Metal surface pretreatment agent and preparation method and application thereof

A treatment agent and metal technology, which is used in the field of metal surface pretreatment agent and its preparation, can not be solved well, generally it will be cross-linked within a few hours to a few days, and the phosphating production line cannot replace the phosphating process. Rinse the film with water and other problems, and achieve the effect of excellent bare mold anti-rust ability, excellent coupling ability with coating, and fast water washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

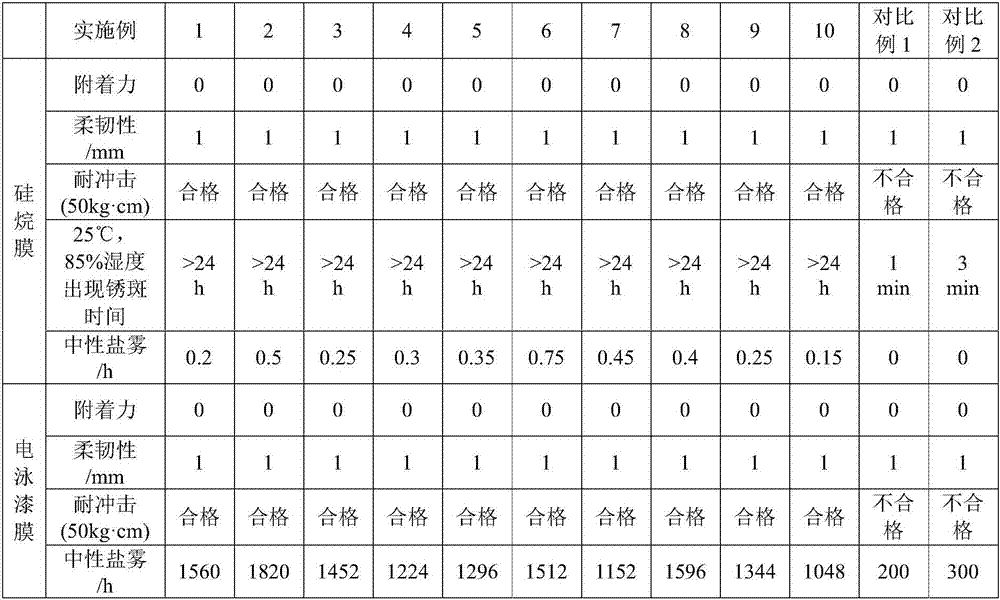

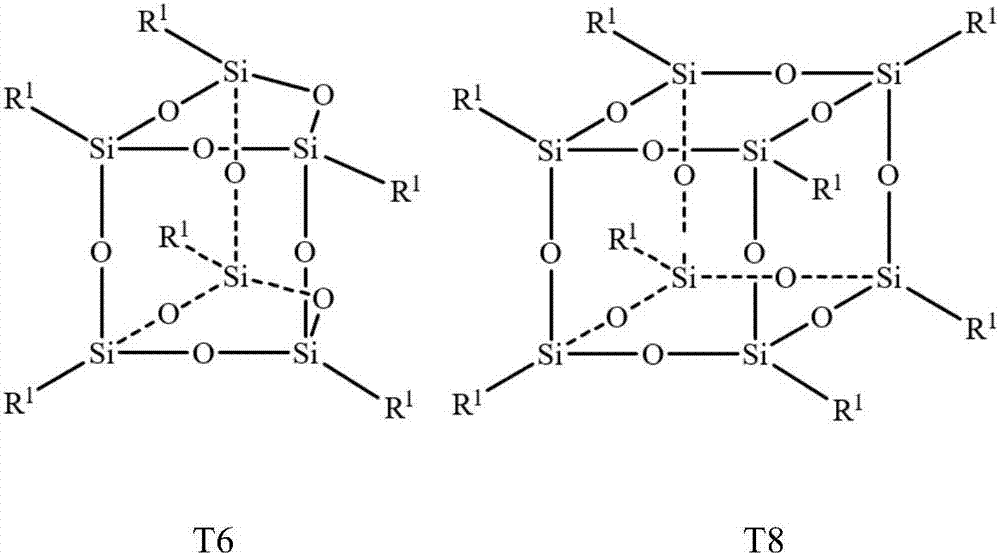

[0038] A metal surface pretreatment agent, the composition of which includes in parts by mass: 99 parts of water, 0.01 part of fluozirconic acid, 0.01 part of octa(3-aminopropyl) T8-POSS (CAS registration number: 150380-11-3 ), 0.08 parts of 1,2-bis(trimethoxysilyl)ethane, 0.9 parts of N-aminoethyl-3-aminopropyltriethoxysilane.

[0039] The preparation method of above-mentioned metal surface pretreatment agent mainly comprises the following steps:

[0040] 1) In terms of parts by mass, add 0.01 part of fluozirconic acid to 74 parts of water under stirring, and obtain component A after completely dissolving;

[0041] 2) Add 0.01 part of octa(3-aminopropyl) T8-POSS (CAS registration number: 150380-11-3) to 25 parts of water under stirring, stir and dissolve, then add 0.08 part of 1,2-di( Trimethoxysilyl) ethane, after stirring and dissolving, add 0.9 part of N-aminoethyl-3-aminopropyltriethoxysilane, stir well and use it as component B;

[0042] 3) Add component B to component...

Embodiment 2

[0046] A metal surface pretreatment agent, its composition includes in parts by mass: 54.95 parts of water, 20 parts of ammonium fluorozirconate, 0.01 octa(N-aminoethyl-3-aminopropyl) T8-POSS (CAS registration number : 1185746-13-7), 0.01 parts of 3-aminopropyltriethoxysilane, 10 parts of glycidoxypropylmethyldiethoxysilane, 2 parts of citric acid, 8 parts of malic acid, 0.03 parts of sulfuric acid Cerium, 5 parts ethanol.

[0047] The preparation method of above-mentioned metal surface pretreatment agent mainly comprises the following steps:

[0048] 1) According to the mass fraction, in 14.95 parts of water, add 20 parts of ammonium fluozirconate under the condition of stirring, after completely dissolving, add 2 parts of citric acid, 8 parts of malic acid and 0.03 part of cerium sulfate at a time, and stir evenly to obtain component A ;

[0049] 2) In 40 parts of water, add 5 parts of ethanol and 0.01 part of octa(N-aminoethyl-3-aminopropyl) T8-POSS (CAS registration numb...

Embodiment 3

[0054] A metal surface pretreatment agent, the composition of which includes: 89.3 parts of water, 0.2 parts of fluozirconic acid, 5 parts of 1 octa(2-aminoethyl) T8-POSS (CAS registration number: 1497436-87- 9), 1 part of 1,2-bis(trimethoxysilyl)ethane, 1 part of 3-aminopropyltrimethoxysilane, 1 part of glycidoxypropyltrimethoxysilane, 0.5 part of 36% concentrated Hydrochloric acid, 2 parts methanol.

[0055] The preparation method of above-mentioned metal surface pretreatment agent mainly comprises the following steps:

[0056] 1) According to the mass fraction, in 80 parts of water, add 0.2 part of fluozirconic acid under the condition of stirring, after completely dissolving, add 0.5 part of hydrochloric acid at a time, and stir evenly to obtain component A;

[0057] 2) In 9.3 parts of water, add 2 parts of methanol and 5 parts of octa(2-aminoethyl) T8-POSS (CAS registration number: 1497436-87-9) under stirring, after stirring and dissolving, add 1 part in turn 1,2-bis(t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com