Novel stainless steel filter

A stainless steel and filter technology, applied in the field of new stainless steel filters, can solve problems such as low service life, difficulty in replacing filter elements, poor filter safety performance, etc., and achieve the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

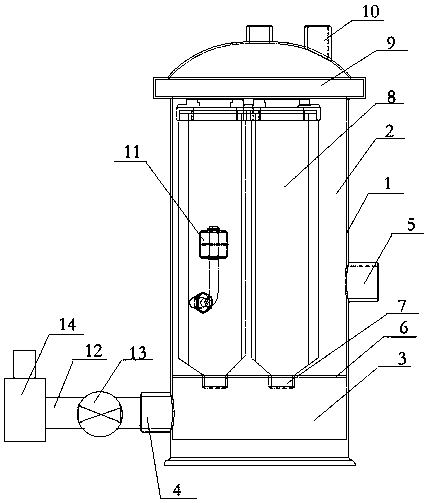

[0021] Such as figure 1 As shown, a novel stainless steel filter includes a cylinder body 1, an upper cover arranged on the upper part of the cylinder body 1, and the upper cover is connected to the cylinder body 1 through a flange. The lower part of the cylinder body 1 is provided with a mounting plate 6, which divides the cylinder body 1 into a filter chamber 2 and a buffer chamber 3, the buffer chamber 3 is located at the lower part of the filter chamber 2, and inside the filter chamber 2, two filter mesh cylinders are arranged side by side 8. The filter screen cylinder 8 is installed on the installation plate 6, and the installation plate 6 is provided with a water inlet hole 7. The water inlet hole 7 communicates with the filter screen cylinder 8, and the filter screen cylinder 8 and the installation plate 6 are detachable. connect. One end of the filter screen cylinder 8 installed on the mounting plate 6 is in the shape of an inverted cone, and the tip of the inverted c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com