Sodium stearoyl lactylate preparation

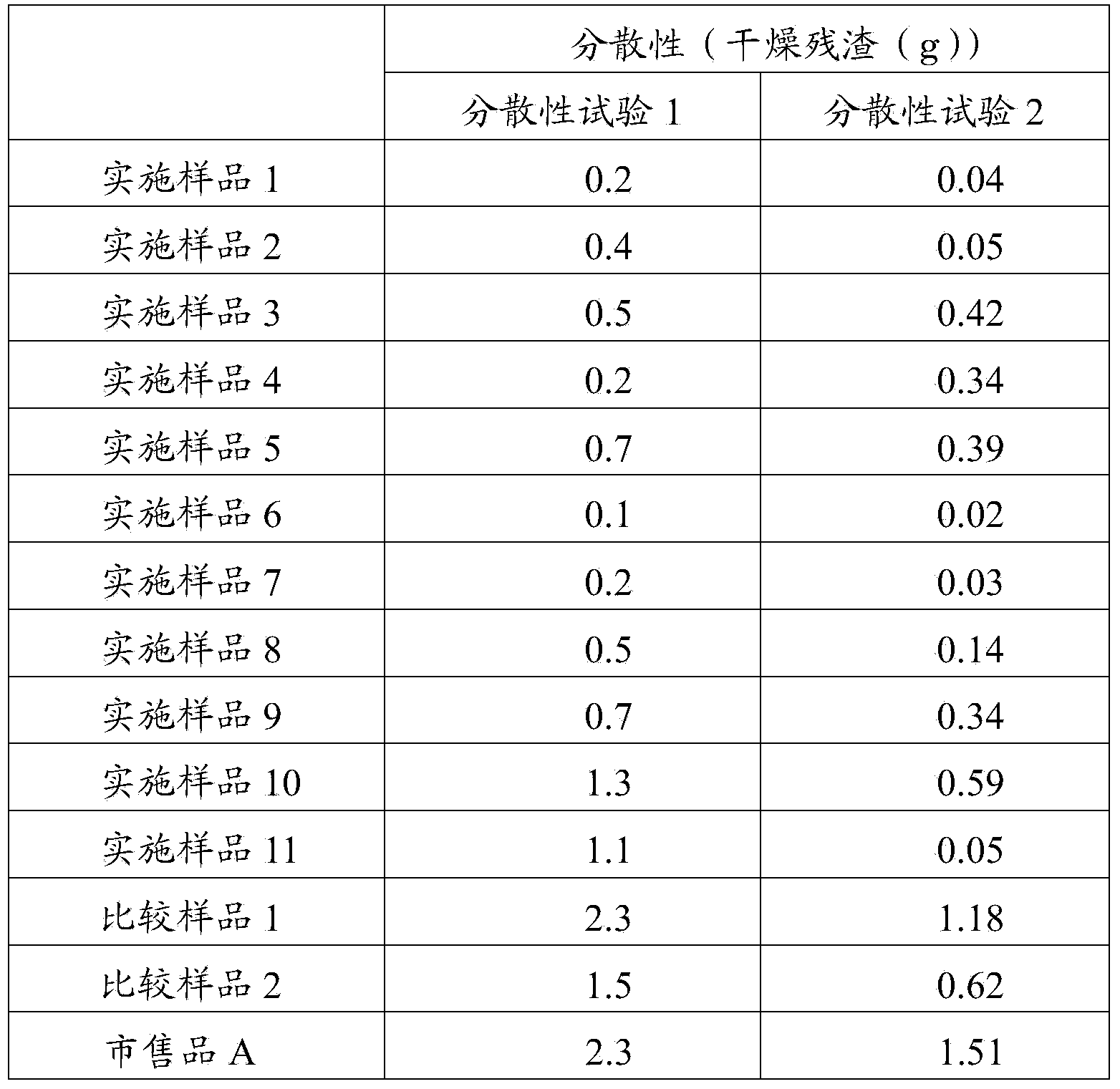

A technology of sodium stearoyl lactylate and preparation, applied in the field of sodium stearoyl lactylate preparation, can solve the problems of imperfect SSL, satisfactory, low solubility, etc., and achieve the effects of improving quality, excellent dispersibility, and excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1( approach 1 preparation manufacture example 1

[0087] 600 g of water was charged into a 1 L beaker, and 20 g of octenyl succinic esterified starch (trade name: Purity Gum BE; manufactured by Japan NSC Co., Ltd.), octenyl succinic esterified starch (trade name 20 g of N creamer 46; manufactured by NSC Corporation) and 140 g of dextrin (trade name: Pinedex #2; DE value 11; manufactured by Matsutani Chemical Industry Co., Ltd.) were heated and dissolved at 80° C. to obtain an aqueous solution.

[0088] Next, put 220 g of SSL (trade name: Poem SSL-100; manufactured by Riken Vitamin Co., Ltd.) in a 500-mL beaker, heat and melt at 80°C, and add the molten solution to the aqueous solution in the above-mentioned 1-L beaker. , stirring at 10,000 rpm for 10 minutes using a stirrer (trade name: TK Homomixer; manufactured by PRIMIX Corporation) while heating at 80° C., to obtain 1,000 g of a liquid composition.

[0089] Thereafter, the liquid composition was spray-dried using a spray dryer (trade name: Spray Dryer L-8i type; manufactu...

Embodiment 2( approach 1 preparation manufacture example 2

[0091] Instead of 220 g of SSL in Example 1, 160 g of SSL (trade name: Poem SSL-100; manufactured by Riken Vitamin Co., Ltd.), 20 g of palm oil (trade name: RPO; manufactured by Ueda Oil Co., Ltd.), and glyceryl succinic acid fat were used Except the ester (trade name: Poem B-10; manufactured by Riken Vitamin Co., Ltd.) 40 g, it carried out similarly to Example 1, and produced 300 g of powdery SSL preparations (implementation sample 2).

Embodiment 3

[0092] [Example 3 (Manufacture Example 1 of Powdered Sodium Stearoyl Lactylate Preparation Based on Method 2)]

[0093] Put 95 g of SSL (trade name: Poem SSL-100; manufactured by Riken Vitamin Co., Ltd.) into a 200 mL beaker, and add diglyceride fatty acid ester (trade name: Poem DO-100V; HLB value 8.0; Riken Vitamin Co., Ltd. company) 5 g was heated and melted at 80° C. to obtain a mixture.

[0094] After that, the mixture was cooled and solidified by standing in a refrigerator at 4° C. for 8 hours, and pulverized for 20 seconds using a food grinder (trade name: Millser 800DG; manufactured by Iwatani Sangyo Co., Ltd.) to prepare powdered SSL. 80 g of preparation (implementation sample 3). As a result of measuring the obtained SSL preparation using a laser diffraction particle size distribution analyzer (model: Mastersizer; manufactured by Malvern Co., Ltd.), the average particle diameter was 371 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com