Preparation method of sodium aescinate

A technology of sodium aescinate and aescin, which is applied in the field of preparation of sodium aescinate, can solve the problems of long time consumption, low total yield, and restrictions on the production efficiency of sodium aescinate, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

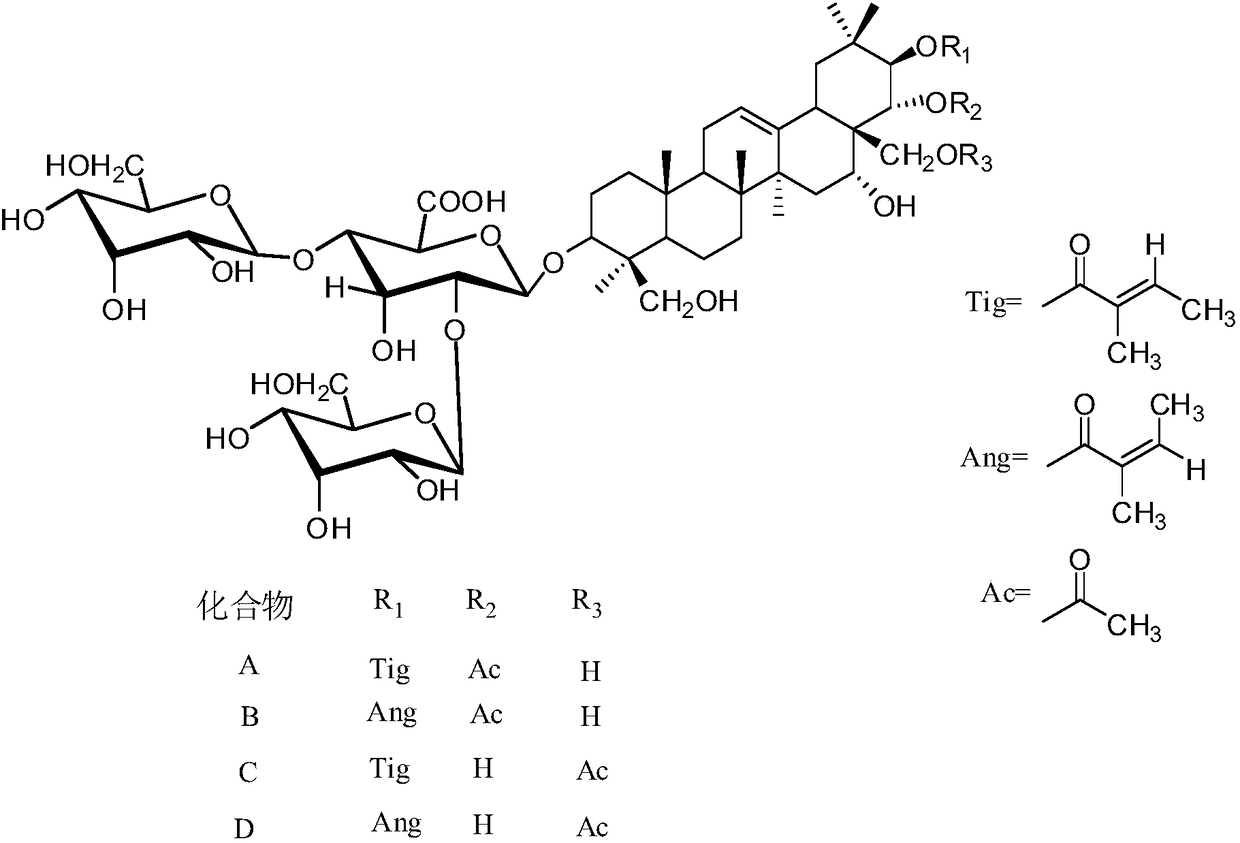

Method used

Image

Examples

Embodiment 1

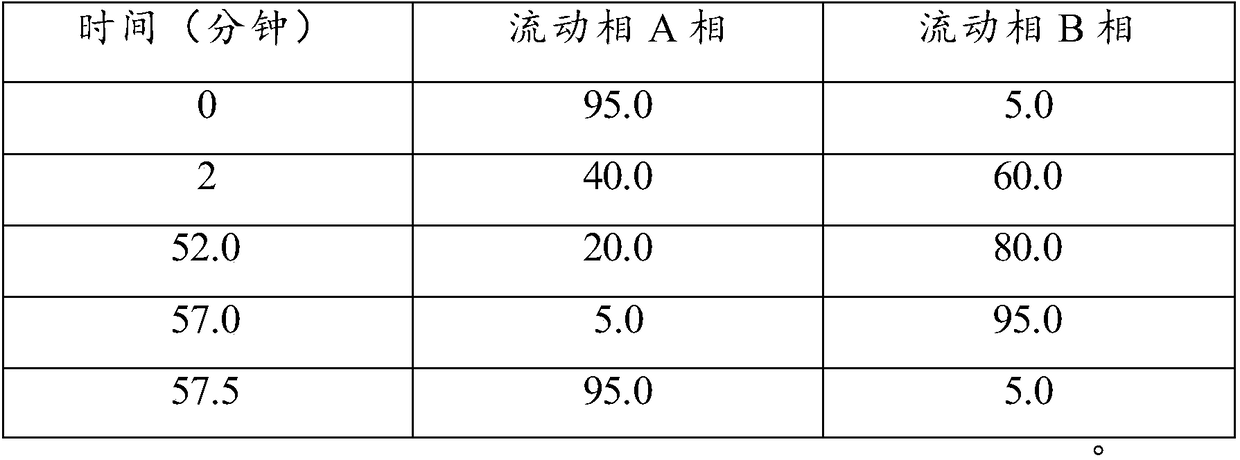

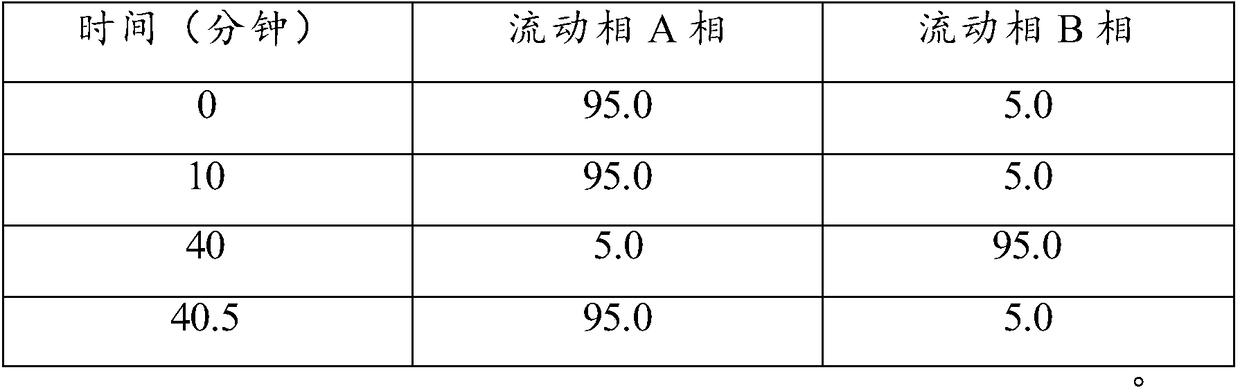

[0037] Embodiment 1: preparation method of the present invention

[0038] Preliminary purification: Weigh 1.0kg of sala seeds, add 4.0L of 50% by volume methanol solution, stir at room temperature for 12 hours, filter, add the filter residue to 2.0L of 50% by volume methanol solution, stir at room temperature for 6 hours, and filter Repeat the above operation once, combine the filtrate, concentrate under reduced pressure until the solution produces foam, adjust the pH to about 3 with a saturated oxalic acid solution, add 300ml of chloroform dropwise, a large amount of solid is produced, and centrifugally filter to obtain the crude aescin solid, to which 100ml of water is added , adjust the pH to about 6 with 1% sodium hydroxide, then add 60 g of needles to decolorize with activated carbon for 2 hours, filter, and concentrate the filtrate to about 100 ml under reduced pressure, drop the solution into 1 L of acetone, centrifugally filter, and vacuum dry to obtain aescin Sodium C...

Embodiment 2

[0042] Embodiment 2: preparation method of the present invention

[0043] Preliminary purification: Weigh 1.0kg of sala seeds, add 4.0L of 80% by volume methanol solution, stir at room temperature for 12 hours, filter, add the filter residue to 2.0L of 80% by volume methanol solution, stir at room temperature for 6 hours, and filter Repeat the above operation once, combine the filtrates, concentrate under reduced pressure until the solution produces foam, adjust the pH to about 4 with saturated citric acid solution, add 300 ml of dichloromethane dropwise, a large amount of solids are produced, and centrifugally filter to obtain aescin. Add 100ml of water to it, adjust the pH to about 5 with 1% sodium hydroxide, then add 80g of needles to decolorize with activated carbon for 6 hours, filter, and concentrate the filtrate to about 100ml under reduced pressure, drop the solution into 1L of acetone, centrifugal filter, vacuum Dry to obtain the crude product of sodium aescinate. Am...

Embodiment 3

[0047] Embodiment 3: preparation method of the present invention

[0048] Preliminary purification: Weigh 1.0kg of sala seeds, add 4.0L of 30% by volume methanol solution, stir at room temperature for 12 hours, filter, add the filter residue to 2.0L of 30% by volume methanol solution, stir at room temperature for 6 hours, and filter Repeat the above operation once, combine the filtrates, concentrate under reduced pressure until the solution produces foam, adjust the pH to about 2 with dilute hydrochloric acid, add 300 ml of ethyl acetate dropwise, a large amount of solids are produced, and centrifugally filter to obtain aescin. Add 100ml of water to it, adjust the pH to about 7 with 1% sodium hydroxide, then add 100g of needles to decolorize with activated carbon for 4 hours, filter, concentrate the filtrate under reduced pressure to about 100ml, drop the solution into acetone, filter, and dry in vacuo to obtain Crude Sodium Aescinate. Among them, the content of sodium aescin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com