Sodium aescinate preparation method

A technology of sodium aescinate and ethanol solution, which is applied to the preparation of sugar derivatives, chemical instruments and methods, steroids, etc., can solve the problems of limiting clinical application, toxicity of sodium aescinate, etc., and achieve simple process and short production cycle Short, safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

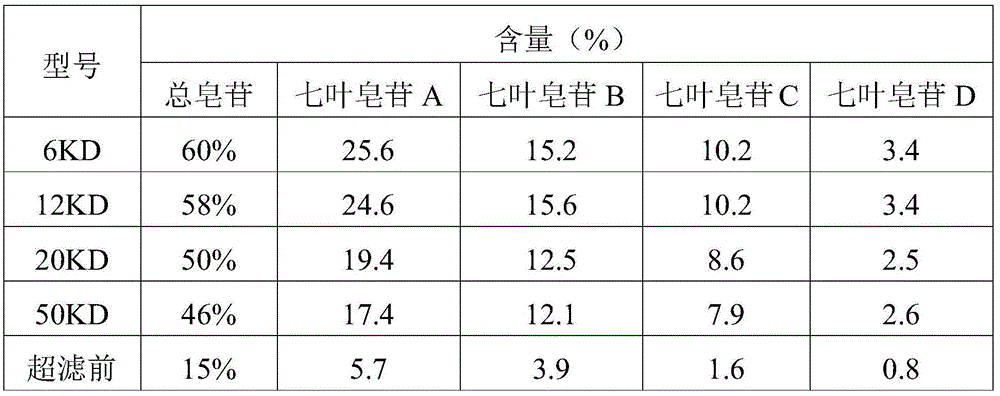

[0028] Embodiment 1 Ultrafiltration process research

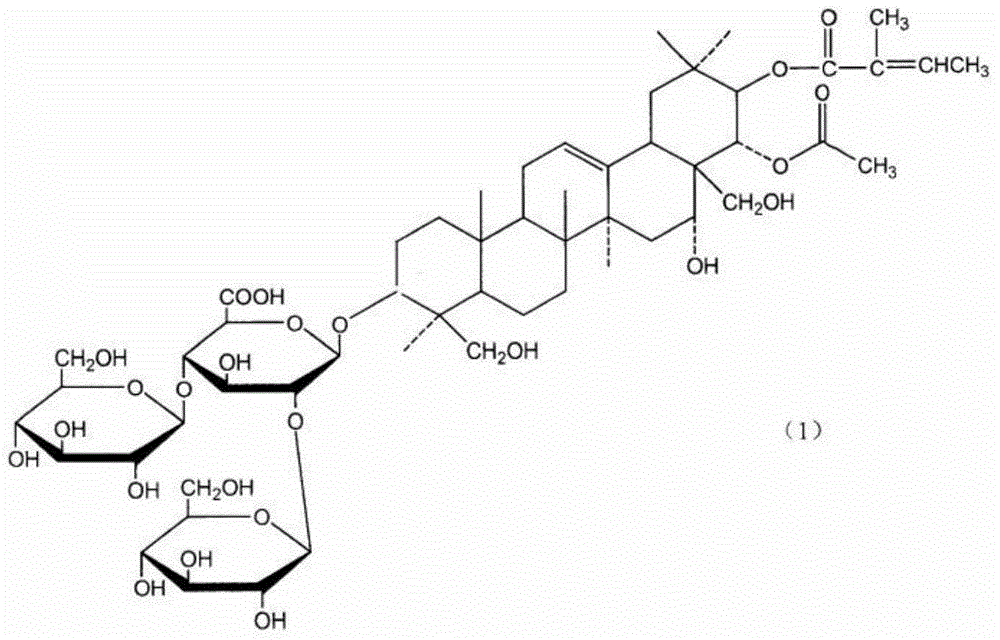

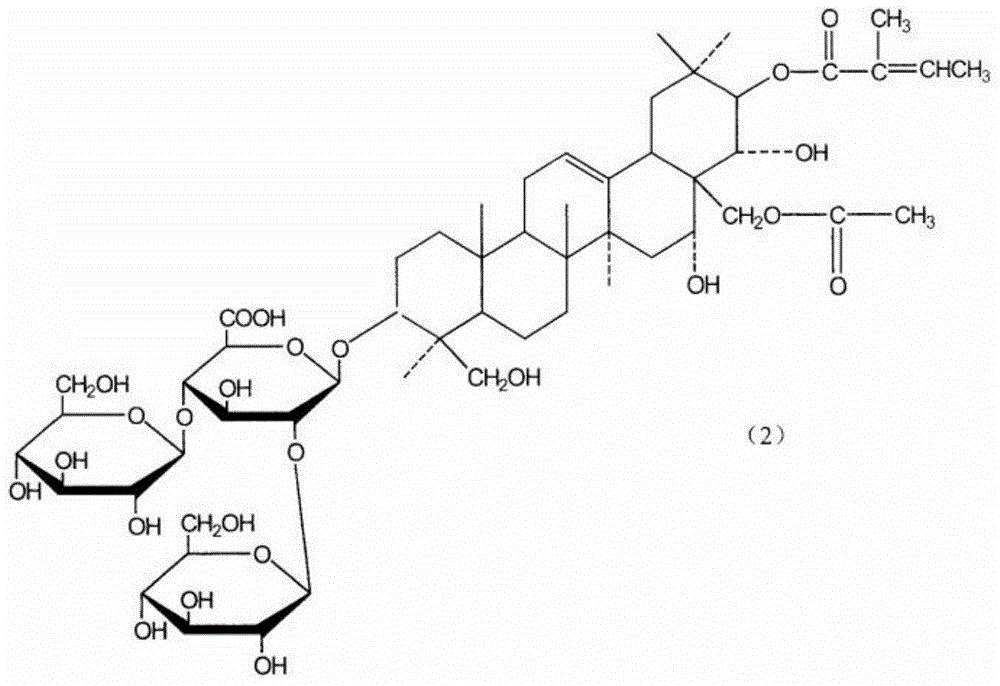

[0029] 1) Aescin sodium A, B, C, D content determination method

[0030] Chromatographic conditions and system suitability: use octadecylsilane bonded silica gel as filler; acetonitrile-phosphoric acid solution (take 5.5ml of 85% phosphoric acid, dilute to 1000ml with water) (33:67) as mobile phase, adjust the pH value to 2.1; The detection wavelength is 220nm. The number of theoretical plates shall not be less than 3500 based on the aescin A peak, and the resolution of the aescin A peak and aescin B peak, as well as the aescin B peak and aescin C peak shall meet the requirements.

[0031] Determination method: Accurately weigh an appropriate amount of aescin reference substance, dissolve and dilute with methanol to make a solution containing 2.5mg per 1ml, as the reference substance solution. Precisely measure 20 μl, inject it into a liquid chromatograph, and record the chromatogram. There are 4 main component peaks in ...

Embodiment 2

[0052] A preparation method of sodium aescinate, the steps are as follows:

[0053] 1) Take 50Kg of Sala seeds, add 200Kg of ethanol solution with a weight concentration of 50% for reflux extraction, the extraction time is 3 hours, and collect the extract;

[0054]2) After high-speed centrifugation and slag removal, the extract is filtered with a polysulfone ultrafiltration membrane with a molecular weight cut-off of 12,000 Daltons, the temperature of the filter is 35°C, the pressure is 0.4MPa, and the pH value of the feed solution is 5.8;

[0055] 3) Recover the ethanol from the filtrate and add 2 times the volume of water to dissolve it, then apply it to the NKA macroporous resin column for adsorption, and use pure water, 30% ethanol solution, and 60% ethanol solution to elute successively, and collect the elution of 60% ethanol solution liquid;

[0056] 4) Recover the collected eluate under reduced pressure until the solvent has no alcohol smell, add 2 times of water to di...

Embodiment 3

[0060] A preparation method of sodium aescinate, the steps are as follows:

[0061] 1) Take 50Kg of Sala seeds, add 150Kg of ethanol solution with a weight concentration of 70% to carry out reflux extraction, the extraction time is 2 hours, and collect the extract;

[0062] 2) After the extract is deslagging by high-speed centrifugation, it is filtered with a polysulfone ultrafiltration membrane with a molecular weight cut-off of 10,000 Daltons, the temperature of the filtration is 40°C, the pressure is 0.3 MPa, and the pH value of the feed solution is 5.0;

[0063] 3) Recover the ethanol from the filtrate and add 1 times the volume of water to dissolve it, then absorb it on a D101 macroporous resin column, elute it with pure water, 20% ethanol solution, and 50% ethanol solution successively, and collect the elution of 50% ethanol solution liquid;

[0064] 4) Recover the collected eluate under reduced pressure until the solvent has no alcohol smell, add 1 times water to disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com