Filtering equipment capable of automatically cleaning middle-deep layer geothermal system and convenient to disassemble

An automatic cleaning and convenient disassembly technology, applied in the field of pipeline cleaning, can solve the problems of small filtration area, insufficient water flow, poor water quality of sewage water source, etc., and achieve the effect of large filtration area, sufficient water flow, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

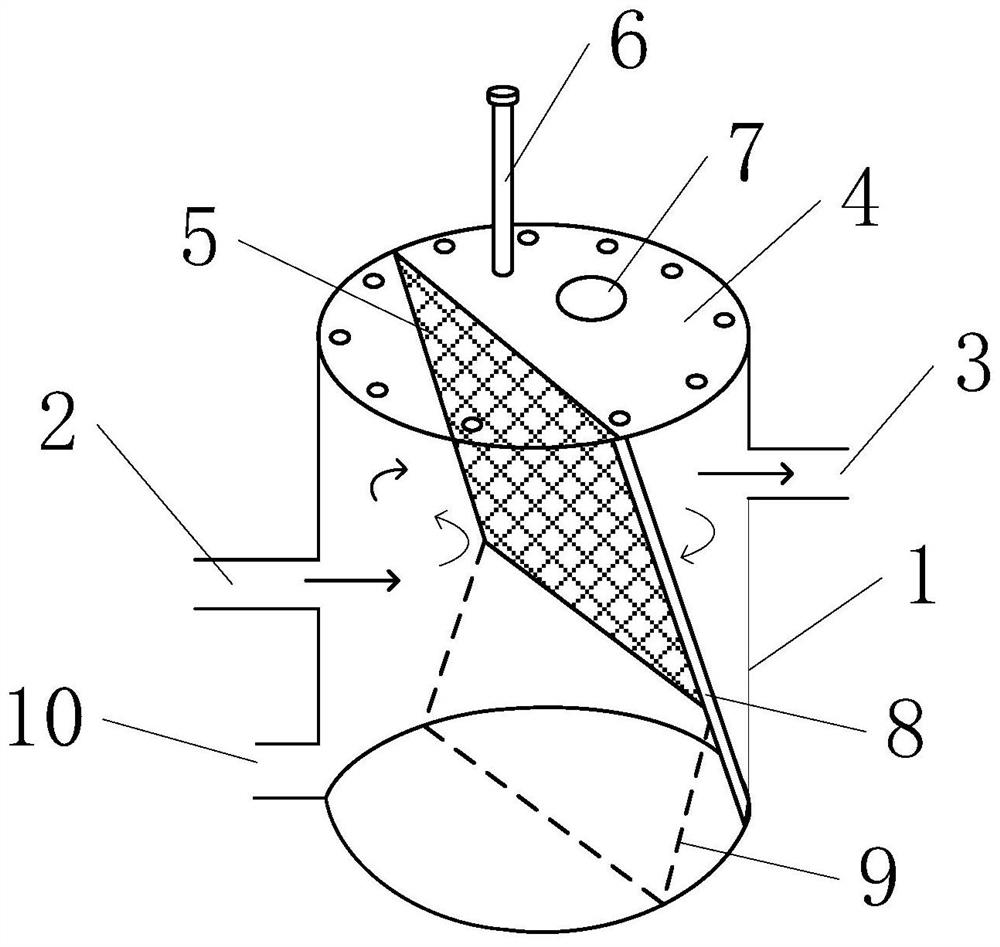

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0026] Aiming at the problems existing in the prior art, the present invention provides a medium-deep geothermal system automatic cleaning and convenient disassembly filtering equipment. The present invention will be described in detail below with reference to the accompanying drawings.

[0027] The technical scheme of the present invention has carried out concrete test application. A sewage source heat pump project uses the traditional filter equipment in the market to filter the sewage source. When the system is running, the floating objects in the sewage will cause the filter equipment to block within ten minutes, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com