Double-drug-loaded nanofiber hydrogel composite cartilage repair system and preparation method thereof

A technology for repairing nanofibers and cartilage, which can be used in pharmaceutical formulations, fiber treatment, cellulose/protein conjugated artificial filaments, etc. It can solve the problems of acidic degradation products, slow degradation rate, and easy to cause inflammation of surrounding tissues. Improve cartilage repair effect, simple preparation method, and favorable adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

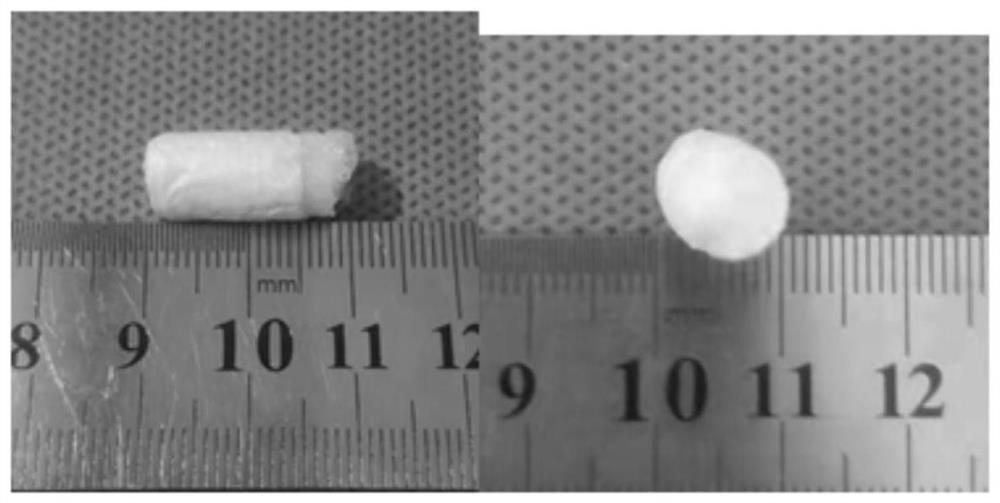

[0041] A double drug-loaded nanofiber hydrogel composite cartilage repair system, the preparation method is as follows:

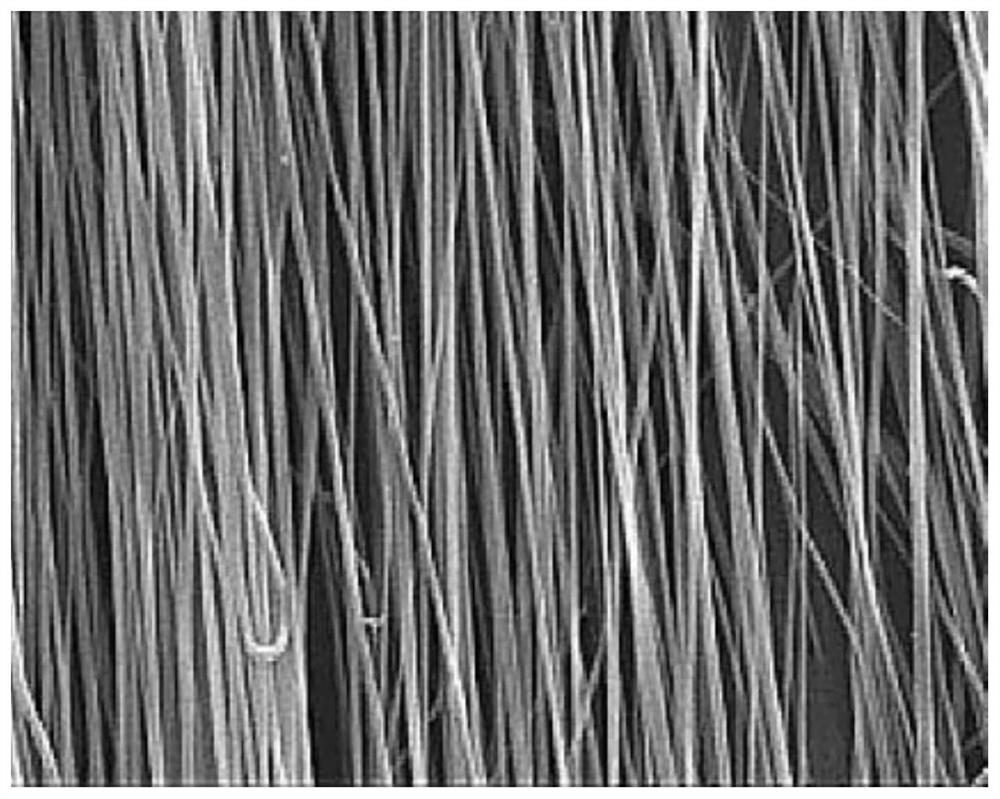

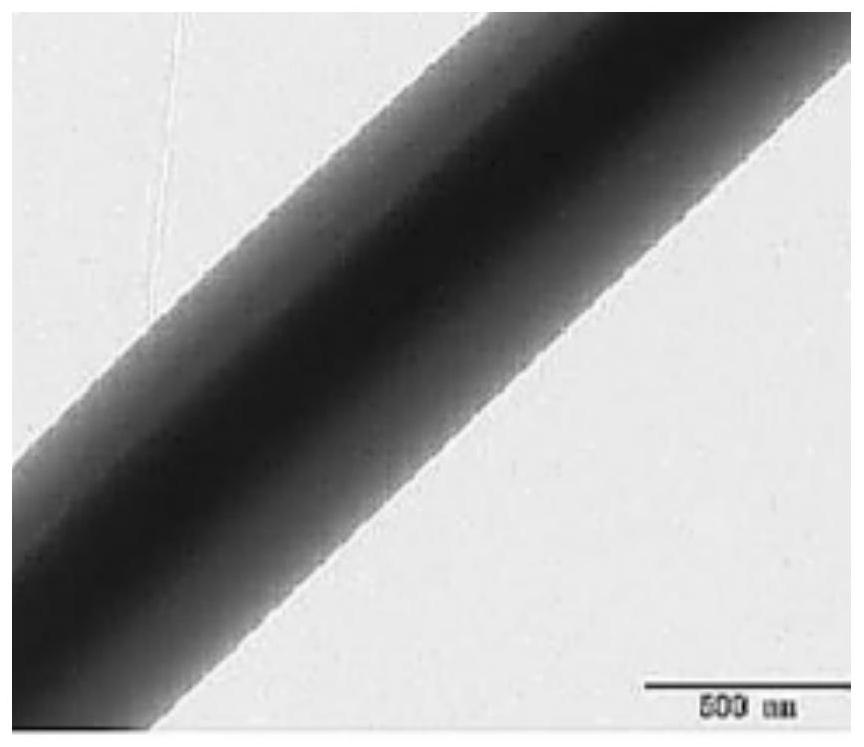

[0042] 1) Preparation of drug-loaded coaxial nanofibers

[0043] Dissolve 1 g of polylactic acid and 0.001 mg of kartogenin powder in 15 mL of dichloromethane as the core spinning solution. Dissolve 0.5g of silk fibroin in 16g of hexafluoroisopropanol as the shell spinning solution. Put the core layer solution and the shell layer solution in 5mL disposable syringes respectively. After connecting the coaxial experimental device, set the core layer solution to be pushed out at a speed of 0.15mm / min, and the shell layer spinning solution to be pushed out at a speed of 0.15mm / min. , the voltage between the coaxial needle tube and the receiving plate is 11KV, the receiving distance is 6cm, the ambient temperature is 25°C, and the relative humidity is 30%. Coaxial electrospinning is carried out to obtain drug-loaded coaxial nanofibers, which are recorded as poly...

Embodiment 2

[0053] A double drug-loaded nanofiber hydrogel composite cartilage repair system, the preparation method is as follows:

[0054] 1) Preparation of drug-loaded coaxial drug-loaded nanofibers

[0055] Dissolve 1 g of polylactic acid and 0.01 mg of kartogenin powder in 15 mL of dichloromethane as the core spinning solution. 1g of silk fibroin was dissolved in 32g of hexafluoroisopropanol as the shell spinning solution. Put the core layer solution and the shell layer solution in 5mL disposable syringes respectively. After connecting the coaxial experimental device, set the core layer solution to be pushed out at a speed of 0.1mm / min, and the shell layer spinning solution to be pushed out at a speed of 0.2mm / min. , the voltage between the coaxial needle tube and the receiving plate is 11KV, the receiving distance is 8cm, the ambient temperature is 25°C, and the relative humidity is 30%. Coaxial electrospinning is carried out to obtain drug-loaded coaxial nanofibers.

[0056] 2) P...

Embodiment 3

[0061] This example is basically the same as Example 1, except that the amount of oxidized hydroxyethyl cellulose in step 2) is 0.3 g.

[0062] 1) Preparation of drug-loaded coaxial drug-loaded nanofibers

[0063] Dissolve 1 g of polylactic acid and 0.0005 mg of kartogenin powder in 15 mL of dichloromethane as the core spinning solution. Dissolve 0.3g of silk fibroin in 16g of hexafluoroisopropanol as the shell spinning solution. Put the core layer solution and the shell layer solution in 5mL disposable syringes respectively. After connecting the coaxial experimental device, set the core layer solution to be pushed out at a speed of 0.1mm / min, and the shell layer spinning solution to be pushed out at a speed of 0.2mm / min. , the voltage between the coaxial needle tube and the receiving plate is 11KV, the receiving distance is 8cm, the ambient temperature is 25°C, and the relative humidity is 30%. Coaxial electrospinning is carried out to obtain drug-loaded coaxial nanofibers, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com