Heavy metal adsorbent and preparation method and application thereof

An adsorbent and heavy metal technology, which is applied in the field of heavy metal adsorbent and its preparation, can solve the problems of poor adsorption effect, complex raw materials, and small application range, and achieve the effect of less raw materials, low preparation process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

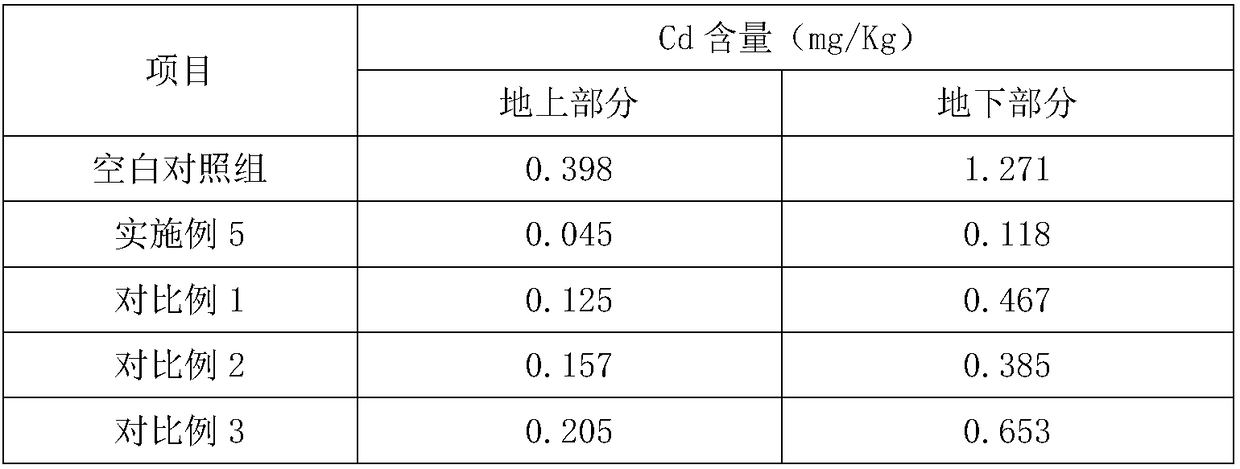

Examples

Embodiment 1

[0019] A heavy metal adsorbent, the heavy metal adsorbent comprises the following raw materials in parts by weight: 6 parts of graphene flakes, 8 parts of sodium aescinate, 7 parts of sodium benzoate, 6 parts of dioctyl sodium dibutyrate, methionine 8 parts of zinc, 4 parts of phloroglucinol, 5 parts of hydrated magnesium silicate superfine powder, and 4 parts of tree ash.

[0020] A preparation method of a heavy metal adsorbent, comprising the following steps: (1) mixing sodium aescinate, sodium benzoate and zinc methionine, adding 40 parts of water, stirring and mixing evenly at 45°C, and the stirring speed is 200r / min; ( 2) Mix the product obtained in the previous step with 15 parts of 75% ethanol, then add dioctyl sodium dibutyrate sulfonate and phloroglucinol, stir and react at 70° C. for 1 hour, and the stirring speed is 125 r / min; ( 3) Mix graphene flakes, hydrated magnesium silicate superfine powder and tree ash evenly and place them at 500° C. for 30 min; grind and si...

Embodiment 2

[0022] A kind of heavy metal adsorbent, described heavy metal adsorbent comprises the raw material of following parts by weight: 17 parts of graphene flakes, 15 parts of sodium aescinate, 11 parts of sodium benzoate, 10 parts of dioctyl sodium dibutyrate sulfonate, methionine 12 parts of zinc, 11 parts of phloroglucinol, 10 parts of hydrated magnesium silicate superfine powder, and 8 parts of tree ash.

[0023] A preparation method of a heavy metal adsorbent, comprising the following steps: (1) mixing sodium aescinate, sodium benzoate and zinc methionine, adding 55 parts of water, stirring and mixing evenly at 60°C, and the stirring speed is 300r / min; ( 2) Mix the product obtained in the previous step with 25 parts of 75% ethanol, then add dioctyl sodium dibutyrate sulfonate and phloroglucinol, stir and react at 85° C. for 3 h, and the stirring speed is 200 r / min; ( 3) Mix graphene flakes, hydrated magnesium silicate superfine powder and tree ash evenly and place them at 800° ...

Embodiment 3

[0025] A heavy metal adsorbent, the heavy metal adsorbent comprises the following raw materials in parts by weight: 12 parts of graphene flakes, 11 parts of sodium aescinate, 10 parts of sodium benzoate, 9 parts of dioctyl sodium dibutyrate sulfonate, methionine 10 parts of zinc, 8 parts of phloroglucinol, 8 parts of hydrated magnesium silicate superfine powder, and 6 parts of tree ash.

[0026] A preparation method of a heavy metal adsorbent, comprising the following steps: (1) mixing sodium aescinate, sodium benzoate and zinc methionine, adding 45 parts of water, stirring and mixing evenly at 50° C., and the stirring speed is 270 r / min. (2) Mix the product obtained in the previous step with 20 parts of 75% ethanol, then add dioctyl sodium dibutyrate sulfonate and phloroglucinol, stir and react at 75° C. for 2 h, and the stirring speed is 180 r / min. (3) Mix graphene flakes, hydrated magnesium silicate superfine powder and tree ash evenly and place them at 700°C for calcinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com