Rapid oil filter

An oil filter, a fast technology, applied in filtration circuits, filtration separation, chemical instruments and methods, etc., can solve the problems of insufficient adsorption force, non-metallic impurities in lubricating oil, and inability to filter out sludge, and achieve good filtering effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

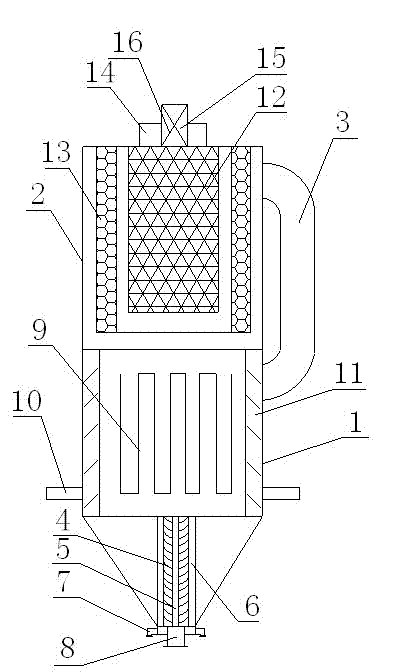

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] The following examples are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

[0013] Such as figure 1 As shown, a kind of fast oil filter of the present invention comprises cooling drum 1 and degreasing drum 2, and degreasing drum 2 is arranged on the top of cooling drum 1, and the side wall of degreasing drum 2 and cooling drum 1 communicates through pipeline 3, cooling The bottom of barrel 1 is connected with a swirl device, and the swirl device includes a swirl pipe 4, an oil riser pipe 5 and a mud pipe 6, the oil riser pipe 5 is placed in the swirl pipe 4, the swirl pipe 4 is arranged in the mud pipe 6, and the mud pipe 6 Both sides of the bottom are connected with mud outlet 7, the bottom of the cyclone device is connected with sewage oil and water inlet 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com