frame structure, filter materials and biochemical cotton.The plant wall comprises a planting blanket and planting bags.The water spray pipeline is located above the stainless steel frame, and water outlets are evenly distributed in the pipe wall.The filter pond is located below the biological filter wall and receives treated sewage.The water spray pipeline conveys the domestic sewage into the filter wall and the plant wall from the filter pond, and the filter wall and the plant wall conduct biological filtration and purification, plant absorption and the like on the sewage.The biological filter wall is vertically unfolded towards the sky, biological filtration, plant absorption and physical filtration are integrated, and the functions of treatment on the domestic sewage in a multi-directional mode and plant viewing are achieved.

Owner:秦立

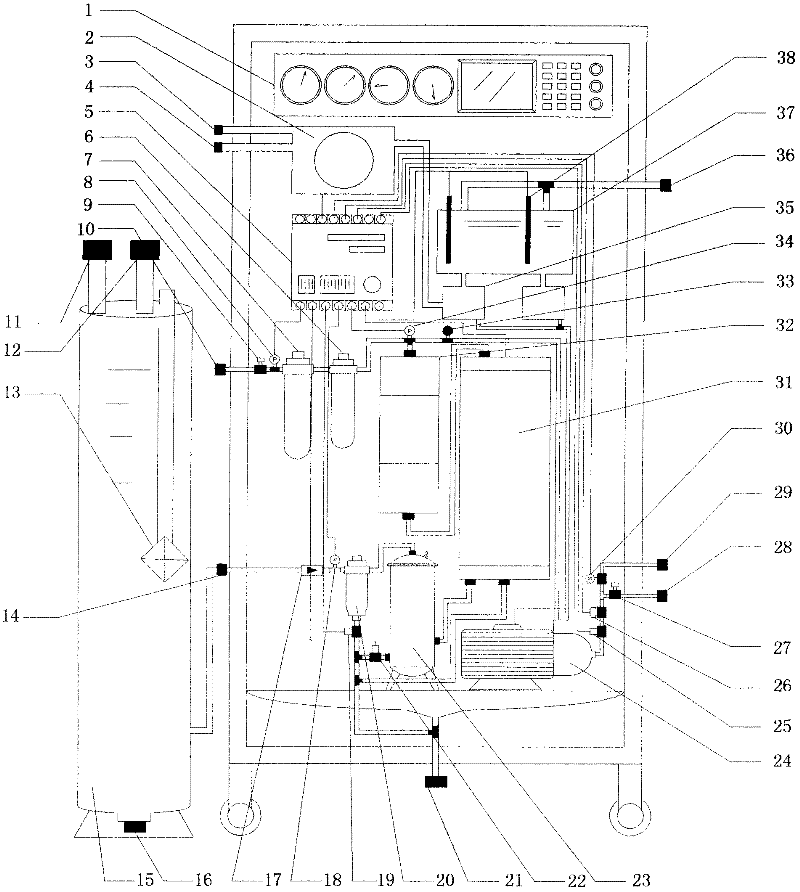

Special pipeline-sterilization water purification system

ActiveCN102515402AConform to sterile medical water standardsWater/sewage treatment by irradiationMultistage water/sewage treatmentFilter systemOzone Sterilization

The invention provides a sterilization water purification system special for medical treatment according to practical condition of dental department, which comprises a water inlet, a flowmeter, a silver-loaded stainless steel filter, a medical grade ultrafilter, an ultra-purification filtering system, a UV (ultraviolet) sterilization system, an ozone sterilization system, a gas-liquid mixer and a water outlet terminal. The sterilization water purification system is controlled by a full-automatic computer, and can carry out automatic timing pollution discharge sterilization and automatic pressure pressurization and stabilization, so as to ensure deep purification of raw water and constant water outlet pressure. Most of impurities in the water can be intercepted by the silver-loaded stainless steel filter, the medical grade ultrafilter and the ultra-purification filtering system, the intercepted impurities are washed out by timing automatic back-washing, and the UV sterilization system and the ozone sterilization system are switched on and off in a timing way, so that disinfectant water is formed as right amount of ozone is contained in the water. The bacteria content contained in pure water generated by the system fully meets aseptic medical water standards.

Owner:青岛澳德龙电子科技有限公司

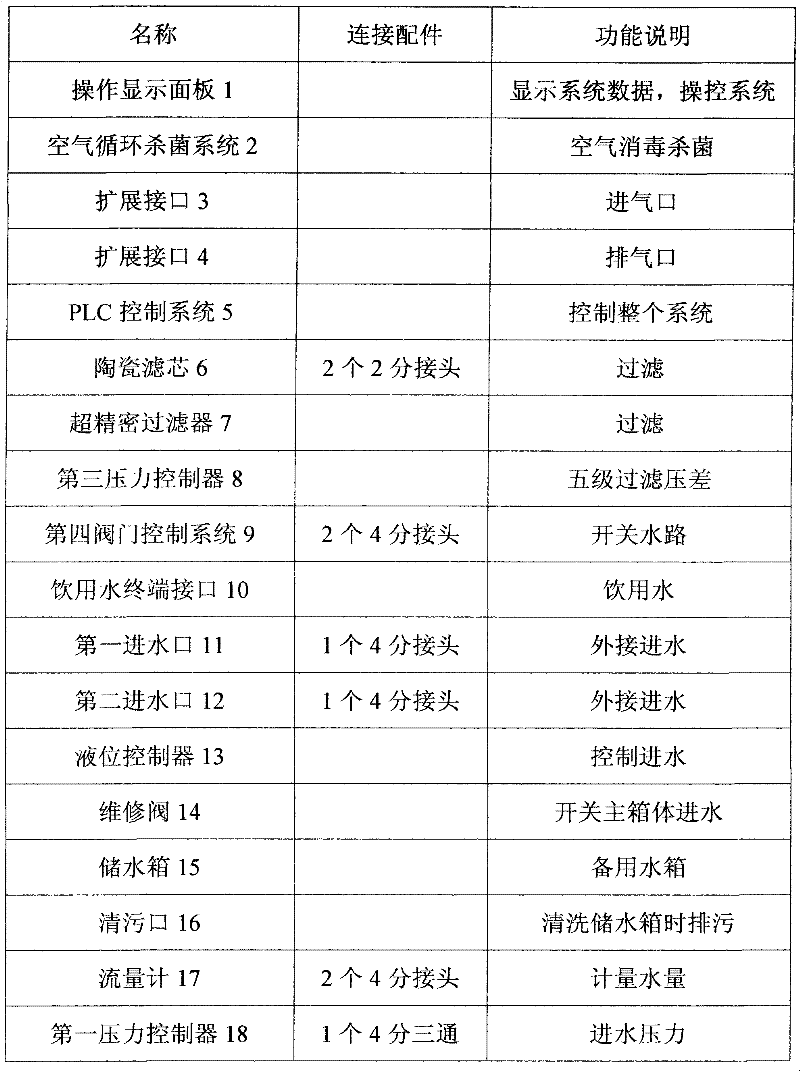

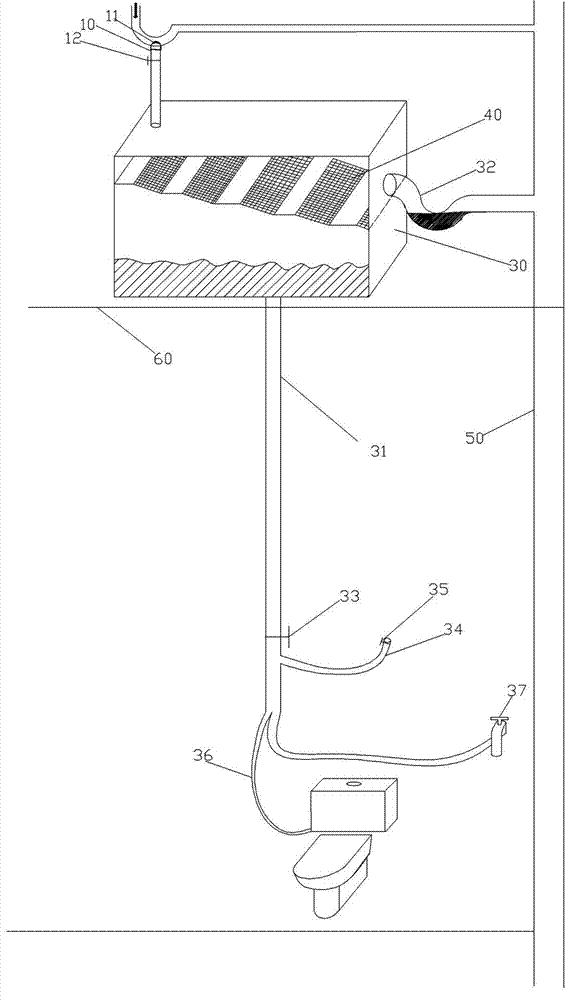

Full-automatic invisible water-saving device

InactiveCN103205996AWon't overflowDoes not take up practical spaceDomestic plumbingWater supply installationWater savingTap water

The invention relates to a full-automatic invisible water-saving device. A water-saving storage tank is disposed between a toilet ceiling and an upper floor. A first water inlet is connected with the bottom end of a U-shaped sewer pipe of a bath floor drain belonging to an upstairs household. A second water inlet is connected with an opening of a bath floor drain belong to the current user, and an inverted-U-shaped stainless steel strainer is disposed at the water inlet. A filter plate is disposed in the water-saving storage tank and is in a layered step structure. A plastic clamp groove is reserved on the filter plate, and a no-clean strainer is arranged on the clamp groove. A drain sensor at the opening of the bath floor drain belonging to the current user is connected with a water pump at the second water inlet. A float switch is disposed in the water-saving storage tank and is connected with a relay box through the water pump. A water outlet is provided with a tap water inlet. The full-automatic invisible water-saving device is capable of recovering waste water from both the upstairs householder and the current user, and filtering the recovered water for reuse. The water-saving storage tank saves the space of a toilet, has the automatic cleaning function, and is low in cost and simple and attractive.

Owner:尚升

Stainless steel tubing/frit with sintered inorganic particle, the chromatography comprising it, and their manufacturing method

InactiveUS7132046B2Simple design convenienceLow costIon-exchange process apparatusOxide/hydroxide preparationSilicon dioxideChromatography column

This invention is about metal tubing / frit applicable in liquid chromatography and a chromatography column manufactured by using the same. In detail, this invention is about manufacturing the metal tubing / frit by treating a powdered inorganic oxide such as silica, alumina, zirconia, and titania with a strong base, drying it with some humidity included, scrubbing it into powders, putting it in the tip of a chromatographic metal tubing at a proper depth, and by sintering the powders to form a durable sintered frit on the inner wall.This invention is also about a liquid chromatographic column manufactured by installing the metal tubing / frit's with a sintered end frit at the column inlet and outlet unions and by placing the cylinder-like column main body tubing packed with a stationary phase between the unions.The metal tubing / frit manufactured according to the description above is not placed inside the column as in the conventional column design, thus it is easily replaced and fixed without disassembling the column, and the column of this design can displace the conventional microcolumn of complicated production process and high cost.

Owner:CHEONG WON JO +1

Preparation method of high-resistance polymer coating liquid

ActiveCN102888158AExcellent oxygen barrier propertiesEasy to prepareStarch dervative coatingsCellulose coatingsHigh resistanceCross-link

A preparation method of high-resistance polymer coating liquid comprises the following steps of: firstly, adding the water-soluble high polymer with high hydroxyl density into part of water with a temperature of 92-99 DEG C, stirring to obtain a solution of the water-soluble high polymer with high hydroxyl density and reducing the temperature to be 30-40 DEG C for later use; secondly, adding nano metal oxide, a viscosity modifier, a polymer dispersant and a coupling agent into part of water and stirring to obtain a homogeneous and transparent dispersion liquid; and thirdly, mixing the solution of the water-soluble high polymer with high hydroxyl density prepared in the first step with the homogeneous and transparent dispersion liquid prepared in the second step, then sequentially adding the balance of water, a drying regulator and a cross-linking agent, stirring at the speed of 50-500 rpm for 30-60 minutes and filtering by using a stainless steel filter with 200-800 meshes to obtain the high-resistance coating liquid. The multi-component environment-friendly coating liquid prepared in the invention has excellent oxygen-resistance performance under the condition that a relatively thin coating is formed and simultaneously has the advantages of simple preparation process and stable performance.

Owner:GREATVIEW BEIJING TRADING CO LTD

Environment-friendly trash bin with solid-liquid separation structure and convenient to clean

InactiveCN111605924AEasy to cleanEasy to crushWaste collection and transferRefuse receptaclesMechanical engineeringDrain tube

The invention discloses an environment-friendly trash bin with a solid-liquid separation structure and convenient to clean, and relates to the technical field of environment-friendly trash bins. The trash bin comprises a bin body, a trash crushing mechanism and a waste liquid treatment mechanism. An upper blocking cover is installed above the bin body; the trash crushing mechanism is installed onthe upper portion of the interior of the bin body; an installation frame is arranged on the lower portion of the interior of the bin body; a stainless steel filter screen is fixed inside the installation frame; reinforcing rods are also fixed inside the installation frame; sliders are fixed at both ends of the installation frame; sliding grooves are formed outside the sides, close to the interiorof the bin body, of the sliders; the waste liquid treatment mechanism is fixed below the installation frame; a convex plate is fixed on the inner bottom surface of the bin body; and the two sides of the lower portion of the bin body are connected with drain pipes. The environment-friendly trash bin with the solid-liquid separation structure and convenient to clean has the beneficial effects that solid-liquid separation of trash inside the bin body is facilitated by arranging the installation frame and the stainless steel filter screen, so that the waste liquid can pass through the stainless steel filter screen to enter the lower part of the bin body.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

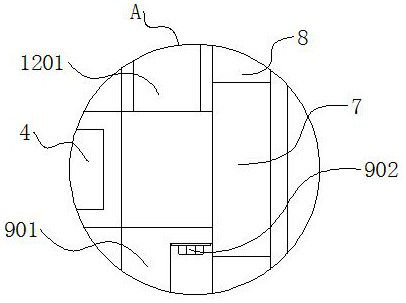

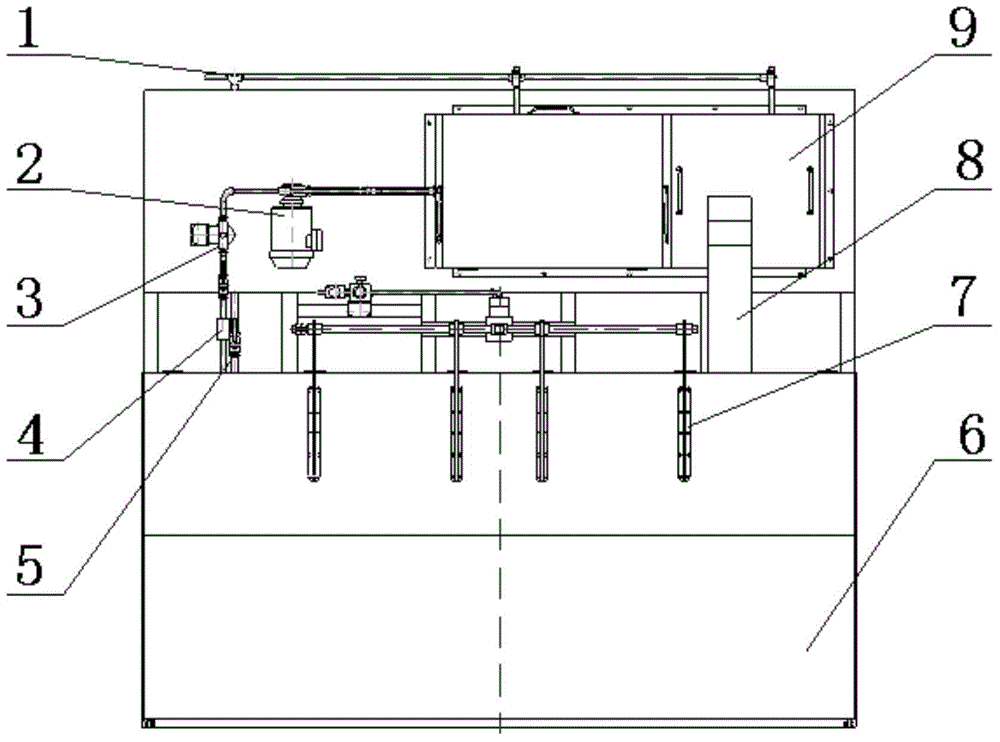

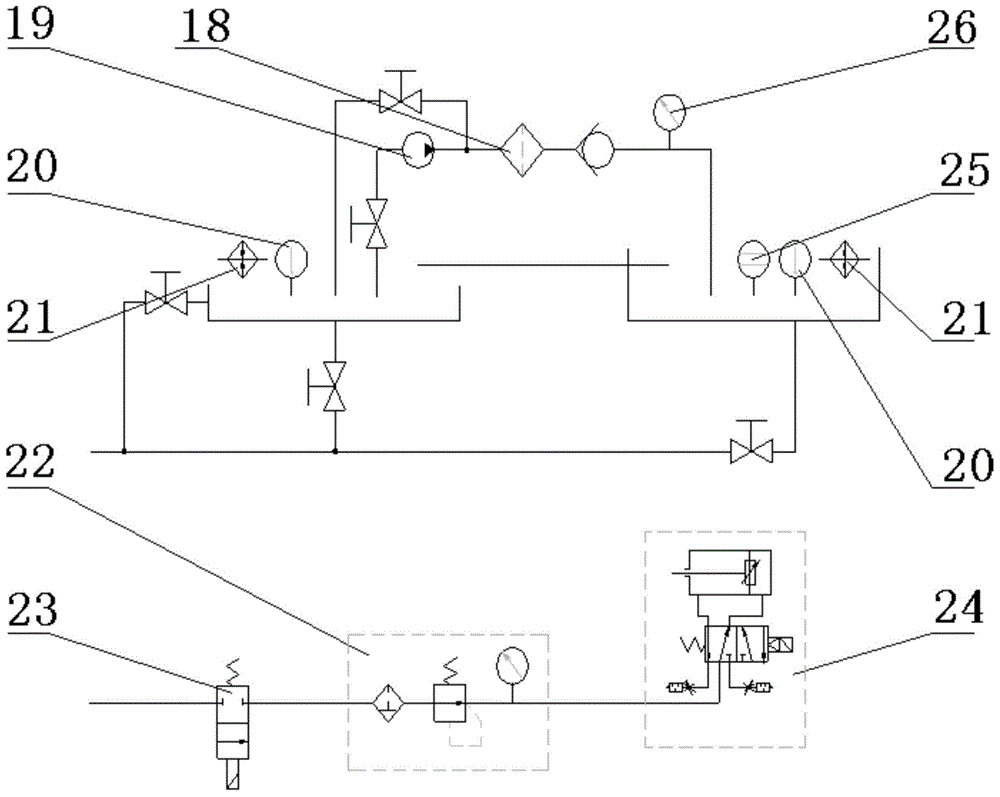

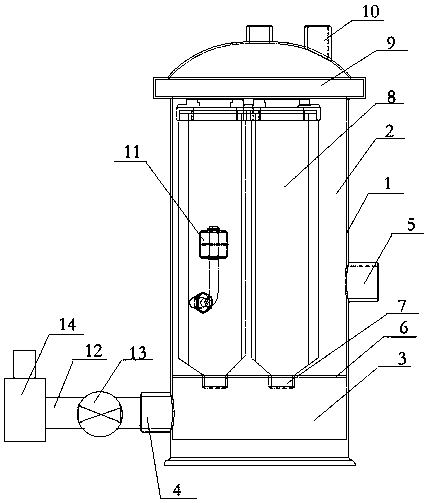

Ultrasonic cleaning device for large disc shaft parts of aircraft engine

An ultrasonic cleaning device for large disc shaft parts of an aircraft engine comprises a main water draining opening, a stainless steel turbulence pump, a stainless steel filter, a pressure gage, a cleaning box water draining valve, a cleaning box, pneumatic control groove covers, an overflow water returning opening, a liquid storage groove, heat preservation layers, side ultrasonic vibration plates, stainless steel heating bars, a bottom ultrasonic vibration plate, a tool protection frame, a part tool frame, an ultrasonic vibration bar and a transverse ultrasonic vibration plate. The stainless steel turbulence pump is connected with the liquid storage groove through a thread pipelinr, the stainless steel filter is connected with the stainless steel turbulence pump through a pipeline, the cleaning box water draining valve is connected with the main water draining opening and the bottom of the cleaning box through a pipeline, and the side ultrasonic vibration plates, the transverse ultrasonic vibration plate and the bottom ultrasonic vibration plate are connected with a liquid storage groove inner cavity through bolts and copper gaskets. The ultrasonic cleaning device has the beneficial effects that oil contamination, carbon deposition and micrometer and submicron dirty marks on the inner surface and the outer surface of the large disc shaft parts can be completely removed, the operation process is simple, and the cleaning cost and the cleaning time are saved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

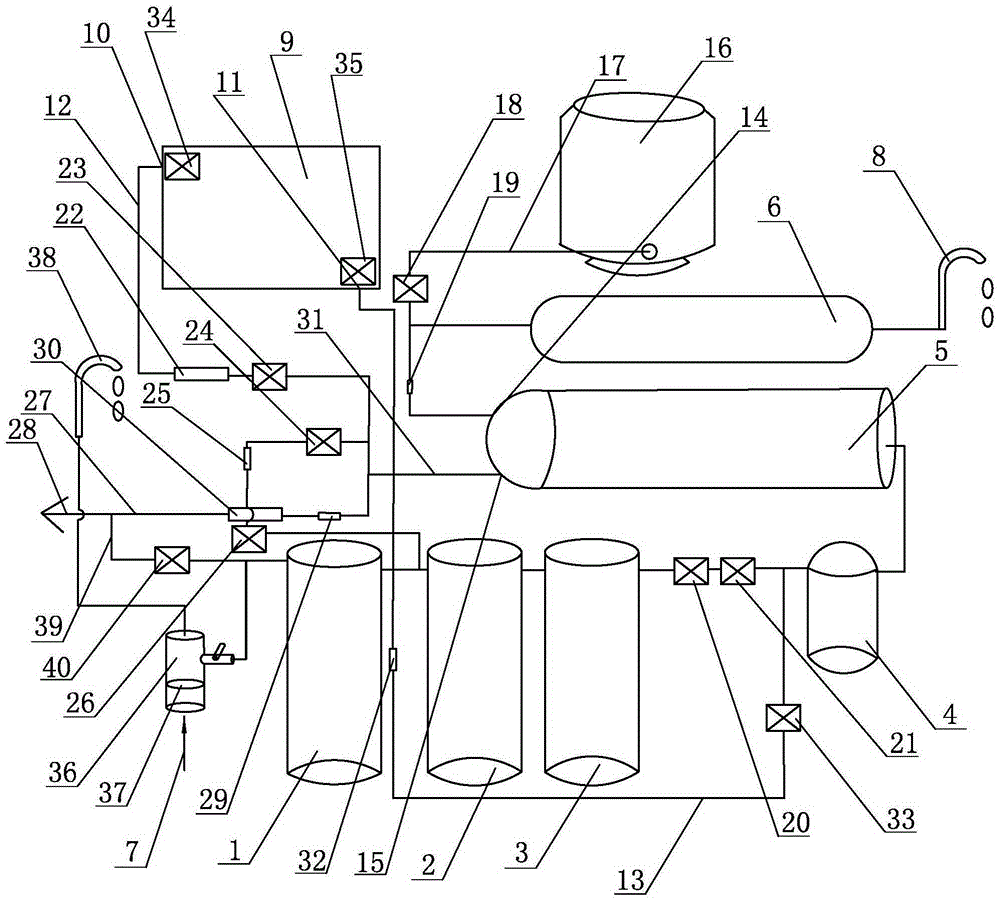

Nitric acid recycling system

The invention relates to the recycling of acidic liquid and particularly relates to a nitric acid recycling system. At present, a waste acid solution passing through nitric acid cleaning and ceramic filtering equipment still has certain acidity and is needed to be neutralized by adding an alkaline solution, and then, the waste liquid is discharged. The process has the defects that the resource is wasted, the cost is increased, the process is complex and not easy to control, and the discharged waste liquid can not be up to the standard frequently and pollutes the environment. The system is composed of a dilute nitric acid recovering, depositing and storing tank, a stainless steel magnetic pump device, a stainless steel delivery and recovery pipeline device, a stainless steel filter device, an automatic concentrated nitric acid liquid replenishing device and an automatic electrical control device; the waste acid solution is mixed with 50% nitric acid output by the automatic concentrated nitric acid liquid replenishing device to be up to the concentration of 3-5% after being deposited and filtered, and then, the waste acid solution is utilized.

Owner:HEBEI PROVINCE FANSHAN PHOSPHORITE CO LTD

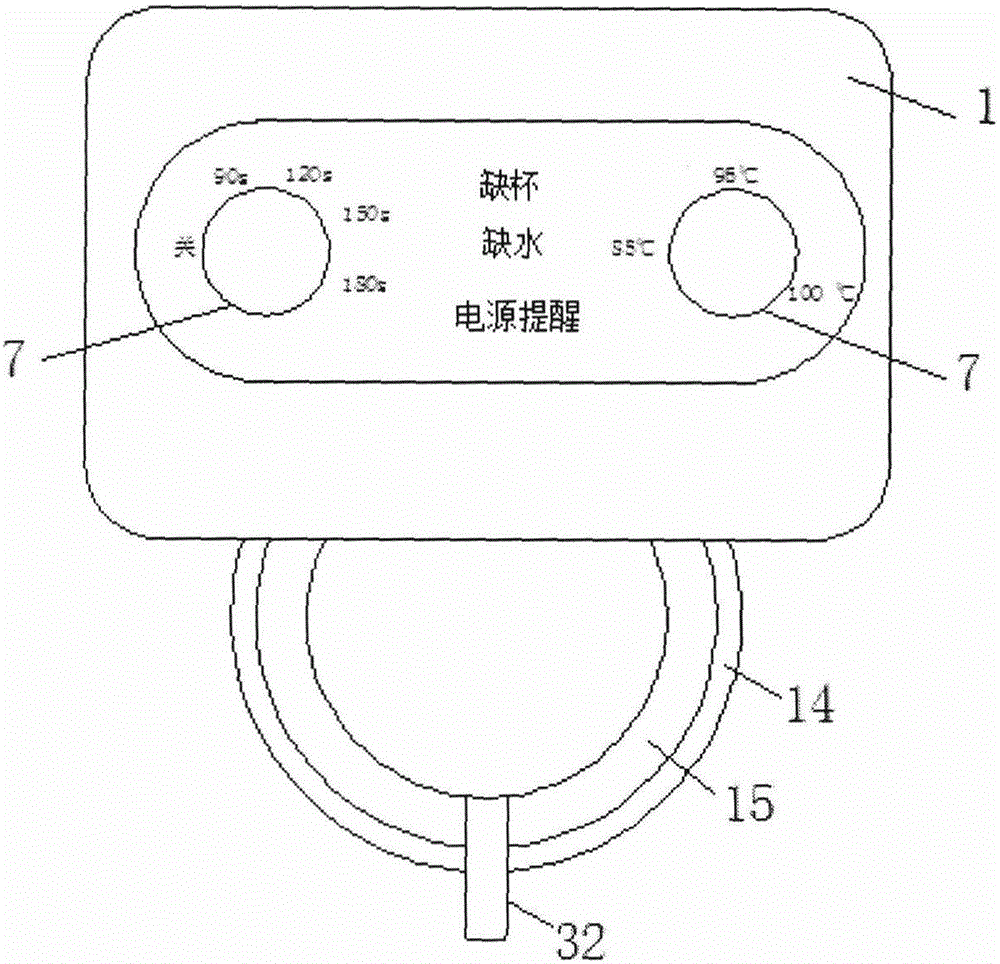

Tea brewing machine

InactiveCN106037482APlay a role in separationIncrease mineralsBeverage vesselsAgricultural engineeringWater flow

The invention discloses a tea making machine, which comprises a body and a base integrated with the body. A water pump, a filter element and a heating module are installed in the inner cavity of the body; The water inlet of the water pump is connected to the inlet of the filter element, the outlet of the filter element is connected to one end of the heating pipe, a heating module is installed on the through pipe, and the other end of the heating pipe extends to the upper end of the body; the side of the body An integral lower tray and an upper tray are also connected, a thermal insulation module is arranged in the inner cavity of the lower tray, and a fairness cup is arranged on the upper end of the lower tray, and the upper end of the fairness cup is movably connected to a glass cup. This tea making machine uses a glass cup to collect hot water to make tea, and the stainless steel filter places the tea leaves to separate the tea and water. The water flow control valve is used to control the outflow of tea into the fair cup; the water flow valve is controlled by the power of the electromagnet. ; The overall structure is simple, the design is novel, and it has high practical value.

Owner:ZHEJIANG SALALA TECH

Manufacturing method for powder stainless steel filter and insert molding

InactiveCN103331450AOvercoming the limitation of not being able to tapExtended service lifeVolumetric Mass DensityMaterials science

The invention overcomes the shortcomings that as a stainless steel filter has holes and is lower in density, threads can not be formed according to the method that the stainless steel filter and an insert are matched in proportion before being sintered and closely connected for formation after being sintered, and after formation, a connection insert can achieve thread processing. Therefore, the stainless steel filter can be in flexible connection with other fittings after being combined with the insert, the filter can be applied to connecting parts in different specifications and wide application is realized.

Owner:KINGSON POWDER METALLURGY STAINLESS STEEL

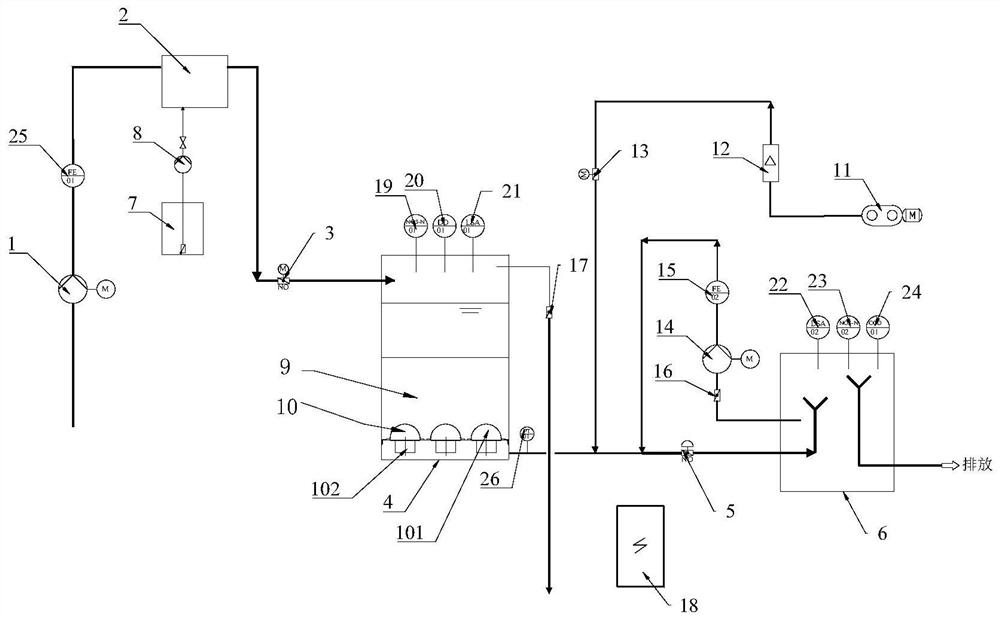

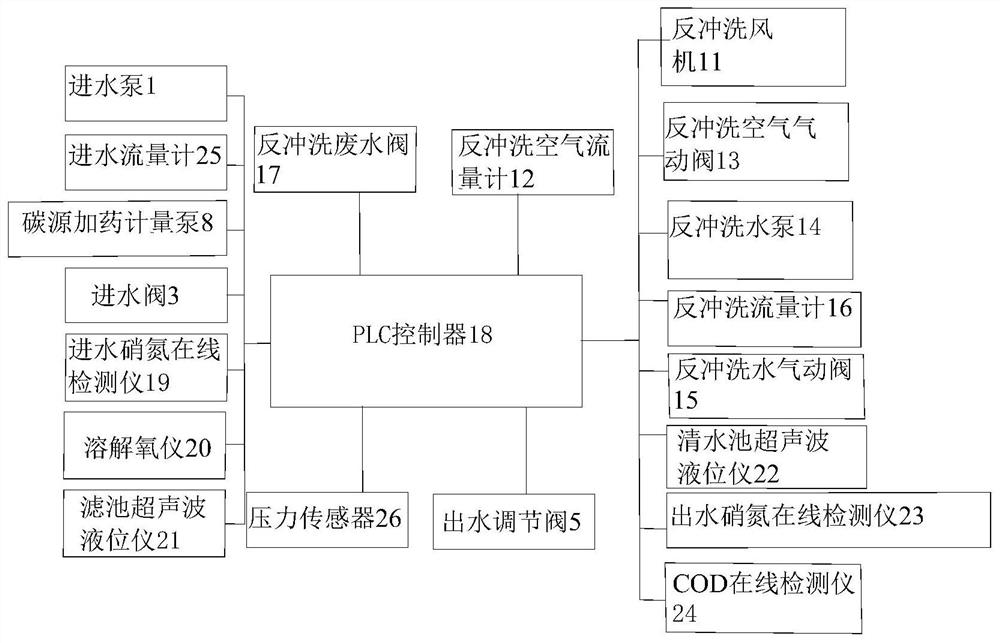

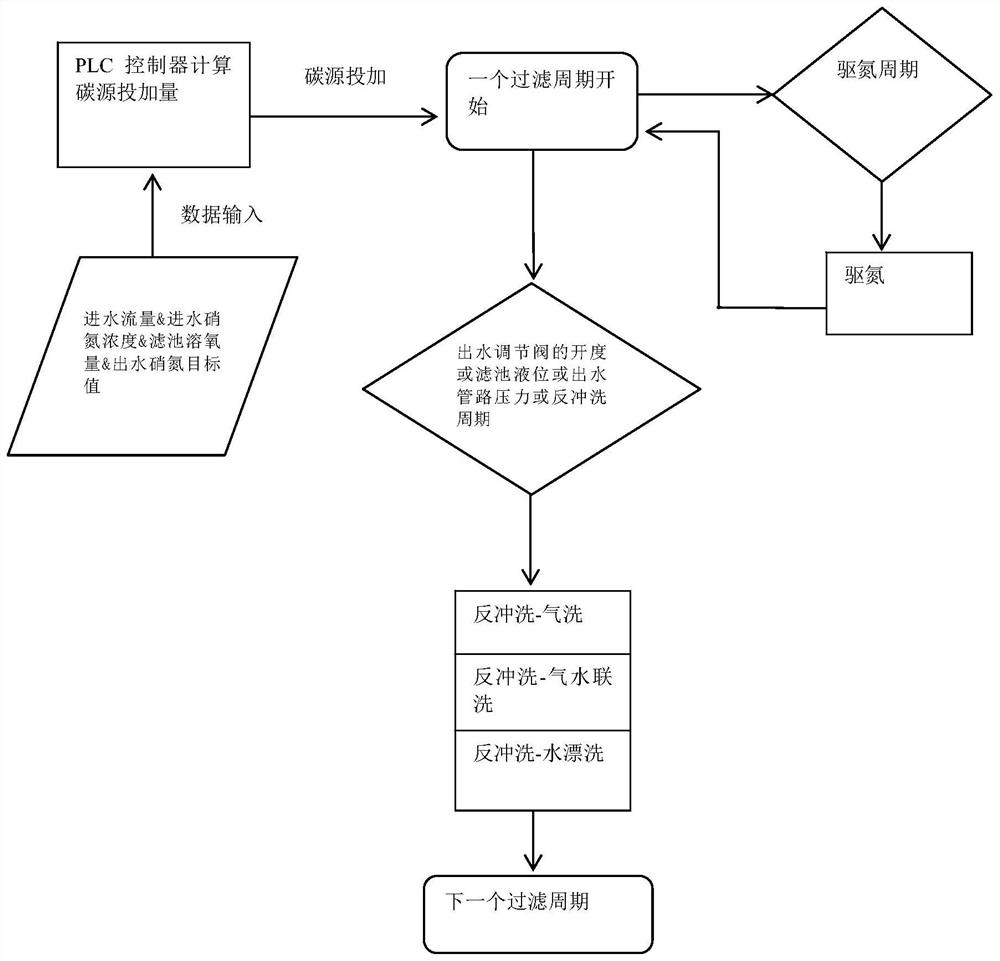

Denitrification deep-bed filter tank denitrification treatment system and method thereof

PendingCN111661919AReduce the overall heightUniform air distributionWater treatment parameter controlSpecific water treatment objectivesDistribution systemSewage treatment

The invention provides a denitrification deep-bed filter tank denitrification treatment system and a method thereof. The invention relates to the technical field of sewage treatment systems. The problems that the tank depth is increased and the investment cost is increased due to the arrangement of a supporting layer in the existing denitrification deep-bed filter tank are solved; the technical problem of poor uniformity of a water and gas distribution system is solved. The system comprises a filter tank, wherein the filter tank comprises an ultrahigh area, a filter head area, a filter material area, a gas-water distribution system and a water collecting channel which are sequentially arranged from top to bottom; the gas-water distribution system comprises a stainless steel filter screen located at the upper part and a pipeline located at the lower part, a filter material is directly supported above the stainless steel filter screen, the pipeline extends to the water collecting channeland is communicated with the water collecting channel, and the longitudinal section of the stainless steel filter screen is of a semi-arc structure. According to the invention, the semi-arc stainlesssteel filter screen and the pipeline are used as a water distribution system for directly supporting the filter material, so that the arrangement of a supporting layer is omitted, and the height andinvestment cost of the filter tank are reduced. Meanwhile, the coverage area of the stainless steel filter screen is large, so that water distribution and gas distribution are more uniform.

Owner:北控水务(中国)投资有限公司

Preparation method of high-resistance polymer coating fluid

ActiveCN102382527AExcellent oxygen barrier propertiesEasy to prepareStarch dervative coatingsCellulose coatingsHigh resistancePolymer science

The invention discloses a preparation method of a high-resistance polymer coating fluid, which comprises the following steps of: firstly, adding the water-soluble high polymer with high hydroxyl density in part of water with the temperature of 92-99DEG C, stirring to obtain a solution of the water-soluble high polymer with high hydroxyl density and reducing the temperature to be 30-40DEG C for later use; secondly, adding nano size metal oxide, a silane coupling agent, a viscosity modifier and a polymer dispersant in part of water and stirring to obtain a homogeneous transparent dispersion liquid; thirdly, mixing the solution of the water-soluble high polymer with high hydroxyl density prepared in the first step with the homogeneous transparent dispersion liquid prepared in the second step, then sequentially adding the balance of water, a carboxyl polymer, an alkali metal salt cross-linking agent and a drying regulator, stirring at the speed of 50-500rpm for 30-60 minutes and filtering by using a stainless steel filter with 200-800 meshes to obtain the high-resistance coating fluid. The multi-component environment-friendly coating fluid prepared in the invention has excellent oxygen resistant performance under the condition that a thinner coating is formed and simultaneously has the advantages of simple preparation process and stable performance.

Owner:GREATVIEW BEIJING TRADING CO LTD

Sodium stearoyl lactylate preparation

InactiveCN104363771AGood dispersionImprove solubilityDough treatmentFood preparationSolubilityPetri dish

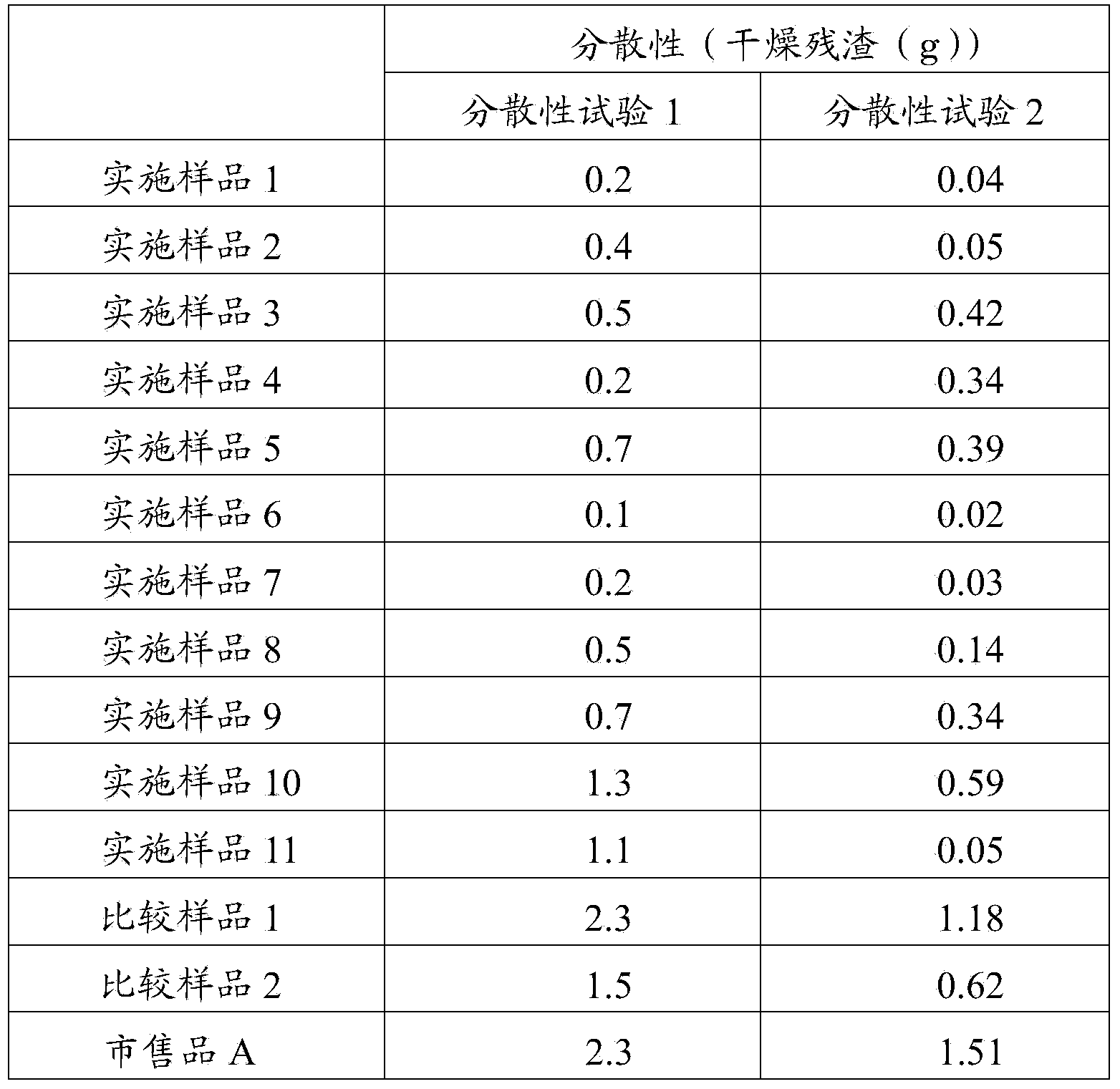

Provided is a sodium stearoyl lactylate preparation which has high solubility in water at 20°C (has excellent dispersibility) and has an excellent effect of improving the loosing property and texture of noodles. A sodium stearoyl lactylate preparation having such a property that the weight of dried residue, which is a measure for evaluating dispersibility and measured in accordance with dispersibility test 1 shown below, is less than 1.4 g. [Dispersibility test 1] 1) 47.5 g of water having a temperature of 20°C is charged in a 100-ml glass beaker, 2.5 g of the sodium stearoyl lactylate preparation having the same temperature is added thereto, and the resultant mixture is agitated using a three-one motor at 500 rpm for 60 seconds under the same temperature condition, thereby preparing a mixed solution. 2) The mixed solution prepared in step 1) is poured onto a stainless-steel strainer having a mesh size of 250 mum, and residue remaining on the strainer is collected. 3) The residue obtained in step 2) is allowed to leave in a glass petri dish and then dried with hot air at 105°C for 2 hours, the weight (g) of a dried product remaining on the glass petri dish is measured, and the dispersibility is evaluated on the basis of the weight of the dried product (dried residue).

Owner:RIKEN VITAMIN COMPANY

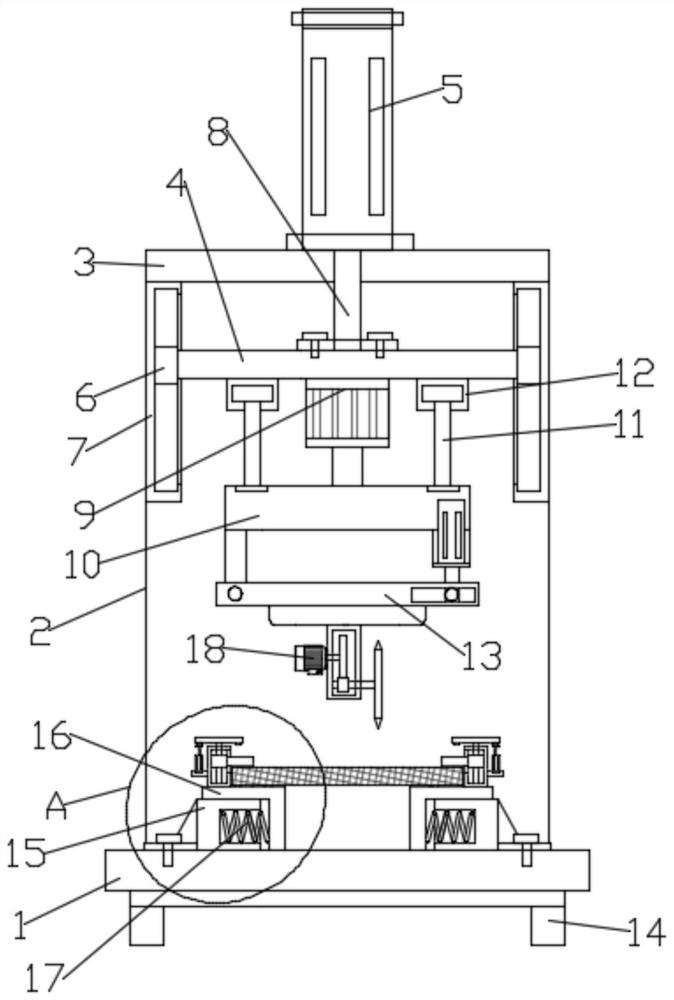

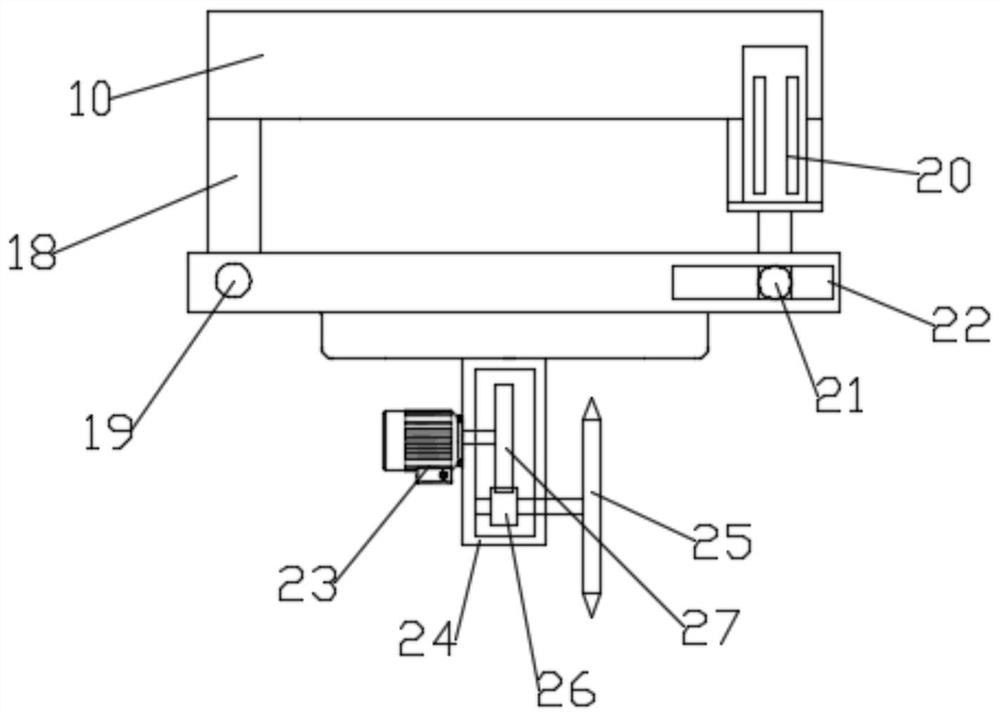

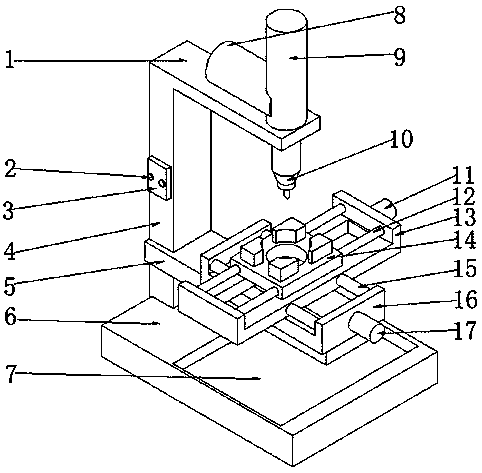

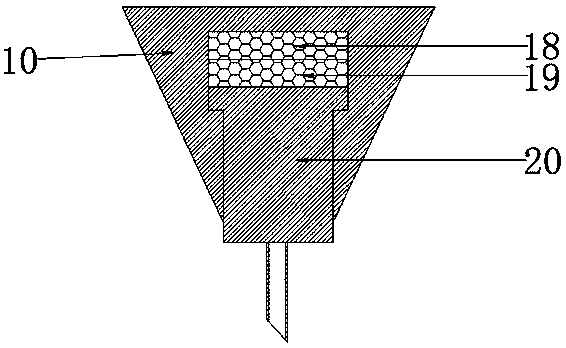

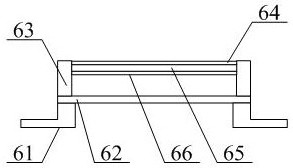

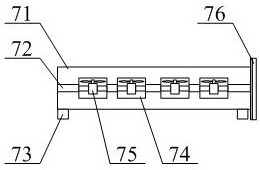

Cutting device for stainless steel filter screen processing

ActiveCN111659837AAchieve regulationIncrease flexibilityMetal-working apparatusElectric machineryStructural engineering

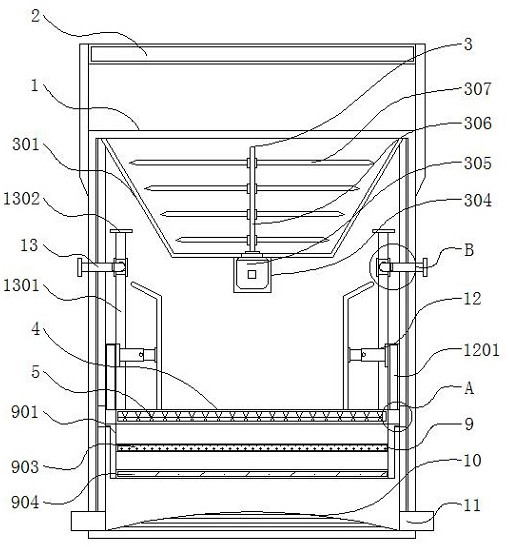

The invention relates to the field of stainless steel filter screen processing equipment and in particular discloses a cutting device for stainless steel filter screen processing. The cutting device comprises a base, wherein a clamping mechanism is arranged on the base and is used for clamping and fixing a stainless steel filter screen; a supporting back plate is further fixedly arranged on the upper surface of the back side of the base, a supporting top late is arranged at the top end of the supporting back plate, a hydraulic telescopic cylinder is arranged on the supporting top plate, a piston rod is arranged at a telescopic end of the hydraulic telescopic cylinder in a linking manner, a lifting cross beam is fixedly mounted at the bottom end of the piston rod, and a first driving motorfor adjusting the horizontal rotating direction of a cutting assembly is arranged on the lifting cross beam. The cutting device provided by the embodiment of the invention can cut the stainless steelfilter screen, and is matched with a vertical adjusting assembly and the first driving motor to further adjust the horizontal position and the vertical angle of the cutting assembly, so that the cutting flexibility of the cutting assembly on the stainless steel filter screen is improved.

Owner:瑞安市邵伟五金经营部

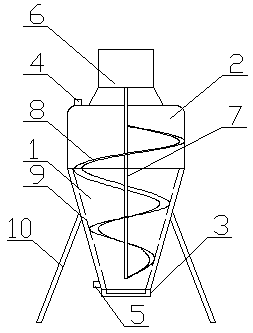

Rapid oil filter

InactiveCN103239931AImprove filtering effectLubricant mounting/connectionPressure lubricationSludgeActivated carbon filtration

The invention discloses a rapid oil filter. The rapid oil filter comprises a cooling barrel and an oil removing barrel, the oil removing barrel is arranged above the cooling barrel, the oil removing barrel is communicated with the sidewall of the cooling barrel through a pipeline, the bottom of the cooling barrel is connected with a swirling device, the swirling device comprises a swirling tube, an oil lifting tube and a sludge tube, the oil lifting tube is arranged in the swirling tube, the swirling tube is arranged in the sludge tube, sludge outlets are arranged at two sides of the bottom of the sludge tube, the bottom of the swirling device is connected with a polluted oil water inlet, cooling tubes are arranged in the cooling barrel, cooling water interfaces are arranged at two sides of the bottom of the cooling barrel, a plurality of liquid uniform flow plates are arranged on the inner wall of the cooling barrel, an activated carbon filter is arranged in the center of the inner cavity of the oil removing barrel, the inner wall of the oil removing barrel is provided with a stainless steel filter, and the top of the oil removing barrel is provided with an air outlet and an oil outlet. According to the invention, lubricating oil enters from the polluted oil water inlet, enters the cooling barrel through the swirling device for filtering out most nonmetal impurities and sludge, and enters the oil removing barrel for filtering out metal debris, so the filtering effect of the rapid oil filter is good.

Owner:NANTONG XINFENGXIANG HYDRAULIC CASTING

Stainless steel strainer machining device

InactiveCN108500127AEasily damagedScientific and reasonable structureMetal-working feeding devicesPositioning devicesHydraulic pumpEngineering

The invention discloses a stainless steel strainer machining device. The device comprises a cross beam, control panels, an electric control cabinet, second threaded rods, a second mobile station, a second servo motor, a first buffer plate, a second buffer plate and a puncher pin. A material storage groove is formed in one side of the top of a base. A stand column is arranged on the other side of the top of the base. A supporting frame is arranged on one side of the stand column. The stainless steel strainer machining device is scientific and reasonable in structure, and safe and convenient touse; a buffer device is arranged, when a hydraulic pump drives the puncher pin to perform perforating, huge pressure is generated instantaneously, equipment and a strainer are prone to being damaged,the instantaneous pressure can be effectively buffered through the buffer device, and the equipment is protected; and a waste recovering device is arranged, powder wastes are generated when general machining equipment is used for perforating, circular wastes convenient to collect are generated through the hollow puncher pin during working of the device and collected and reutilized through the material storage groove, the materials are saved, and the manufacturing cost is lowered.

Owner:王鼎兴

Filtering equipment capable of automatically cleaning middle-deep layer geothermal system and convenient to disassemble

PendingCN113457240AEasy to cleanPrevent dirty cloggingLighting and heating apparatusGeothermal energy generationSewage outfallOutfall

The invention belongs to the technical field of pipeline cleaning, and discloses filtering equipment capable of automatically cleaning a medium-deep layer geothermal system and convenient to disassemble. The upper end of a cylinder is blocked by a flange cover plate, the middle of the left side of the cylinder is communicated with a water inlet, the upper end of the right side of the cylinder is communicated with a water outlet, a stainless steel filter screen is detachably arranged in the cylinder, the upper end of the stainless steel filter screen inclines towards the water inlet, and the lower end inclines towards the water outlet; and a dirt isolation plate is arranged at the lower end in the cylinder, the upper end of the dirt isolation plate abuts against the middle of the right side of the stainless steel filter screen, a sewage draining outlet is formed in the lower end of the left side of the cylinder, filter screen clamping grooves are obliquely formed in the inner wall of the cylinder, and the two ends of the stainless steel filter screen are clamped in the filter screen clamping grooves. The equipment can be automatically flushed, dirt is convenient to clean, and the system can be cleaned at any time under the condition that normal operation of system equipment is not influenced; the product specification and the filtering grade can be flexibly customized according to requirements; the filtering area is large, the water passing amount is sufficient, and filth blockage is not easy to form; and floaters in the sewage are not easy to attach to the filter screen to form filth blockage.

Owner:SHAANXI SIJICHUN CLEANING HEAT

Distribution ring main unit with good dehumidification and ventilation effects

InactiveCN111769470AAvoid corrosionEasy maintenanceGas treatmentSubstation/switching arrangement cooling/ventilationActivated carbonEngineering

The invention provides a power distribution ring main unit with good dehumidification and ventilation effects. The power distribution ring main unit comprises a ring main unit, a first hollowed-out plate, a second hollowed-out plate, a ventilation cooling cavity, an electrical equipment fixing cavity, a fixable damp-proof supporting frame structure, a maintainable air blowing box structure, a slidable cooling electrical equipment fixing frame structure, an insertable heat dissipation protective cover structure, a hollowed-out bottom plate, a heat dissipation cavity, a stainless steel filter screen, a cabinet door, an observation window and a door handle; the first hollowed-out plate is in bolted connection with the lower part of the inner wall of the ring main unit; the second hollowed-outplate is in bolted connection with the upper part of the inner wall of the ring main unit. L-shaped support frames, a spacing plate, support rods, a first fixed net, an activated carbon adsorption net, a second fixed net, the ring main unit and the hollowed-out bottom plate are adopted, the moisture adsorption work on gas entering the ring main unit through the activated carbon adsorption net inthe use process is facilitated, and the moisture is prevented from entering the ring main unit to corrode electrical equipment.

Owner:马士波

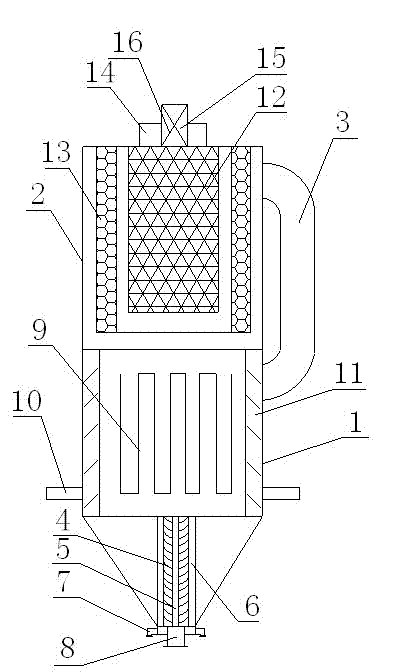

Novel stainless steel filter

InactiveCN109954307AReduce security risksAvoid damageStationary filtering element filtersInternal pressureGas-discharge lamp

The invention discloses a novel stainless steel filter. The filter comprises a cylinder body, an upper cover arranged on the upper part of the cylinder body, and an installation plate arranged on thelower part of the cylinder body, wherein the cylinder body is divided into a filtration cavity and a buffer cavity by the installation plate, the interior of the filtration cavity is provided with a filtration net cylinder, the filtration net cylinder is installed on the installation plate, a water inlet is arranged on the buffer cavity, a water outlet is arranged on the filtration cavity, a liquid level switch is arranged inside the filtration cavity, the height of the liquid level switch is lower than the height of the water outlet, a gas discharge valve is arranged on the upper cover, and the gas discharge valve communicates with the interior of the cylinder body. The filter has the following beneficial effects: (1) the gas discharge valve is arranged, and the gas discharge valve can beautomatically opened to protect the water inlet system when the internal pressure of the filter is too high; (2) the liquid level switch is additionally arranged, when the filter is blocked, the water level is lower than a designated liquid level, and the running of a water inlet pump group is stopped; and (3) when the filtration net cylinder needs to be replaced, the gas discharge valve is opened to balance the air pressure inside and outside the filter, and thus the replacement is convenient.

Owner:上海弦力清洗设备有限公司

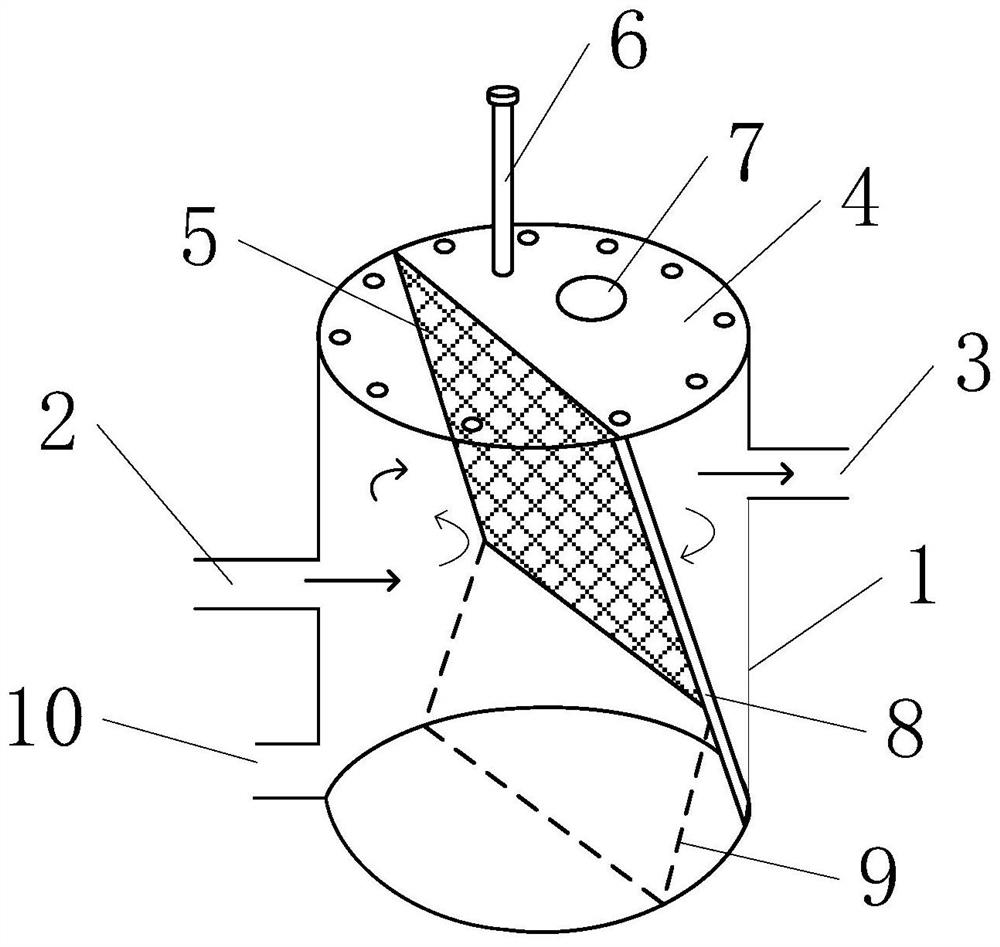

Solid-liquid separation precision filter

InactiveCN111085028AEasy to separateAvoid deformationMembrane filtersStationary filtering element filtersHelical bladeEngineering

The invention provides a solid-liquid separation precision filter. A circle of stainless steel filter screen is arranged in a filter cavity, the mesh size of the steel screen is fixed, deformation isnot likely to happen, and filtering is precise; the filter screen is internally stirred by a stirring device, vortexes are generated during stirring to promote the solution to scour the filter screen,separation of the solution is promoted, solid substances in meshes can be flushed off, and blockage is prevented; the filtering cavity is sealed by an upper cover and a lower cover, a pressurizing port is formed in the upper cover, and high-pressure gas is added into the pressurizing port to promote the filtering efficiency; the stirring device are spiral blades from top to bottom, filtrate is pushed downwards while stirring is conducted, the filtrate is pressed downwards in the funnel-shaped filtering cavity, and filtering is also promoted.

Owner:鲁玉玲

Filter part

InactiveCN104083919AProtects against corrosion damageImprove filter adsorption effectStationary filtering element filtersArchitectural engineeringWedge shape

The invention provides a filter part which comprises an upper inner sleeve, a lower inner sleeve and a top inner sleeve, wherein the upper inner sleeve, the lower inner sleeve and the top inner sleeve are in fit with interior of an internal thread stainless steel filter valve; a thread consistent with the internal thread stainless steel filter valve is arranged on the outer layer of the upper inner sleeve; an ejector table is arranged at the center of the top inner sleeve; multiple wedge-shaped grooves are formed in the upper surface of the top inner sleeve and are uniformly distributed; multiple filtering contact handles are arranged on the inner wall of the lower inner sleeve; an adsorption device is arranged on the top ends of the filtering contact handles. The inner sleeves can effectively prevent the inner wall of the stainless steel filter from being corroded and damaged, dirt accumulation and blockage can be avoided, the inner sleeves can be tightly attached to the stainless steel filter, installation is stable, and the filtering and adsorbing effects of the filter can be further enhanced through the filtering contact handles on the lower inner sleeve.

Owner:天津恒远阀门有限公司

Water purifier without wastewater discharge

PendingCN105384274AEfficient use ofAvoid wastingMultistage water/sewage treatmentWater/sewage treatment apparatusActivated carbonWater storage tank

The invention discloses a water purifier without wastewater discharge. The water purifier is characterized in that the water purifier comprises a one-micrometer stainless steel filter, a front active carbon processor, a 10-cun extruded activated carbon filter, a booster pump, a reverse osmosis membrane filter and a rear T33 filter, the above units are orderly connected by water pipes, a water inlet of the one-micrometer stainless steel filter is connected to a raw water connector, a water outlet of the rear T33 filter is connected to a water purification tap, the water purifier also comprises a water storage tank, the water storage tank is provided with a first water opening and a second water opening, the first water opening is connected to a water inlet of the front active carbon processor through the first water pipe, the second water opening is connected to a water inlet end of the booster pump through the second water pipe, the reverse osmosis membrane filter is provided with a clean water outlet and a waste water outlet, the clean water outlet is connected to the rear T33 filter through the water pipe, and the waste water outlet is connected to the first water pipe through the water pipe. The water purifier without wastewater discharge improves a water resource utilization rate and reduces water resource waste.

Owner:SUZHOU YADU WATER PURIFICATION TECH CO LTD

Sodium stearoyl lactylate preparations

InactiveUS20150147459A1Improve solubilityGood dispersionDough treatmentFood preparationSolubilityPetri dish

Provided is a sodium stearoyl lactylate preparation having high solubility (excellent dispersibility) in water at 20° C. and excellent effects of improving the easiness of loosening noodles and improving the texture of noodles. In particular, provided is a sodium stearoyl lactylate preparation of which the dried residue weight measured, by Dispersibility Test 1, as an evaluation index of dispersibility is less than 1.4 g, Dispersibility Test 1 comprising the following steps 1) to 3):1) placing 47.5 g of water at 20° C. in a 100 mL glass beaker, adding 2.5 g of the sodium stearoyl lactylate preparation at the same temperature thereto, and stirring the content at the same temperature at 500 rpm for 60 seconds using a three-one motor to prepare a mixed liquid;2) pouring the mixed liquid in 1) into a stainless steel strainer with a pore size of 250 μm and collecting the residue remaining in the strainer; and3) placing the residue in 2) on a glass petri dish, hot-air drying the residue at 105° C. for 2 hours, and measuring the weight (g) of the dry matter (dried residue) remaining on the glass petri dish for evaluation of the dispersibility.

Owner:RIKEN VITAMIN COMPANY

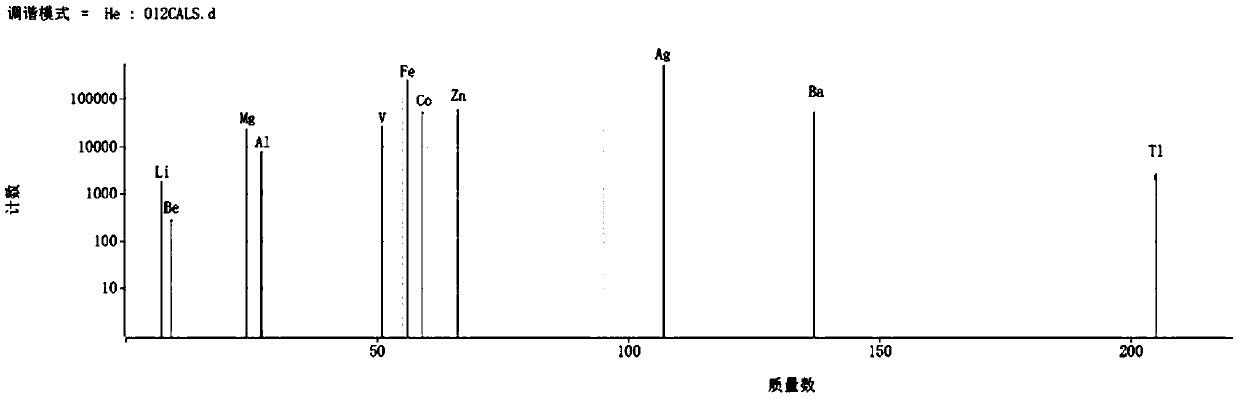

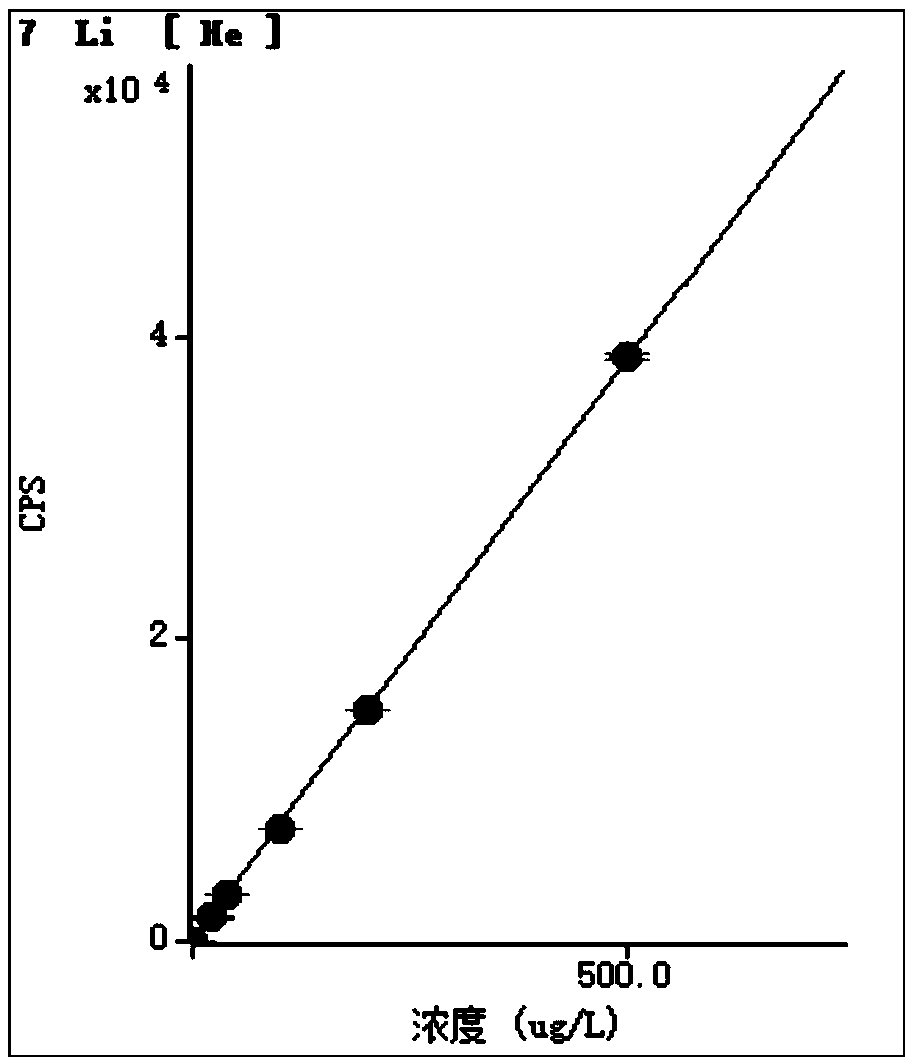

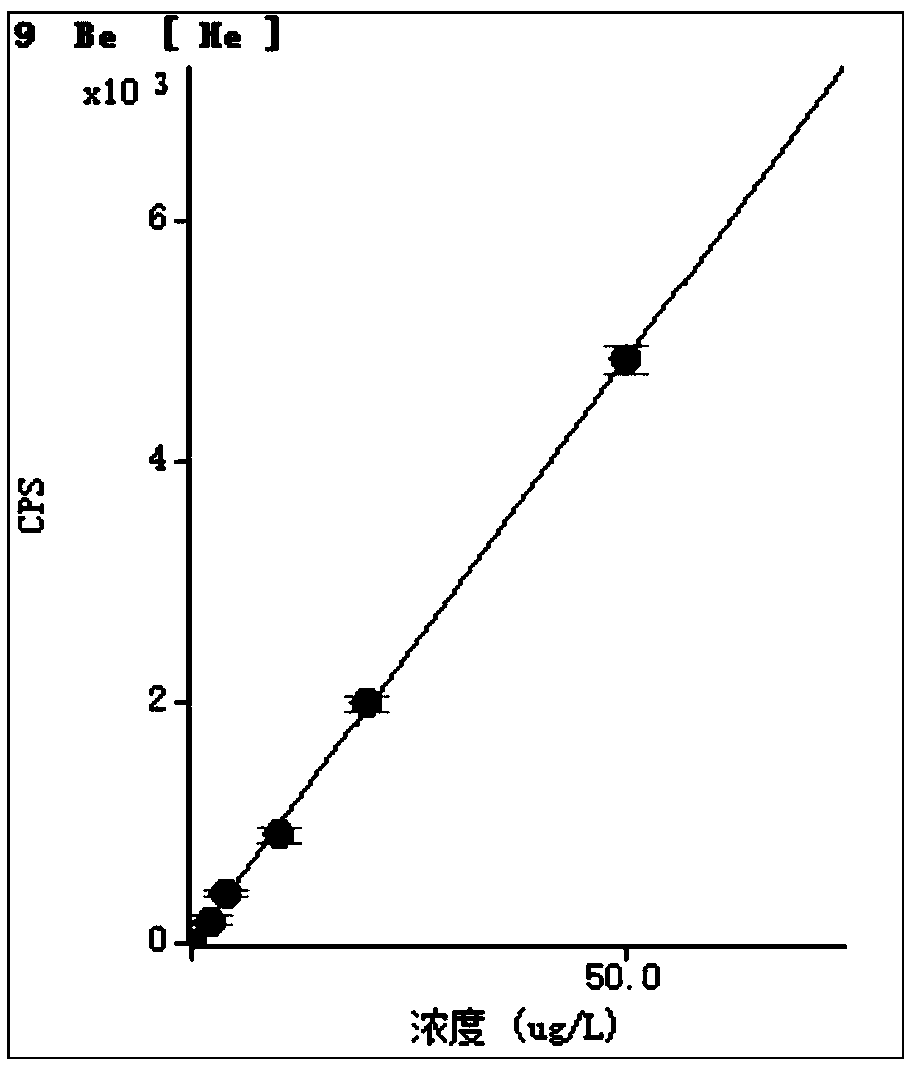

Method for detecting migration of 11 elements in stainless steel food container

InactiveCN109613103AReduce dosageLow detection limitMaterial analysis by electric/magnetic meansPeristaltic pumpTest efficiency

The invention discloses a method for detecting migration of 11 elements in a stainless steel food container, comprising the following steps of: 1) pretreating the sample: adding 5 g / L of the citric acid simulating solution to the stainless steel food container to soaked for a period of time, and taking out the simulating solution for testing; 2) preparing the standard solution; 3) measuring the simulating solution in step 1) and the standard solution in step 2) by inductively coupled plasma mass spectrometry, wherein the measuring condition of the inductively coupled plasma mass spectrometry is: RF power: 1550 W; plasma gas flow rate: 15 L / min; auxiliary gas flow: 1.0L / min; atomizing gas flow rate: 1.03L / min; peristaltic pump speed: 0.10rps; sample introduction speed:0.5rps. The method fordetecting migration of 11 elements in stainless steel food container adopts 5g / L citric acid as a simulating solution to pretreat the sample, and the requirements for the product are more strict. Theinductively coupled plasma mass spectrometry can simultaneously measure 11 elements, thereby greatly improving the measuring efficiency and reducing the reagent dosage and saving test time, thereforesimultaneous measuring of 11 elements can be completed in 3 minutes.

Owner:GUANGZHOU GRG METROLOGY & TEST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com