Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72 results about "Sodium aescinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

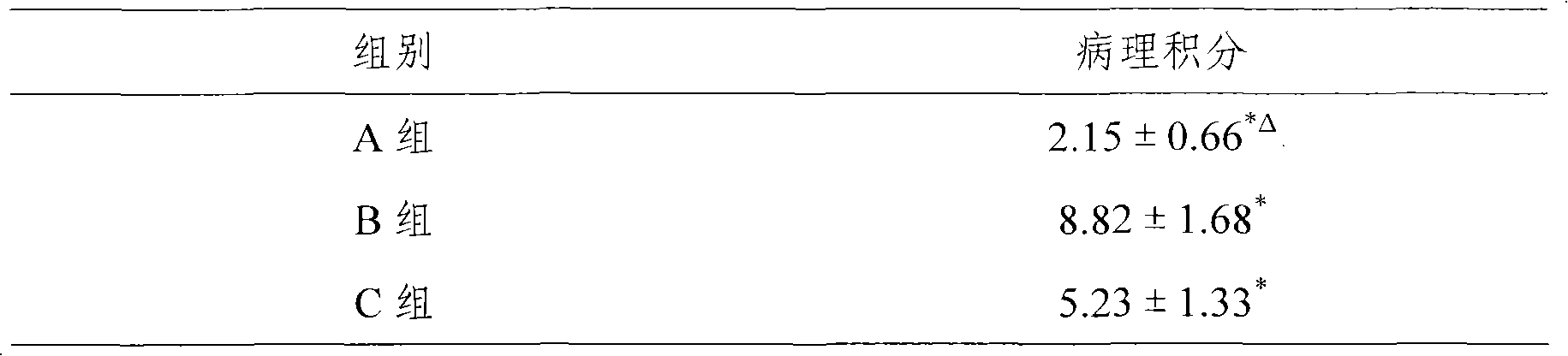

Sodium Aescinate administration also ameliorated liver injury induced by methyl parathion poisoning. The findings indicate that Sodium Aescinate protects against liver injury induced by methyl parathion and that the mechanism of action is related to the antioxidative and anti-inflammatory effects of Sodium Aescinate.

Method for purifying sodium aescinate

InactiveCN102532241AReduce dissolutionSolve the cumbersome extractionSugar derivativesSteroidsHydrogenSodium aescinate

The invention relates to a method for purifying sodium aescinate. The method comprises the steps of crushing Chinese buckeye seed, adding 80-95% ethanol with amount of 5-10 times than that of the Chinese buckeye seed to carry out circumfluence extraction for 2 to 3 times, pressure-reducing the extraction liquid, recycling the ethanol, dispersing and filtering mother liquor by adding right amount of water, adding macroporous resin columns for absorption, eluting by using 50-70% ethanol solution with 4-6 BV, collecting the eluting liquid, pressure-reducing and recycling the ethanol, adding cation exchange resin columns into concentrated solution, adjusting the pH (potential of hydrogen) value of the lower resin column liquid to be 7.5-8.5, adding the macroporous resin columns again for absorption, adding acetone solution into the lower column liquid, mixing fully to obtain precipitation, dissolving the precipitate by using the ethanol solution, shortening the column by using peroxide aluminum, pressure-reducing the column filtering liquid, recycling the ethanol to be in a small volume, placing for crystallization, carrying out circumfluence dissolving on crystallization products by using the ethanol solution and re-crystallizing for 1-3 times, and drying the crystallization products to obtain sodium aescinate products with content not less than 95%. By using the method for purifying sodium aescinate to produce the sodium aescinate, the process is simple, the operation is easy, the content of obtained products is high, and the method can be directly used on medicine production.

Owner:苏州宝泽堂医药科技有限公司

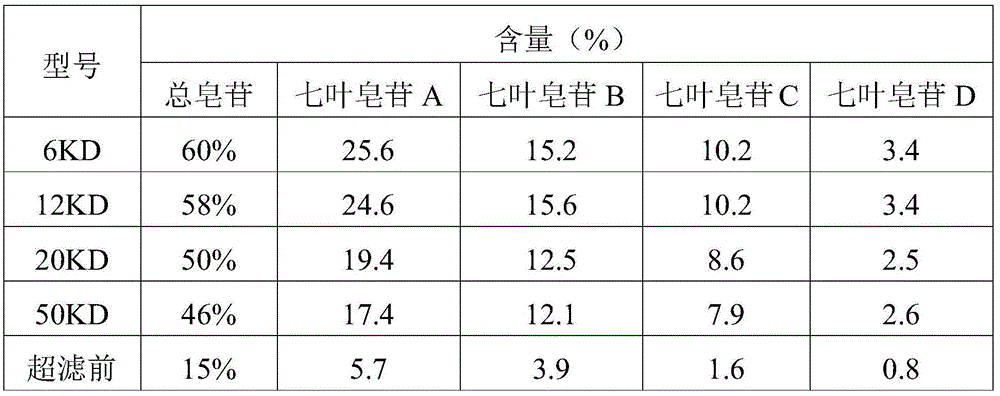

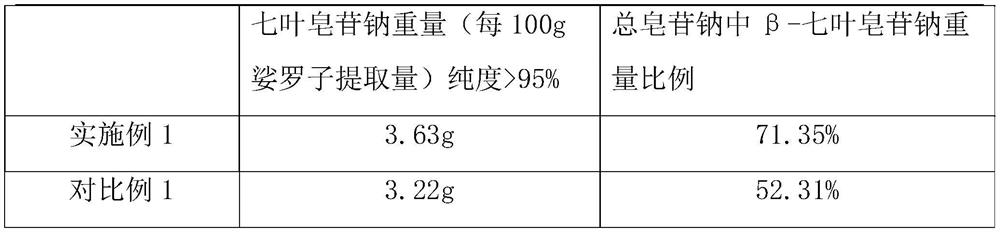

Sodium aescinate preparation method

ActiveCN104402963AImprove securitySimple processSugar derivativesSteroidsSodium aescinateMacroporous resin

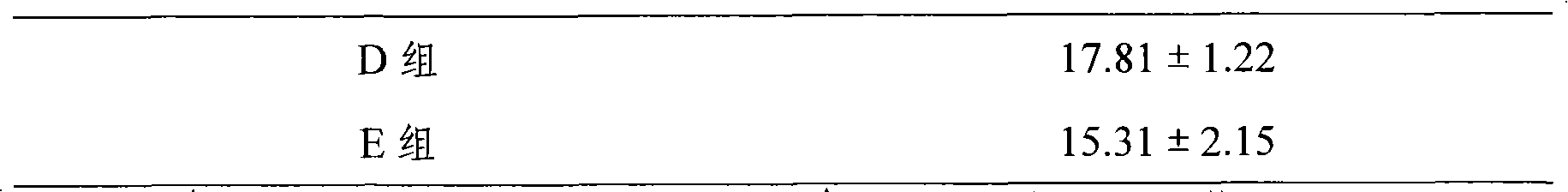

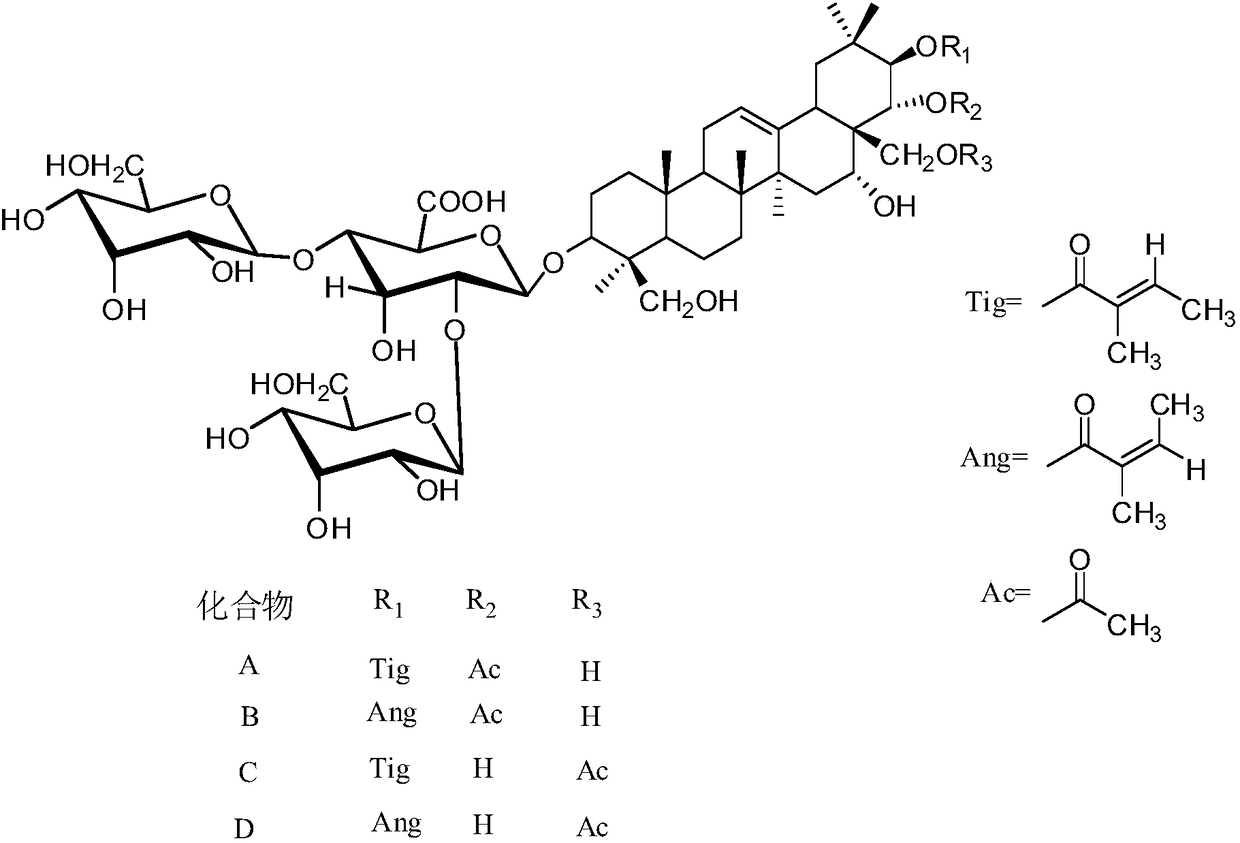

The invention discloses a sodium aescinate preparation method. According to the invention, Chinese buckeye seed is extracted with 30%-70% ethanol; an extraction liquid is filtered with an ultrafiltration membrane with molecular weight cutoff of 10000-15000Dalton; a filtrate is sequentially purified with a macroporous resin column and a polyamide resin column; purified aescine is subjected to a reaction with sodium hydroxide, such that sodium aescinate is produced; and crystallization is carried out, such that a sodium aescinate pure product is obtained. The purity of the sodium aescinate provided by the invention reaches 100%, wherein the content of sodium aescinate A is 30-40%, the content of sodium aescinate B is 15-20%, the content of sodium aescinate C is 25-30%, the content of sodium aescinate D is 10-15%, and the total content of sodium aescinate A, B, C and D accounts for 85-90% of that of total saponins. As a toxicity test result, with the sodium aescinate provided by the invention, intravenous administration in mice LD50 is 12.45mg / Kg, such that the safety of the sodium aescinate is relatively high.

Owner:WUHAN AIMIN PHARMA

Preparing method of sodium aescinate, external use preparation comprising same and application thereof

ActiveCN104804060AEasy to prepareReduce usageOrganic active ingredientsSugar derivativesTissue edemaIon exchange

The invention relates to a preparing method of sodium aescinate, an external use preparation comprising the sodium aescinate,and application thereof, in particular to the preparing method of the sodium aescinate, preparation of the external use preparation and application to the preparation of medicine for preventing or treating tissue edema due to trauma. The preparing method is characterized by comprising extraction and separation and purification steps, wherein for the extraction, buckeye powder is extracted by 0-80-percent of ethanol or methanol solution (preferably methanol solution), the separation and purification step comprises the ion exchange chromatography by using inorganic sodium salt water solution as a flowing phase. The method has the advantages that the purity of prepared products is high, the production period is short, the cost is low, the problems such as environment pollution are avoided, and the like, and the method conforms to the development trends of preparing natural safe and high-purity aescin.

Owner:西安蓝绿卓生物科技有限公司

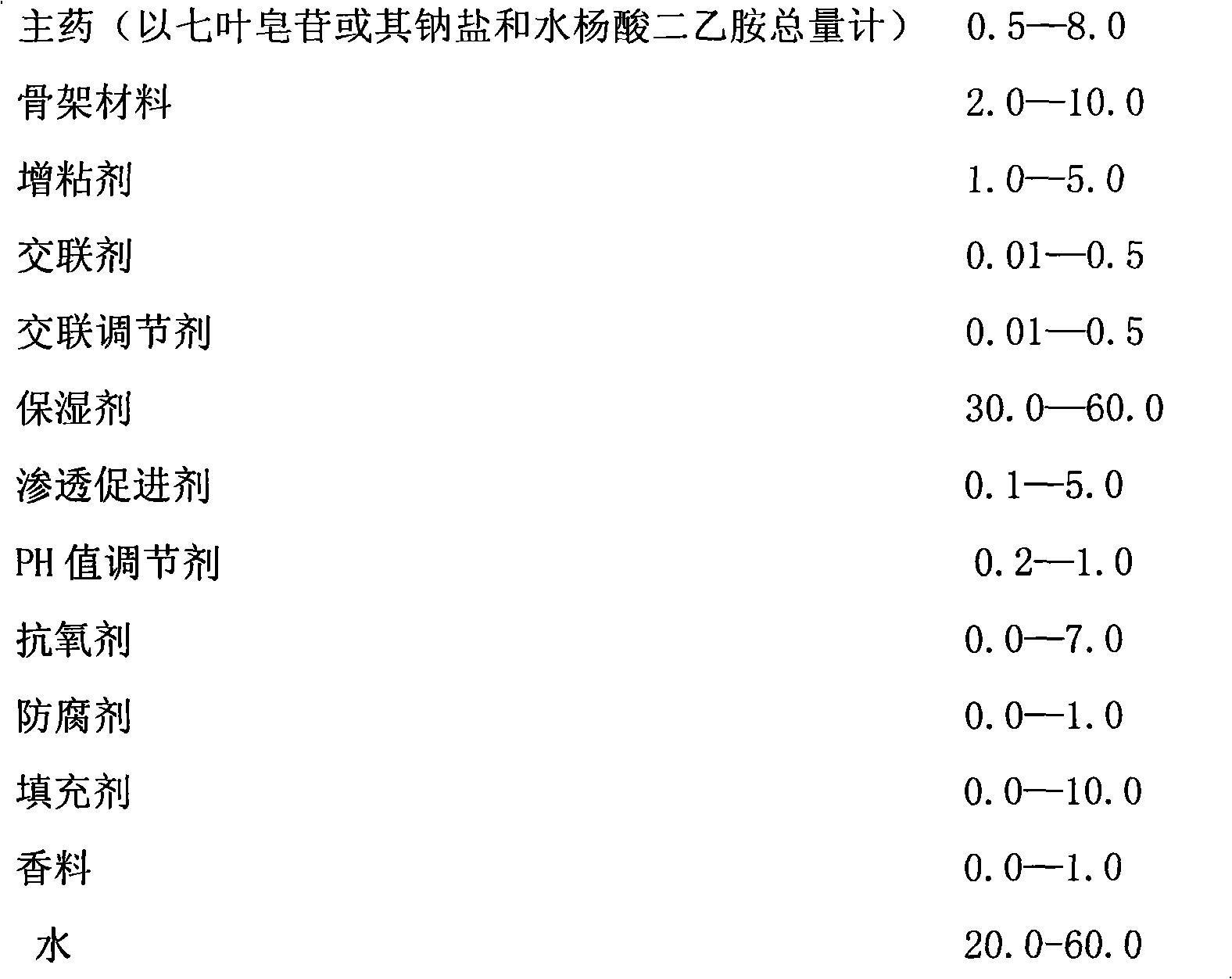

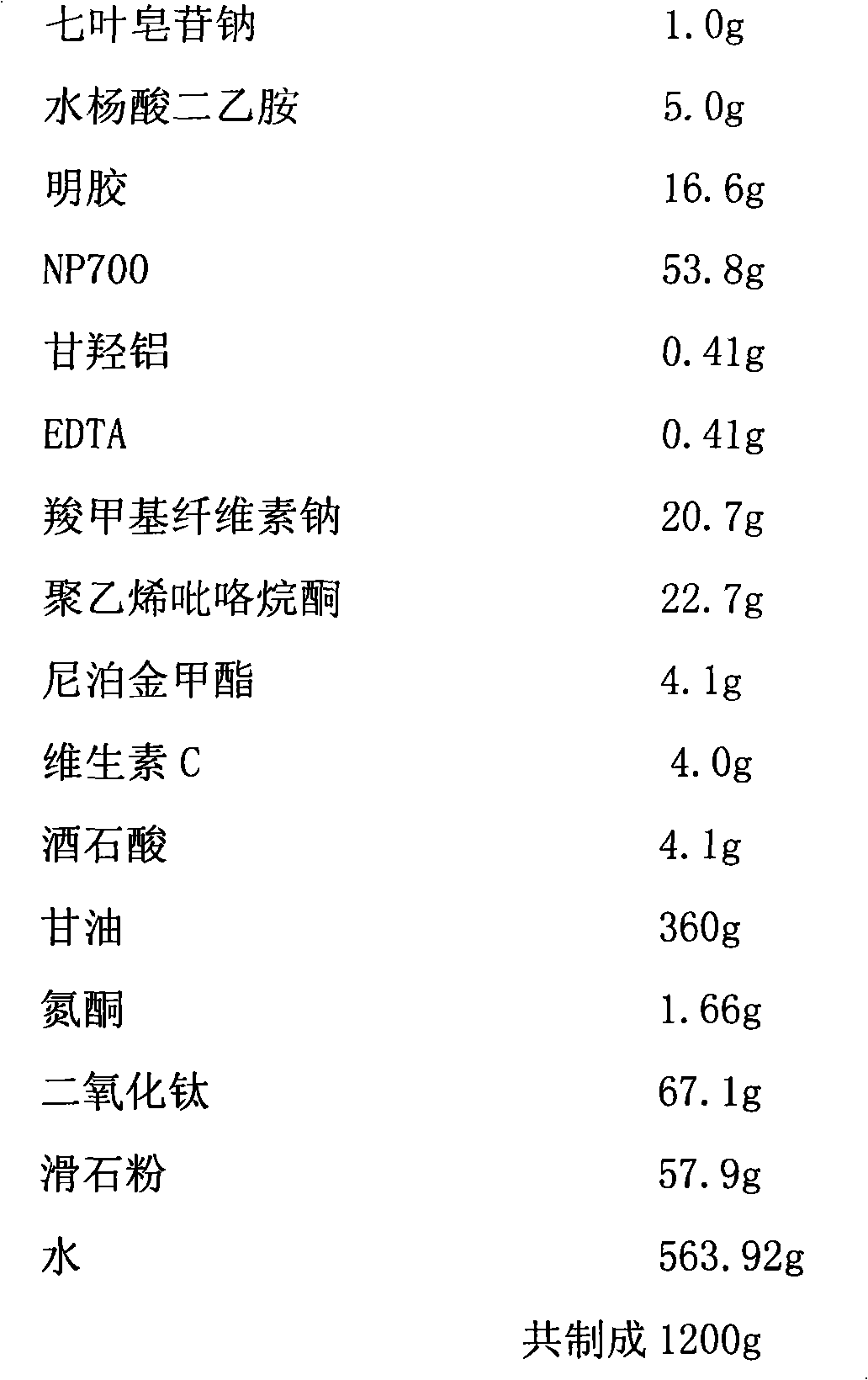

Compound sodium aescinate cataplasm

The invention relates to a compound sodium aescinate cataplasm, which comprises an outer lining layer, a medicament tank and a protective layer, wherein the medicament tank layer comprises sodium aescinate, diethylamine salicylate, a framework material, a tackifier, a humectants, a penetration enhancer, a cross-linking agent, a cross-linking regulator, a pH value regulator, A preservative, a spice, a filler, water, antioxygen and the like. The compound sodium aescinate cataplasm can carry a large amount of medicament, has high moisturizing performance and breathability, is convenient to use, can improve treatment effect and is free from side effects such as sensitization.

Owner:CHONGQING PHARMA RES INST

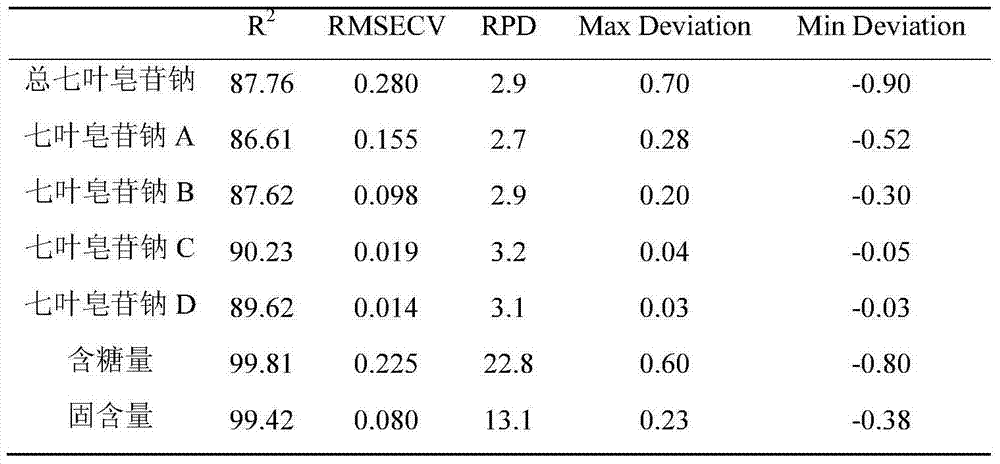

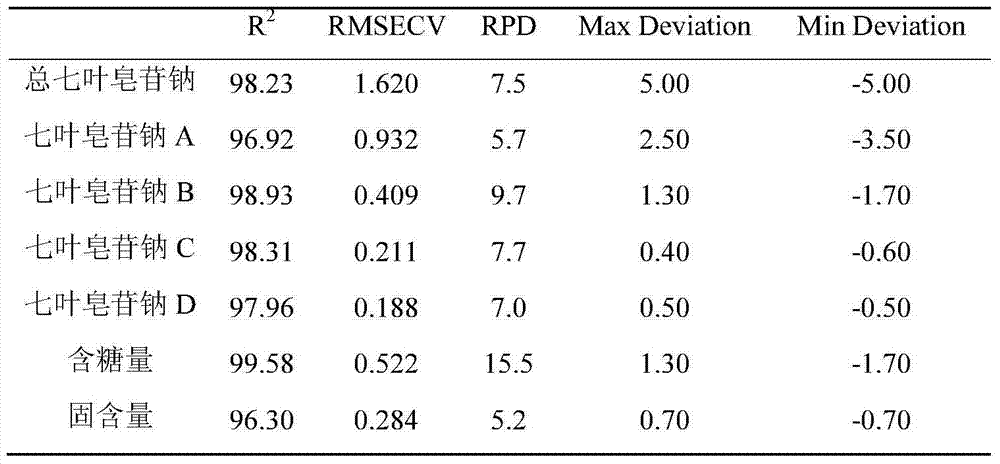

Method for determining content of multi-index components in purification process of Chinese buckeye seed extractive

InactiveCN103808665AImprove performanceEliminate the effects ofColor/spectral properties measurementsQuality controlSodium aescinate

The invention discloses a method for rapidly determining the content of multi-index components in a sample feeding and eluting process of a Chinese buckeye seed extractive, namely sodium aescinate, in macro-porous resin and rapidly judging an eluting terminal point. The method comprises the following steps: (1) scanning near infrared spectrums and collecting a macro-porous effluent liquid sample; (2) determining the content of the multi-index components in a sample by using a reference method; (3) establishing a near-infrared multi-element correction model in a macro-porous purification process; (4) carrying out model evaluation; and (5) rapidly judging the eluting terminal point. The method provided by the invention has the advantages of rapidness, no loss, capability of simultaneously detecting a plurality of components and the like, can be used for an online analysis of a traditional Chinese medicine production process, and provides a novel thought for production and quality control of traditional Chinese medicines.

Owner:SHANDONG LUYE PHARMA CO LTD

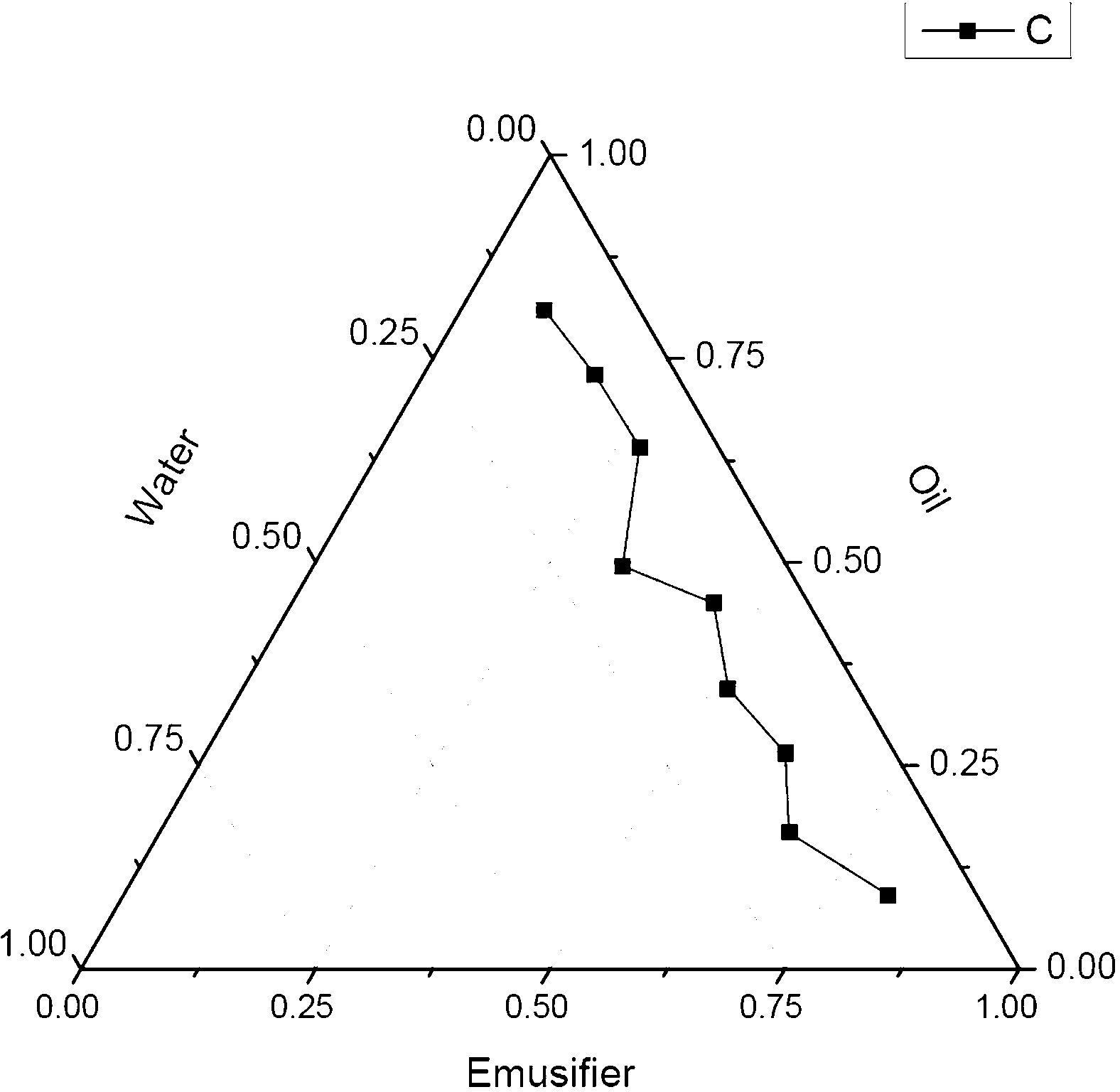

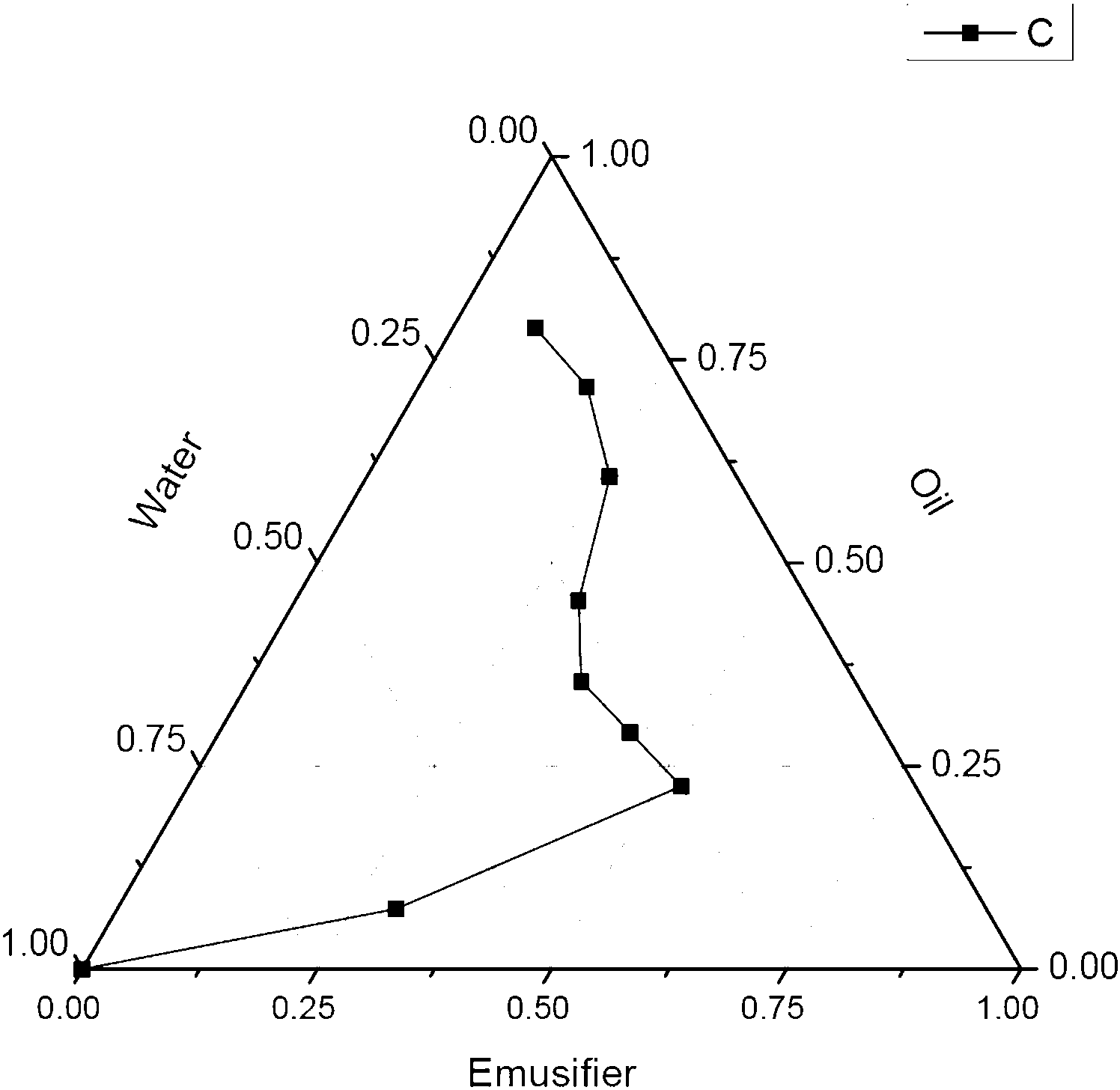

Sodium aescinate micro-emulsification injection and preparation method thereof

ActiveCN102793664AImprove bioavailabilityIncrease concentrationOrganic active ingredientsAntipyreticSide effectIrritation

The invention discloses a sodium aescinate micro-emulsion injection. The formula of the sodium aescinate micro-emulsion injection comprises sodium aescinate, an oil phase, a surfactant and a cosurfactant. Compared with the oral gavage, the sodium aescinate micro-emulsion injection for intravenous injection provided by the invention has the advantages that the bioavailability is high, the concentration of the injection in the liver can be increased obviously, the concentration of the injection in the kidney can be reduced, meanwhile, the irritation on the wall of the blood vessel is alleviated, and the generation times of phlebophlogosis can be reduced, so that the curative effect is improved, and the toxic and side effect is lowered.

Owner:TAIJI GROUP

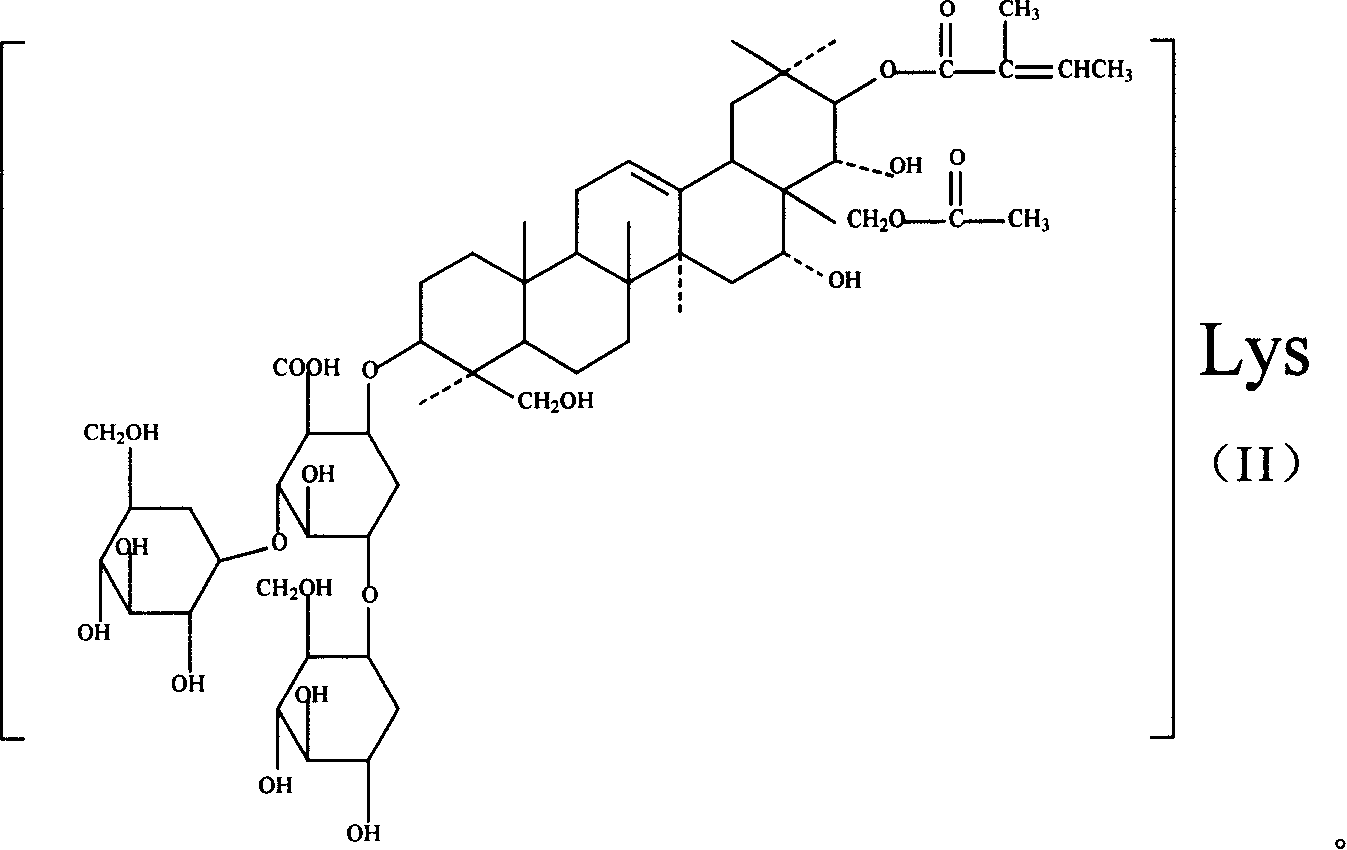

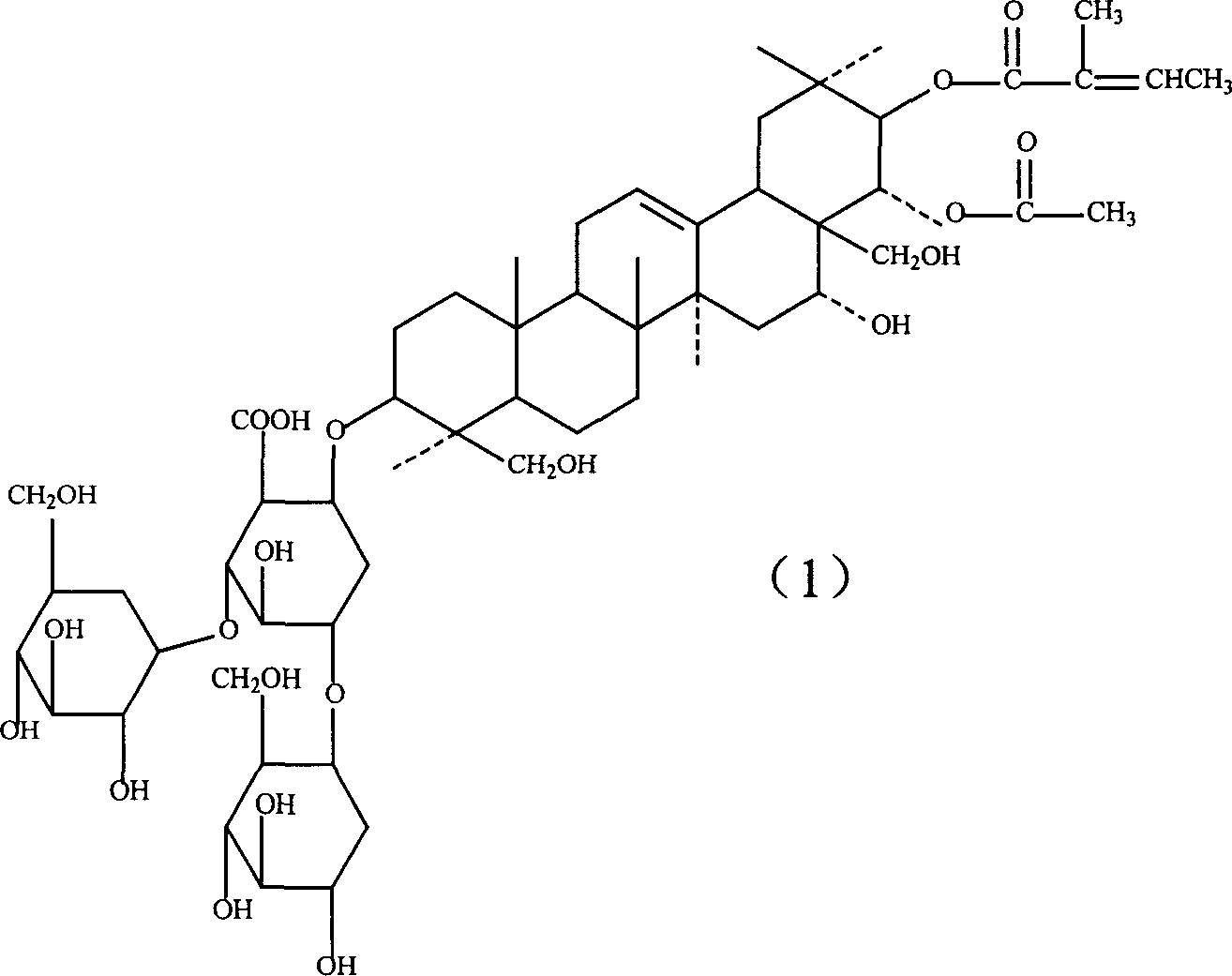

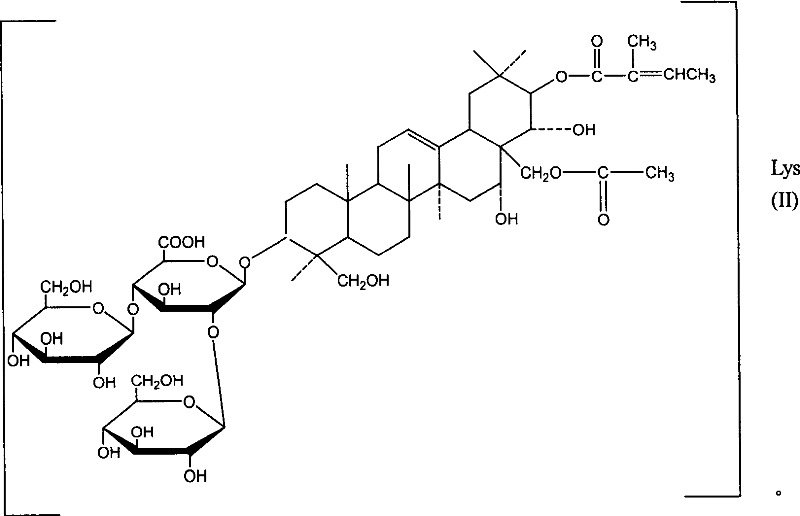

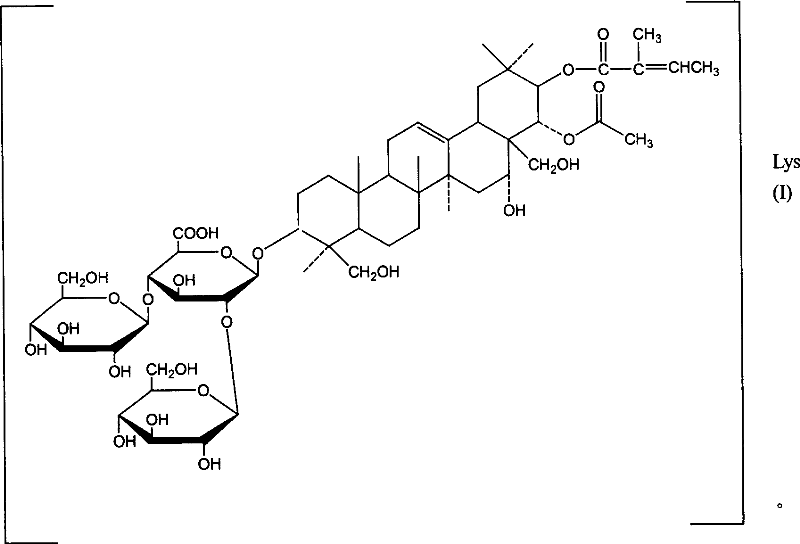

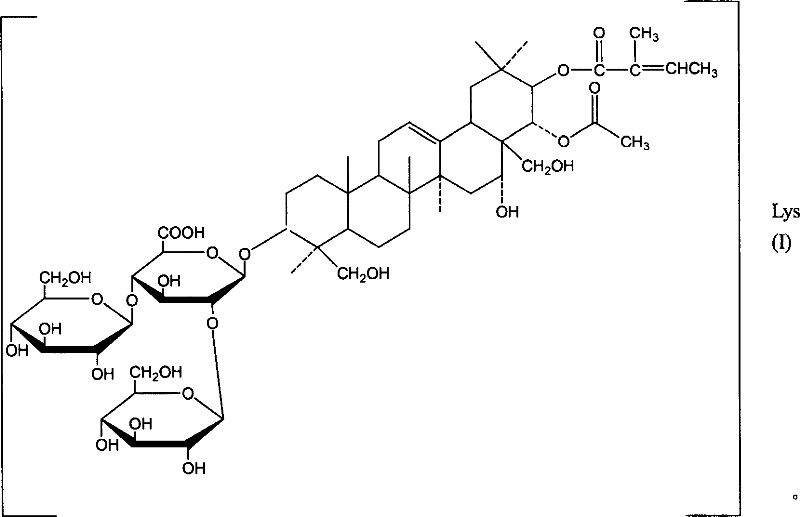

Lysine aescin saponin, its preparation and use

A lysine escin, its compound, production and use are disclosed. The compound consists of beta-escin lysine salt, isoescin lysine salt or their mixture and / or the other accepted carriers. It has better anti-inflammatory and anti-exudative performances, better suppressant for brain edema and medicinal safety. It can also improve blood circulation increase venous tension.

Owner:WUHAN AIMIN PHARMA

Notoginsenoside sodium freezing-dried emulsion and preparation method thereof

InactiveCN101084911ALess irritatingImprove toleranceOrganic active ingredientsAntipyreticAdjuvantFreeze-drying

An escin sodium lyophilization dry emulsion for injection comprises therapeutically-effective amount of escin sodium and carrier material comprising phospholipid, emulsifying agent, water-soluble adjuvant and freeze-dried stabilizer. Its preparation method comprises preparing escin sodium into internal water phase, adding organic phase containing phospholipid, preparing into colostrum, adding outer water phase, preparing into emulsion of w / o / w, adding freeze-dry protective agent, and freeze-drying into solid.Berore application, water for injection is added as required for hydration, and oscillating, and emulsion is otbtained after recovery. The escin sodium lyophilization dry emulsion for injection has the advantages of reduced stimulatory function, increased toleration of clinical application and stability of medicament due to the protection of water-soluble stabilizer in adjuvant and phospholipid, thereby avoiding direct contact of lyophilization dry emulsion with wall of blood vessel.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

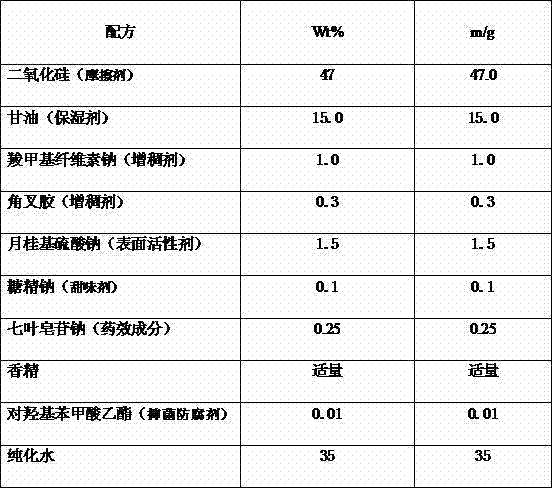

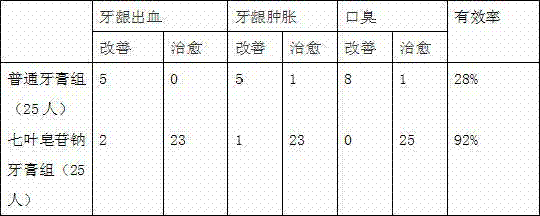

Sodium aescinate toothpaste and preparation method thereof

InactiveCN104490619AAnti-inflammatoryAnti-exudationCosmetic preparationsToilet preparationsChemical productsDissolution

The invention discloses sodium aescinate toothpaste and relates to the technical field of daily chemical products. The toothpaste disclosed by the invention comprises the following components in percentage by weight: 0.05%-2% of sodium aescinate, 20-55% of a friction agent, 20-30% of a moisturizing agent, 2-3% of a surfactant, 1-2% of a thickening agent, 0.05-0.25% of a sweetener, 0.05-0.5% of a preservative, 1-2% of essence, other special ingredients and the balance of water, and sodium aescinate toothpaste is prepared from the components by one of an intermittent two-step paste making method, a dry process one-step paste making method and a wet process one-step paste making method. The toothpaste disclosed by the invention has anti-inflammatory, detumescent and anti-exudation effects, and can be used for improving micro-circulation, promoting dissolution and absorption of hematoma, and well preventing and treating bleeding, swelling and halitosis caused by gum swelling and pain; and the toothpaste does not pass through a gastrointestinal tract and blood circulation, so that adverse reactions can be avoided and safety is realized.

Owner:FUJIAN MINDONG REJUVENATION PHARMA

Preparation of medicine preparation of orthopedics department and its use

The present invention discloses a kind of medicine composition for preventing and treating orthopaedics diseases, and the medicine composition consists of deer bone extract and saponin extract with the functions of promoting blood circulation to disperse blood clots. Experiments show that the deer bone extract has obvious synergistic effect on notoginseng saponin, achyranthes root saponin and beta-aescin sodium, and the medicine composition can remit various symptoms of osteoarthritis and speed the healing of fracture. The medicine composition may be prepared into different preparation forms and has wide application foreground.

Owner:SHANXI PUDE PHARMA CO LTD

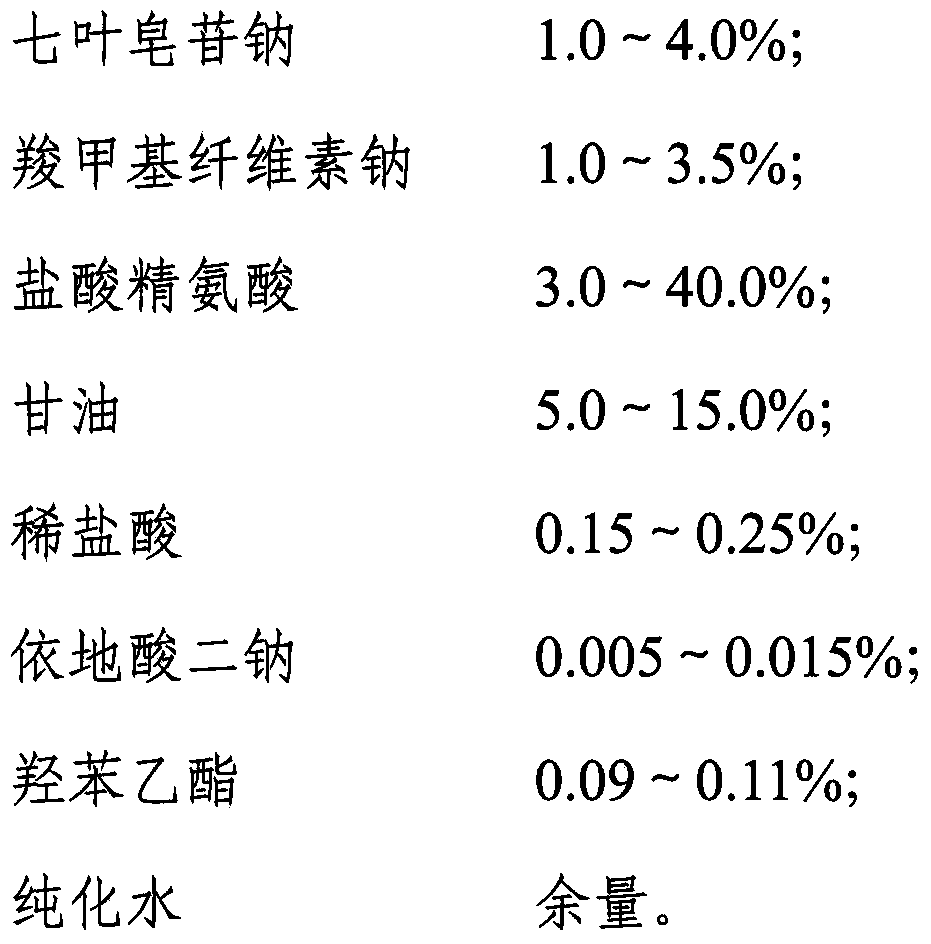

Sodium aescinate preparation curing haemorrhoids and preparation method for sodium aescinate preparation

ActiveCN104288167ALess irritatingImprove complianceOrganic active ingredientsAerosol deliverySodium aescinateARGININE HYDROCHLORIDE

The invention discloses a sodium aescinate preparation curing haemorrhoids and a preparation method for the sodium aescinate preparation. The sodium aescinate preparation comprises the effective components of sodium aescinate and arginine hydrochloride; a gelata can be prepared by adding corresponding auxiliary materials. According to the invention, the arginine hydrochloride is adopted to reduce the thrill of the sodium aescinate to rectum mucosa; the sodium aescinate preparation directly acts on haemorrhoids part through part external administration, is fast to play function, enhances compliance of patients, and provides a novel administration route for the patients.

Owner:MAYINGLONG PHARMA GROUP

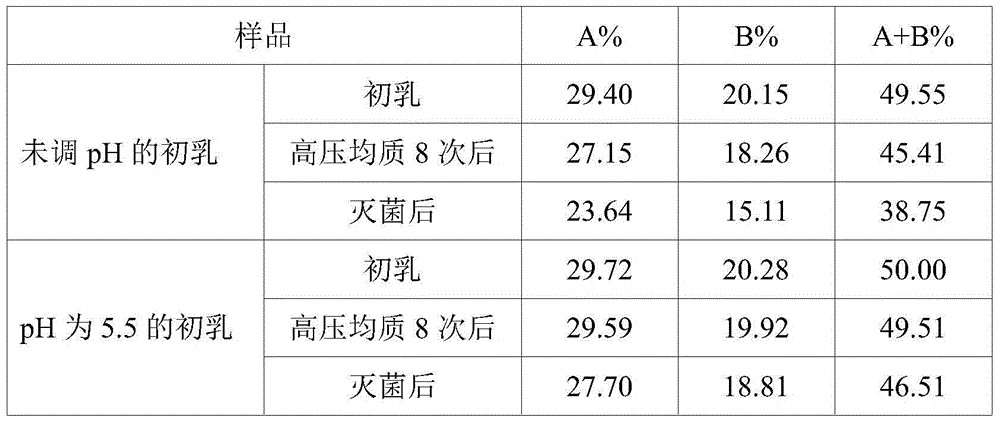

Preparation method for sodium aescinate freeze-dried emulsion for injection

ActiveCN104873469AGood resolubilityIncrease contentPowder deliveryOrganic active ingredientsMicropore FilterEthylene diamine

The invention discloses a preparation method for a sodium aescinate freeze-dried emulsion for injection. The preparation method comprises the following steps: dissolving sodium aescinate in a non-polar organic solvent, then adding to oil for injection together with lecithin and oleic acid, uniformly stirring, and then removing the non-polar organic solvent to obtain an oil phase; dissolving glycerin and EDTA (Ethylene Diamine Tetraacetic Acid)-2Na to water for injection to obtain an aqueous phase; adding the oil phase to the aqueous phase, and shearing to obtain a primary emulsion; adjusting pH of the primary emulsion to 5-7 and homogenizing to obtain an emulsion; adding a freeze-drying protective agent to the homogenized emulsion, stirring till the freeze-drying protective agent is completely dissolved, then filtering with a micropore filter membrane, subpackaging and freeze-drying to obtain a finished product. The freeze-dried emulsion prepared by the preparation method is stable in property and good in product redissolution property; the emulsion with uniform and stable particle size can be formed after redissolution, and no demulsification phenomenon happens; sodium aescinate in the preparation is stable in contents of components A and B.

Owner:WUHAN AIMIN PHARMA

Medicament compound containing hyaluronic acid and beta-aescine sodium

InactiveCN101822689AShort treatment cycleGood effectOrganic active ingredientsSkeletal disorderDiseaseCurative effect

The invention provides a medicament compound containing hyaluronic acid and beta-aescine sodium and application thereof in preparing medicaments for treating diseases of osteoarthritis and the like. The compound can play the function of the hyaluronic acid for treating osteoarthritis and the function of the beta-aescine sodium for resisting inflammation and free radicals. In addition, used as an inhibitor of hyaluronidase, the beta-aescine sodium can delay the degradation of the hyaluronic acid by the hyaluronidase, thereby the curative effect is remarkably delayed and improved, and the occurrence of complications is reduced.

Owner:INST OF BIOPHARM OF SHANDONG PROVINCE

Preparation method for sodium aescinate

InactiveCN107759656ASolving Solubility ConundrumsReduce usageSugar derivativesSteroidsOxalateCacodylic acid

The invention provides a preparation method for sodium aescinate. The sodium aescinate is prepared from Semen Aesculi through crushing, extraction, separation and purification. The preparation methodis characterized in that in the step of separation, the crude extract of Semen Aesculi is added into a saturated aqueous oxalic acid solution; then chloroform is used for extraction; and obtained chloroform extract is added into a cation exchange resin column treated with a sodium hydroxide solution so as to prepare sodium aescinate. The method provided by the invention is high in overall yield, low in solvent consumption and beneficial for treatment of waste gas, waste water and industrial residues.

Owner:黑龙江迪龙制药有限公司

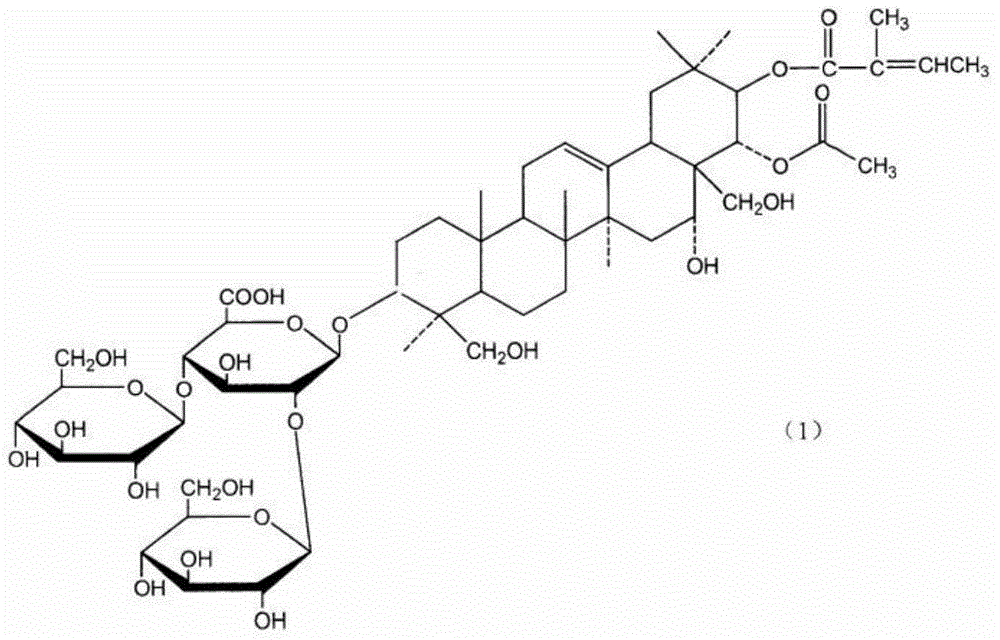

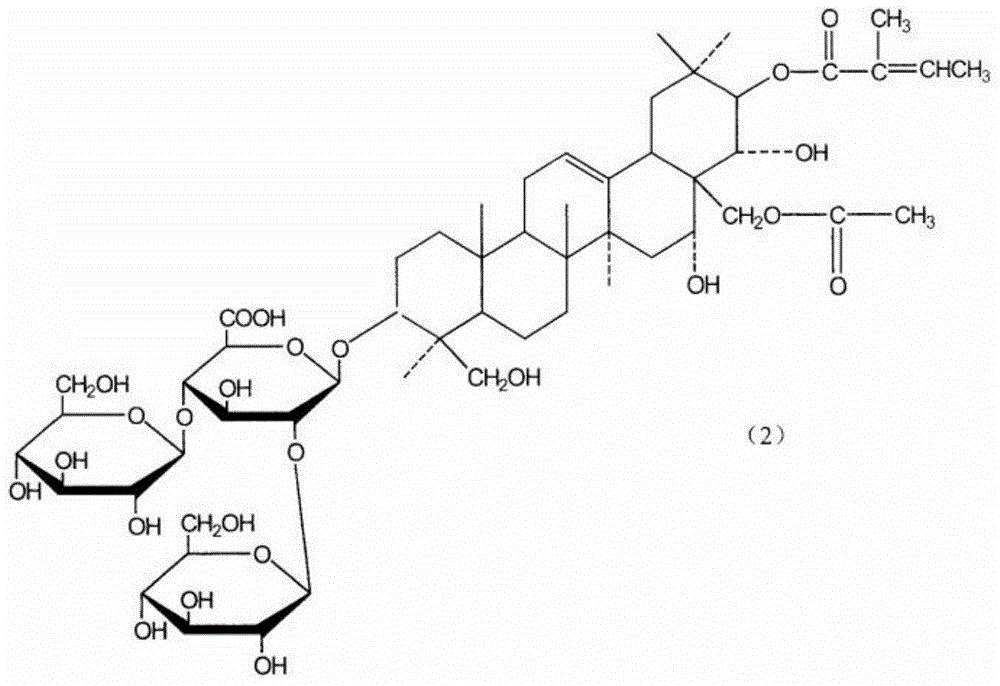

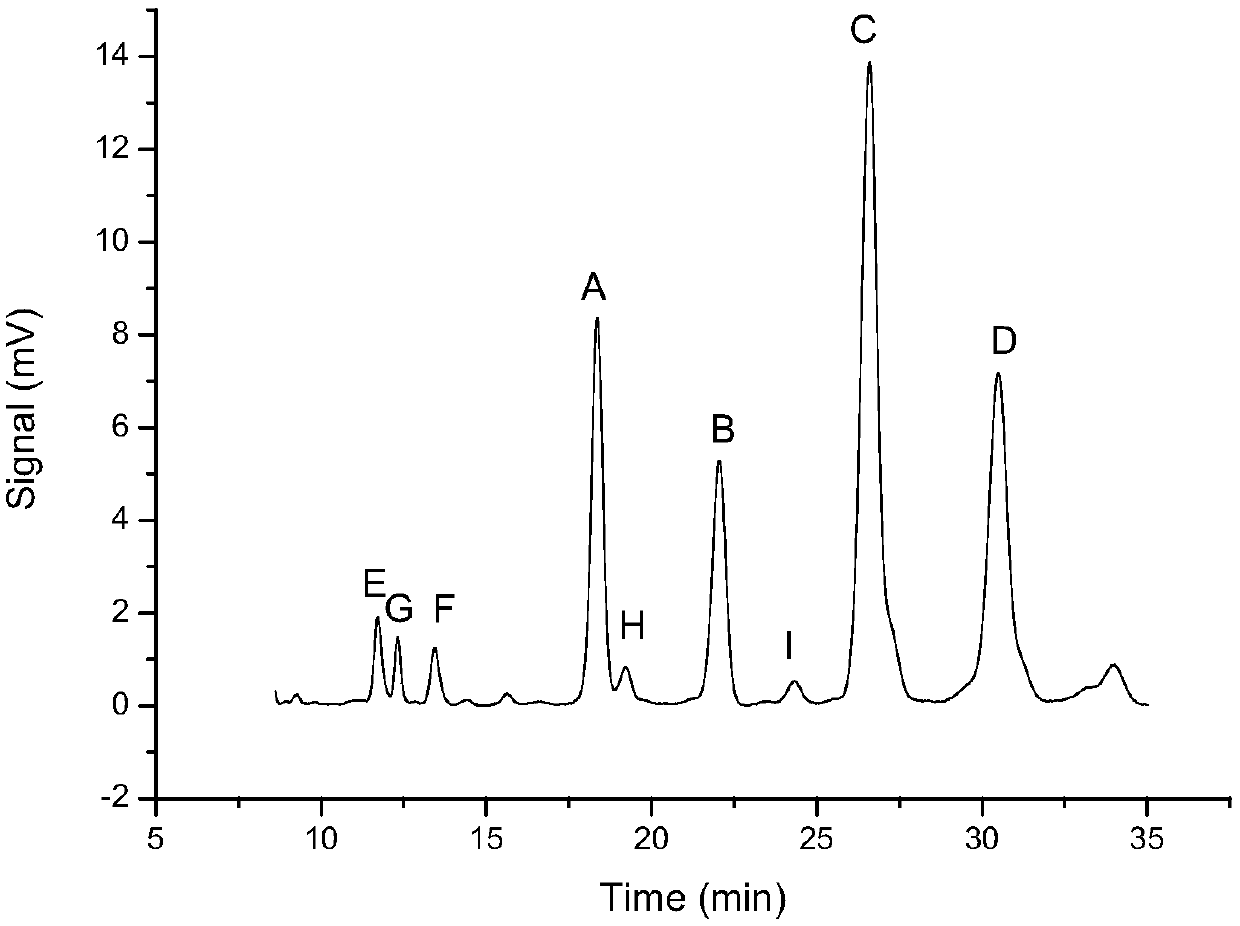

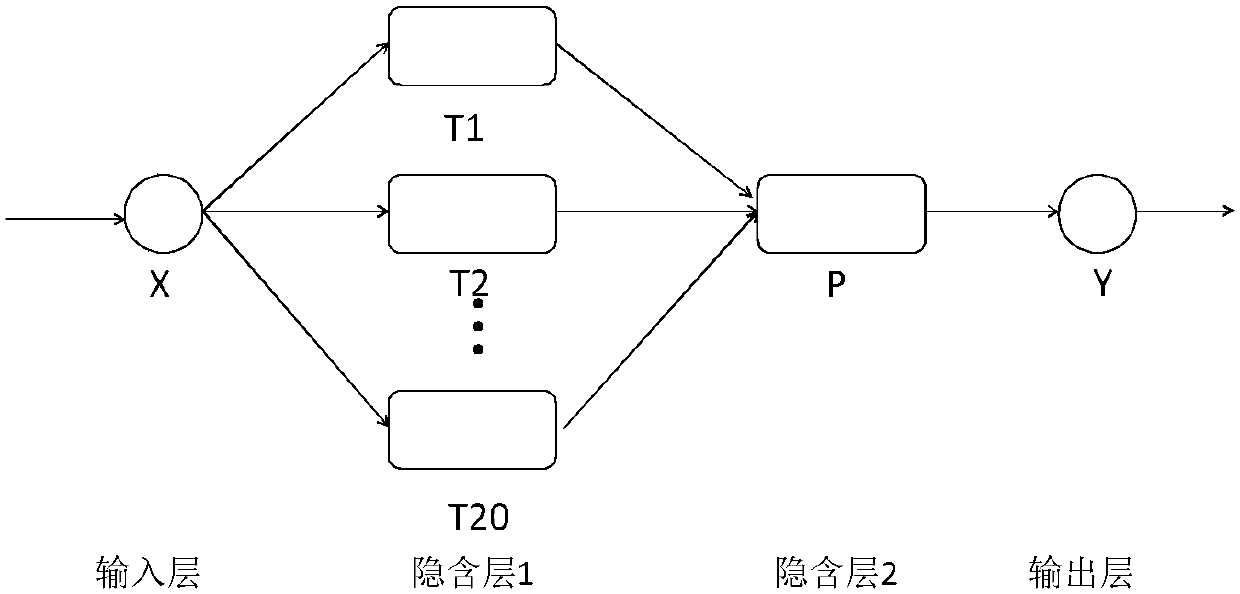

Component proportions and screening method of chemical components of sodium aescinate

InactiveCN108226347ALess irritatingGood stimulationComponent separationColor/spectral properties measurementsPharmacyGrey correlation analysis

The invention relates to component proportions and a screening method of chemical components of sodium aescinate and relates to the field of pharmacy. The screening method comprises the following steps: obtaining sodium aescinate samples with different component proportions; performing detection to obtain a chemical fingerprint chromatogram of the samples, the dosage of the samples to test bodiesas well as corresponding irritation test data and pharmacodynamic test data; performing grey correlation analysis to obtain a first analytic result of an irritation sequence and a pharmacodynamic sequence of all components of the sodium aescinate; constructing a neural network by taking the dosage as an input layer and taking the irritation test data and the pharmacodynamic test data which are subjected to normalized weighting treatment as an output layer; predicting all components of the sodium aescinate by using the trained neural network, and then, performing comparison with the first analytic result; and performing screening and verification. The component proportions and the screening method provided by the invention have the advantages that the screening is fast and effective, the screening time is effectively shortened, the screening cost is lowered, sodium aescinate chemical components with low irritation and good pharmacodynamic effects are obtained, and medicinal effects andclinical compliance are improved.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Method for preparing aescin of Chinese buckeye seeds

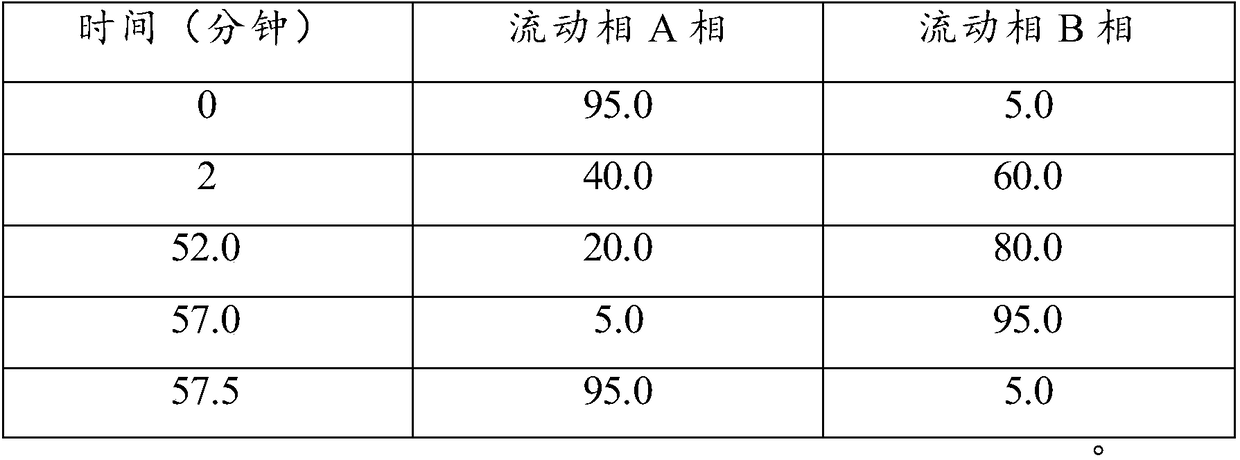

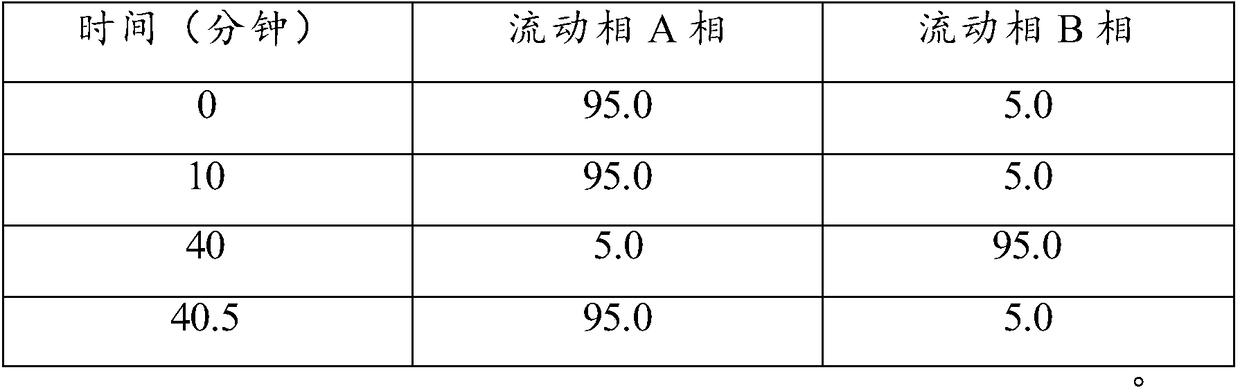

ActiveCN106589045AHigh purityEfficient removalSugar derivativesSteroidsActivated carbonGradient elution

The invention discloses a method for preparing aescin of Chinese buckeye seeds and a method for preparing sodium aescinate. The method for preparing aescin of Chinese buckeye seeds comprises the following steps: (1) extracting the Chinese buckeye seeds by adopting a 10-70vol% ethanol solution as a solvent, so as to obtain an extract; (2) preparing the extract into a fed sample, feeding the sample onto a reverse-phase chromatographic column, performing gradient elution by using a 8-25vol% ethanol solution and a 35-80vol% ethanol solution in sequence, and collecting the 35-80vol% ethanol solution, thereby obtaining an eluant. By adopting the method disclosed by the invention, impurities can be effectively removed, meanwhile the loss amount of aescin components is small, and in addition, decoloring can be achieved without additional activated carbon decoloring operation.

Owner:BEIJING UNIV OF CHINESE MEDICINE

Notoginsenoside sodium freezing-dried emulsion and preparation method thereof

InactiveCN101084911BLess irritatingImprove toleranceOrganic active ingredientsAntipyreticAdjuvantFreeze-drying

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

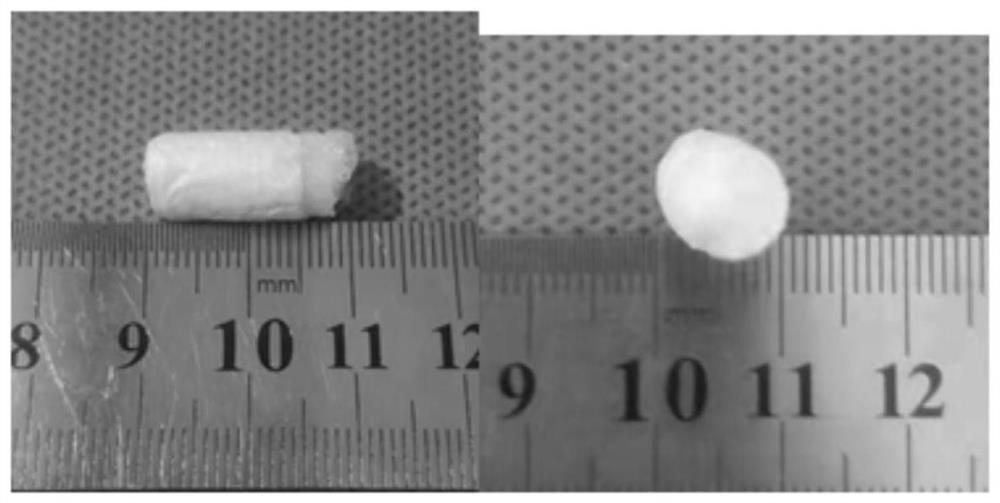

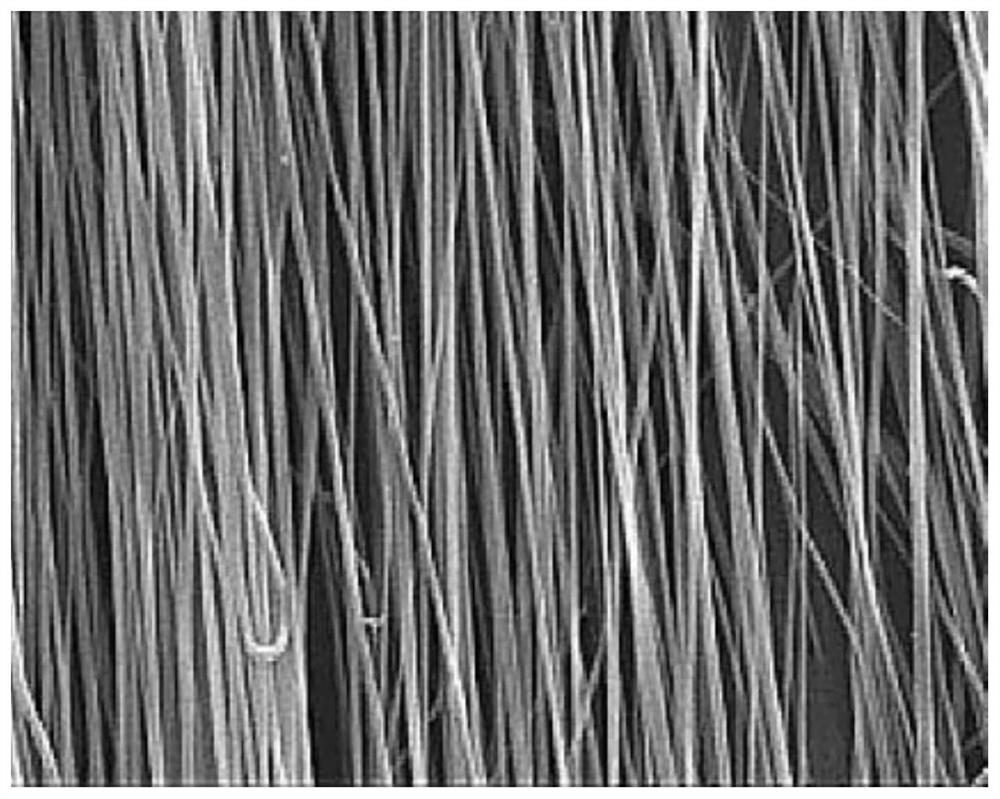

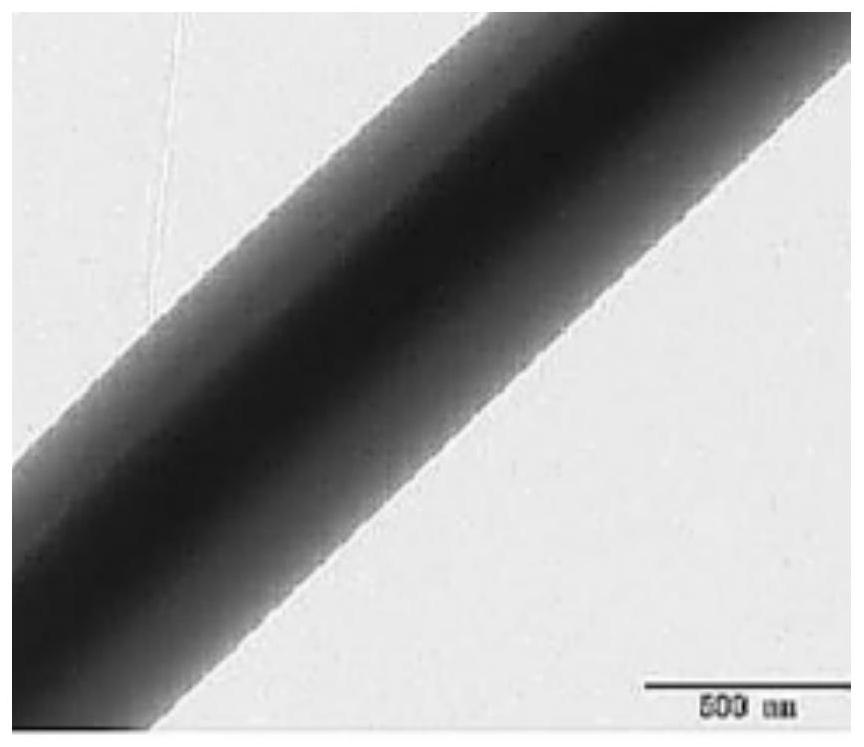

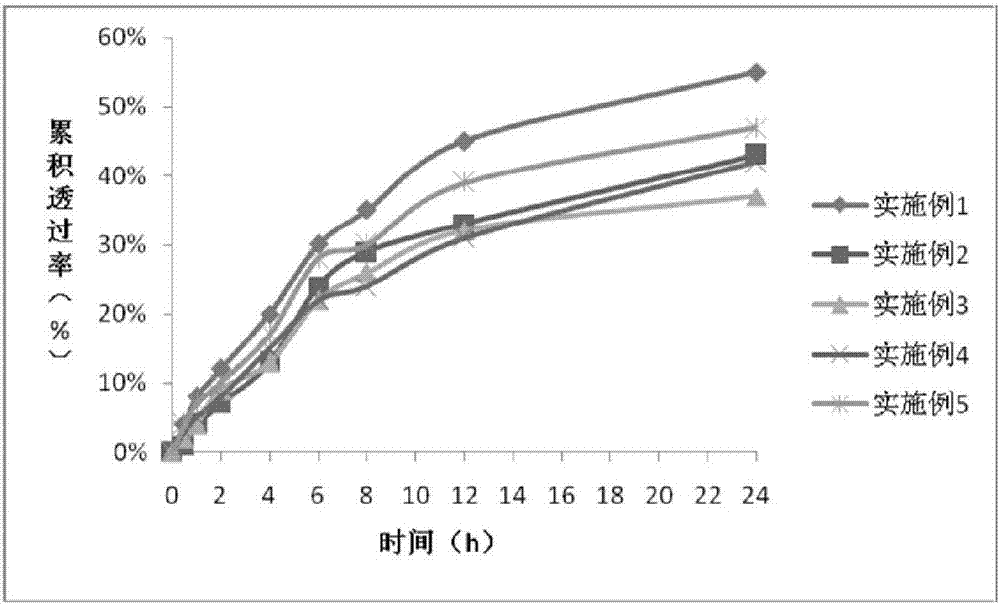

Double-drug-loaded nanofiber hydrogel composite cartilage repair system and preparation method thereof

ActiveCN113941033AImprove repair effectGood biocompatibilityConjugated cellulose/protein artificial filamentsPharmaceutical delivery mechanismCelluloseFiber

The invention discloses a double-drug-loaded nanofiber hydrogel composite cartilage repair system. Kartogenin-loaded coaxial nanofibers are used as a skeleton, and gaps of the skeleton are filled with sodium aescinate-loaded composite hydrogel, so that an elastic cylinder is finally formed, wherein the coaxial nanofibers consist of a core layer and a shell layer, the core layer is polylactic acid, the kartogenin is uniformly dispersed in the polylactic acid, and the shell layer is silk fibroin; the composite hydrogel consists of sodium aescinate, chitosan and oxidized hydroxyethyl cellulose, and the sodium aescinate is uniformly dispersed in the chitosan. The double-drug-loaded nanofiber hydrogel composite cartilage repair system has excellent biocompatibility and mechanical properties, a coaxial fiber membrane can provide correct guidance for cartilage regeneration, and meanwhile, double-drug-loaded gradient release can promote cartilage repair in different stages, so that the quality of cartilage repair is guaranteed.

Owner:湖北华旭达药业有限公司

Detumescence and analgesia compound preparation containing sodium aescinate and preparation method thereof

InactiveCN112546083AHigh encapsulation efficiencyPromote transdermal absorptionHydroxy compound active ingredientsAntipyreticAllergyPhospholipid

The invention relates to a detumescence and analgesia compound preparation containing sodium aescinate and a preparation method thereof, and belongs to the technical field of pharmacy. In order to solve the problems that the dosage form of sodium aescinate can easily cause adverse reactions, the preparation method of sodium aescinate liposome is provided. The sodium aescinate is encapsulated in phospholipid membranes to relieve the stimulation generated when the sodium aescinate directly enters blood vessels, so that phenomenon such as swelling and pain and allergy can be reduced. In the compound preparation, the sodium aescinate liposome is compounded with menthol and artemisia argyi leaf oil, so that drug absorption can be promoted, and allergy can be further relieved. A gel preparationis provided and used for realizing detumescence and analgesia after wisdom tooth extraction, and has the effects of antibiosis and antiphlogosis and detumescence and analgesia after compounding honeysuckle flower and a dahurian angelica root extract. A cream preparation is also provided and used for achieving detumescence and analgesia after facial cosmetic surgery, and can have the effect of improving blood circulation and dispersing stasis, maintaining beauty and keeping young and preserving moisture and rejuvenating skins after compounding safflower oil and vitamin E.

Owner:黑龙江迪龙制药有限公司

Aescin gel and preparation method thereof

InactiveCN107157922AGood oil-water partition coefficientGood curative effectOrganic active ingredientsAntipyreticMedicineActive component

The invention discloses aescin gel. Active components of the aescin gel are aescin A and aescin B, the aescin A accounts for 0.3-1.5% of the total weight of the gel, the aescin B accounts for 0.1-0.8% of the total weight of the gel, and the rest gel substrates. The aescin gel is sufficient and rapid in transdermal absorption and short in effect time, and the aescin gel is more controllable in quality, good in stability and low in skin irritation as compared with an external sodium aescinate preparation.

Owner:WUHAN AIMIN PHARMA

Lysine aescin saponin, its preparation and use

A lysine escin, its compound, production and use are disclosed. The compound consists of beta-escin lysine salt, isoescin lysine salt or their mixture and / or the other accepted carriers. It has better anti-inflammatory and anti-exudative performances, better suppressant for brain edema and medicinal safety. It can also improve blood circulation increase venous tension.

Owner:WUHAN AIMIN PHARMA

Sodium aescinate compound lozenge for treating oral ulcer and preparation method thereof

InactiveCN110354136AEffective treatmentPromote meltingOrganic active ingredientsDigestive systemSide effectOral ulcers

The invention belongs to the technical field of medicine, and particularly relates to a sodium aescinate compound lozenge for treating oral ulcer and a preparation method thereof. The compound lozengeis composed of the following raw materials in parts by weight: 5-20 parts of sodium aescinate, 210-40 parts of vitamin B, 2-15 parts of a sweetener, 2-15 parts of flavor, 5-20 parts of a food binder,1 to 6 parts of borneol, and 1 to 6 parts of mannitol. The preparation method comprises the following steps: grinding the raw materials into fine powder and directly pressing the tablets by a powdertableting method. The compound lozenge has anti-inflammatory, detumescence, and anti-exudation functions, promotes the dissolution and absorption of the hematoma, and promotes the effect of oral cellregeneration. Compared with the prior art, the oral ulcer can be treated quickly and effectively, and the active ingredient is derived from the natural extract, and the side effects are small.

Owner:武汉长联来福制药股份有限公司

Application of sodium aescinate in preparation of spasmolysis medicines for treating gastrointestinal smooth muscle spasm

InactiveCN106727761AGood treatment effectLittle side effectsDigestive systemPlant ingredientsDiseaseSide effect

The invention discloses novel pharmaceutical application of sodium aescinate and in particular discloses application of sodium aescinate in preparation of spasmolysis medicines for treating gastrointestinal smooth muscle spasm. The sodium aescinate has an obvious tension reduction effect on gastric tissue spasm caused by acetyl choline and can be used for treatment of diseases caused by gastrointestinal smooth muscle spasm such as acute gastroenteritis, colonitis, peptic ulcer, acute intestinal obstruction and the like. The clinical tests prove that the sodium aescinate has an obvious effect of treating gastric and intestinal colic caused by smooth muscle spasm, the total effective rate reaches 96.7%, and compared with atropine, the sodium aescinate does not have any obvious curative effect difference while is small in side effects.

Owner:WUHAN AIMIN PHARMA

Cleansing mousse containing fullerene

InactiveCN108403549AAntioxidantImprove antioxidant capacityCosmetic preparationsToilet preparationsNaringinPuerariae Radix extract

The invention discloses cleansing mousse containing fullerene. The cleansing mousse is prepared from the following raw materials in parts by weight: 1-10 parts of glycerol, 0.5-5 parts of potassium lauryl phosphate, 0.1-0.8 part of xanthan gum, 2-6 parts of sodium lauryl sarcosine, 0.05-0.5 part of citric acid, 0.02-2 parts of EDTA disodium, 0.01-0.1 part of essence, 2-10 parts of fullerene, 0.1-0.5 part of naringin, 0.2-1.0 part of sodium aescinate, 0.5-2 parts of kudzuvine root extract, 0.5-3 parts of malt extract, 2-6 parts of eucommia bark extract and 70-120 parts of water. The main activecomponents of the cleansing mousse disclosed by the invention include the fullerene, the naringin, the sodium aescinate, the kudzuvine root extract, the malt extract and the eucommia bark extract; and the traditional Chinese medicine extracts, including the kudzuvine root extract, the malt extract and the eucommia bark extract, which are extracted by a new process are used together with the fullerene, the naringin and the sodium aescinate, so that the cleansing mousse has excellent effects of resisting oxidation, controlling oil and removing acnes.

Owner:广州雷诺生物科技有限公司

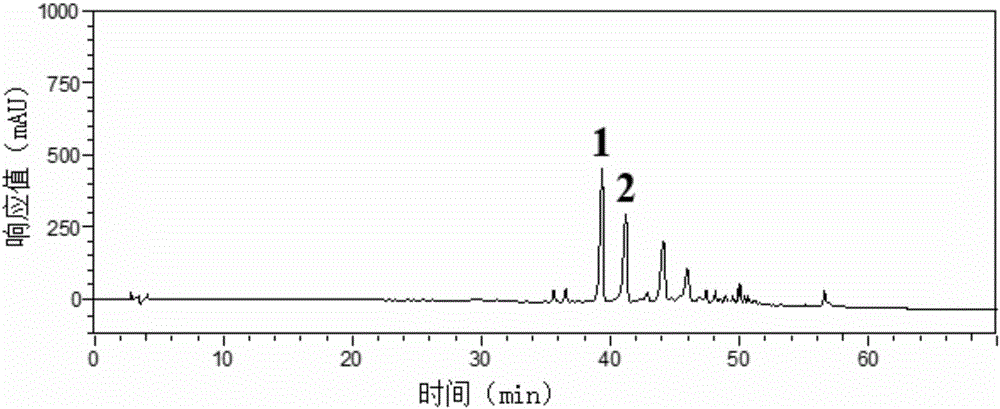

Preparation method of sodium aescinate

ActiveCN108218948AHigh yieldIncrease productivitySugar derivativesSteroidsEthyl acetateTime-Consuming

The invention relates to the technical field of plant extraction and discloses a preparation method of sodium aescinate. The preparation method comprises the following steps: taking semen aesculin foralcohol extraction; extracting an obtained extract with chloroform, dichloromethane or ethyl acetate under acidic conditions; sequentially performing salification, decolorization and acetone precipitation on an obtained coarse product of aescine to obtain a coarse product of sodium aescinate; purifying the coarse product of sodium aescinate by a high performance liquid chromatography (HPLC); collecting aescines A, B, C and D; combining to obtain a mixture of the aescines; then, continuing to desalt by the HPLC; collecting a purified product of aescine; and salifying to obtain a purified product of sodium aescinate. The preparation method provided by the invention extracts and preliminarily purifies the semen aesculin by an organic solvent, avoids adopting macroporous adsorption resin andother existing time-consuming processes, and performs HPLC deep purification and desalination processes on this basis, so as to integrally achieve the purposes of significantly shortening a purification cycle and increasing a total yield of sodium aescinate and to improve the production efficiency of sodium aescinate.

Owner:GANSU CHANGEE BIO PHARMA

Multifunctional soap

InactiveCN105238593AClean thoroughlyAchieve healingSoap detergents with organic compounding agentsSoap detergents with inorganic compounding agentsLanolinBeta-Escin

Disclosed multifunctional soap concretely comprises the following materials in percent: 65%-75% of sodium dodecyl sulfate, 10%-15% of lanolin, 2%-5% of essential balm, 3%-5% of rosin, 3%-4% of sodium silicate, 1%-2% of boric acid, and 5%-10% of beta-aescine sodium. Through the above material ratio, the multifunctional soap is capable of simultaneously realizing body surface cleaning, inhibiting rhinitis, treating body odour and hemorrhoid, and keeping health, in other words, the multifunctional soap possesses the characteristics of multiple functions.

Owner:符思哲

Plaster for promoting blood circulation for removing stasis

InactiveCN108938858ASafe and convenient for external applicationNo side effectsHydroxy compound active ingredientsAntipyreticSalvia miltiorrhizaSide effect

The invention discloses a plaster for promoting blood circulation for removing stasis. The plaster comprises the following raw materials: pseudo-ginseng, ligusticum chuanxiong hort, safflower carthamus, salvia miltiorrhiza, olibanum, angelica sinensis, leonurus, raw cattail pollen, borneol, litsea cubeba oil, fructus forsythiae oil, rhizoma acori graminei oil, pollen extractive, sodium aescinate,albiflorin std and gypsum. According to the traditional Chinese medicine theoretical formula, all the herbal medicines are synergic and coordinated with each other; the plaster has the effects of supporting the healthy energy, removing cold and wet, warming meridians and dredging collaterals, promoting circulation to remove stasis and stopping pain; the plaster is externally applied, is safe and convenient and is free from toxic side effect; compared with the prior art, the plaster for promoting blood circulation for removing stasis disclosed by the invention has the advantages that the activeingredients can quickly permeate into skin for absorption and the effects of promoting blood circulation for removing stasis and relieving swelling and pain can be achieved; the skin environment canbe improved; the pores can be dredged; the skin barrier function can be improved; the damaged skin can be repaired; the plaster has the effects of resisting against oxidization and removing free radicals.

Owner:东莞权利得工业设计有限公司

A kind of preparation method of sodium aescinate

Disclosed is a method for preparing sodium aescinate, relating to the technical field of plant extraction. The method comprises: semen aesculi is taken and subjected to alcohol extraction, the resulting extracting solution is subjected to extraction with chloroform, dichloromethane or ethyl acetate under acidic conditions, and the resulting aescine crude product is successively subjected to salifying, decoloring and acetone precipitation to obtain a sodium aescinate crude product: the sodium aescinate crude product is purified by high-performance liquid chromatography, aescine A, B, C and D are collected and combined to obtain an aescine mixture, wherein same is then further desalinized by high-performance liquid chromatography, and the aescine pure product is collected and salified to obtain the sodium aescinate pure product. The semen aesculi is subjected to extraction and primary purification by an organic solvent, the use of the existing long-lasting processes, such as using macroporous adsorption resins, is avoided, and HPLC deep purification and desalinization steps are carried out on this basis, thereby generally achieving the purpose of significantly shortening the purification cycle and improving the total yield of sodium aescinate, and thus improving the production efficiency of sodium aescinate.

Owner:GANSU CHANGEE BIO PHARMA

A method for preparing sodium aescinate by extracting sorghum seeds

Owner:SHANGHAI JAKA BIOTECH CO LTD

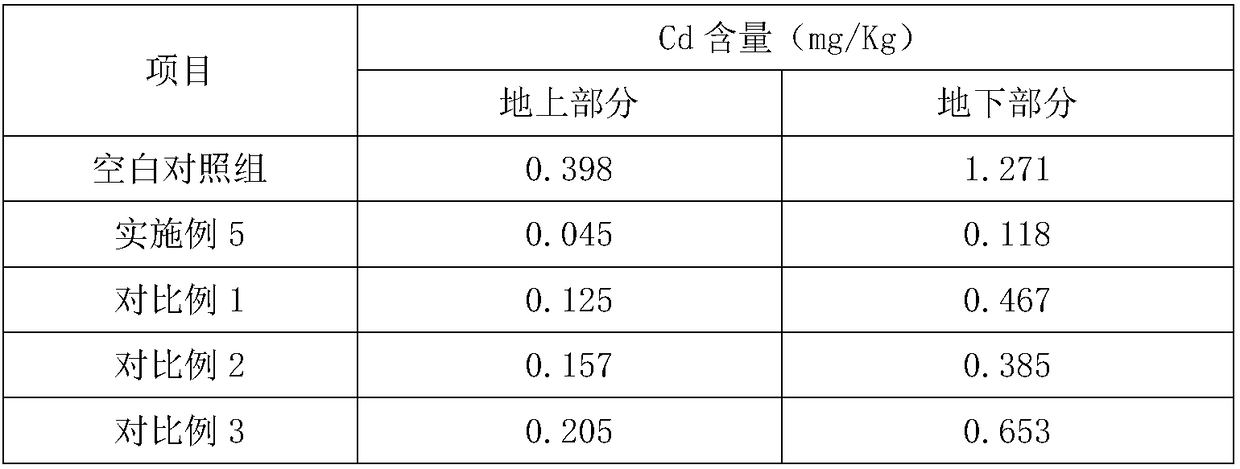

Heavy metal adsorbent and preparation method and application thereof

InactiveCN108176367AReduce contentEasy to handleOther chemical processesWater contaminantsSorbentCadmium Cation

The invention discloses a heavy metal adsorbent and a preparation method and an application thereof. The heavy metal adsorbent comprises the following raw materials in parts by weight: 6-17 parts of flake graphene, 8-15 parts of sodium aescinate, 7-11 parts of sodium benzoate, 6-10 parts of dioctyl dibutyrate sodium sulfonate, 8-12 parts of zinc methionine, 4-11 parts of phloroglucinol, 5-10 partsof hydrated magnesium silicate micropowder, and 4-8 parts of tree ash. The heavy metal adsorbent can effectively process the heavy metal sewage, can reduce content of cadmium in a plant overground part and a underground part for soil restoration, has the advantages of good adsorption effect, less raw material, and low preparation technology, is in favor of realizing industrial production, and hasa wide application scope and good market promotional value.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com