Ultrasonic cleaning device for large disc shaft parts of aircraft engine

A technology for aero-engines and cleaning devices, which is applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of equipment volume, ultrasonic power, and inability to meet requirements, and achieve shortened cleaning time, The effect of saving cleaning time and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

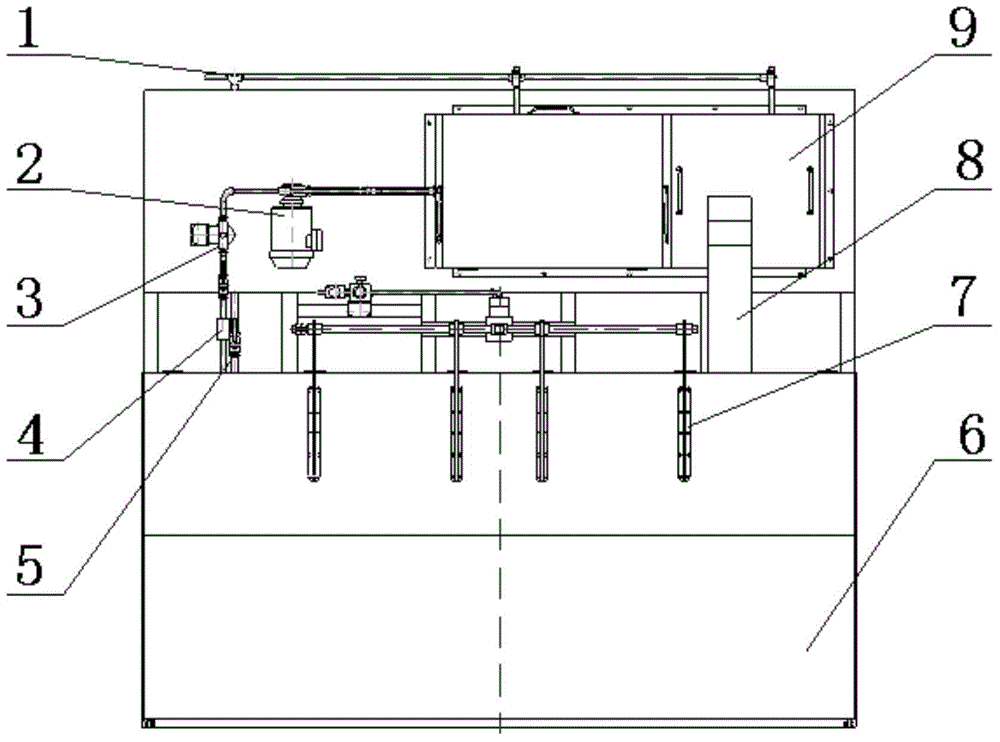

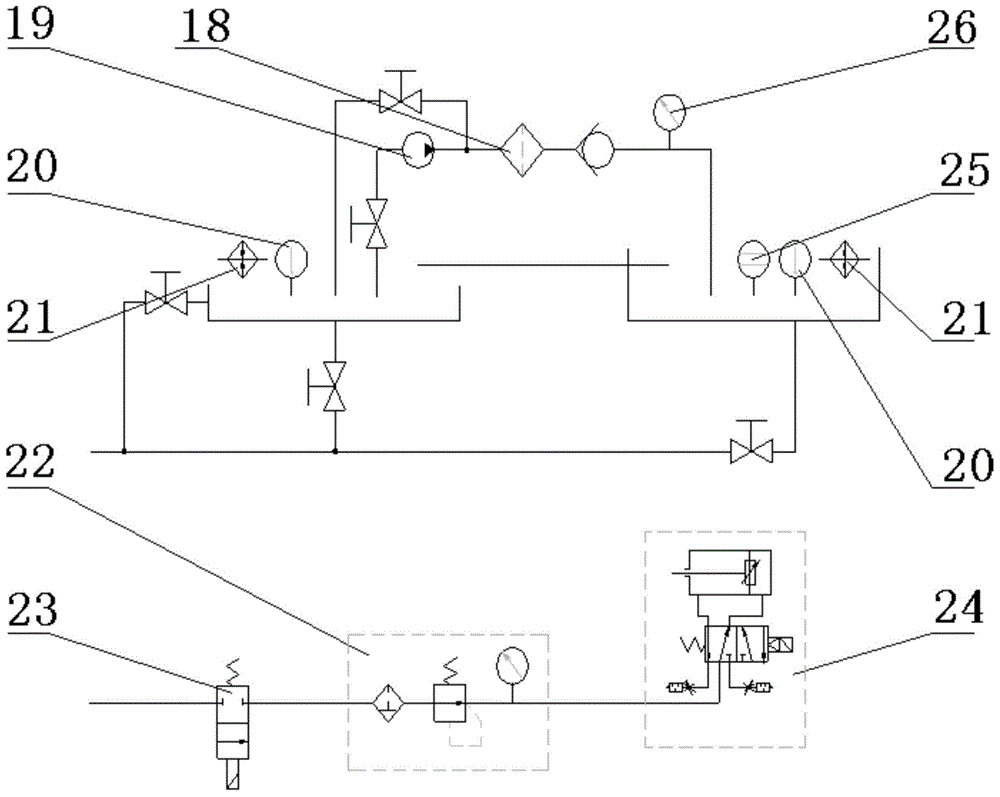

[0017] This embodiment provides an ultrasonic cleaning device for large disc shaft parts of aero-engines, which is characterized in that: the ultrasonic cleaning device for large disc shaft parts of aero-engines includes a main drain 1, a stainless steel vortex pump 2, and a stainless steel filter 3. Pressure gauge 4, cleaning tank drain valve 5, cleaning tank 6, pneumatic control tank cover 7, overflow return port 8, liquid storage tank 9, insulation layer 10, lateral ultrasonic vibration plate 11, stainless steel heating rod 12, bottom Ultrasonic vibrating plate 13, tooling protection frame 14, parts tooling frame 15, ultrasonic vibrating rod 16, transverse ultrasonic vibrating plate 17;

[0018] Among them: the liquid storage tank 9 and the cleaning box 6 are welded to the bottom frame, the main drain 1 is connected to the liquid storage tank 9 through a welded pipeline and a valve, the stainless steel vortex pump 2 is connected to the liquid storage tank 9 through a threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com