Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185 results about "Siloxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

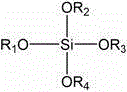

Siloxides are chemical compounds with the formula R₃SiOM, where R is usually an organic group and M is usually a metal cation. Also called silanoates, they are derived by deprotonation of silanols.

Preparation method of hydrophilic block polyether aminosilicone

InactiveCN102617863AThe reaction steps are simpleThe reaction conditions are mild and simpleFibre treatmentEpoxyAcetic acid

The invention discloses a preparation method of hydrophilic block polyether aminosilicone. The method comprises the following steps of: preparing terminal hydrogen-containing silicone oil: mixing hydrogen-containing double end enclosures, polysiloxane and acid, reacting, adding sodium carbonate under a vacuumizing condition, adjusting the pH, filtering a solid out, and extracting a low-boiling-point substance under reduced pressure to obtain low hydrogen-containing silicone oil; preparing epoxy silicone oil: mixing the obtained terminal hydrogen-containing silicone oil with allyl epoxy polyether and a catalyst, and reacting to obtain epoxy silicone oil; and preparing block polyether aminosilicone: and mixing the obtained epoxy silicone oil, polyetheramine, a catalyst and a solvent, reacting, cooling, adding an emulsifier for emulsifying, and adding glacial acetic acid for adjusting the pH to obtain the block polyether aminosilicone. According to the hydrophilic block polyether aminosilicone prepared with the method, the handfeel of a treated fabric can reach the handfeel of ordinary aminosilicone, and the treated fabric can keep a hydrophilic function permanently, is prevented from yellowing, and has high antistatic property.

Owner:GUANGDONG UNIV OF TECH

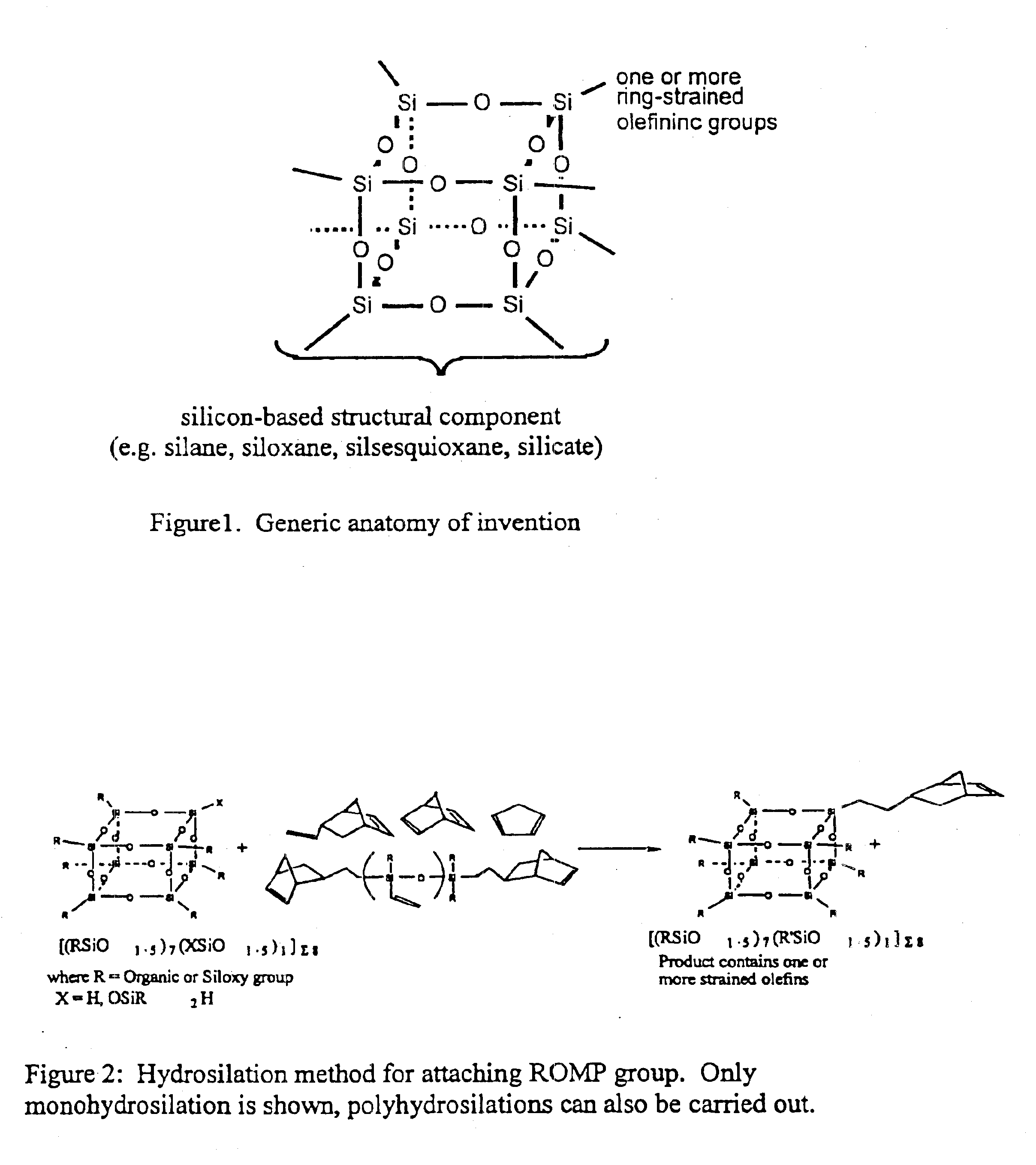

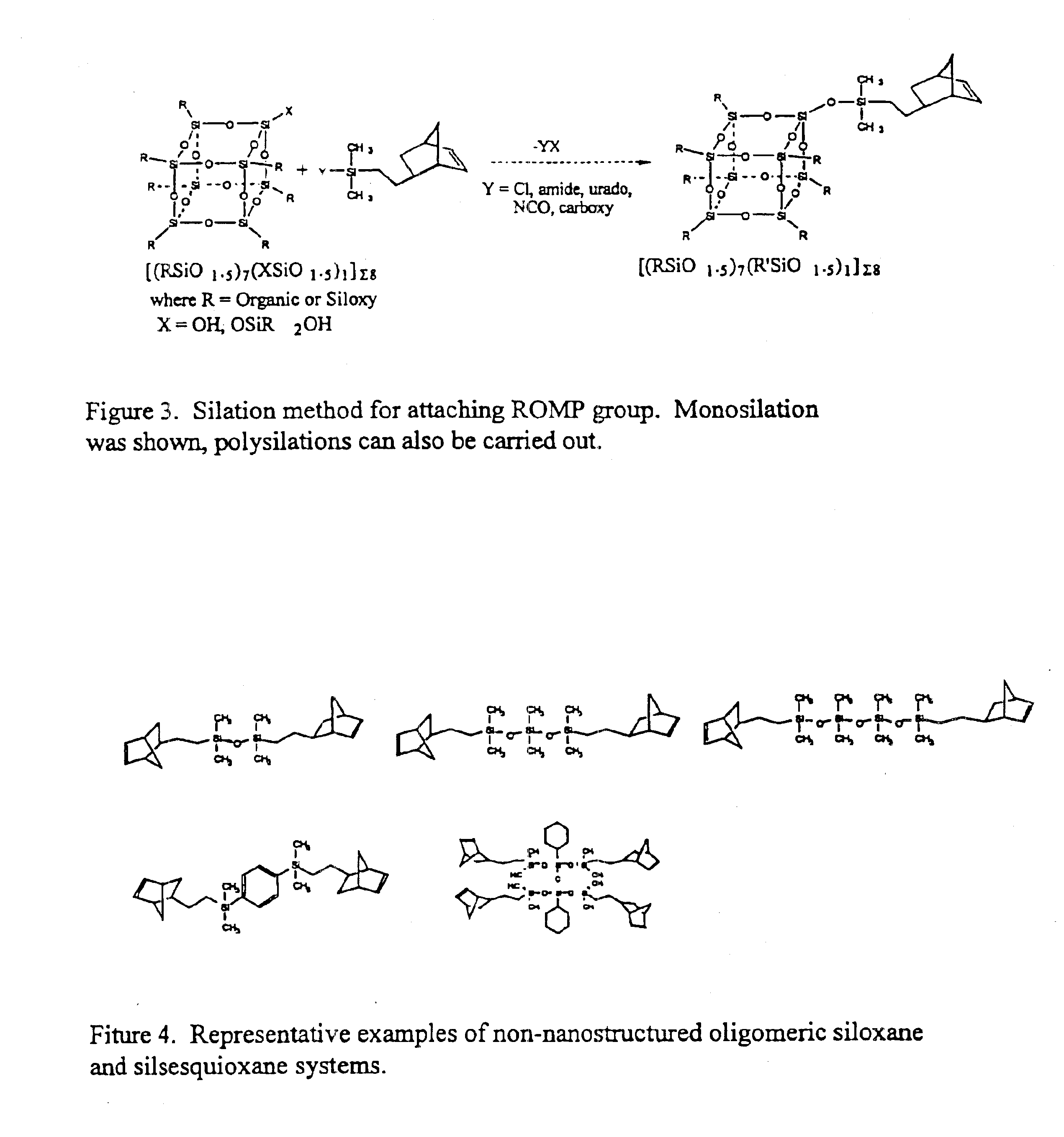

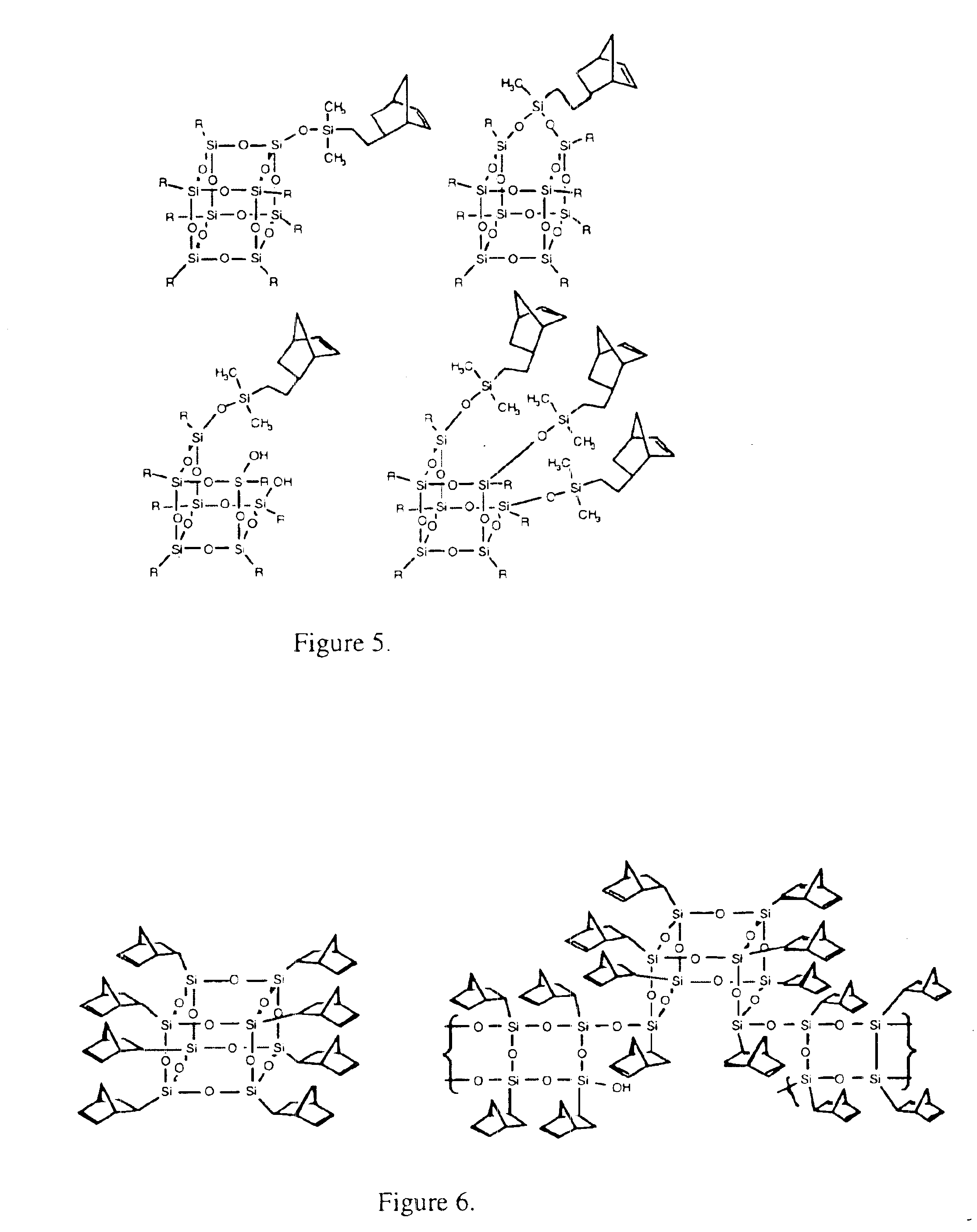

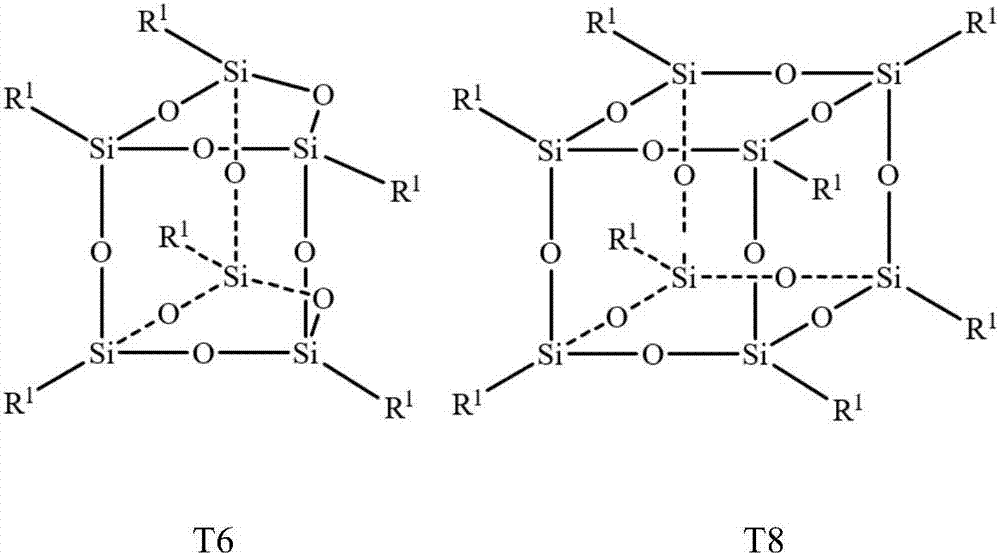

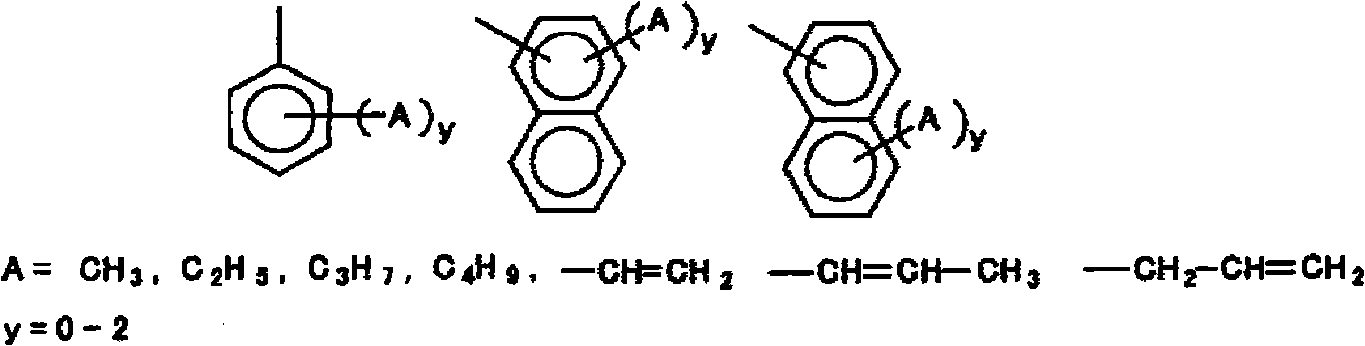

Polyhedral oligomeric -silsesquioxanes, -silicates and -siloxanes bearing ring-strained olefinic functionalities

InactiveUS6911518B2Improving biocompatabilityImprove fire resistanceSilicon organic compoundsGroup 6/16 organic compounds without C-metal linkagesAlkaline earth metalChemical reaction

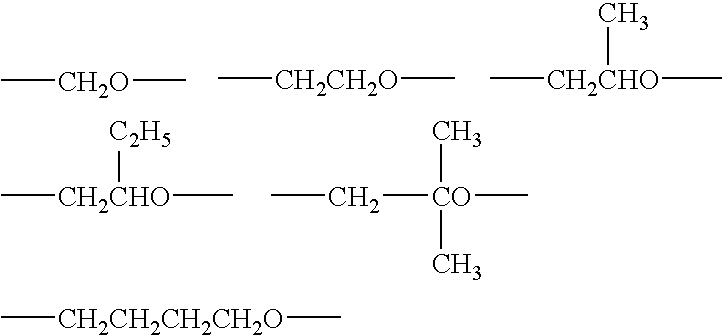

Processes have been developed for the manufacture of polyhedral oligomeric silsesquioxanes (POSS), polysilsesquioxanes, polyhedral oligomeric silicates (POS), and siloxane molecules bearing reactive ring-strained cyclic olefins (e.g. norbornenyl, cyclopentenyl, etc. functionalities). The preferred manufacturing processes employ the silation of siloxides (Si—OA, where A=H, alkaline or alkaline earth metals) with silane reagents that contain at least one reactive ring-strained cyclic olefin functionality [e.g., X3-ySi(CH3)y(CH2)2 where y=1-2 and X=OH, Cl, Br, I, alkoxide OR, acetate OOCR, peroxide OOR, amine NR2, isocyanate NCO, and R]. Alternatively, similar products can be prepared through hydrosilation reactions between silanes containing at least one silicon-hydrogen bond (Si—H) with ring-strained cyclic olefin reagents [e.g., 5-vinyl, 2 norbornene CH2═CH, cyclopentadiene]. The two processes can be effectively practiced using polymeric silsesquioxanes [RSiO1.5]∞ where ∞=1-1,000,000 or higher and which contain unreacted silanol or silane groups at chain terminus or branch points, on POSS nanostructures of formulas [(RSiO1.5)n]Σ#, homoleptic, [(RSiO1.5)m(R′SiO1.5)n]Σ#, heteroleptic, and {(RSiO1.5)m(RXSiO1.0)n}Σ#, functionalized heteroleptic nanostructures, on silanes RSiX3, linear, cyclic, oligomeric and polymeric siloxanes (polymeric formula RX2Si—(OSiRX)m—OSiRX2 where m=0-1000, X=OH, Cl, Br, I, alkoxide OR, acetate OOCR, peroxide OOR, amine NR2, isocyanate NCO, and R). Each of the processes result in new chemical species bearing one or more ring strained olefins that can undergo polymerization, grafting, or other desirable chemical reactions to form polymeric products. These polymeric systems are most desirably utilized in polymerizations for the modification of properties of thermoplastic or thermoset resin systems or for the preparation of polymers with utility in electronics, medical devices, sporting goods, and aerospace as coatings and structural components.

Owner:HYBRID PLASTICS INC

Curing composition with improved heat resistance

The present invention provides a curable composition including: an organic polymer (A) which has on average 1.1 to 50 groups per one molecule thereof each represented by the general formula (1) and has one or more silicon-containing functional groups capable of cross-linking by forming siloxane bonds: —NR1—C(═O)— (1) wherein R1 is a hydrogen atom, or a substituted or unsubstituted monovalent organic group; and a metal carboxylate and / or a carboxylic acid (B), the curable composition giving a cured article excellent in curability and also excellent in heat resistance although a non-organotin catalyst is used.

Owner:KANEKA CORP

Use of high-purity phenylsilsesquioxane liquids for the preparation of cosmetic and pharmaceutical compositions

InactiveUS20030077240A1Feel goodBroaden applicationCosmetic preparationsSilicon organic compoundsSilanolOrganic compound

Owner:CLARIANT INT LTD

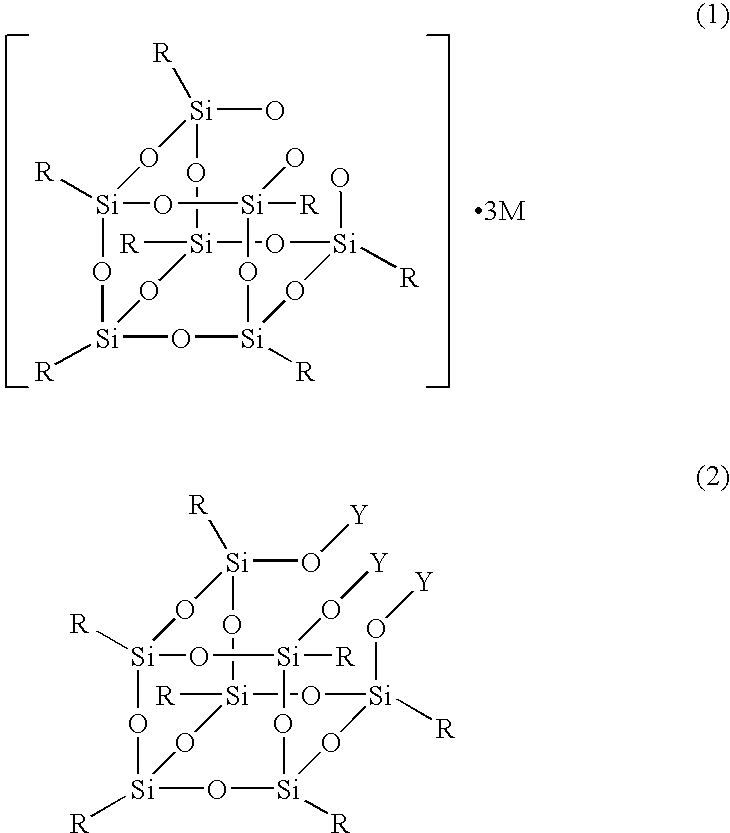

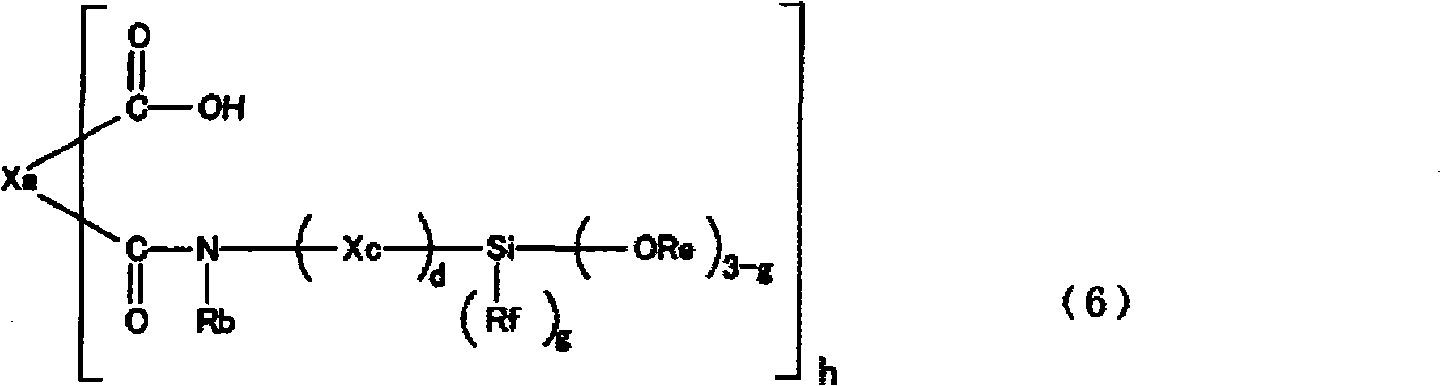

Production process for silsesquioxane derivative having functional group and silsesquioxane derivative

A conventional silsesquioxane derivative has the problems that the functional groups are restricted and the chemical structure is not readily controlled and that it is expensive. The present inventors have developed a process for producing a silsesquioxane derivative at a high yield by a simple process in order to solve such problems. The novel silsesquioxane derivative according to the present invention is controlled in a structure thereof and has a functional group, which is excellent in reactivity with a target compound, to be modified. The present invention relates to a production process for a silsesquioxane derivative represented by Formula (2), characterized by using a silicon compound represented by Formula (1). In Formula (1) and Formula (2), R is a group selected from hydrogen, alkyl, aryl and arylalkyl; M is a monovalent alkaline metal atom; at least one of Y is a group represented by Formula (3), and the remainder of Y is hydrogen; R<1 >and R<2 >in Formula (3) represent the same group as defined for R; and Z is a functional group or a group having a functional group.

Owner:JNC CORP

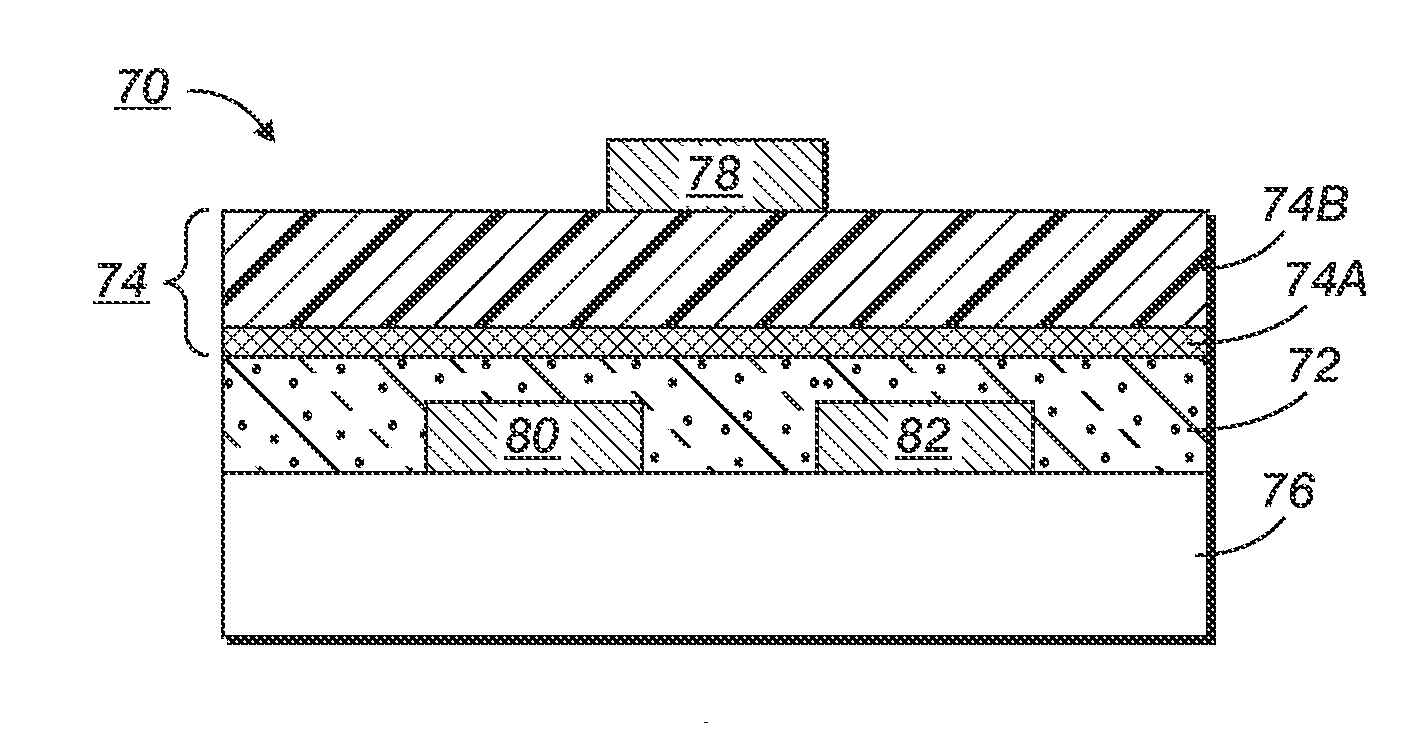

TFT fabrication process

ActiveUS20060234430A1Solid-state devicesSemiconductor/solid-state device manufacturingDielectricGate dielectric

A process for fabricating a thin film transistor including: (a) depositing a semiconductor layer; and (b) depositing a multilayer gate dielectric prior to or subsequent to the depositing the semiconductor layer, wherein the multilayer dielectric comprises: (i) a first layer comprising a first material selected from the group consisting of an optionally substituted silsesquioxane, an optionally substituted silsesquioxane-metal oxide hybrid composition, an optionally substituted siloxane-metal oxide hybrid composition, and a mixture thereof, and (ii) a second layer in contact with the first layer, wherein the second layer comprises a second material, wherein the first layer is closer to the semiconductor layer than the second layer.

Owner:XEROX CORP

Process for the formation of polyhedral oligomeric silsesquioxanes

Three methods for preparing polyhedral oligomeric silsesquioxanes (POSS), which utilize the action of a base that can attack silicon atoms or anything that can react with protic solvents (such as ROH, H2O, etc.) and produce hydroxides [ OH]-, alkoxide [RO]- and other compounds. The first method uses these bases to effectively redistribute the silicon-oxygen skeleton structure in the polymerized silsesquioxane [RSiO1.5]∞ to become a POSS nanostructure, that is, the formula [(RSiO1.5)n]∑ Homoleptic fragments represented by #, functionalized homoleptic fragments represented by [(RXSiO1.5)n]∑#, hybrid compounds represented by [(RSiO1.5)m(R'SiO1.5)n]∑# fragments (heteroleptic) and functionalized heterosegment nanostructures represented by {(RSiO1.5)m(RXSiO1.0)n}∑#, where ∞=1-1,000,000 or higher. The second method uses a base to help form POSS nanostructures from the silane RSiX3 and the linear or cyclic silsesquioxane represented by the formula RX2Si-(OSiRX)m-OSiRX2, that is, the formula [(RSiO1.5)n ]∑#, the homogeneous fragments shown and the miscellaneous fragments shown in [(RSiO1.5)m(R'SiO1.5)n]∑# and the heterogeneous fragments shown in [(RSiO1.5)m(RXSiO1.0)n]∑# Functionalized heterosegment nanostructure, where m=0-10, X=OH, Cl, Br, I, alkoxide OR, acetate OOCR, peroxide OOR, amine NR2, isocyanate NCO and R. The third method uses alkali to selectively open the silicon-oxygen-silicon (Si-O-Si) bonds in the POSS structure to form POSS species with incompletely condensed nanostructures. These methods also provide stereochemical control of X. These three methods can generate new POSS species, which can ultimately be transformed into POSS species suitable for polymerization, grafting, or other desired chemical reactions through additional chemical control.

Owner:HYBRID PLASTICS INC

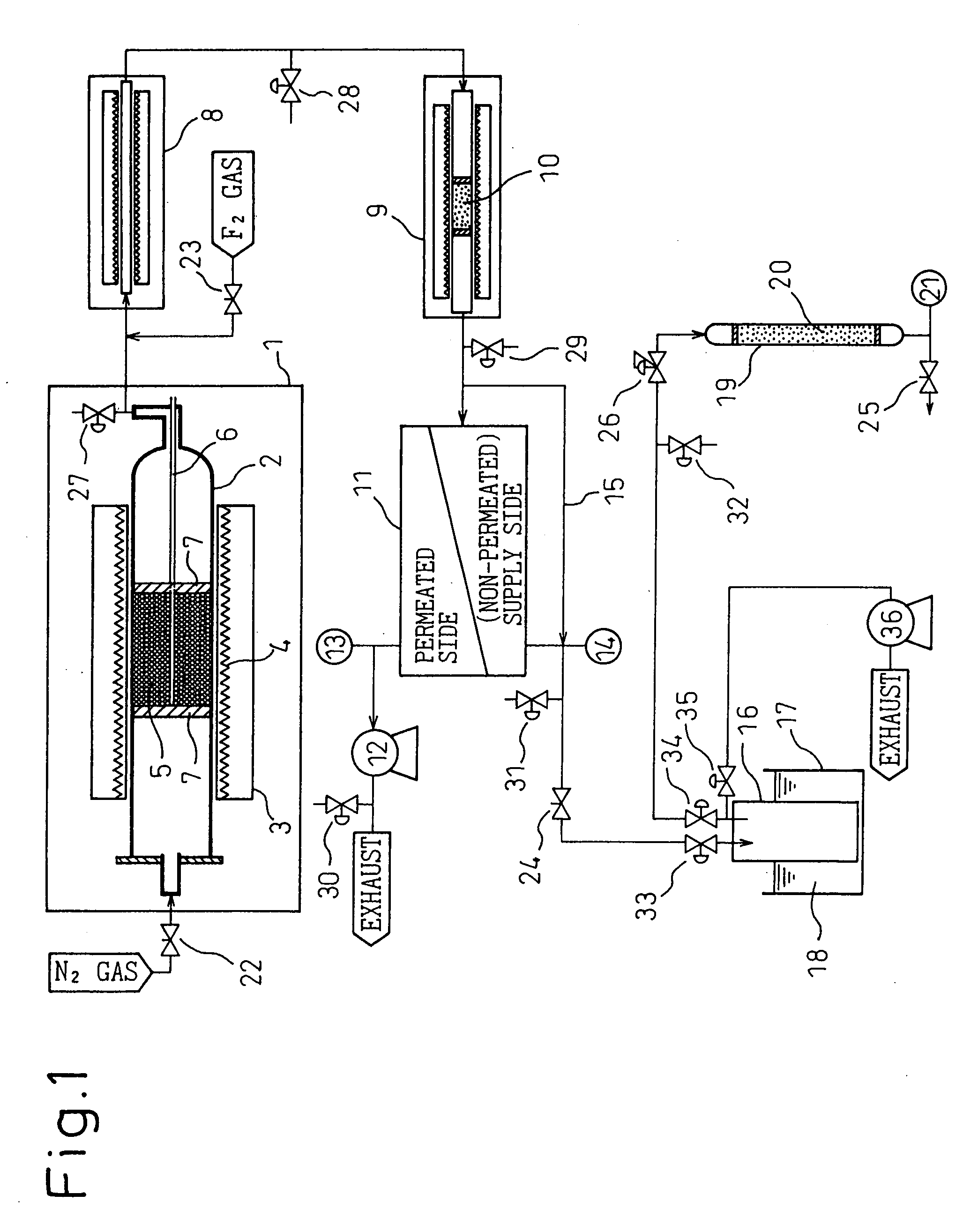

Production and use of tetrafluorosilane

Tetrafluorosilane is produced by a process comprising a step (1) of heating a hexafluorosilicate, a step (2-1) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a fluorine gas, a step (2-2) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a highvalent metal fluoxide, or a step (2-1) of reacting a tetrafluorosilane gas containing hexafluorodisiloxane produced in the step (1) with a fluorine gas and a step (2-3) of reacting a tetrafluorosilane gas produced in the step (2-1) with a highvalent metal fluoride. Further, impurities in high-purity tetrafluorosilane are analyzed.

Owner:SHOWA DENKO KK

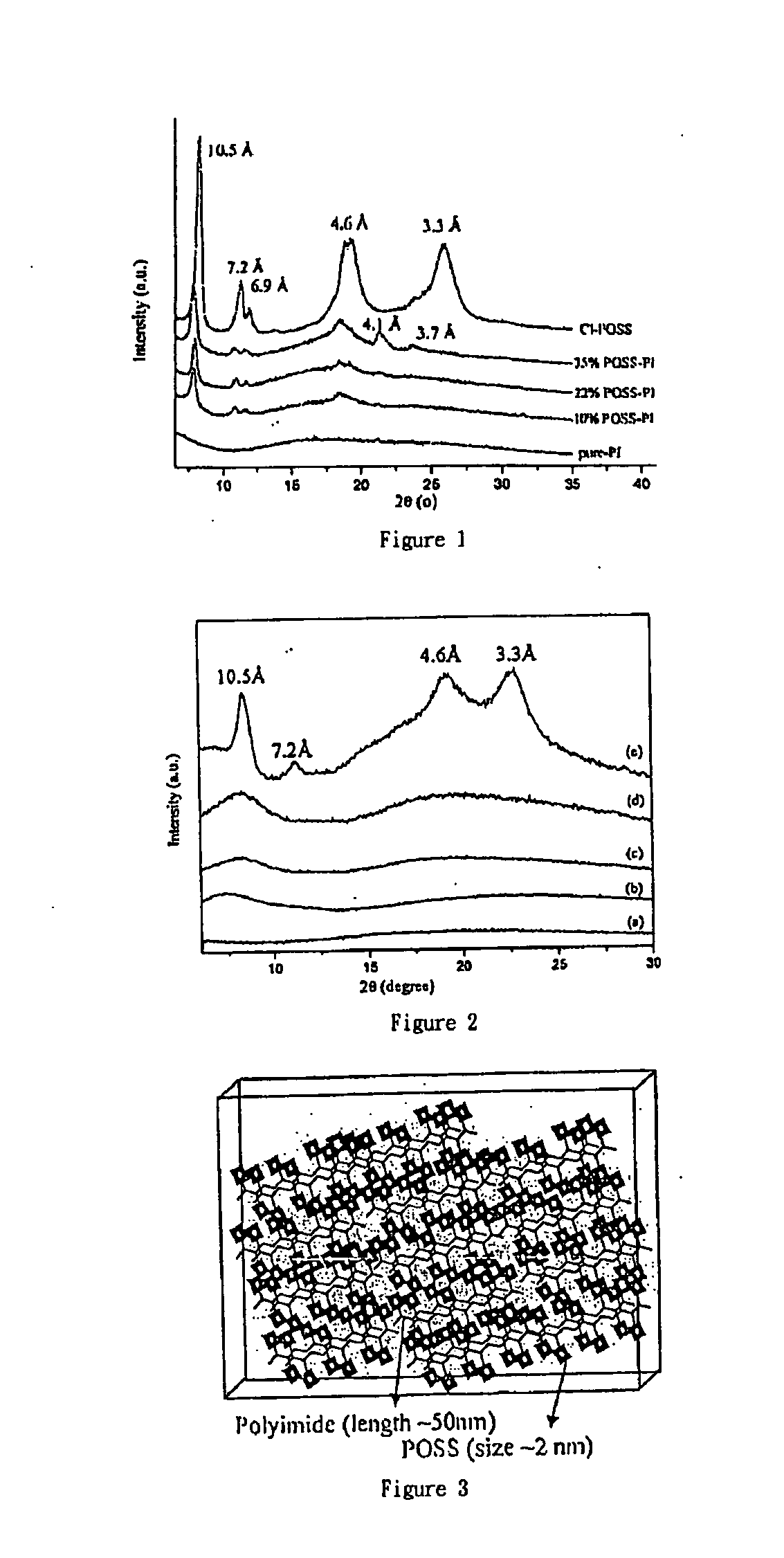

Convalently bonded polyhedral oligomeric silsesquioxane/polyimide nanocomposites and process for synthesizing the same

Polyhedral oligomeric silsesquioxane / polyimide nanocomposites with certain mechanical properties and low dielectric constant is synthesized by covalently tethering functionalized polyhedral oligomeric silsesquioxane molecules to polyimide. These nanocomposites appear to be self-assembled systems. A process for synthesizing said polyhedral oligomeric silsesquioxane / polyimide nanocomposites also is provided, comprising a step of forming porous type polyhedral oligomeric silsesquioxane, and a subsequent step of reacting with dianhydride or directly reacting with synthesized polyimide.

Owner:NAT CHIAO TUNG UNIV

Self-crosslinking Silicone Pressure Sensitive Adhesive Compositions, Process For Making and Articles Made Thereof

Disclosed herein are self-crosslinking compositions containing a hydrosilation catalyst and the reaction product of a mixture comprising (i) a resinous copolymer having both silicon-bonded hydrogen and silanol groups, and (ii) one or more vinyl-functional polyorganosiloxanes. These compositions have stable post-cure adhesive properties and are suitable for use in electronic applications.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Preparation method of dimethicone with controllable viscosity

The invention relates to a preparation method of dimethicone with controllable viscosity, and belongs to the technical field of downstream products of organic silicon. The method is characterized in that hexamethylcy (D3) is adopted as a raw material, low-viscosity dimethicone (MDnM) with the viscosity of 5 to 50 mpa.s and hexamethyldisiloxane (MM) are adopted as end-capping reagents, tetramethyl ammonium hydroxide silicon alkoxide and potassium hydroxide (KOH) silica-alkoxide are catalyzed to generate the dimethicone with controllable viscosity in a polymerization-free manner, and the viscosity range of the dimethicone is 100-100000 mpa.s. Main raw materials used in the method are dissolved without a solvent, so that pollution is avoided; the end-capping reagents are good in end-capping effect, cheap and safer; the catalyst is easy to obtain and less in consumption; the dimethicone with high purity and controllable viscosity can be prepared in a polymerization-free manner only by changing the dispensing ratio of the hexamethylcy (D3) and the low-viscosity dimethicone (MDnM).

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Process for producing polyorganosiloxane with solid-acid zirconium oxide catalyst

InactiveUS20050119434A1Improve productivityHigh yieldSilicon organic compoundsSilicon oxygenSolid acid

The method for producing polyorganosiloxane from at least one type of organosilicon compound having a siloxane unit or alkoxysilane by the equilibrating reaction involving cleavage and recombination of the silicon-oxygen bond as a method carried out in the presence of an acidic catalyst capable of giving the product in high productivity and yield, corrosive to the system to a limited extent, and remaining in the product to a limited extent or degrading product quality to a limited extent if it remains, wherein a solid, acidic zirconium oxide catalyst is used as the acidic catalyst.

Owner:DOW TORAY CO LTD

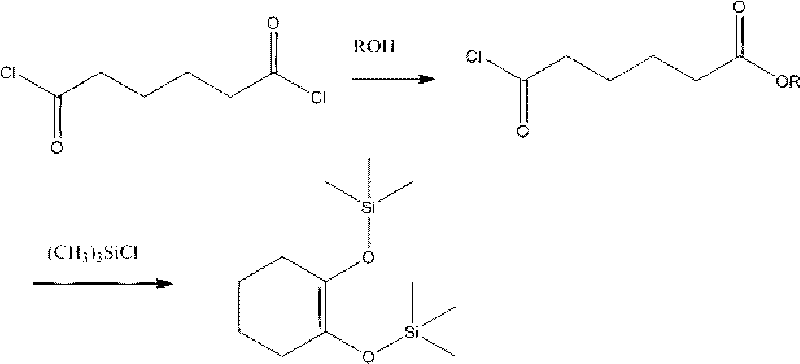

Preparation method of 1,2-bi-trimethylsilyloxy cyclohexene

ActiveCN101735261AMild responseLess side effectsGroup 4/14 element organic compoundsMeth-Cyclohexene

The invention discloses a preparation method of 1,2-bi-trimethylsilyloxy cyclohexene. In the traditional methods, some methods have large consumption of trimethyl chlorosilane and higher production cost; and some methods have lower yield and are not suitable for industrialization. The preparation method of the 1,2-bi-trimethylsilyloxy cyclohexene in the invention comprises the step of reacting adipic acid monoalkyl ester monochloride as a raw material with the trimethyl chlorosilane and metal sodium in a solvent to obtain the 1,2-bi-trimethylsilyloxy cyclohexene. Compared with the prior art adopting adipoyl dichloride as a raw material, the method of the invention has mild reaction, less side reactions and high yield; and compared with the prior art adopting diethyl adipate as a raw material, the method of the invention saves the consumption of 1 mol of the trimethyl chlorosilane, and saves the cost.

Owner:ZHEJIANG NHU CO LTD +1

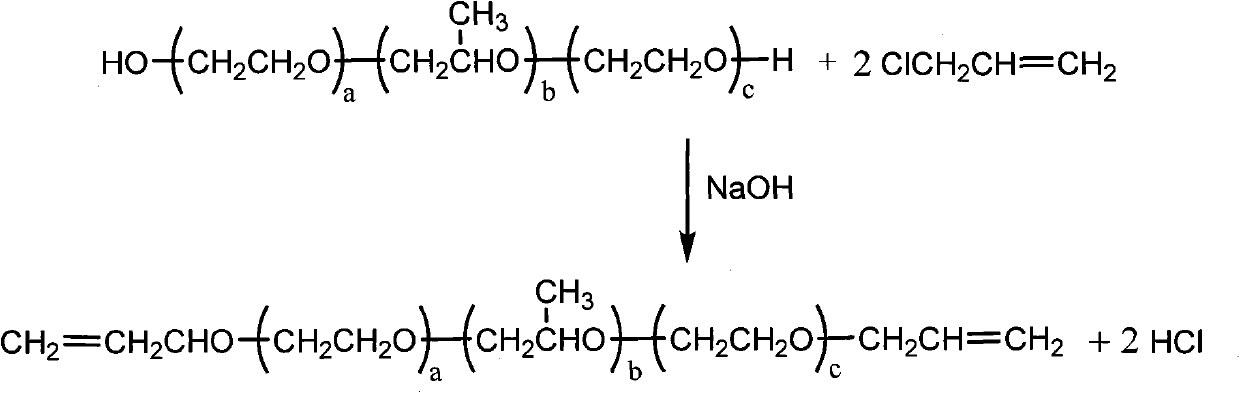

Organic silicon compounds, and preparation method and application thereof

ActiveCN101942083AReduce surface tensionEasy to prepareSilicon organic compoundsFatty/oily/floating substances removal devicesOrganosiliconAlkali hydroxide

The invention discloses organic silicon compounds. The organic silicon compounds have the structure shown in a formula (I), wherein a is equal to 0 to 40, b is equal to 0 to 30, c is equal to 0 to 40, a, b and c are all integers and the sum of a, b and c is more than 6. the invention discloses a method for preparing the organic silicon compounds, and the method comprises the following steps of: reacting alpha-hydrogen-omega-hydroxyl polyether with halogenated propylene which serve as raw materials in the presence of alkali metal hydroxides to form diallyl polyether; and reacting the obtained diallyl polyether with 1,1,1,3,5,5,5-heptamethyltrisiloxane in the presence of a Pt catalyst to obtain the finished product. The organic silicon compounds have the advantages of unique structure, low surface tension, no toxin and high oil-collecting effect, and can be widely applied to the field of oil spill pollution treatment in water areas.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

Catalyst for preparing p-xylene through benzene and methanol alkylation and preparation method of catalyst

ActiveCN105214714AEasy to makeSimple modification stepsMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAlkaline earth metal

The invention relates to a fluidized bed catalyst for preparing p-xylene through benzene and methanol alkylation in a high selectivity way and a preparation method of the fluidized bed catalyst. The fluidized bed catalyst is prepared from an active ingredient, a substrate material, a bonding agent and modified ingredients, wherein the active ingredient is a sodium type or hydrogen type ZSM-5 molecular sieve; the modified ingredients are a silicone alkyl compound and alkaline earth metal. The active ingredient, the substrate material and the bonding agent are mixed and sprayed for formation; then, the modified ingredients are used for modification to prepare the fluidized bed catalyst; or the active ingredient is modified by the modified ingredients at first, and is then mixed with the substrate material and the bonding agent for spraying to prepare the fluidized bed catalyst. The fluidized bed catalyst is used for benzene and methanol alkylation reaction; the single-pass conversion rate of the benzene reaches a value higher than 55 percent; the isomerization process is not needed; the obtained major product is the p-xylene; the selectivity of the p-xylene in the isomer is as high as more than 95 percent; the partial middle product is methylbenzene.

Owner:陕西煤化工技术工程中心有限公司

Mono-dispersed Pd-Pt nano-catalyst and preparation method therefor

InactiveCN105013475AImprove catalytic performanceIncrease profitMaterial nanotechnologyCell electrodesNano catalystFuel cells

The invention discloses a mono-dispersed Pd-Pt nano-catalyst and a preparation method therefor. According to the invention, with H2PtCl6.6H2O and PdCl2 as metal precursors, octa(amidocarboxyl silsesquioxane) as a protecting agent, and formaldehyde as a reducing agent, the mono-dispersed Pd-Pt nano-catalyst is prepared by a hydrothermal method. The prepared nano-catalyst has the advantages of good dispersing performance, higher electrochemical active specific surface area, and high electrocatalytic activity. The preparation provided by the invention is simple in required equipment and convenient in operation, and has great utilization value in a commercialization process of direct formic acid fuel cells.

Owner:SOUTHEAST UNIV

Suit finishing agent and preparation method thereof

The invention provides a suit finishing agent and a preparation method thereof. The suit finishing agent comprises the following components in parts by weight: 4-6 parts of ethoxy aminopropyl dimethicone, 2-4 parts of ammonium dihydrogen phosphate, 3-5 parts of calcium hydrophosphate, 7-9 parts of sodium carboxymethylcellulose, 5-6 parts of mannan, 3-5 parts of octylphenol polyoxyethylene, 35-55 parts of ethanol and 210-220 parts of water. The suit finishing agent prepared through the steps of heating the components of the finishing agent after adjusting the temperature, agitating the components with an agitator, filling nitrogen and the like has better water and oil repellent and anti-wrinkle effects. A set of suit has water and oil repellent and anti-wrinkle performances.

Owner:HUNAN DONGFANG FASHION

Preparation technique of medium/high-viscosity dimethyl silicone oil

The invention discloses a preparation technique of medium / high-viscosity dimethyl silicone oil, which comprises the following steps: swelling chloromethylated polystyrene balls in a trimethylamine water solution, and adding perfluoro tertiary amine; supporting potassium hydroxide to obtain a composite catalyst, and adding octamethylcyclotetrasiloxane (D4) and hexamethyl disiloxane (MM) into the reaction kettle; and after the reaction finishes, filtering to recover the catalyst, extracting under reduced pressure and recovering the low-boiling-point substances, thereby obtaining the methyl silicone oil product.

Owner:广州市亿成有机硅有限公司

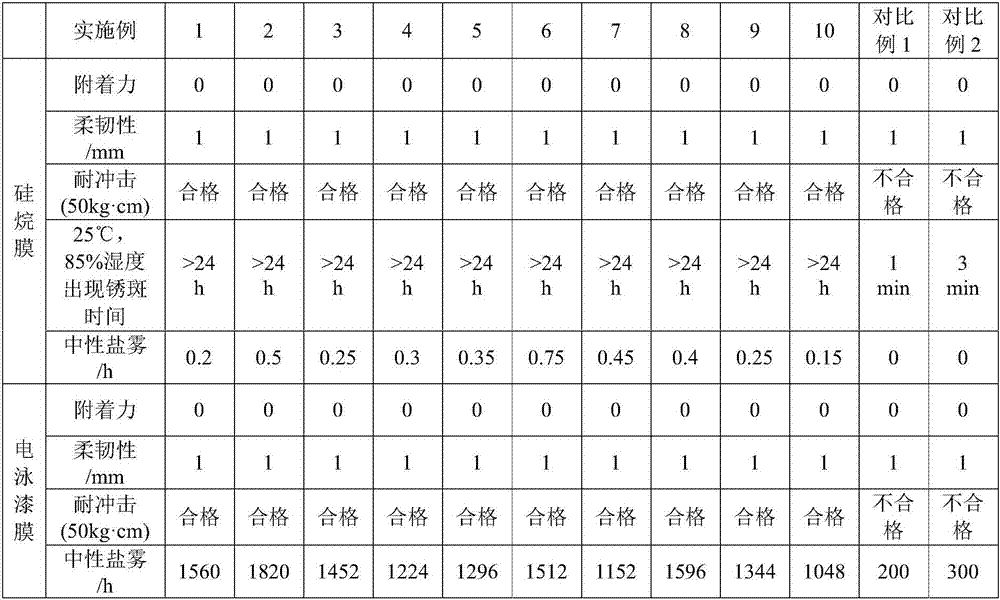

Metal surface pretreatment agent and preparation method and application thereof

InactiveCN106906462ASimple structurePromote repairMetallic material coating processesPolymer scienceSilanes

The invention discloses a metal surface pretreatment agent. Water is used as a solvent, silane is used as a main film forming agent, fluorozirconate and / or fluorozirconic acid are / is used as a second film forming agent, amidogen cage type silsesquioxane (amidogen POSS) is added and used as a film sealant and a repair agent, and acid, a metal promoter, a rare earth compound and a stabilizer can be included as well. In the film forming process of the metal surface coating pretreatment agent, silane film forming and fluorozirconate ceramic film forming are conducted synchronously, mutual doping is conducted, and a dense inorganic-organic hybrid film is formed; and the defects existing in the fluorozirconate film forming process can be repaired in time through silane, the film structure is optimized, multiple kinds of amidogen of the amidogen POSS can react with multiple sites in the film at the same time, the sealing effect can be improved remarkably, and the defects in the film can be well repaired and sealed.

Owner:WUHAN UNIV

Photosensitive polyorganosiloxane composition

InactiveCN101965542AGood spreadabilityReduce viscositySemiconductor/solid-state device manufacturingPhotosensitive material processingPolymer sciencePtru catalyst

Disclosed is a photosensitive polyorganosiloxane composition comprising component (a): 100 parts by mass of a polyorganosiloxane wherein the polyorganosiloxane has been obtained by mixing a silanol compound represented by general formula (1): R2Si(OH)2, an alkoxysilane compound represented by general formula (2): R'Si(OR'')3, and an alkoxysilane compound represented by general formula (3): R'''Si(OR'''')3 in a specific molar ratio range with a catalyst selected from the group consisting of metal alkoxides represented by general formula (4): M(OR''''')4, metal alkoxides represented by general formula (5): M'(OR'''''')3, and Ba(OH)2 and polymerizing the mixture without the addition of water, and component (b): 0.1 to 20 parts by mass of a photopolymerization initiator. The groups in the general formulae (1) to (5) are as defined in the claims.

Owner:ASAHI KASEI KK

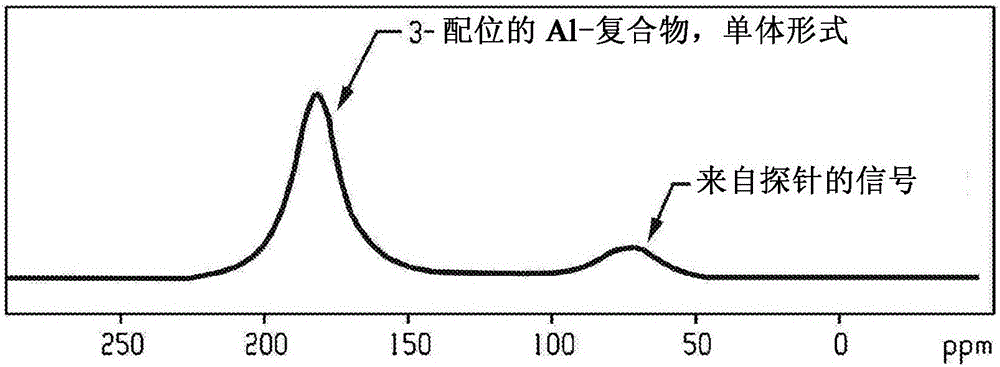

Modifying organoaluminum co-catalysts for improved performance

ActiveCN105980053AOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsCarbamateSilylene

The invention provides modifying organoaluminum co-catalysts for improved performance. Processes of making catalyst compositions are provided. In an exemplary embodiment, the processes include modifying an organoaluminum compound with a modifier that decreases the initial reducing strength of the organoaluminum compound, where the modifier can be an ether, an anhydride, an amine, an amide, a silicate, a silyl ether, a siloxane, an ester, a carbonate, a urea, a carbamate, a sulfoxide, a sulfone, a phosphoramide, or a combination thereof. The processes further include adding a transition metal complex to the mixture of the organoaluminum compound and the modifier; and obtaining a catalyst composition including the organoaluminum compound and the transition metal complex.

Owner:SABIC GLOBAL TECH BV

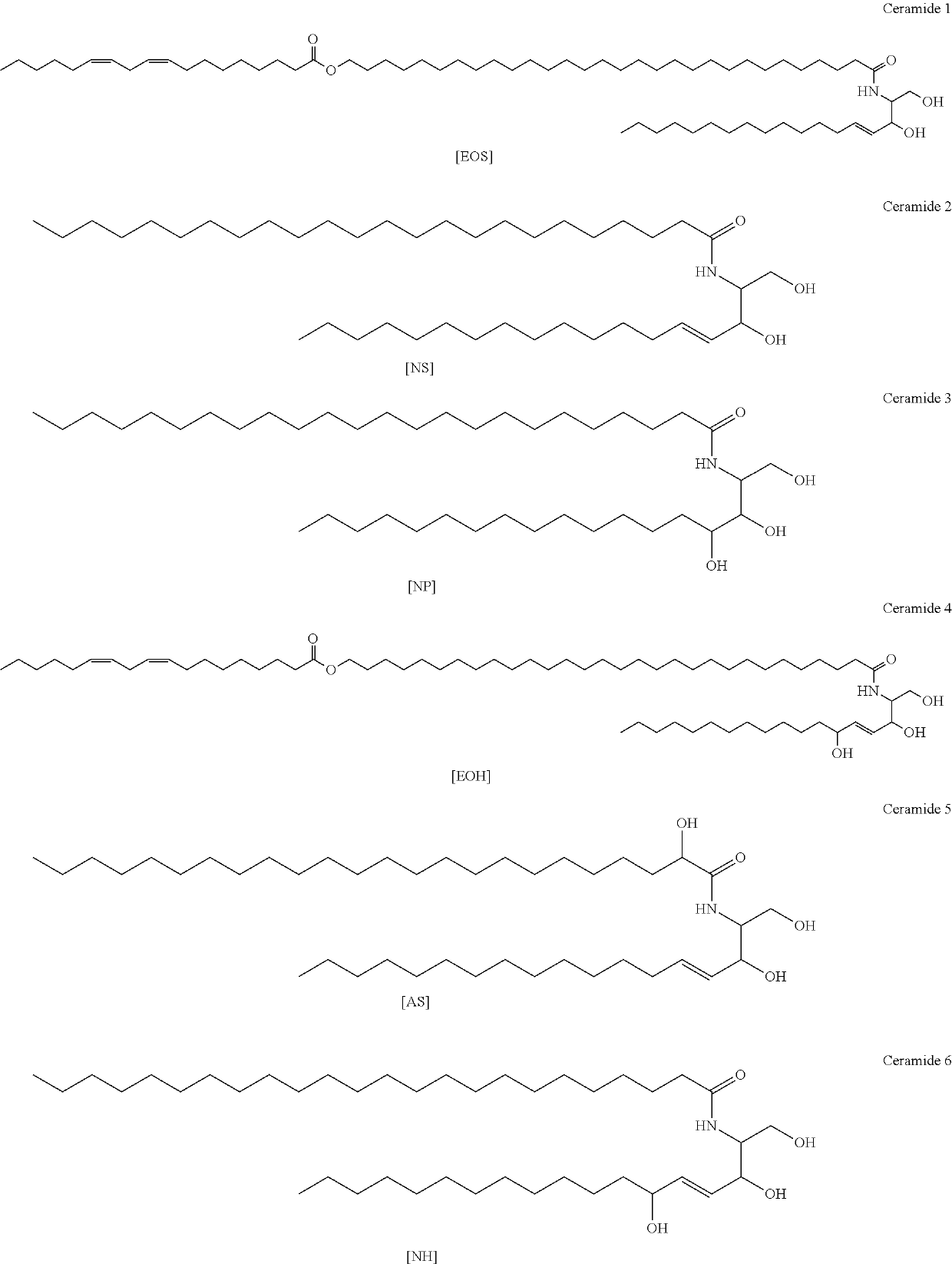

Bi-phase micellar liquid product comprising ceramides

The present disclosure relates to bi-phase micellar liquid products that include ceramides and other components that are beneficial to the skin. In particular, the products include: (a) a fatty phase comprising one or more fatty compounds and one or more silicones; and (b) an aqueous phase comprising one or more ceramides, one or more water-soluble solvents, one or more surfactants, and water. The products are particularly unique because the ceramides are solubilized in the aqueous phase of the products. In addition to being useful for cleansing the skin, the products support natural lipid barrier function of the skin and improve skin hydration.

Owner:LOREAL SA

Dandruff removing oil control shampoo and preparation method thereof

ActiveCN110840754AGood anti-dandruff and oil control abilityEasy to prepareCosmetic preparationsHair cosmeticsChemical productsCnidium

The invention provides dandruff removing oil control shampoo and a preparation method thereof, and relates to the field of daily chemical products. The anti-hair loss shampoo comprises a fresh gingerextracts, lightyellow sophora root extracts, clerodendranthus spicatus extracts, common cnidium fruit extracts, propylene glycol, cleaning agent, Cocamide MEA(mercaptoethylamine), PCA (pyrrolidone carboxylic acid) zinc, Guar gum hydroxypropyl trimethyl ammonium chloride, polyquaternium-10, zinc pyrithione, dimethiconol, zinc gluconate, Carbopol, erythritol, benzyl alcohol, sodium benzoate, coloring agents, sodium hydroxide, essence and the rest water. The preparation method of the shampoo is simple and convenient, the shampoo prepared from raw materials has better effects in the aspects of removing dandruff and controlling oil, safety of the shampoo is high, irritation and sensitization are avoided, and public experience is good.

Owner:广州市发雅丝精细化工有限公司

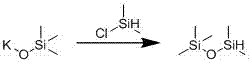

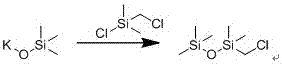

Preparation method and application of trimethyl silicon alkoxide

InactiveCN107235996AImprove solubilityImprove responseSilicon organic compoundsPotassium hydroxideTrimethylsilanol

The invention discloses a preparation method and an application of trimethyl silicon alkoxide. The preparation method includes the preparation steps: placing hexamethyldisiloxane and potassium hydroxide into a 10L three-mouth flask; adding 10ml of alcohol preparations; performing heating reflux for 48 hours; dividing water by a water knockout trap; cooling, filtering and drying materials to obtain white solid potassium trimethylsilanolate. Inexpensive trimethyl silicon alkoxide (MM) in industrial production serves as a raw material, and the trimethyl silicon alkoxide and the potassium hydroxide are subjected to heating reflux reaction under various catalysts to prepare potassium trimethylsilanolate with high content. All the catalysts are beneficial to dissolution of the potassium hydroxide, and reaction is facilitated.

Owner:壮铭新材料科技江苏有限公司

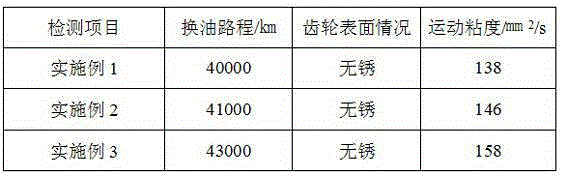

Novel corrosion inhibitor composition and preparation method thereof

The invention relates to a novel corrosion inhibitor composition and a preparation method thereof. The corrosion inhibitor composition comprises hydrogen-containing polydimethylsiloxane, a benzotriazole derivative, an alkaline catalyst and a solvent. The preparation method of the corrosion inhibitor composition comprises the following steps: under nitrogen protection and continuous stirring conditions, adding the hydrogen-containing polydimethylsiloxane into the solvent, heating up to 75-80 DEG C, continuing to heat up to 90-100 DEG C after the hydrogen-containing polydimethylsiloxane is dispersed uniformly, adding the benzotriazole derivative and the alkaline catalyst after the temperature is stable, fully reacting for 1-8 hours, removing the solvent from the reaction mixture, and filtering to obtain the product, namely the corrosion inhibitor composition. Compared with the prior art, the corrosion inhibitor product provided by the invention has a higher applicable temperature, stronger film forming stability, low use amount and good continuous corrosion resistance, and is a novel and efficient metal surface corrosion inhibitor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Formulation for gear oil for automobile transmission

ActiveCN105255565AImprove rust resistancePlay a lubricating effectAdditivesSulfite saltButylated hydroxytoluene

The invention discloses a formulation for gear oil of an automobile transmission and relates to the field of automobile lubrication oil. The formulation for the gear oil of the automobile transmission comprises, by mass, 76-80% of hydrogenated basic oil, 2.6-4.3% of sodium sulfite, 2.6-4.7% of dodecylbenzene sodium carbonate, 0.7-1.6% of butylated hydroxytoluene, 1.9-2.6% of potassium borate, 5.7-8.2% of dimethione and 4.8-6.1% of oleamide. Compared with common gear oil, the gear oil has the better extreme pressure anti-wear property and higher oxidation resistance.

Owner:HANGZHOU POLYTECHNIC

Self-crosslinking silicone pressure sensitive adhesive compositions, process for making and articles made thereof

Disclosed herein are self-crosslinking compositions containing a hydrosilation catalyst and the reaction product of a mixture comprising (i) a resinous copolymer having both silicon-bonded hydrogen and silanol groups, and (ii) one or more vinyl-functional polyorganosiloxanes. These compositions have stable post-cure adhesive properties and are suitable for use in electronic applications.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Synthesis method of hydroxyl silicone oil

The invention provides a synthesis method of hydroxyl silicone oil. The method comprises the following steps: step one, adding hexamethylcyclotrisiloxane, an end-capping reagent, a solvent and a catalyst into a reaction kettle, performing heating until the solvent is boiled, and making a reaction for 1-5 hours at the boiling point of the solvent until the reaction is complete; step two, adding a neutralizer to neutralize until the pH value is 6-8, pumping out the solvent, the end-capping reagent and unreacted hexamethylcyclotrisiloxane under vacuum to obtain a crude product, and filtering outsalt in the crude product to obtain a hydroxyl silicone oil finished product; and step three, analyzing the proportion of each component of the solvent, the end-capping reagent and the unreacted hexamethylcyclotrisiloxane extracted in the step two by using a gas chromatograph, and adding the components into the next batch of reaction production for recycling. The synthesis method has the advantages of no use of controlled chemical raw materials, simple process, completion in one reaction kettle, no generation of waste water and waste gas in the process, generation of less than 10KG per ton ofsalt, cyclic use of the solvent in the reaction, very low process cost, environmental protection, simple process and easy control.

Owner:苏州歌诗夫新材料有限公司

Humic acid-containing surfactant and preparation method thereof

InactiveCN101913945AImprove surface activityImprove effective utilizationFertilizer mixturesSURFACTANT BLENDChemistry

The invention relates to a humic acid-containing surfactant and a preparation method thereof. The humic acid-containing surfactant comprises the following components in percentage by weight: 40-60 percent of polyether modified trisiloxane, and 40-60 percent of humic acid-containing compound. The preparation method of the humic acid-containing surfactant comprises the following step of uniformly mixing the 40-60 percent by weight of the polyether modified trisiloxane and 40-60 percent by weight of the humic acid-containing compound. The humic acid-containing surfactant can overcome the defect of low surface activity of fulvic acid and improve the effective utilization ratio and the efficacy of the fulvic acid; meanwhile, by compounding with pesticides, fertilizers, and the like, the humic acid-containing surfactant can reduce the usage amount of the pesticides, the fertilizers, and the like, thereby remarkably improving the application effect of the pesticides, the fertilizers, and the like.

Owner:内蒙古永业农丰生物科技有限责任公司

Catalyst for catalyzing efficient conversion of silane to silanol, preparation and application thereof

InactiveCN104707651AEvenly dispersedInhibition of agglomerationSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventSilanes

The invention discloses a method for preparation of a heterogenous catalyst SBA-PIL-Au by loading Au nanoparticles in SBA-15 mesopore channels and application of the catalyst to reaction for efficient catalysis of silane conversion to silanol. In order to enhance the action force between a substrate and nanogold particles, the invention, for the first time, proposes in-situ graft growth of an ionic liquid polymer brush: poly(1-(4-allyl phenyl)-3-methyl imidazolium chloride) to the hole walls of a mesoporous material SBA-15. SBA-PIL-AU shows a high conversion rate (greater than 98%) and high selectivity (in the product, with the ratio of silanol to silicone being greater than 99:1) on a series of various silane-to-silanol conversion reactions. The catalytic performance of the catalyst does not decline after reuse 3 times, only water is used as the solvent and oxidant in the reaction process, and no organic solvent is used, thus being green and environment-friendly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com