Catalyst for preparing p-xylene through benzene and methanol alkylation and preparation method of catalyst

A technology for para-xylene and fluidized bed catalyst, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complicated catalyst preparation steps, low xylene selectivity, and low benzene conversion rate. , to achieve the effects of high stability, lower production costs, and higher yield per pass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 3Kg hydrogen ZSM-5 (SiO 2 / Al 2 o 3 =25, particle size 1-4μm) molecular sieve, 4Kg kaolin, 2Kg silica sol, add appropriate amount of water, stir evenly, spray dry and shape, roast at 600℃ for 3h, record as raw powder A.

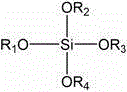

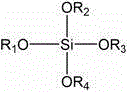

[0032] Take 0.9Kg tetraethyl orthosilicate to make ethanol solution, impregnate in raw powder A, and dry to get raw powder A-I; make 0.1KgMgO (precursor is magnesium nitrate hexahydrate) into aqueous solution, dip in the roasted raw powder A-I, the original powder A-II is obtained after drying. The catalyst BTPX-01 was obtained after the raw powder A-II was roasted.

Embodiment 2

[0034] 3.5Kg hydrogen ZSM-5 (SiO 2 / Al 2 o 3 =150, particle size 20-500nm) molecular sieve, 1.5Kg pseudoboehmite, 0.5Kg alumina sol, 2Kg kaolin, add appropriate amount of water, stir evenly, spray dry and shape, roast at 600°C for 3h, record as raw powder B.

[0035] Take 2Kg tetraethyl orthosilicate to prepare ethanol solution, impregnate in raw powder B, and dry to obtain raw powder B-I; make 0.5KgCaO (precursor is calcium nitrate tetrahydrate) into an aqueous solution, impregnate in raw powder B-I, after drying Obtain the original powder B-II. The catalyst BTPX-02 was obtained after the raw powder B-II was roasted.

Embodiment 3

[0037] 1.5Kg sodium ZSM-5 (SiO 2 / Al 2 o 3 =25, particle size 1-4μm) molecular sieve, 3Kg pseudo-boehmite, 3Kg silica, 1.5Kg aluminum sol, add appropriate amount of water, stir evenly, spray dry and shape, roast at 600°C for 3h, record as raw powder C.

[0038]Make 0.01KgMgO (the precursor is magnesium chloride) into an aqueous solution, impregnate it in Kg raw powder C, and dry it to obtain raw powder C-I; take 0.99Kg tetrabutyl orthosilicate to make an ethanol solution, and dip it in the roasted raw powder C-I, After drying, the original powder C-II was obtained. The catalyst BTPX-03 was obtained after the raw powder C-II was calcined.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com