Novel process for extracting not smaller than 98% of natural ferulic acid from rice bran oil processing leftovers

A technology of leftovers and rice bran oil, which is applied in the field of ferulic acid, can solve the problem of low yield and achieve the effects of low production cost, low heavy metals, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

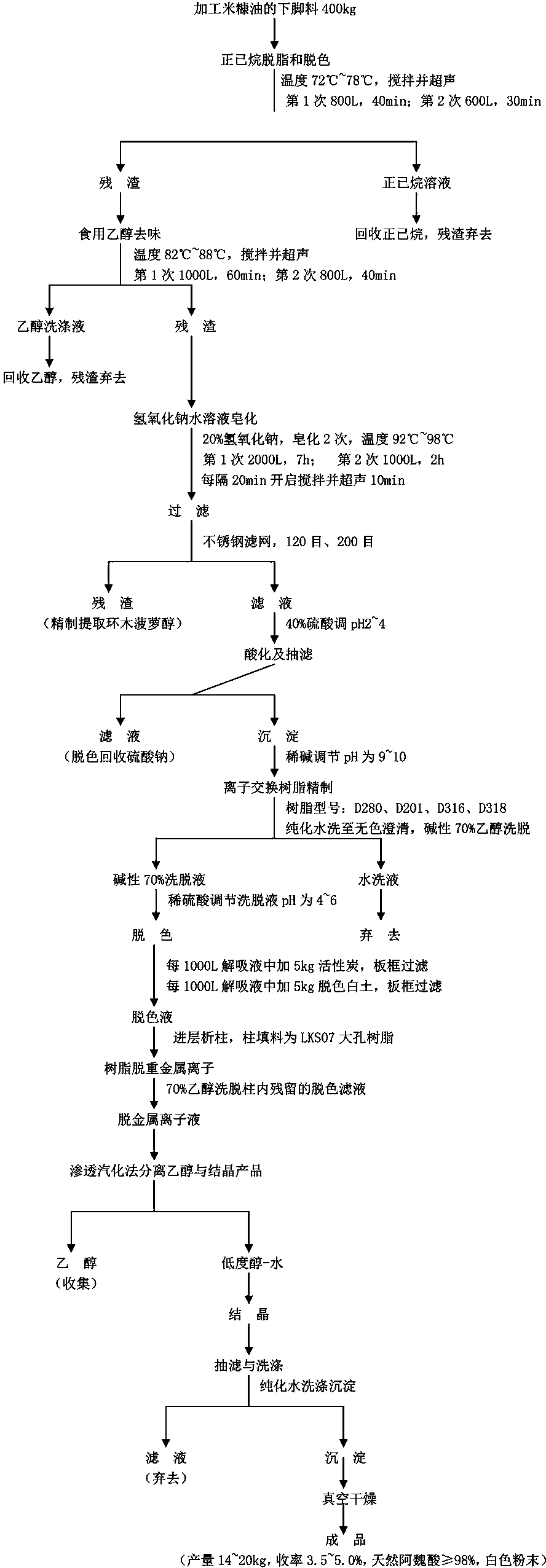

[0029] refer to figure 1 , a new technique for extracting ≥98% natural ferulic acid from the leftovers of processed rice bran oil of the present invention, its technological process is:

[0030] Processing leftovers of rice bran oil→n-hexane degreasing and decolorization→deodorization of edible ethanol→saponification of sodium hydroxide aqueous solution→acidification and suction filtration→ion exchange resin refining→decolorization of activated carbon and decolorizing clay→resin removal of heavy metal ions→pervaporation separation Ethanol and crystallization products→suction filtration and washing→vacuum drying→finished natural ferulic acid.

[0031] The specific processing technology includes the following steps:

[0032] 1. Degreasing and decolorizing of n-hexane: Take 400kg of leftovers from processing rice bran oil and put them into 3m 3 Add 2.0 and 1.5 times the amount of n-hexane to the extraction tank equipped with heating and an external ultrasonic generator. Mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com