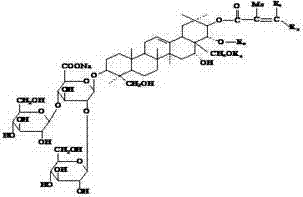

Sodium aescinate toothpaste and preparation method thereof

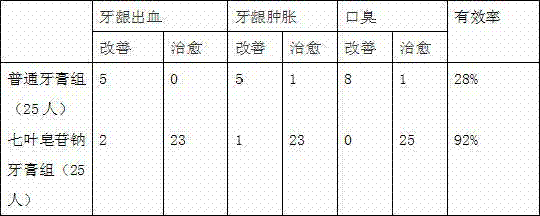

The technology of aescin sodium and toothpaste is applied in the field of daily chemicals, which can solve the problems that have not yet been discovered, and achieve the effects of avoiding adverse reactions, preventing and treating bleeding, and promoting the dissolution and absorption of hematoma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

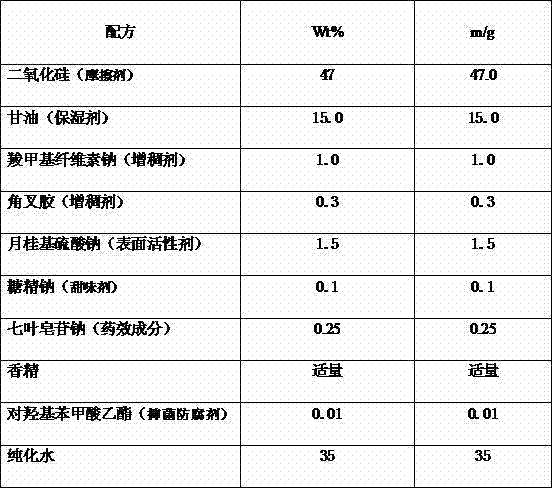

[0022] Embodiment 1: a kind of sodium aescinate toothpaste, calculated in 100g paste, contains the following components:

[0023]

Embodiment 2

[0024] Embodiment 2. Intermittent two-step paste method

[0025] Weigh the materials according to the amount of medicine marked in the formula;

[0026] Put glycerin and sodium carboxymethyl cellulose into the glue pot, moisten and stir, then add dissolved saccharin sodium, refined water and other raw materials, and continue to stir, so that the prepared glue is in a uniform translucent viscous liquid state, and then stored , let it fully melt and expand before use;

[0027] Put all kinds of solid powder raw materials and prepared glue, essence, etc. into the mixing pot according to the formula and operation requirements, and mix them evenly through mechanical mixing to make a paste with certain viscosity and appropriate thickness;

[0028] After the paste is ground by a grinder, the over-coarse and hard particles can be ground to make the paste fine, uniform and stable. The grinding can be divided into two times. The first grinding is stored after the second grinding, and th...

Embodiment 3

[0030] Embodiment 3. dry method one-step paste method

[0031] The medicinal ingredients in the above formula (aescin sodium), glycerin (humectant), sodium carboxymethylcellulose (thickener), carrageenan (thickener), sodium saccharin (sweetener), Ethyl hydroxybenzoate (antibacterial preservative) and purified water are put into the paste making machine and vacuumized. When the pot reaches a certain vacuum degree (-0.096Mpa), silicon dioxide (friction agent) and sodium lauryl sulfate ( Surfactant), homogeneous stirring, homogenization while degassing, after homogenization is completed, add spices, homogeneous degassing for several minutes, to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com