Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Proximate analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Proximate analysis is a type of scientific inquiry done to determine the approximate amounts of substances within a material. This is utilized by different types of scientists to study such things as animal feed, coal, and bio-fuels.

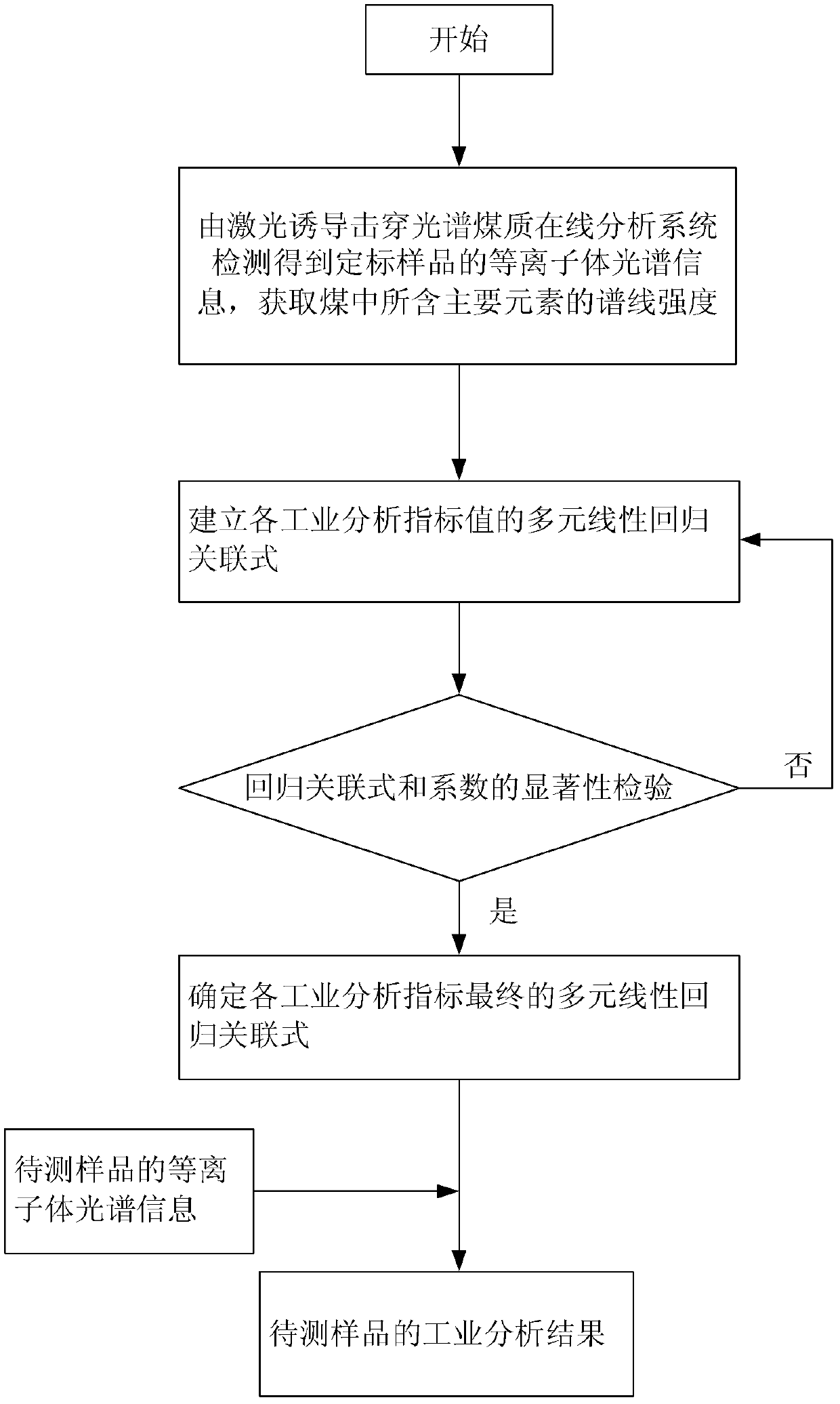

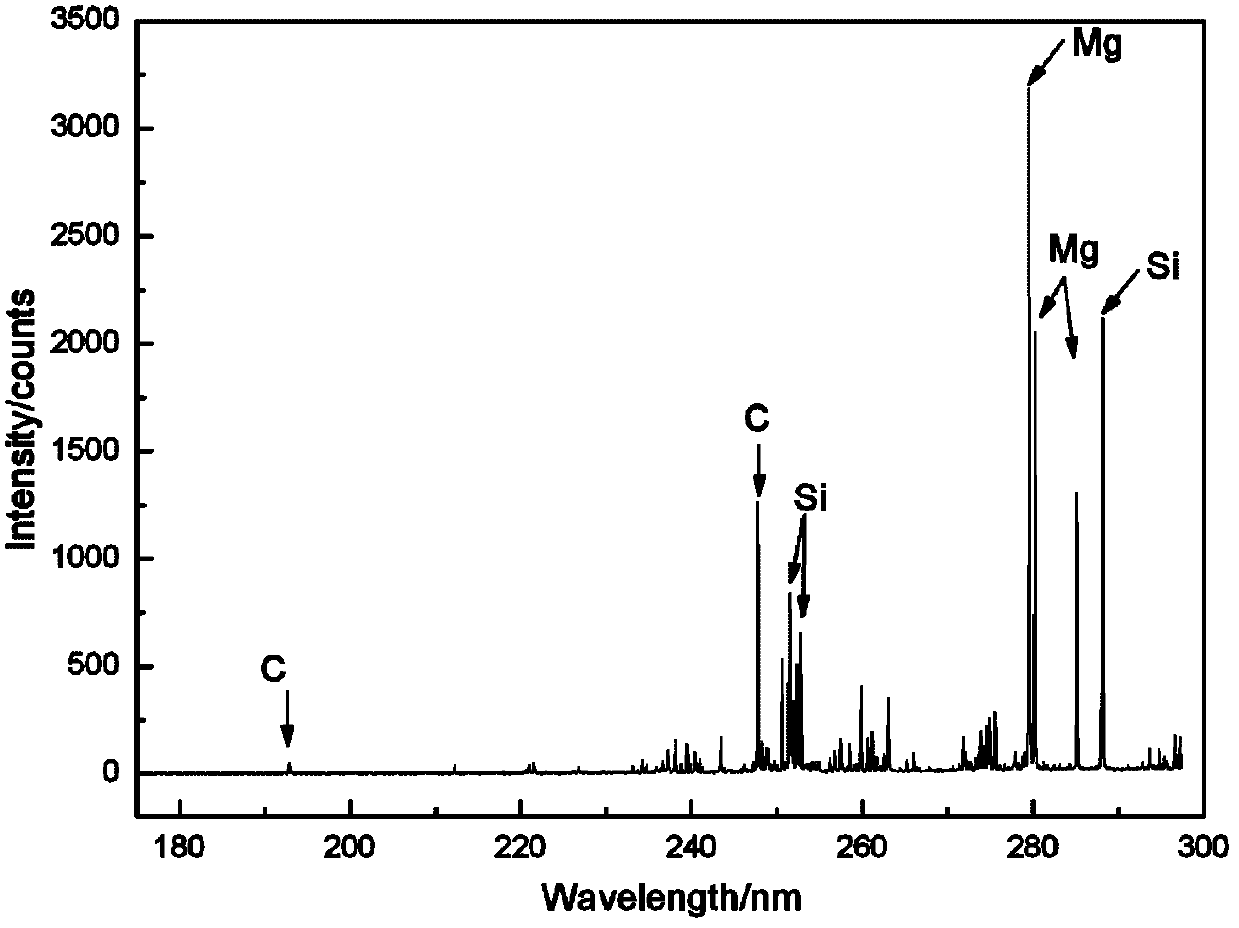

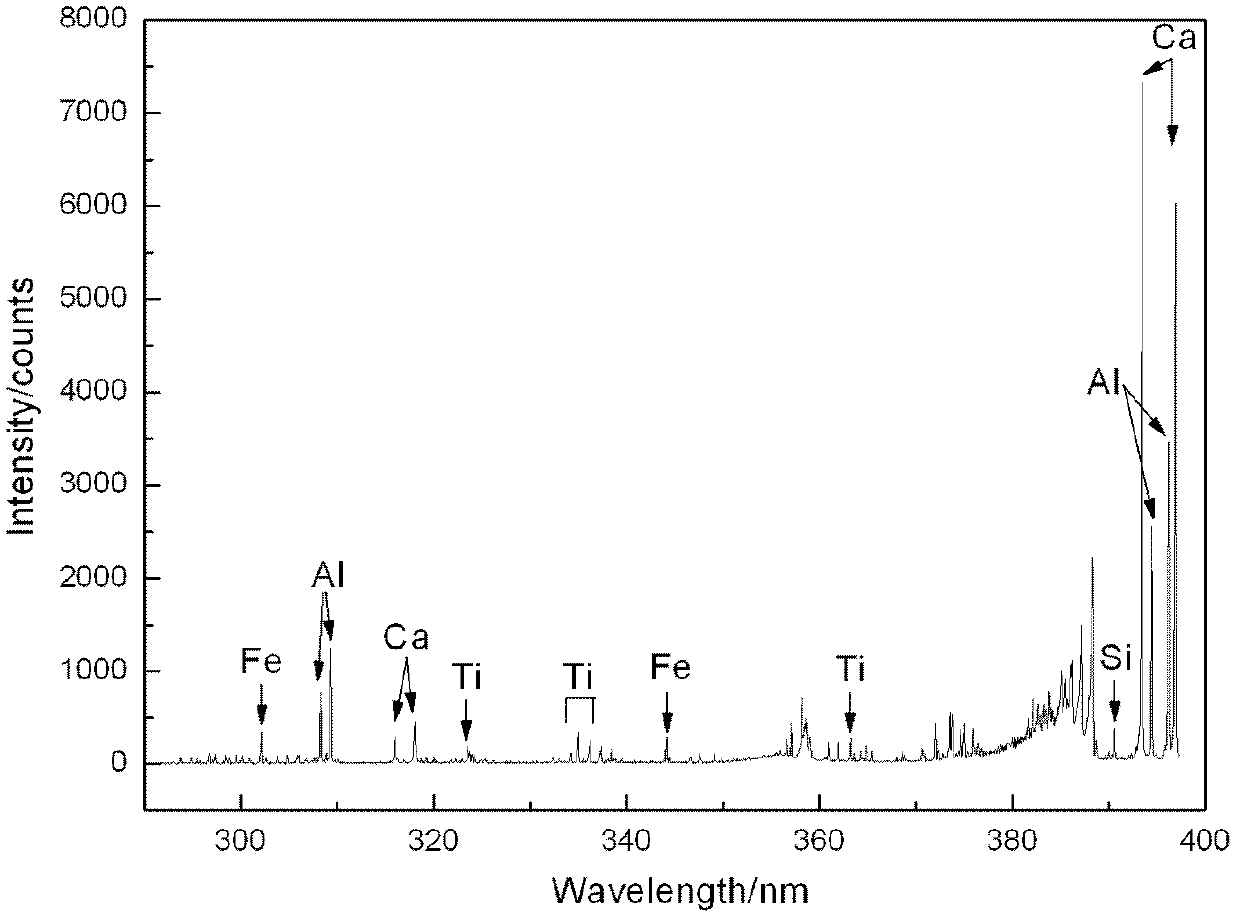

Proximate analyzing method for coal quality base on multivariate linear regression

ActiveCN102313722AImprove resource utilizationImprove energy efficiencyAnalysis by material excitationProximateLaser-induced breakdown spectroscopy

The invention discloses a proximate analyzing method for coal quality base on multivariate linear regression, The invention is characterized in that a set of samples with known proximate analysis index values is used, plasma spectrum data is obtained by detection of a coal quality on-line analysis system of LIBS (Laser-Induced Breakdown Spectroscopy), the proximate analysis of fire coal samples to be measured by a multivariate linear regression correlation of each proximate analysis index value are respectively established, the characteristic spectral line strength which has substantial contribution to proximate analysis index values is respectively introduced through the established multivariate linear regression correlation to obtain the proximate analysis results. According to the invention, the spectral line information of correlative elements which has substantial contribution to each proximate analysis index is comprehensively utilized, the process for analyzing the index by fire coal proximate analyzed by the LIBS can be simplified, and the speed and the accuracy of the quantitative analysis can be raised.

Owner:SOUTH CHINA UNIV OF TECH +1

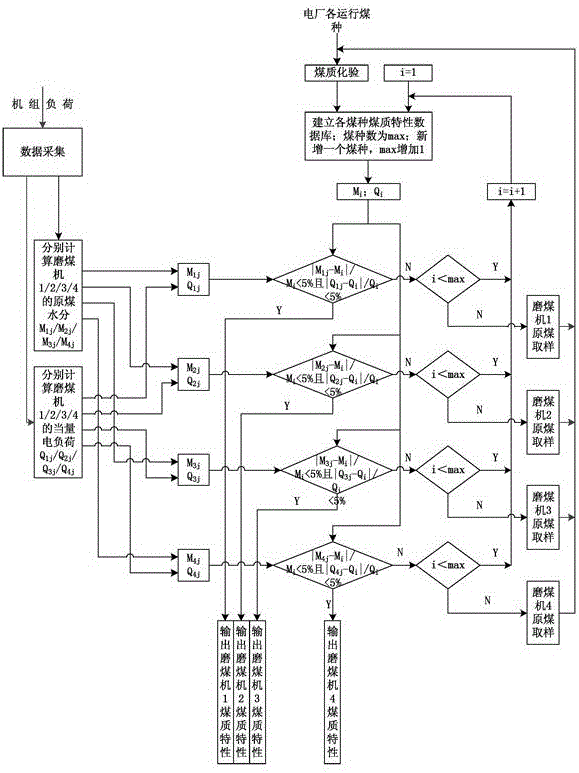

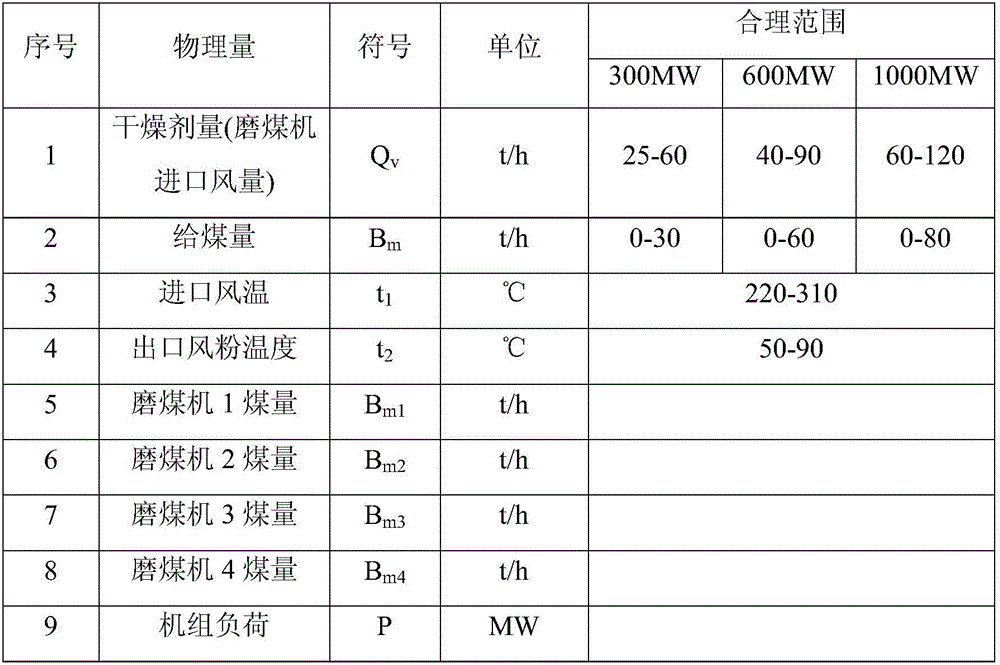

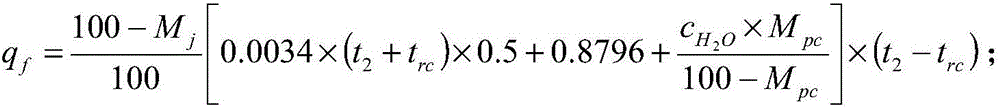

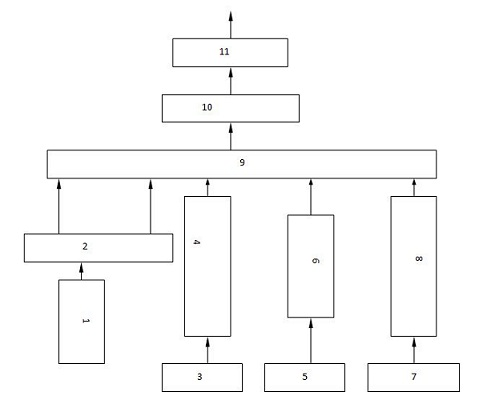

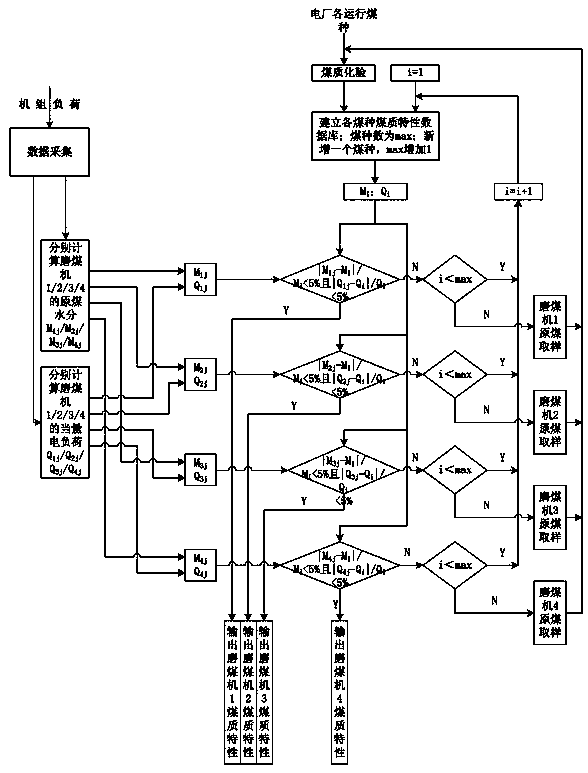

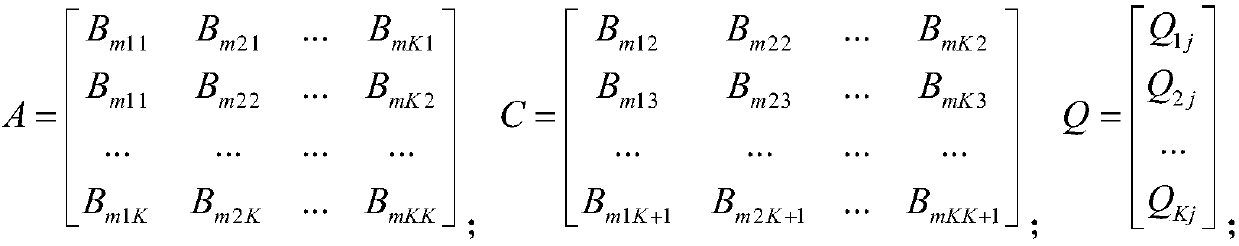

Intelligent monitoring method for coal components of heat-engine plant coal pulverizer

The invention discloses an intelligent monitoring method for the coal components of a heat-engine plant coal pulverizer. The method comprises the steps of 1) continuously collecting the operation data of each coal pulverizer, the coal amount of the coal pulverizer and the power generation load of a generator set; 2) respectively calculating the raw coal moisture MNJ and the equivalent electrical load QNJ of each coal pulverizer according to obtained data; 3) subjecting all coal components to proximate analysis, elemental analysis, calorific value analysis, ash fusion point analysis and combustion characteristic analysis, and establishing a coal component characteristic analysis database with the raw coal moisture MNJ and the equivalent electrical load QNJ as an index; 4) outputting the inquired characteristics of raw coal components with a raw coal moisture Mi and an equivalent electrical load Qi monitored during the operation of the coal pulverizer in real time as an index. On the condition that no inquired characteristic is obtained, the raw coal component of the coal pulverizer is deemed as a new coal component or a mixed coal component. After that, the new coal component or the mixed coal component is manually sampled to be subjected to coal component analysis and characteristic analysis, and then the obtained data of the new coal component or the mixed coal component are added into the coal component characteristic analysis database. According to the technical scheme of the invention, the coal characteristics of each coal pulverizer can be inquired in the online manner, and the advantages of high accuracy and complete analysis data are realized. Meanwhile, the boiler combustion is instructed to be optimized.

Owner:NANJING INST OF TECH

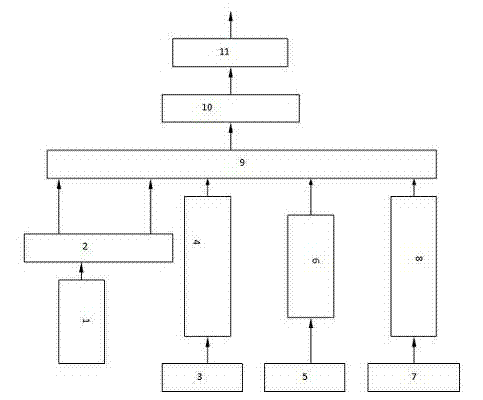

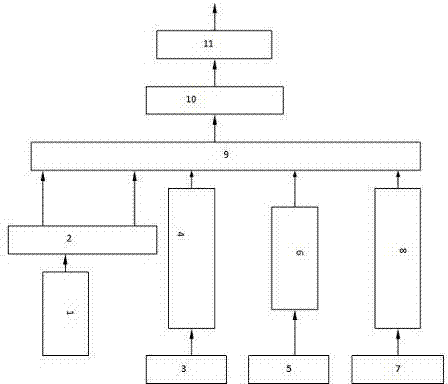

Diagnosis and prevention system and method of high temperature corrosion state of boiler water cooled wall

ActiveCN101858591AWeather/light/corrosion resistanceBoiler indication operationsEngineeringHigh-temperature corrosion

The invention relates to diagnosis and prevention system and method of a high temperature corrosion state of a boiler water cooled wall. The system comprises a plurality of temperature sensors, a coal fired quality sampling module, a coal fineness sampling module, a flue gas sampling module, a data layer module, a characteristic layer data processing module and a decision layer module, wherein the temperature sensors collect the temperature of the water cooled wall through a multi-channel A / D conversion collection module; the coal fired quality sampling module sends coal quality information into a coal quality analysis module, and the coal quality analysis module carries out proximate analysis; the coal fineness sampling module sends collected coal fineness information into a fineness analysis module; the flue gas sampling module sends collected flue gas information into a component analysis module; the data layer module carries out wave filtering treatment on the temperature information, the coal quality information, the fineness information and the flue gas information and rejects abnormal data; the characteristic layer data processing module extracts the characteristic quantity from the data after processing of the data layer module; and the decision layer module comprehensively analyzes and judges the data extracted by the characteristic layer data processing module by an expert system to obtain a reasonable and accurate result, and the result is output and participate into operation regulation.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

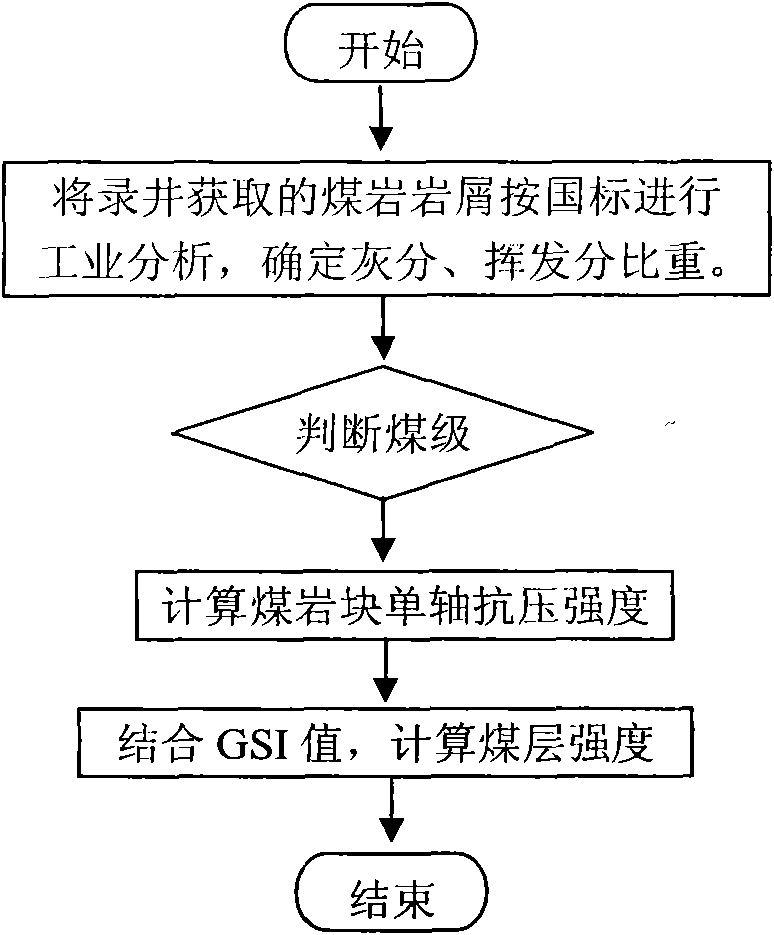

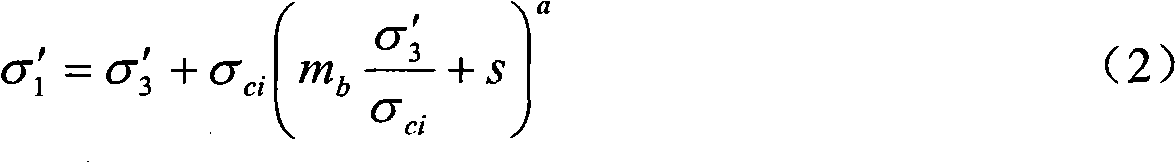

Technology for determining coal bed intensity by using coal ash

InactiveCN102102514AGood application effectBorehole/well accessoriesWell drillingGeological Strength Index

The invention relates to a technology for determining coal bed intensity by using coal ash, which is suitable for the technical field of well wall stabilization in well drilling for coal bed methane. The method comprises the following steps of: classifying, cleaning, baking and crushing coal rock debris obtained by logging, performing proximate analysis of coal according to the national standard, and determining the ratio of ash to volatile; judging the coal grade of the coal rock according to the volatile value; selecting the corresponding empirical formula of the relationship between the ash and the intensity according to the coal grade and calculating the intensity of coal rock blocks; and solving the coal reservoir intensity by combining a geological strength index (GSI) value and applying a Hoek-Brown rock mass strength empirical formula. The method is provided by combining the field on the basis of the Hoek-Brown rock mass strength empirical formula, and is suitable for the requirement for acquiring the parameters of the coal bed intensity in the well wall stabilization prediction of well drilling for the coal bed methane, and the prediction method is simple and has a good effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

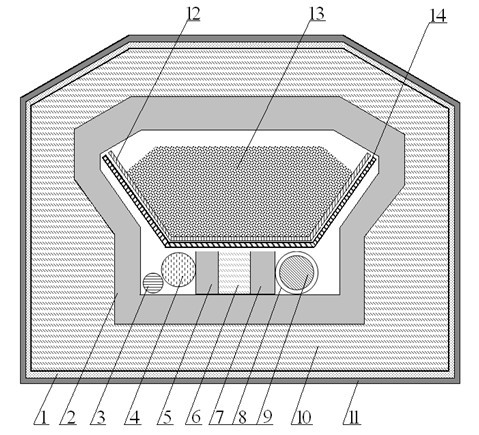

On-line analysis device of pulsed neutron coal element content and proximate analysis indexes

InactiveCN102608141AHigh precisionReduce entryMaterial analysis by transmitting radiationD t neutronCoal

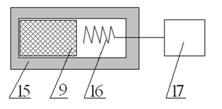

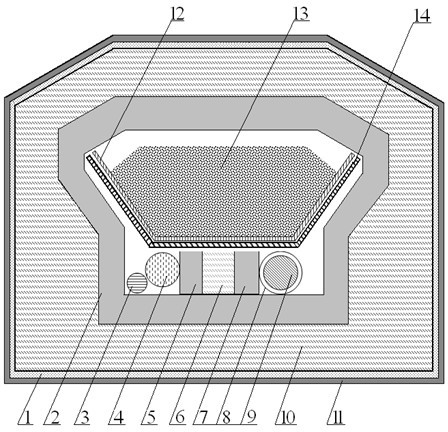

The invention belongs to the technical field of nucleus technology application, and relates to an on-line analysis device of pulsed neutron coal element content and proximate analysis indexes. The on-line analysis device comprises a radiation protector, a coal conveying channel and a detection device; the coal conveying channel and the detection device are arranged in the radiation protector; the detection device is positioned below the coal conveying channel; the detection device comprises a neutron detector, a pulsed D-T neutron generator and a BGO (bismuth germanium oxide) detector and is characterized in that a lead plate a, a polyethylene plate and a lead plate b are sequentially arranged between the pulsed D-T neutron generator and the BGO detector; and the BGO detector is positioned in a BGO detector constant temperature control system, with a temperature range kept at -4.5 DEG C to -5.5 DEG C. According to the invention, the on-line analysis device is not influenced by parameters such as changes of coal type, speeds of a belt for conveying coal, thickness changes of coal seams, particle sizes of coal and the like, so that the precision for measuring parameters of coal property is high.

Owner:NANJING LONGYUAN ENVIRONMENTAL CO LTD

Chinese cordyceps sinensis protein polysaccharide and preparation and application thereof

ActiveCN103130907AImprove orderClear structureImmunological disordersHorticultureAqueous extractChemistry

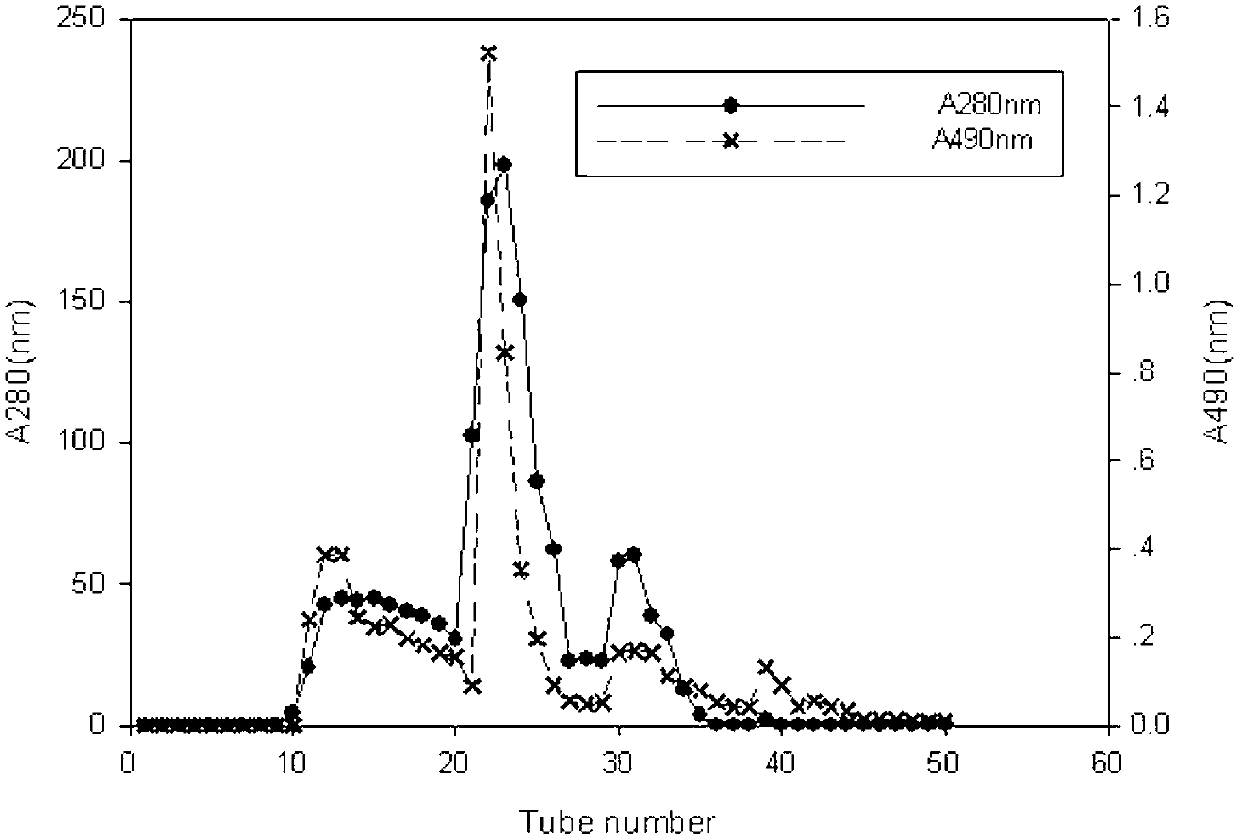

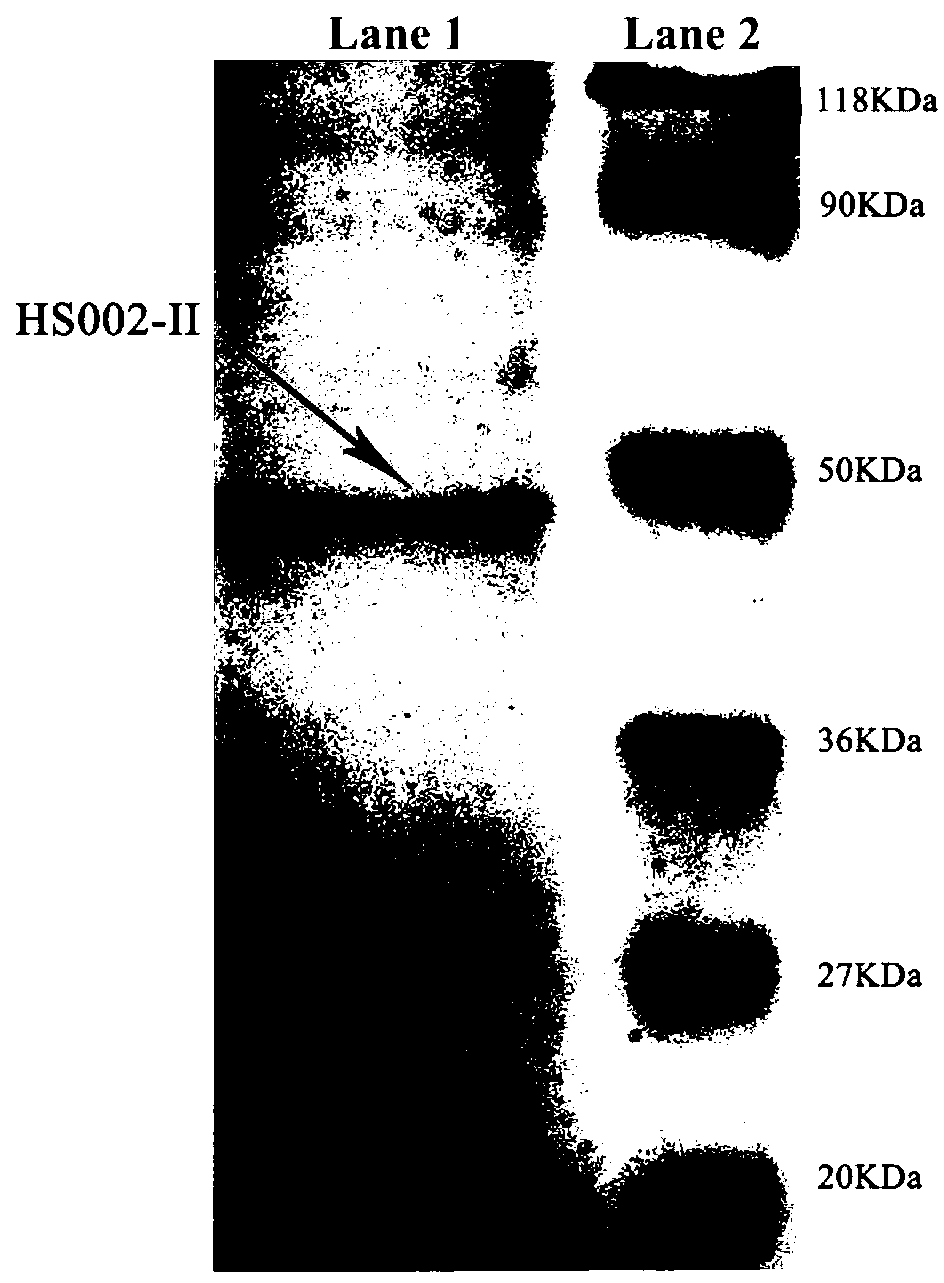

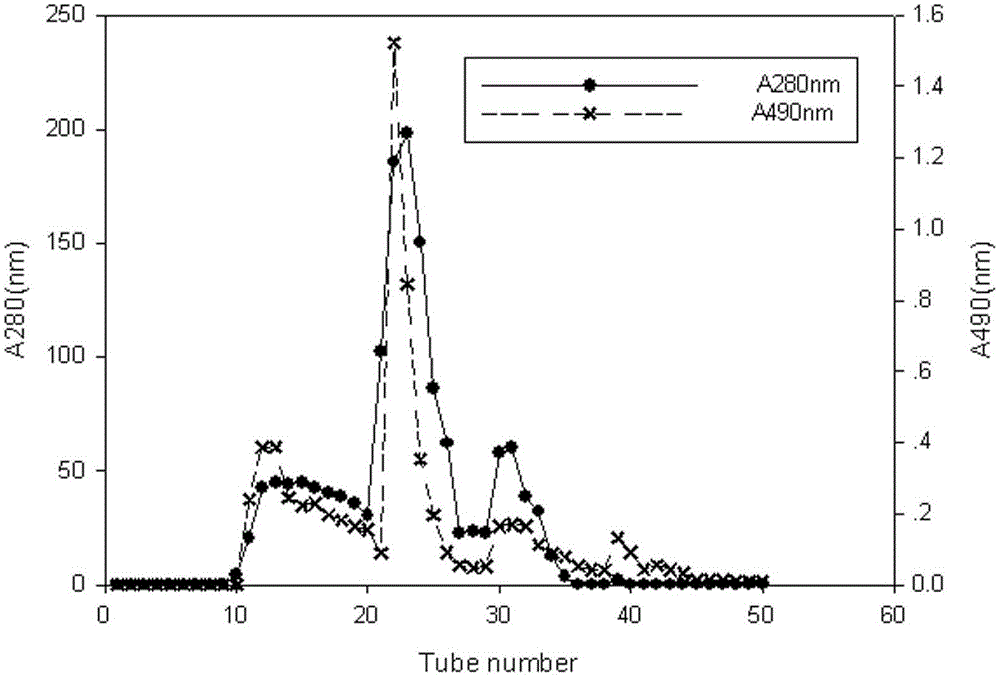

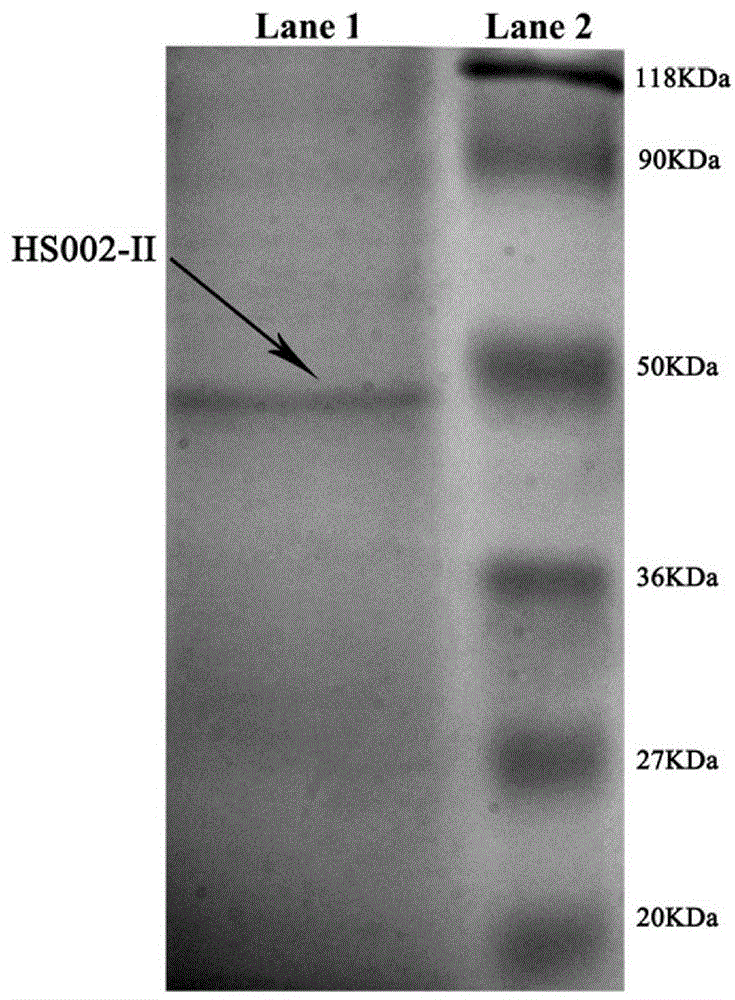

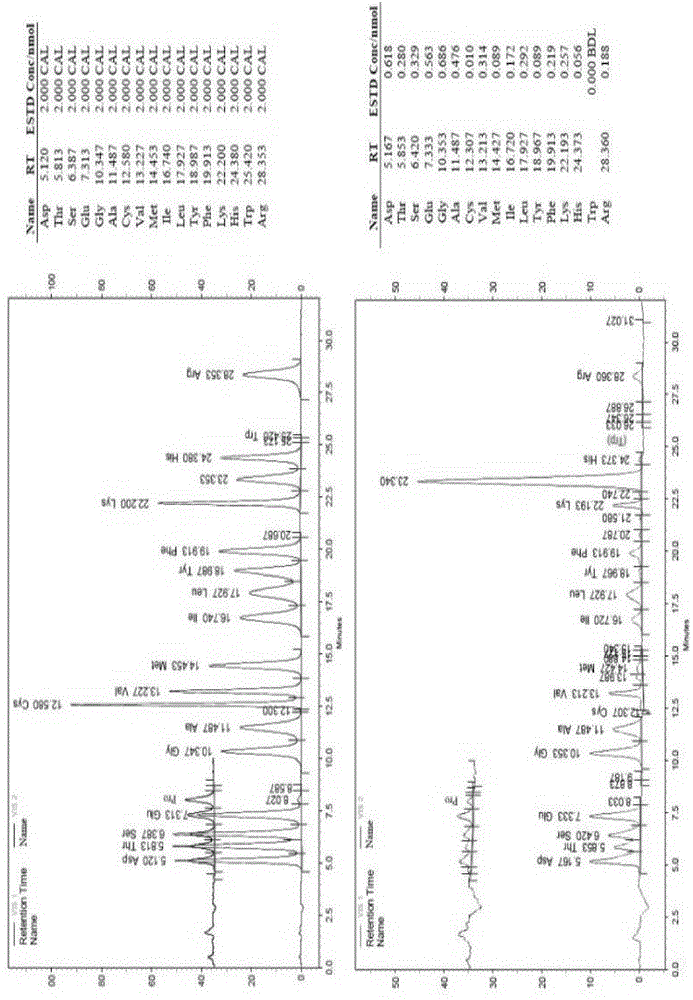

The invention discloses a Chinese cordyceps sinensis protein polysaccharide and preparation and application thereof. The Chinese cordyceps sinensis protein polysaccharide is composed of polysaccharide with 55%-60% weight percentage and protein with 40%-45% weight percentage; and the ingredients of the polysaccharide are mannose, ribose, glucose, galactose, xylose and arabinose; the ratio of amount of substances among the mannose, the ribose, the glucose, the galactose, the xylose and the arabinose is 6.42-6.51: 2.20-2.32: 65.85-65.95: 2.10-2.18: 4.20-4.30. The Chinese cordyceps sinensis protein polysaccharide preparation method comprises the following steps: extracting the Chinese cordyceps sinensis protein polysaccharide by aqueous extract and alcohol precipitation, removing the protein, dialyzing, exchanging chromatography by anion and purifying gel filter layer chromatography through an enzyme-Sevage combination method, and freezing, drying and separating purification components in vacuum, and the Chinese cordyceps sinensis protein polysaccharide is acquired. According to the preparation and the application thereof, proximate analysis, structural identification and immunologic function study are carried out on the components of polysaccharide after purification, and the facts that the Chinese cordyceps sinensis protein polysaccharide has strong immunoregulation activity and is a potential immunological enhancement substance are discovered.

Owner:ZHEJIANG FORESTRY ACAD

Tobacco rapid industrial analysis method

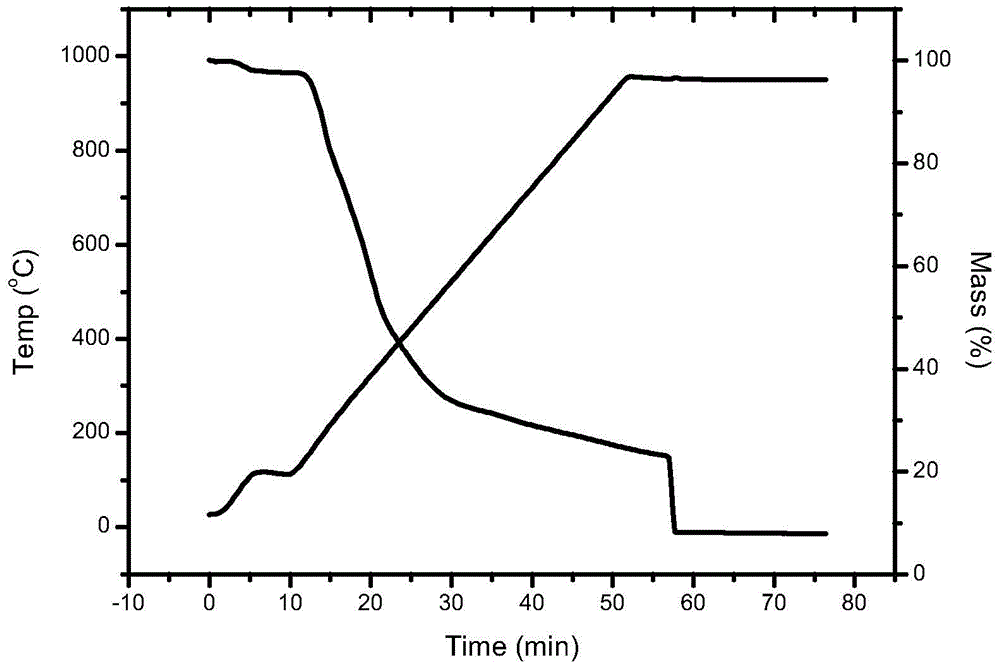

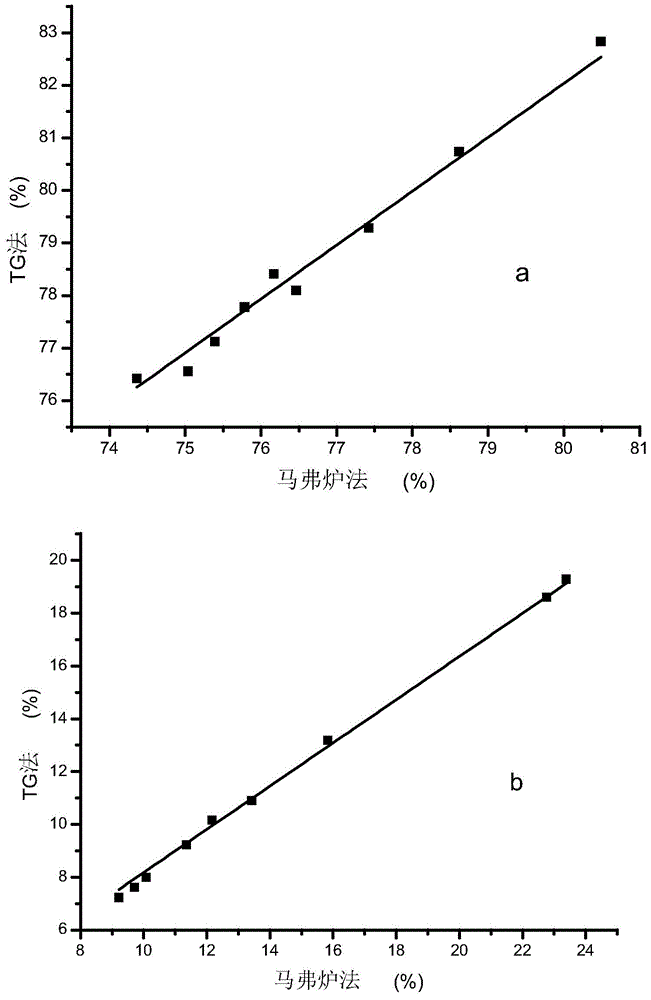

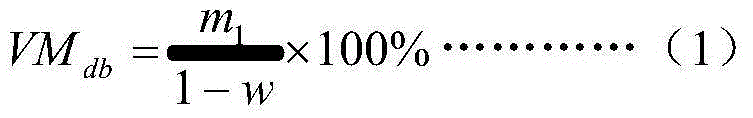

InactiveCN105043924AReduce total time for industrial analysis testingEnsure consistencyWeighing by removing componentSmall sampleEngineering

The invention discloses a tobacco rapid industrial analysis method. According to the invention, a thermogravimetric analysis method replaces a drying oven method and a Muffle furnace method which are used for traditional proximate analysis, and a moisture value, an ash content value, a volatile matter value and a fixed carbon value of a tobacco sample are obtained through a TG curve at the same time. The method has the advantages of small sample amount for detection, short analysis time, low cost, simple operation and accurate experimental result, and is a tobacco rapid industrial analysis method capable of meeting rapid on-line analysis requirement of industrial current environment.

Owner:CHINA TOBACCO ANHUI IND CO LTD

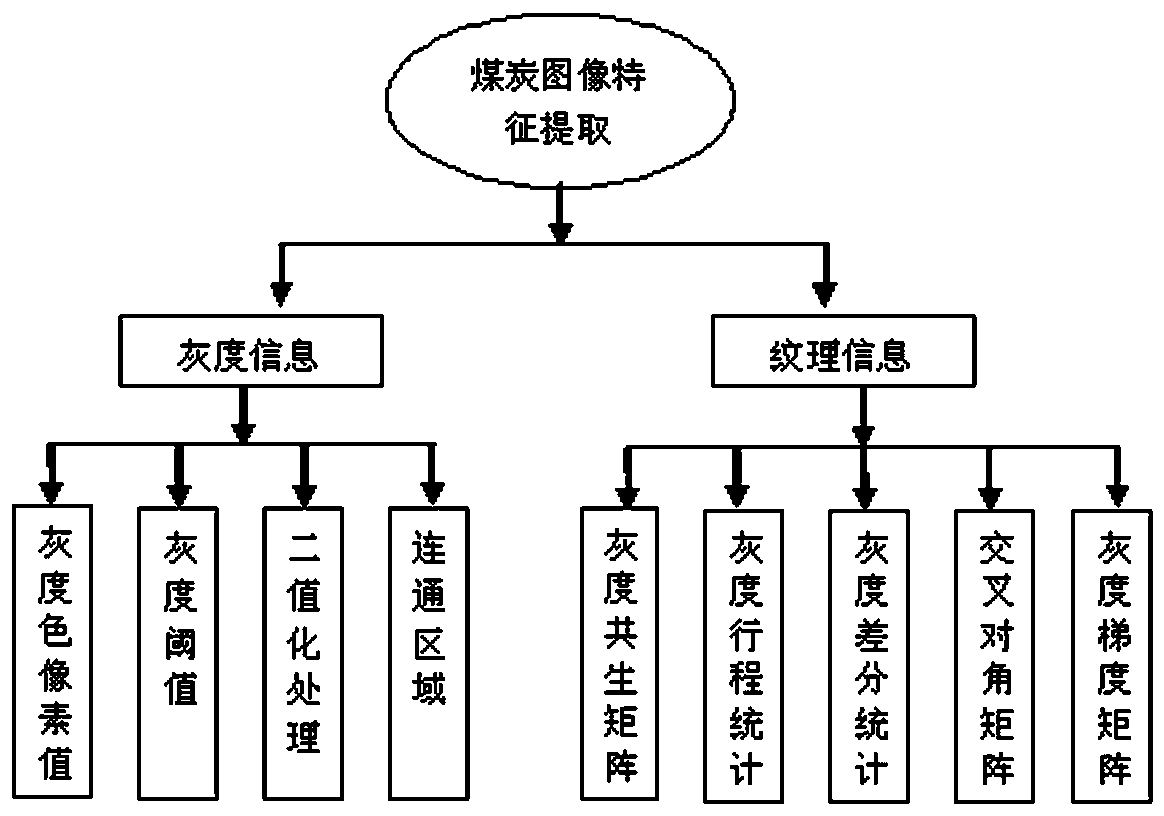

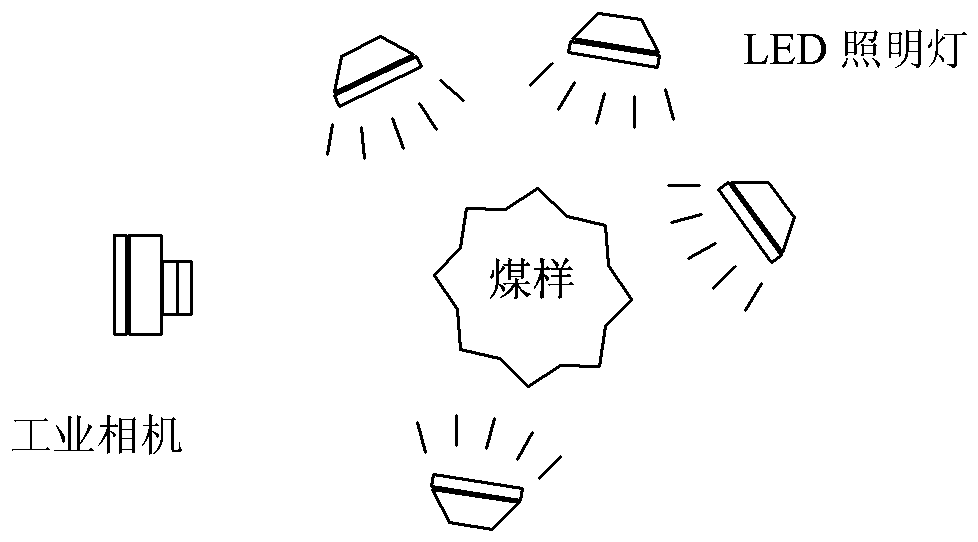

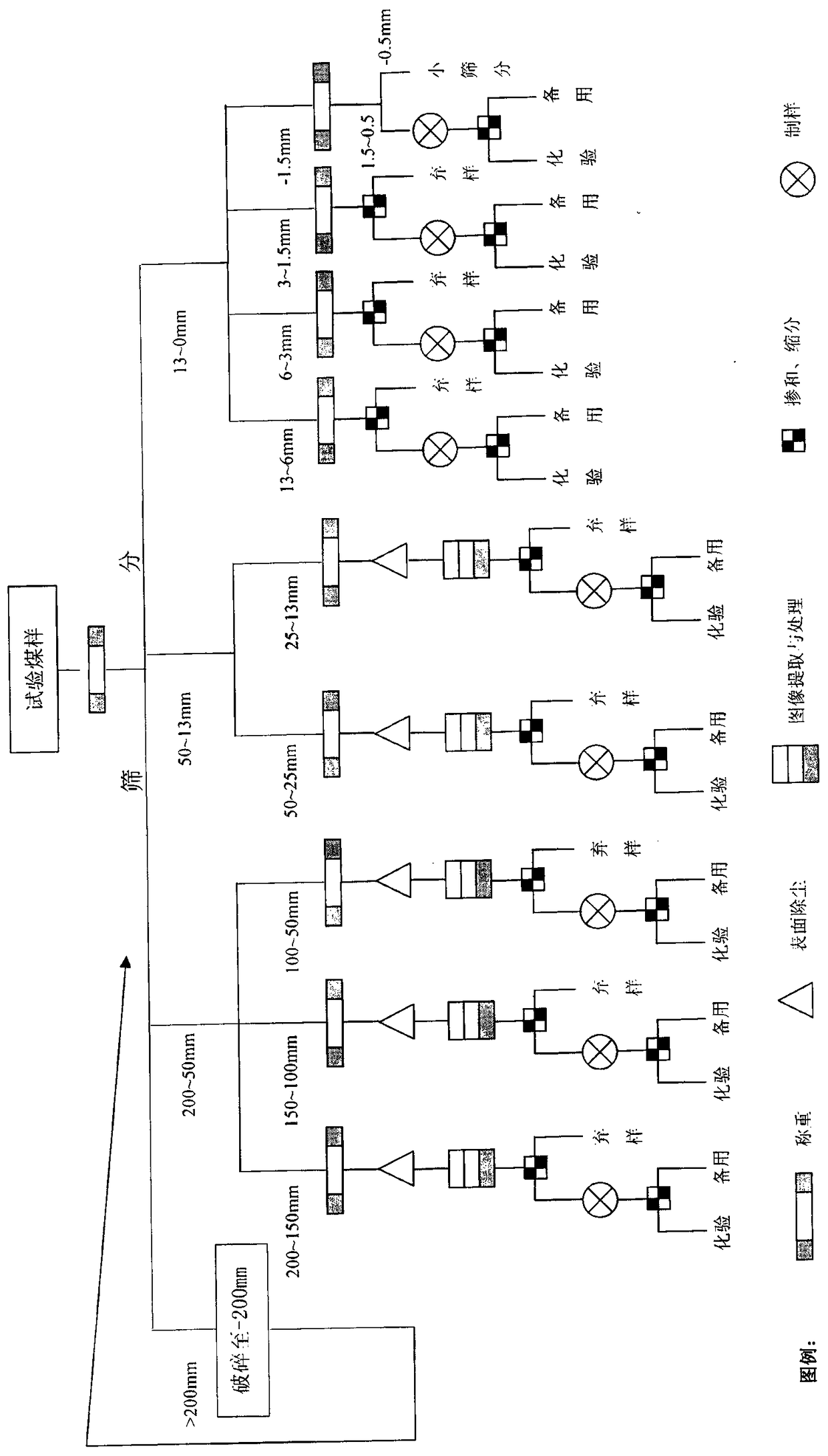

Method for evaluating washability in coal separation process according to image recognition method

InactiveCN108932529ASolve the problem of product quality controlCharacter and pattern recognitionFeature extractionElement analysis

The invention relates to a method for evaluating the washability in the coal separation process according to an image recognition method. In the method, raw coal separation is realized according to the grayscale and texture structure difference by using an image recognition technology. The washability evaluating method comprises the steps of raw coal sampling, raw coal gross sample analysis, raw coal particle size analysis, raw coal image analysis, washability curve drawing and washability evaluation, wherein the sampling of raw coal samples should be representative; the raw coal gross sampleanalysis includes element analysis, industrial analysis, coal ash component analysis and physical property analysis; screening is performed according to 200mm, 150mm, 100mm, 50mm, 25mm, 13mm, 6mm and0.5mm, and test samples are taken from each particle size of the screened coal samples for industrial analysis and element analysis; the coal samples with the particle size being 6mm and above are respectively sampled for image feature extraction, and the image recognized coal samples are sampled again for industrial analysis and element analysis; and a screening-image feature washability curve for the particle size of 6mm and above is drawn.

Owner:HENAN POLYTECHNIC UNIV

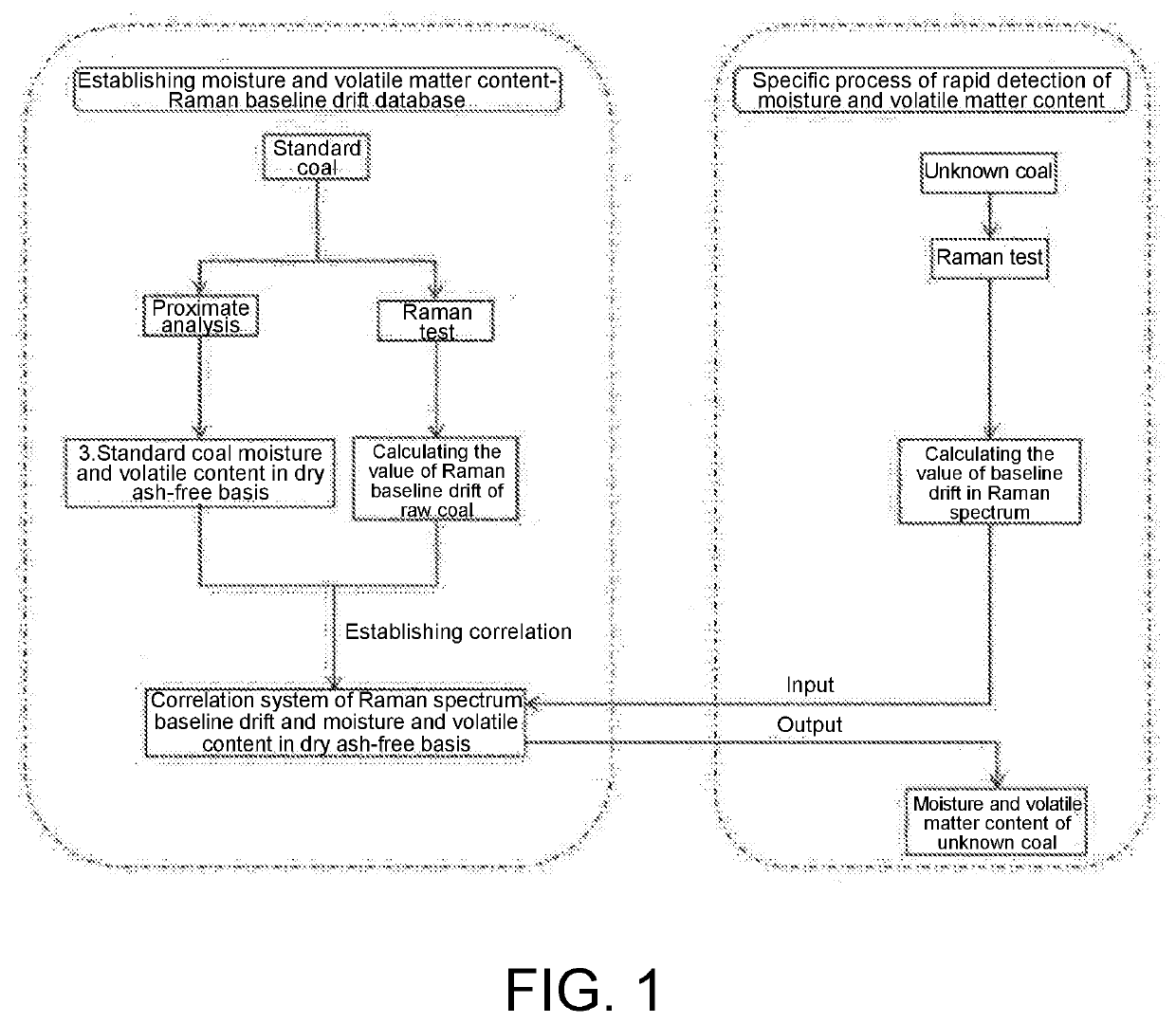

Method for detecting moisture and volatile matter content of raw coal by using value of baseline drift

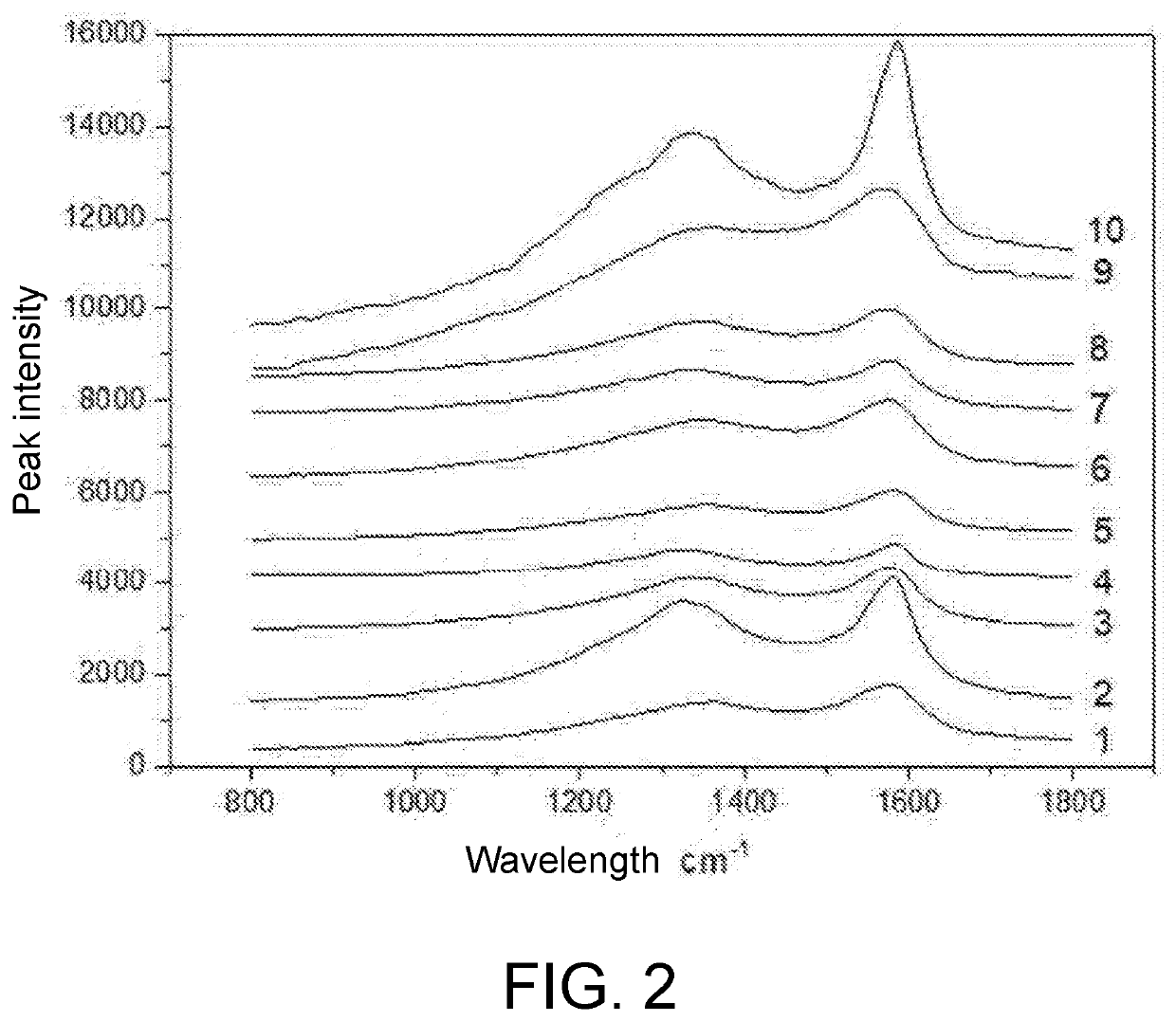

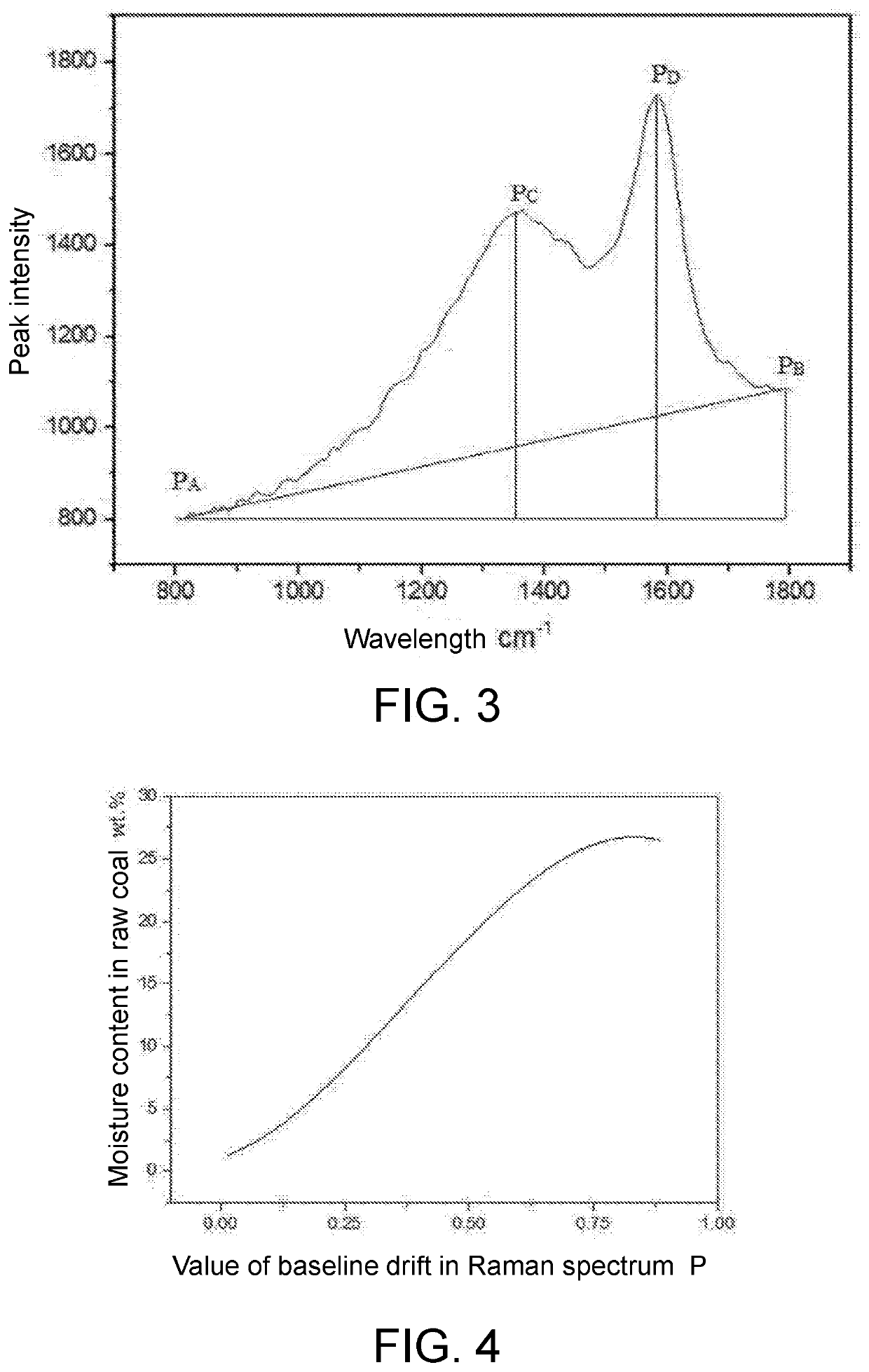

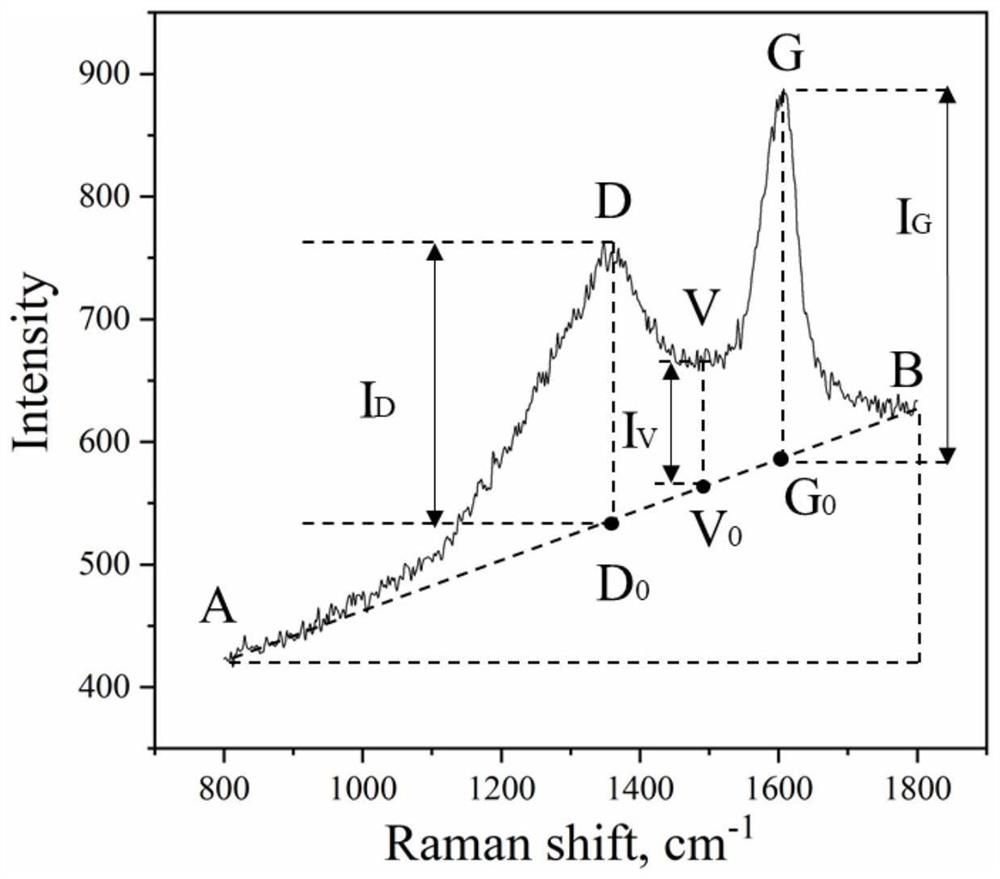

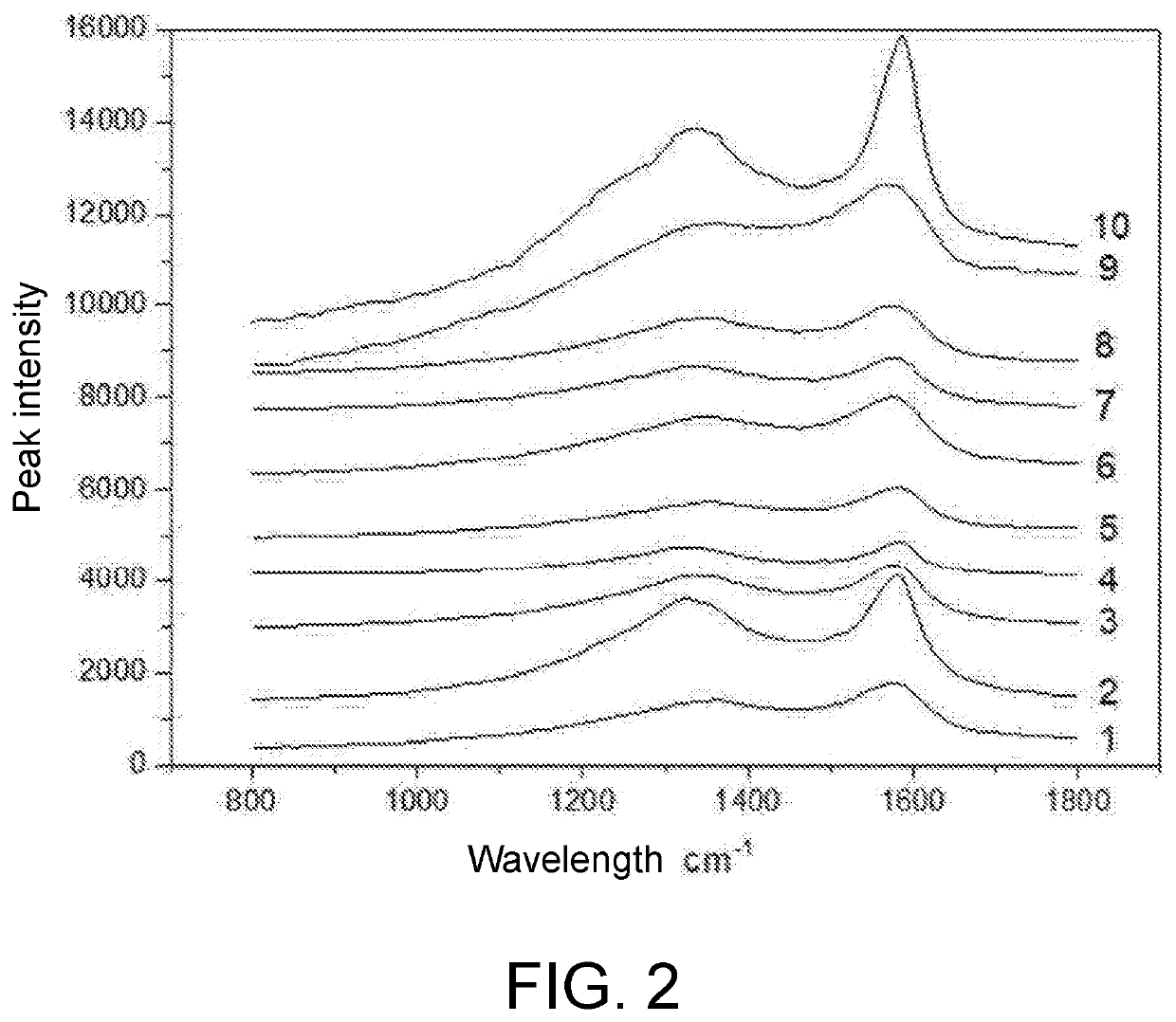

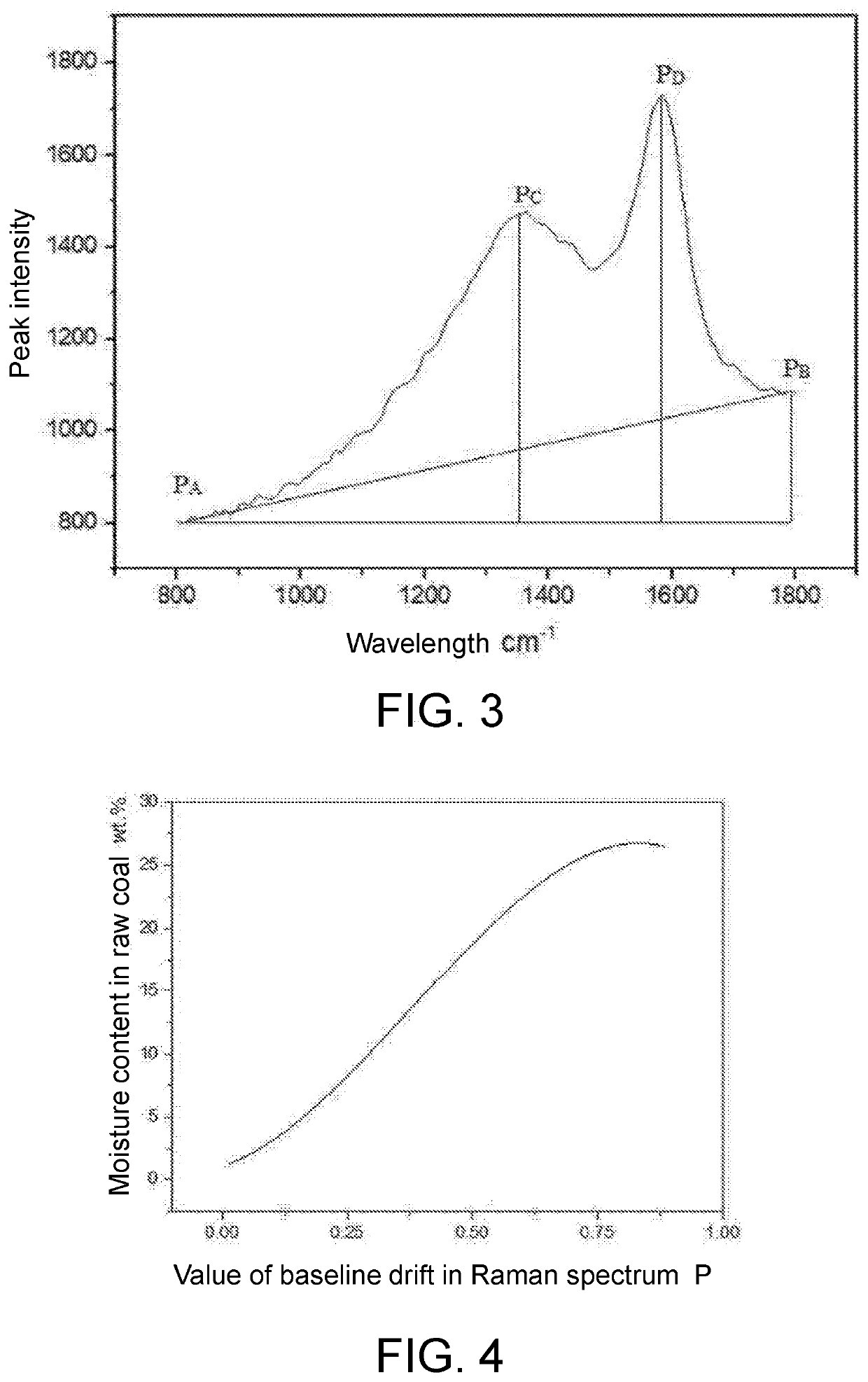

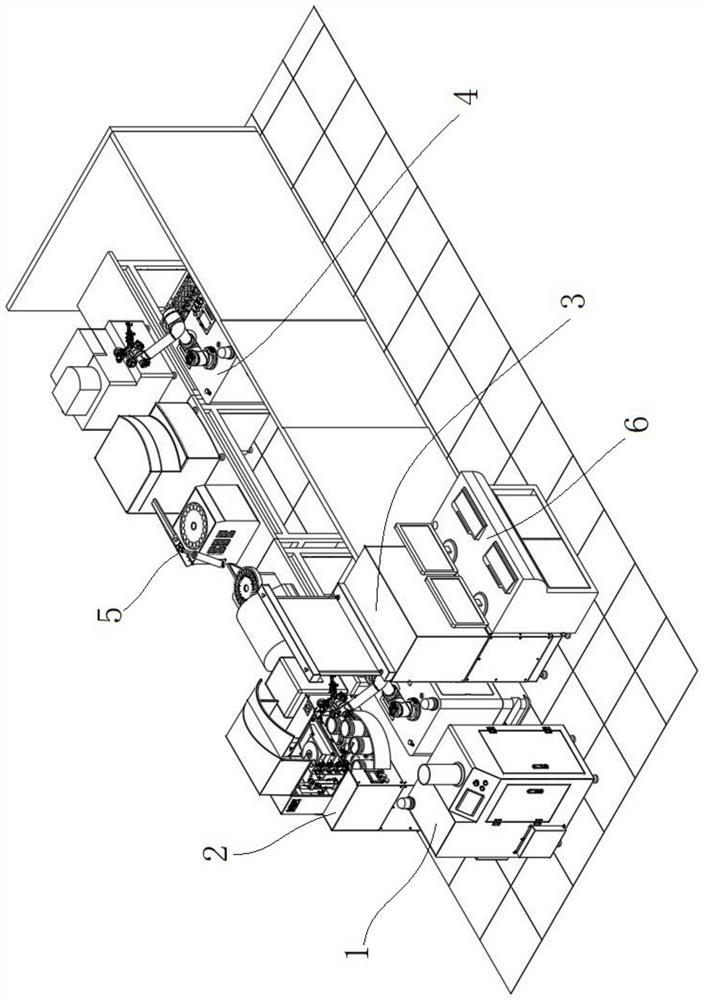

ActiveUS20200264106A1Automatic recognitionAppropriate controlFuel testingRaman scatteringProximate analysisCoal rank

The present invention relates to a method for detecting moisture and volatile matter content in raw coal using the value of baseline drift, comprising the following steps: selecting a plurality of types of standard coal having different coal ranks and different ash contents, performing a Raman spectroscopy test and a proximate analysis on each type of standard coal, calculating the value of baseline drift in the Raman spectrum, and setting up the mapping relationship between the value of baseline drift in the Raman spectrum and the characteristic parameters of the moisture and the volatile matter content. The same method and reference are used to perform a Raman spectroscopy test on raw coal to be tested, so as to calculate the value of baseline drift in a Raman spectrum of the raw coal to be tested, and obtain the moisture and volatile matter content of the raw coal to be tested.

Owner:HUAZHONG UNIV OF SCI & TECH

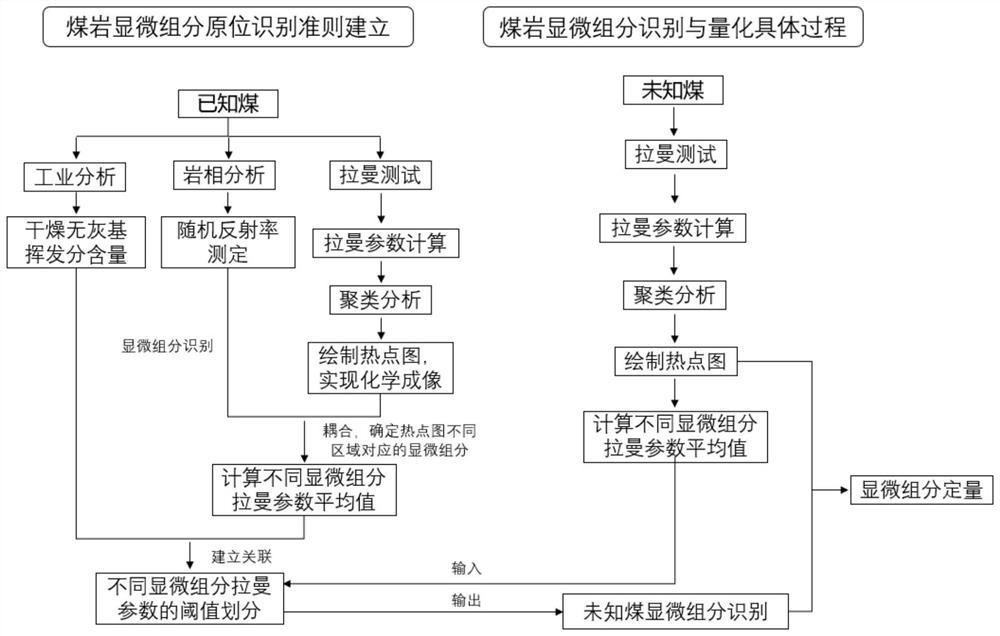

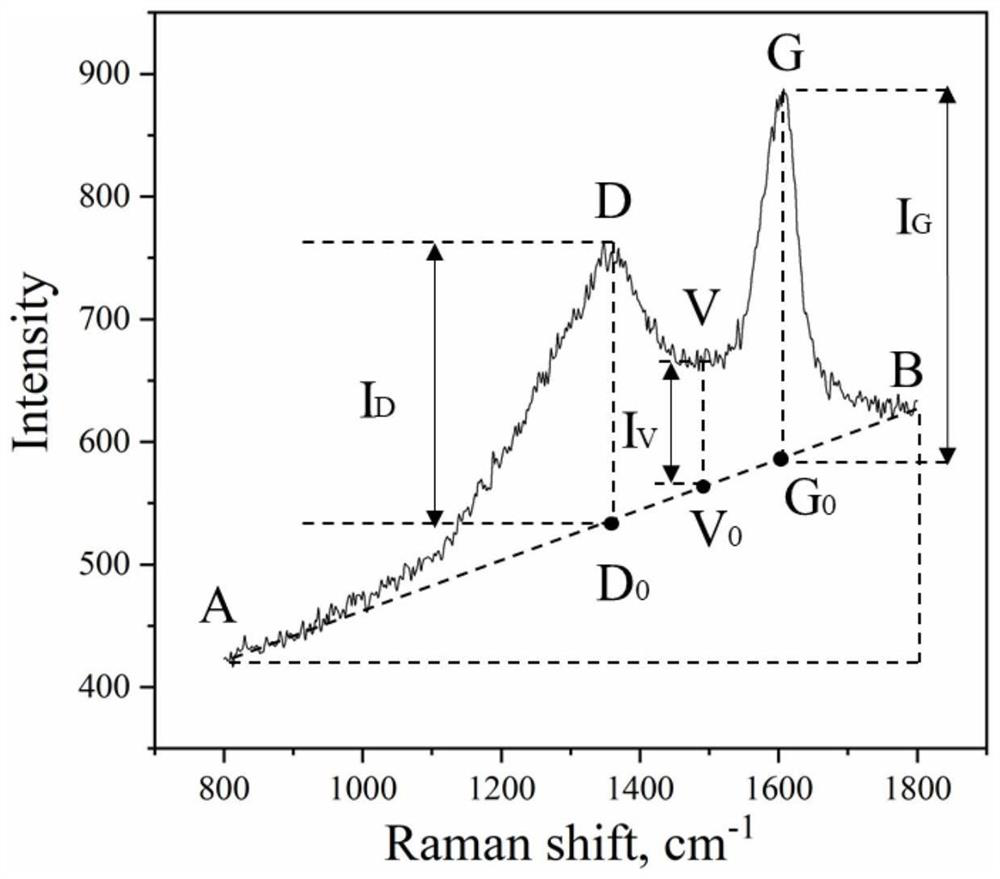

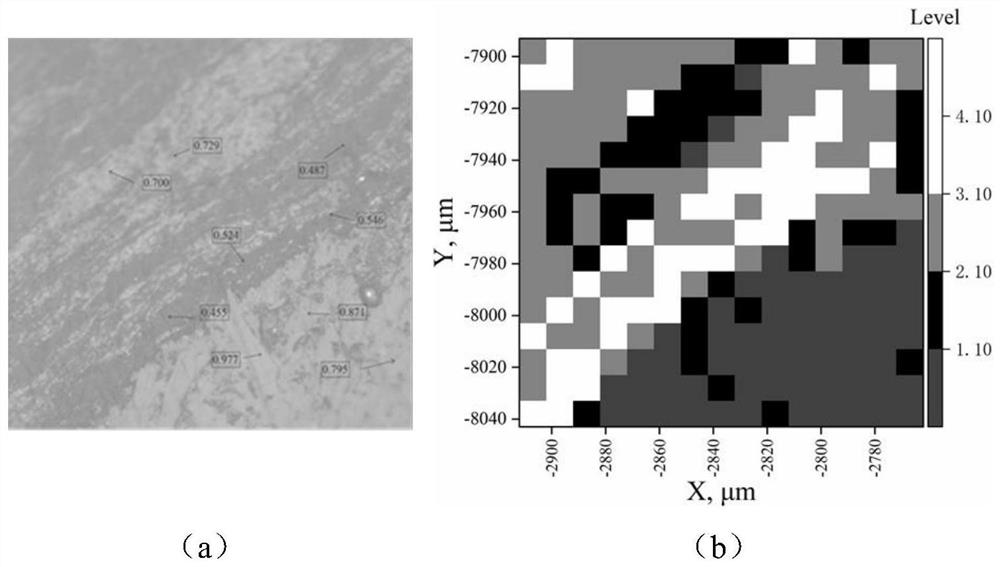

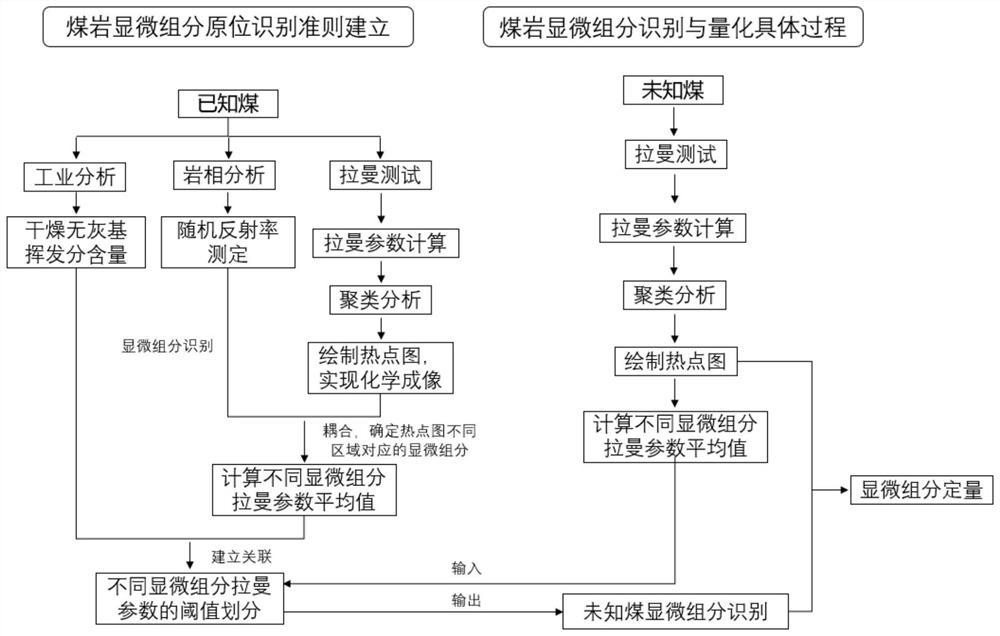

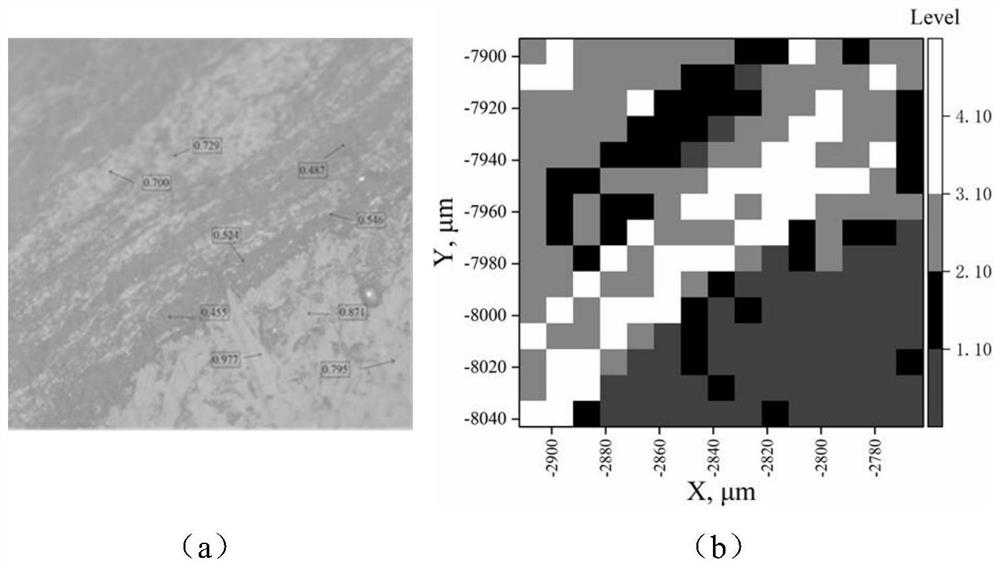

In-situ identification and rapid quantification method for coal rock macerals

The invention discloses an in-situ identification and rapid quantification method for coal rock macerals. The method comprises the following steps: firstly, selecting a plurality of different coal rank standard coals to carry out industrial analysis, lithofacies analysis and Raman spectrum surface scanning to obtain dry ash-free base volatile component content Vdaf, macerate type determination results and Raman characteristic parameters; selecting a plurality of Raman characteristic parameters for clustering analysis, drawing a hot spot map according to a clustering result, comparing the hot spot map with a lithofacies analysis result, and determining microcomponent types corresponding to different colors of the hot spot map; establishing a corresponding relationship between the Raman characteristic parameters and Vdaf, determining a threshold interval where the Raman characteristic parameters of different microscopic components of each coal rank are located, and establishing a microscopic component in-situ identification criterion according to the interval; during detection, performing industrial analysis and Raman test on coal to be detected, identifying the macerals by utilizingthe criterion, and determining the content of the corresponding macerals according to the proportion of each color point in the hot spot map. The experiment and data processing method is simple, andthe detection is rapid and accurate.

Owner:HUAZHONG UNIV OF SCI & TECH

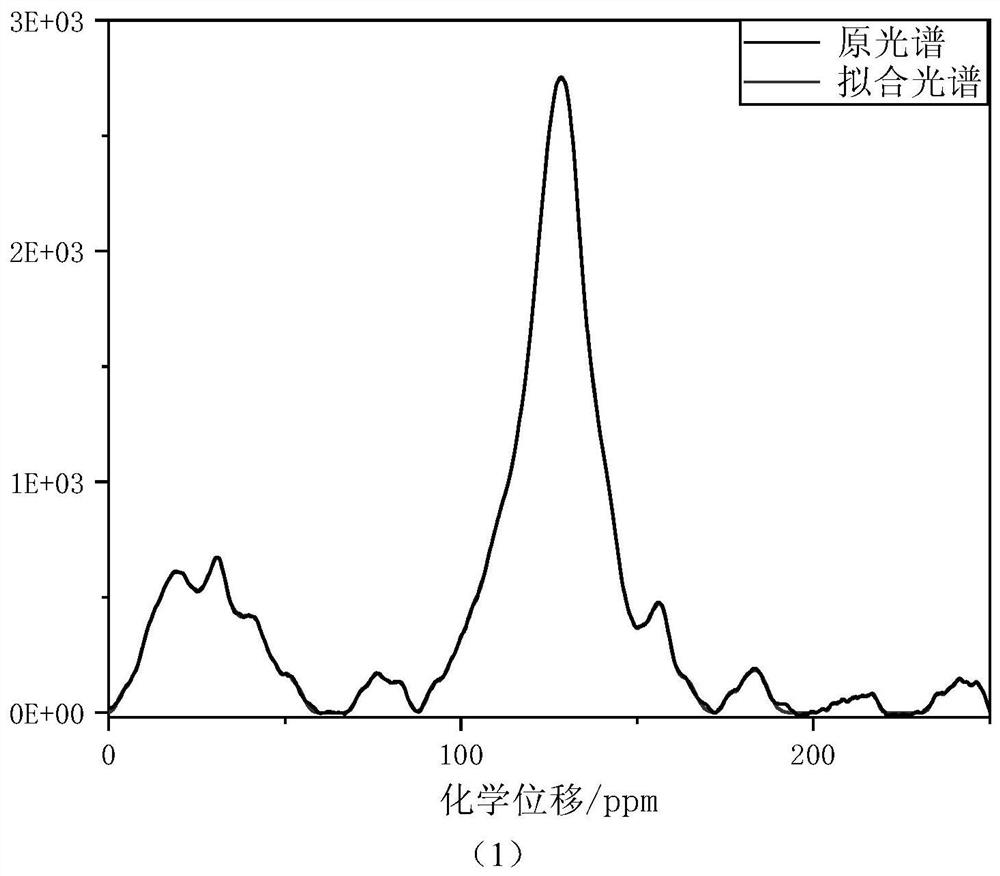

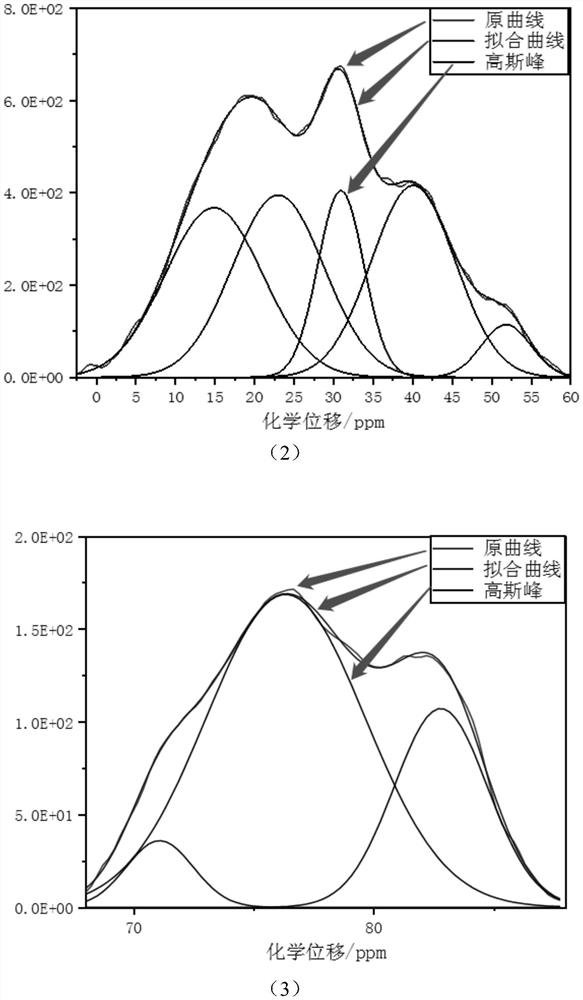

Coal molecule model establishing method based on multiple characterization means

ActiveCN112903621AUnderstanding Combustion CharacteristicsImprove combustion efficiencyMolecular designFuel testingElemental analysisIr microscope

The invention provides a coal molecular model establishing method based on multiple characterization means. The method comprises the following steps: (1) carrying out industrial analysis, elemental analysis, <13>C-NMR analysis, FTIR absorption characteristic analysis, surface structure characteristic analysis, nuclear magnetic resonance analysis and infrared spectroscopic analysis on a coal sample; (2) establishing a relation between a skeleton structure and surface functional groups of the coal; (3) obtaining molecular structure parameters of the coal sample; and (4) constructing a molecular structure model of the coal sample by using ACD / ChemSketch10.0 software. The structural data of the coal sample is obtained through a plurality of physical and chemical analysis experiments, and by combining the analysis result, molecular composition structures of the coal samples with different metamorphic degrees are researched by virtue of physical and chemical analysis methods such as <13>C-NMR, FTIR and a chemical experiment method; and the establishment of the coal molecular structure model has milestone value for the development of the coal chemical industry, and also has important reference significance for knowing the combustion characteristics of the coal sample and improving the combustion efficiency.

Owner:CHINA UNIV OF MINING & TECH

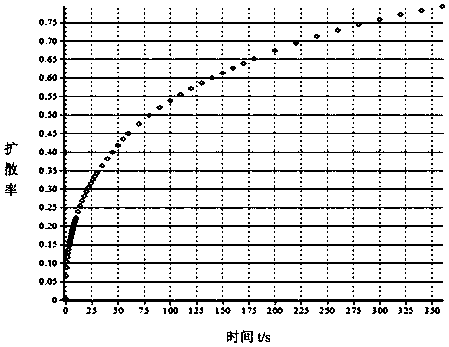

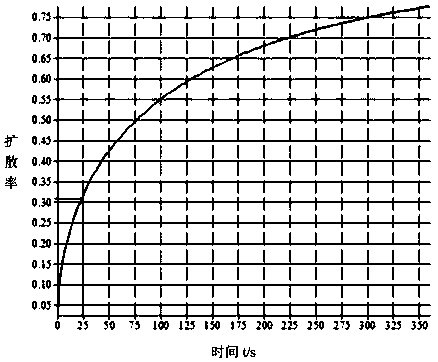

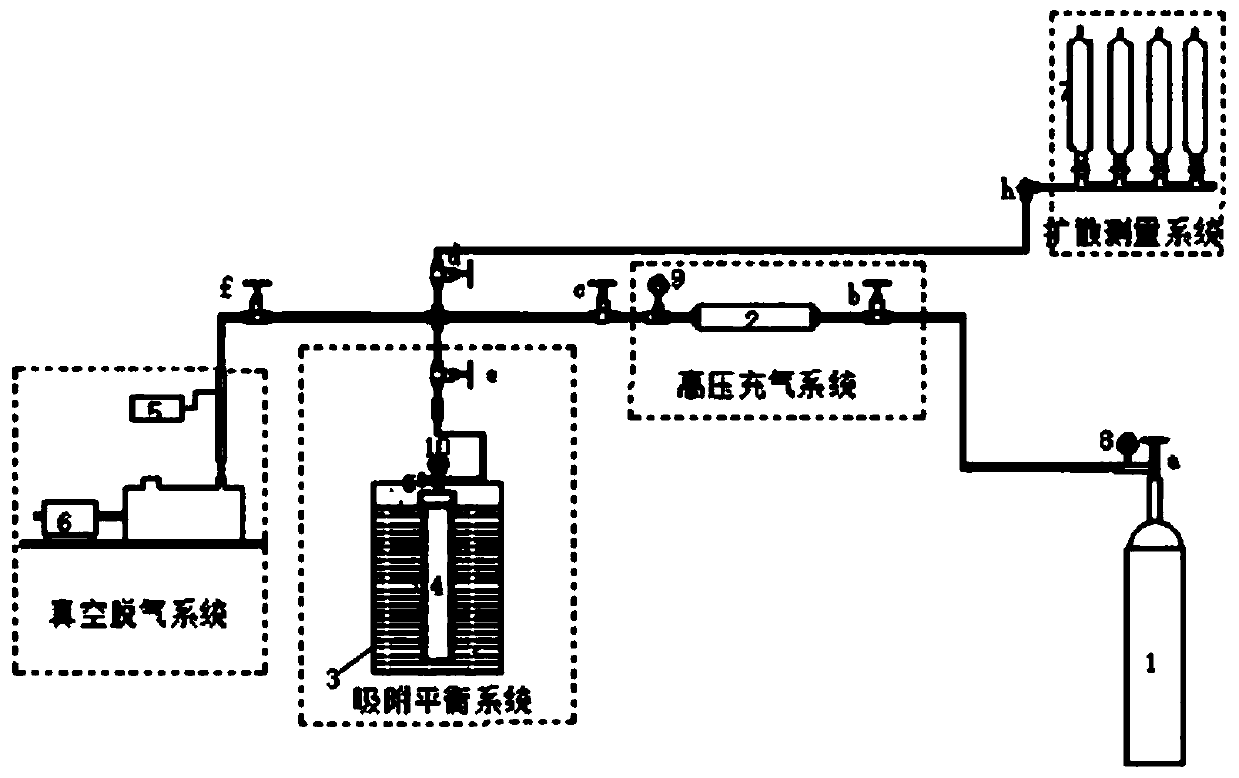

Method for quickly measuring coal seam gas content based on diffusivity curve subtraction

InactiveCN111337388AAccurate and convenient measurementAvoid measurement errorsFuel testingDiffusion analysisThermodynamicsCoal particle

The invention discloses a method for rapidly measuring coal seam gas content based on diffusivity curve subtraction, relates to the technical field of coal seam gas basic parameter measurement, and can accurately, conveniently and rapidly measure coal seam original gas content. The method mainly comprises the following steps: a, field sampling; b, laboratory coal sample industrial analysis; c, a laboratory coal sample gas diffusion experiment; d, fitting of a coal sample gas diffusivity curve by the new model of the dynamic diffusion coefficient of the spherical coal particles; e, field desorption test; f, calculating of the original gas content of the coal sample. The method is different from the conventional method, avoids the gas content measurement error caused by the calculation errorof a desorption model, does not need to calculate the gas residual amount, and does not need to consider the gas loss amount. The determination process is simple and feasible, the determination timeis short, and the method is suitable for determining the original gas content of coal seams with various metamorphic degrees under various complex geological conditions.

Owner:HENAN POLYTECHNIC UNIV

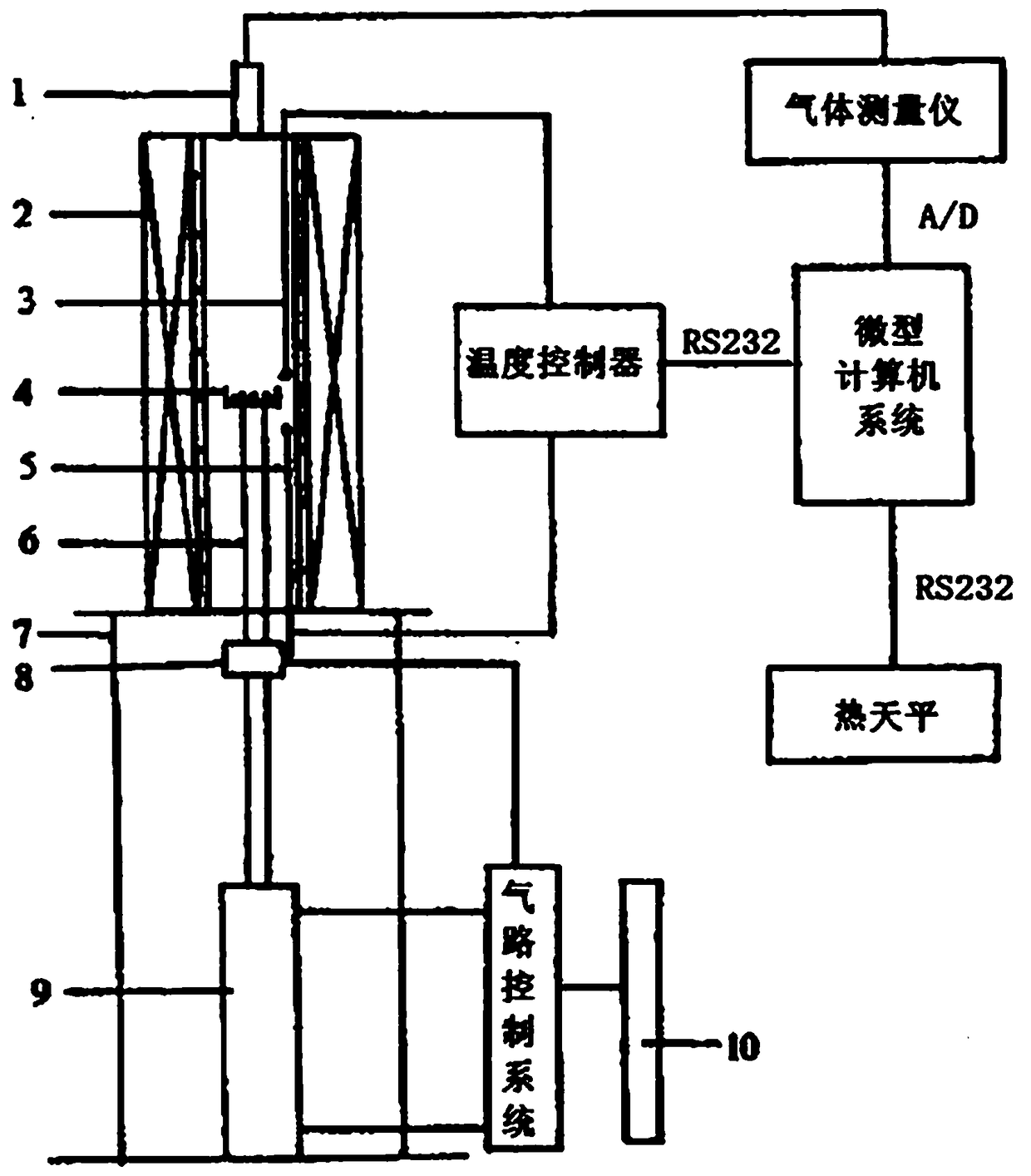

Coal combustion characteristic comprehensive tester

The invention relates to a coal combustion characteristic comprehensive tester, which comprises a combustion furnace, a temperature controller, an atmosphere pneumatic control system, a thermobalance,a gas measurement instrument and a microcomputer system. According to the present invention, the ignition temperature, the burn-out time and the proximate analysis value of coal are measured by usinga steady-state measurement method, data processing and analysis is performed by a computer, the basic evaluation is performed on the coal quality, and the scientific basis is provided for the reasonable coal use.

Owner:张琳

Rapid technical analysis method of coal

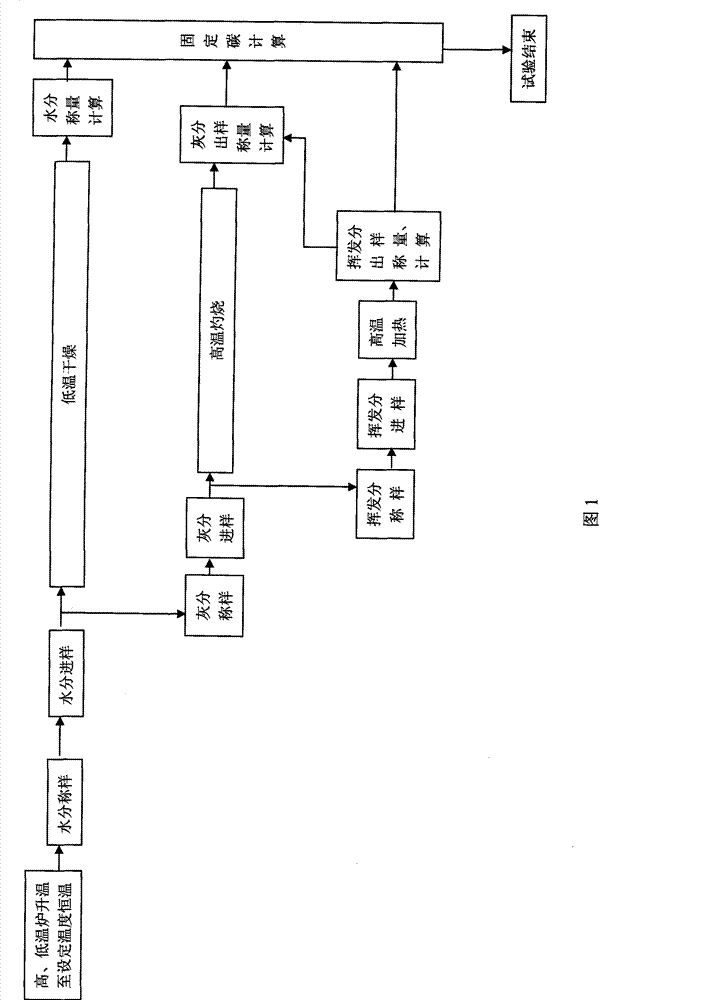

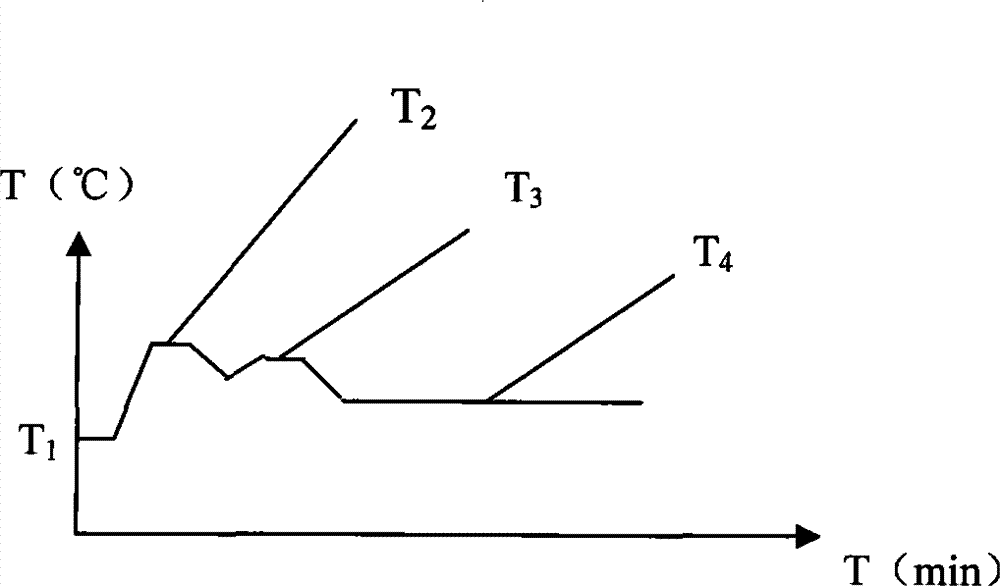

ActiveCN101377483BReduce total time for industrial analysis testingEliminate experimental errorWeighing by removing componentFuel testingPhysical chemistryProcess engineering

Disclosed is an industrial analysis method for coals, which gets a moisture value, an ash value, a volatile value and a fixed carbon value in a coal sample after carrying out a moisture test, an ash test and a volatile test on the coal sample; the method carries out a test on an ash air-dried coal sample and a volatile air-dried coal sample at the same time in an identical high temperature furnace to get the ash value and the volatile value. The invention is the industrial analysis method which has the advantages of short test time, high work efficiency and accurate test results, as well as can satisfy the rapid on-line analysis requirements for an industrial field.

Owner:HUNAN SUNDY SCI & TECH DEV

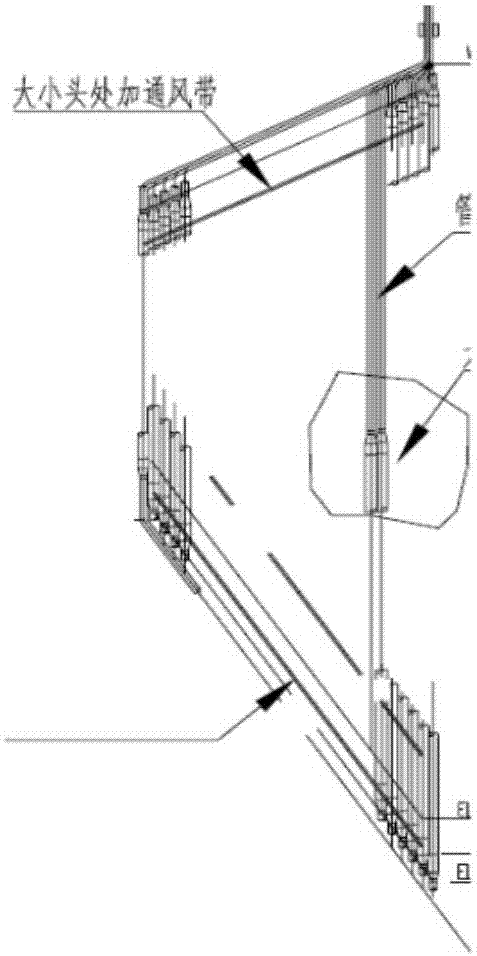

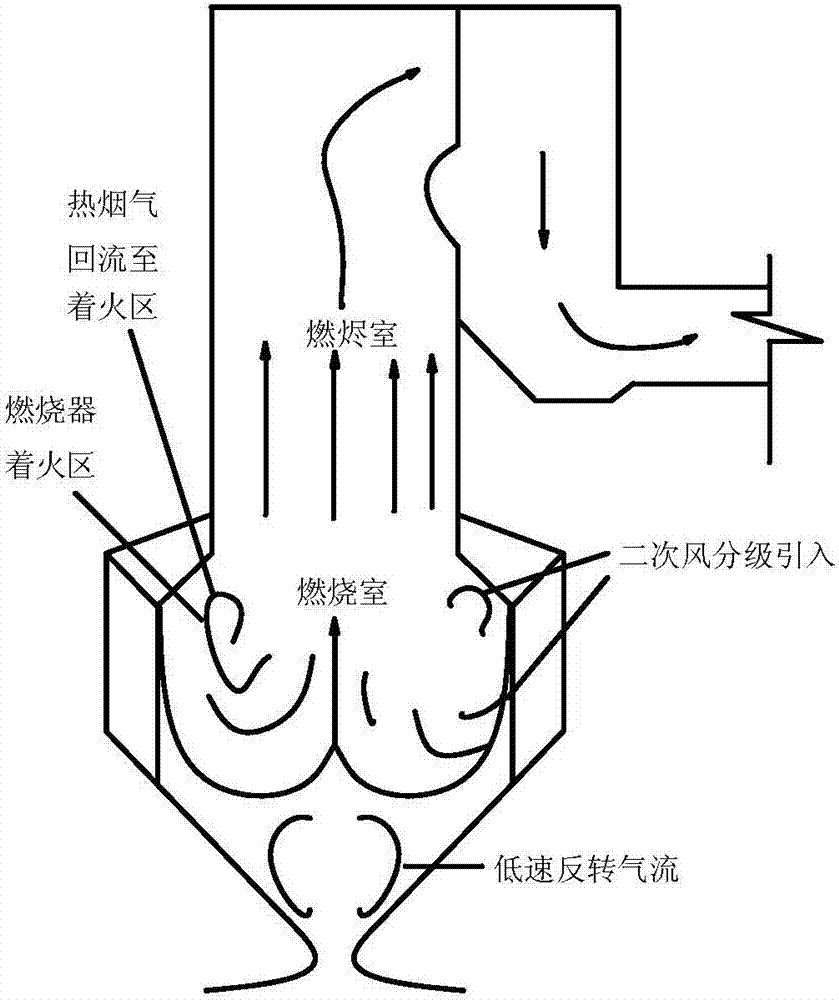

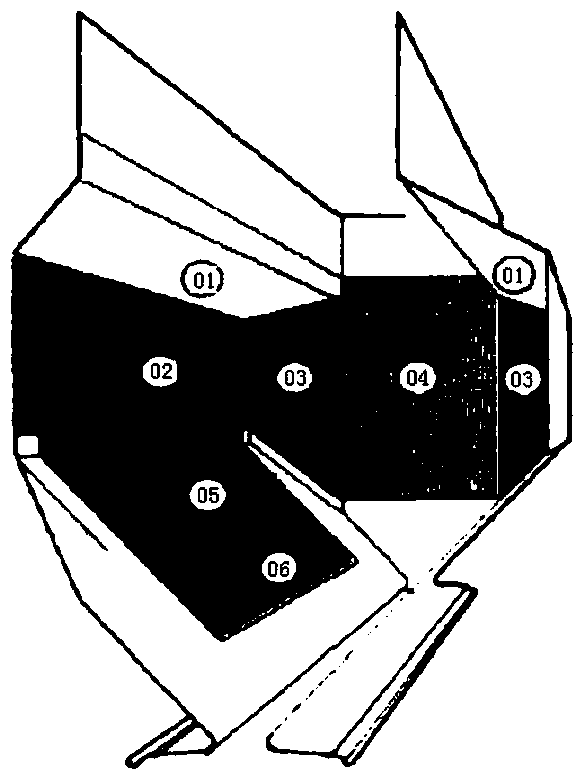

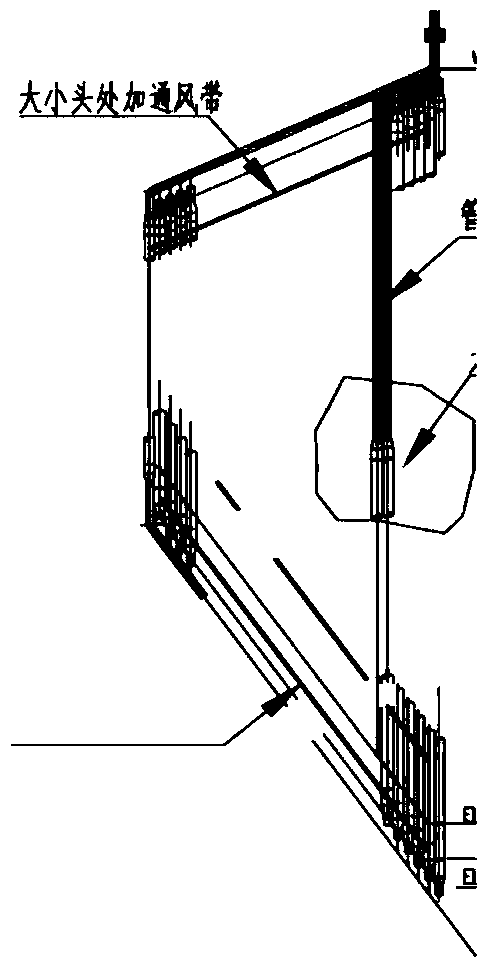

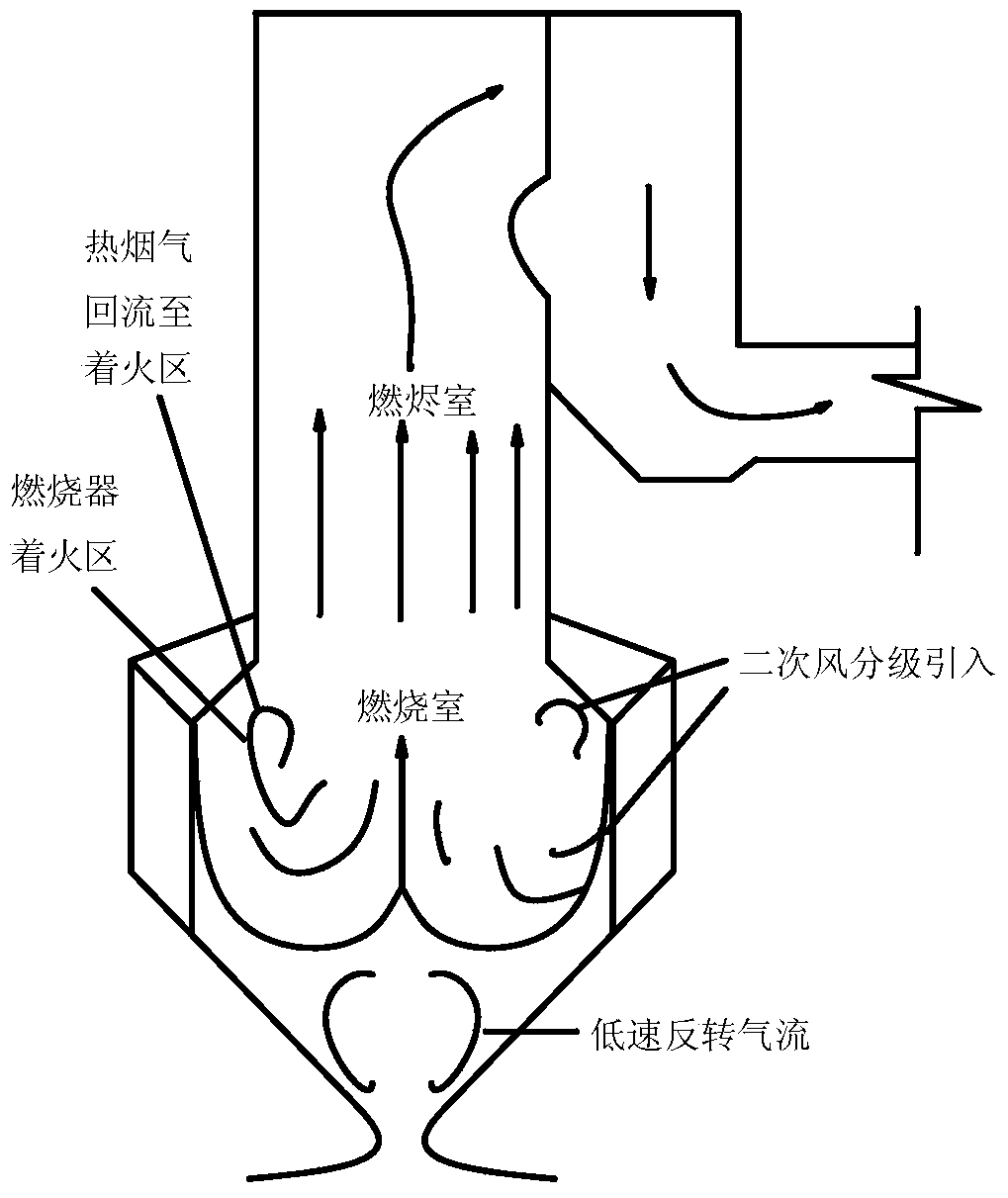

Efficiency-improving method for W-type flame boiler grading combustion

InactiveCN107355804ABurn fullyIncreased burning distanceAir supply regulationIndirect carbon-dioxide mitigationAnthraciteEngineering

The invention relates to an efficiency-improving method for W-type flame boiler grading combustion. The efficiency-improving method comprises steps of analyzing coaly element and proximate analysis to selected coal, presetting a boiler combustion strategy, simulating boiler fuel combustion according to the preset combustion strategy to acquire a boiler work condition, and conducting comparison analysis to boiler work conditions according to different combustion strategies to acquire an optimal boiler grading combustion coal proportion and a coal injection way of a coal grinding machine. Burning coal and anthracite proportion during the boiler grading combustion process can be well determined.

Owner:中国大唐集团科学技术研究总院有限公司

Chinese cordyceps sinensis protein polysaccharide and preparation and application thereof

ActiveCN103130907BImprove orderClear structureImmunological disordersHorticultureAqueous extractChemistry

The invention discloses a Chinese cordyceps sinensis protein polysaccharide and preparation and application thereof. The Chinese cordyceps sinensis protein polysaccharide is composed of polysaccharide with 55%-60% weight percentage and protein with 40%-45% weight percentage; and the ingredients of the polysaccharide are mannose, ribose, glucose, galactose, xylose and arabinose; the ratio of amount of substances among the mannose, the ribose, the glucose, the galactose, the xylose and the arabinose is 6.42-6.51: 2.20-2.32: 65.85-65.95: 2.10-2.18: 4.20-4.30. The Chinese cordyceps sinensis protein polysaccharide preparation method comprises the following steps: extracting the Chinese cordyceps sinensis protein polysaccharide by aqueous extract and alcohol precipitation, removing the protein, dialyzing, exchanging chromatography by anion and purifying gel filter layer chromatography through an enzyme-Sevage combination method, and freezing, drying and separating purification components in vacuum, and the Chinese cordyceps sinensis protein polysaccharide is acquired. According to the preparation and the application thereof, proximate analysis, structural identification and immunologic function study are carried out on the components of polysaccharide after purification, and the facts that the Chinese cordyceps sinensis protein polysaccharide has strong immunoregulation activity and is a potential immunological enhancement substance are discovered.

Owner:ZHEJIANG FORESTRY ACAD

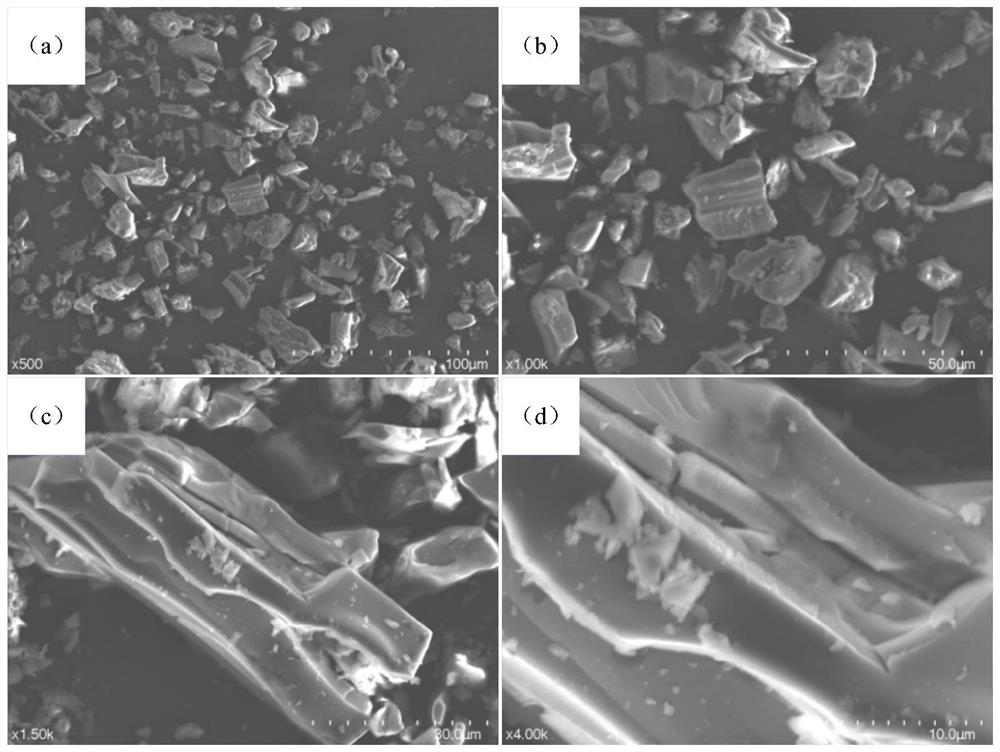

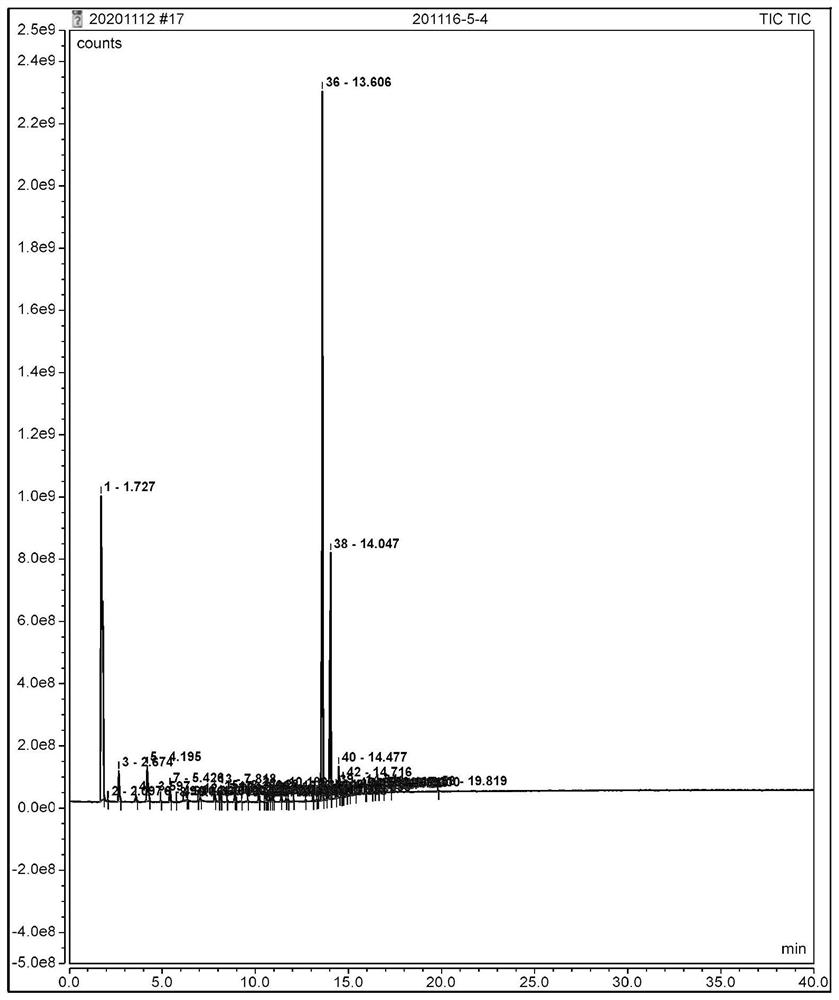

Analysis method of oil-rich coal

InactiveCN113234460AImprove pyrolysis efficiencyHigh yieldSpecial form destructive distillationScanning electron microscopeComponents of crude oil

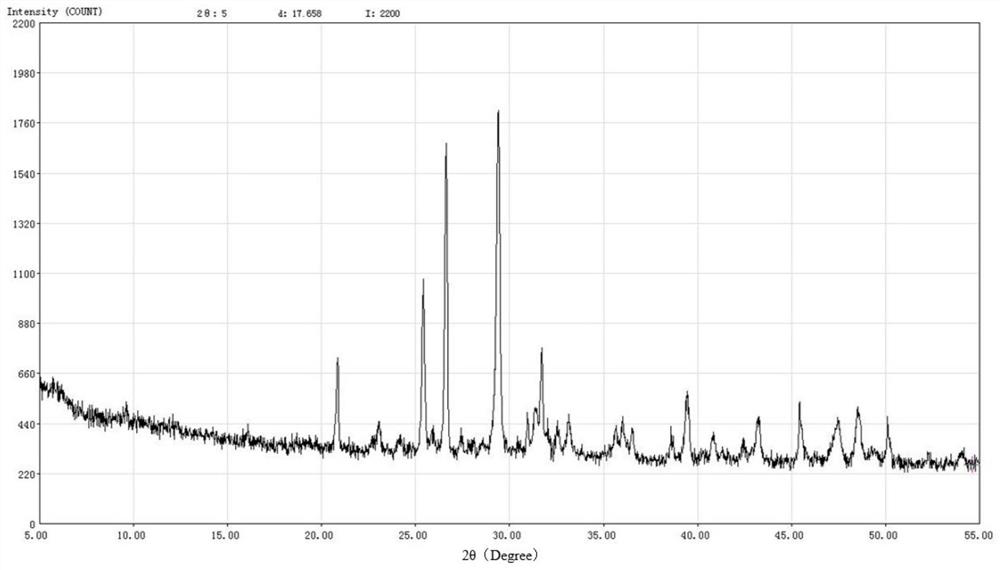

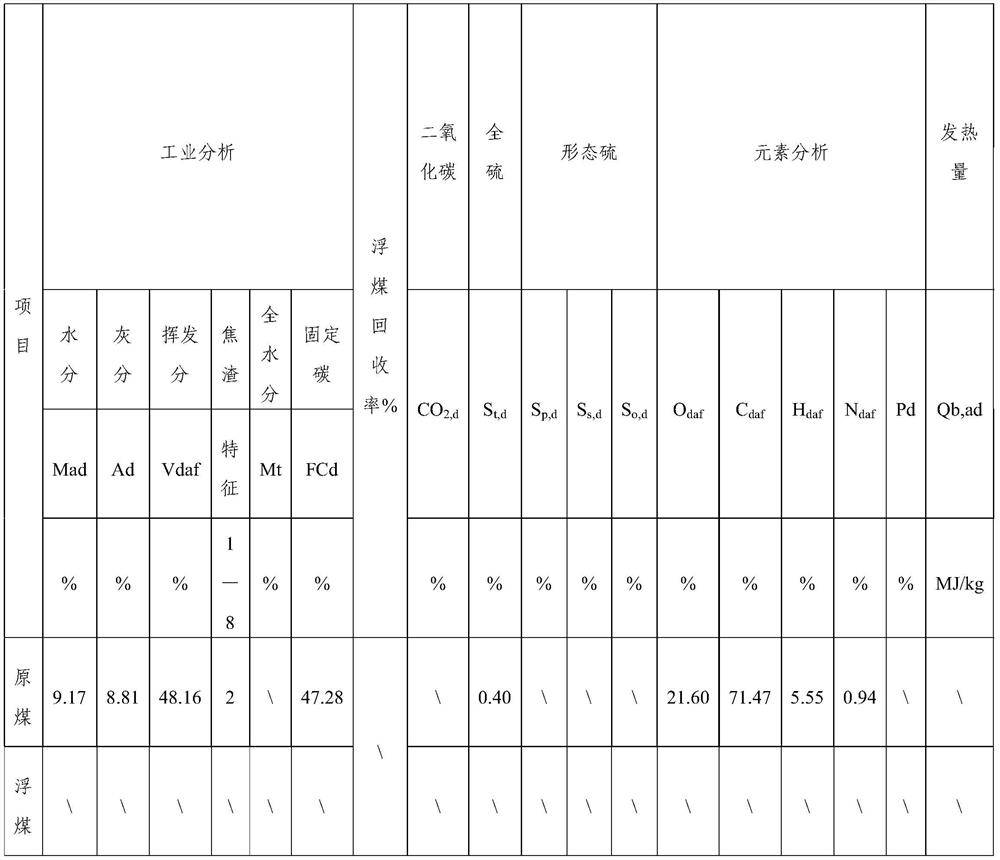

The invention relates to the field of oil-rich coal resource evaluation and oil product extraction, in particular to an analysis method of oil-rich coal. The analysis method comprises the following steps: firstly, carrying out industrial analysis, total sulfur analysis, hydrocarbon analysis, ash component analysis, nitrogen analysis, Gray-King low-temperature dry distillation analysis, vitrinite reflectivity analysis, maceral classification analysis, scanning electron microscope analysis, energy spectrum quantitative analysis and X-ray diffraction total rock analysis on the oil-rich coal, and then carrying out pyrolysis treatment. The pyrolysis treatment conditions are as follows: heating is started from room temperature, the temperature is raised to 550-650 DEG C at the rate of 15 + / -0.5 DEG C / min, and the temperature is kept for 25-35 minutes. The pyrolysis treatment conditions of the oil-rich coal are determined by analyzing the oil-rich coal, and high-quality pyrolysis coke, pyrolysis liquid and pyrolysis gas can be obtained by performing pyrolysis treatment on the oil-rich coal under the conditions.

Owner:中国煤炭地质总局勘查研究总院

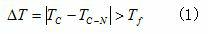

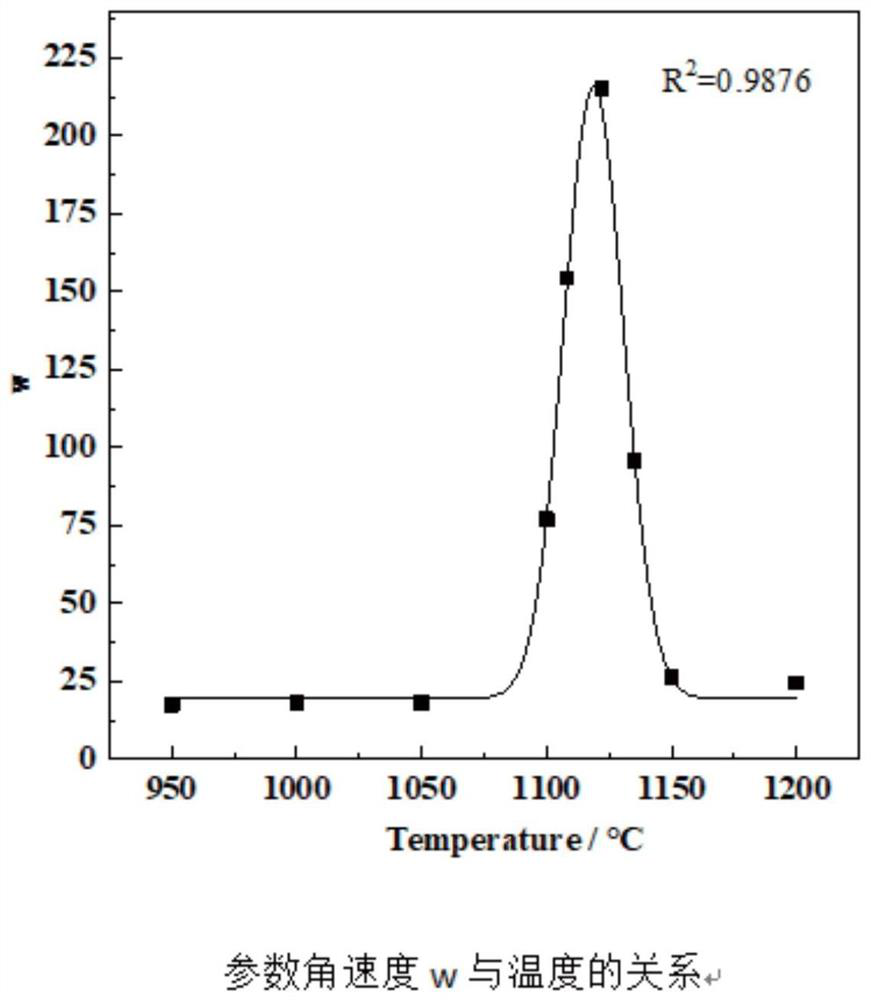

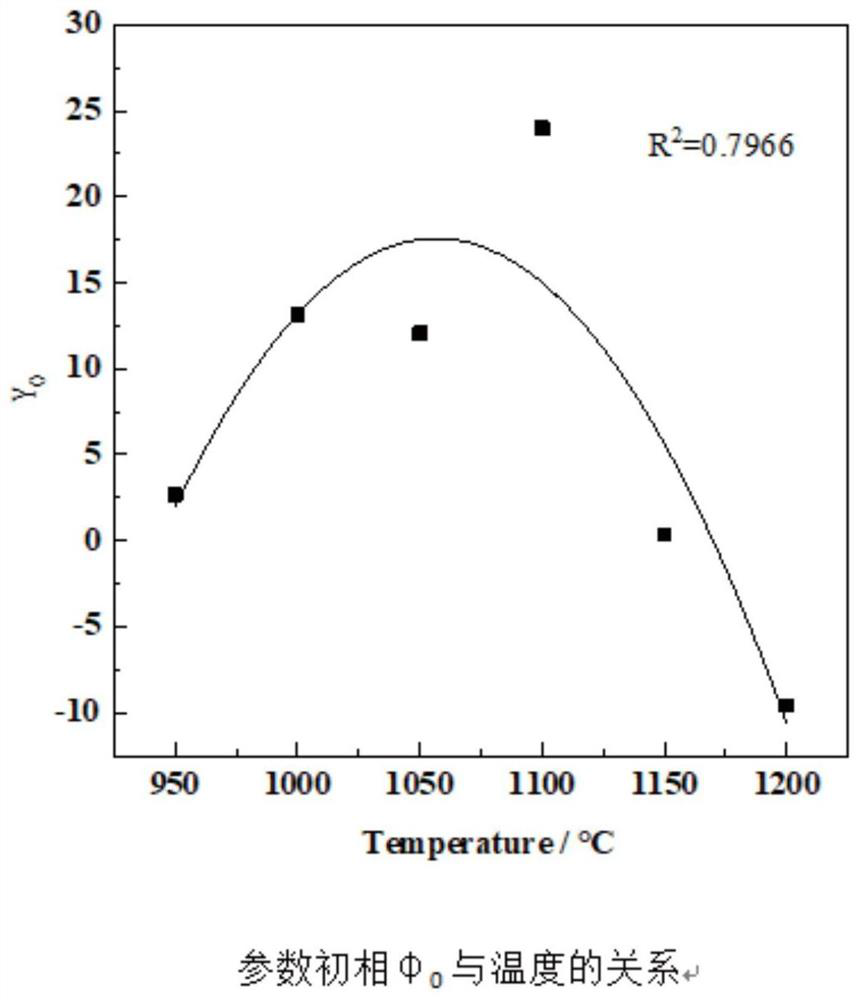

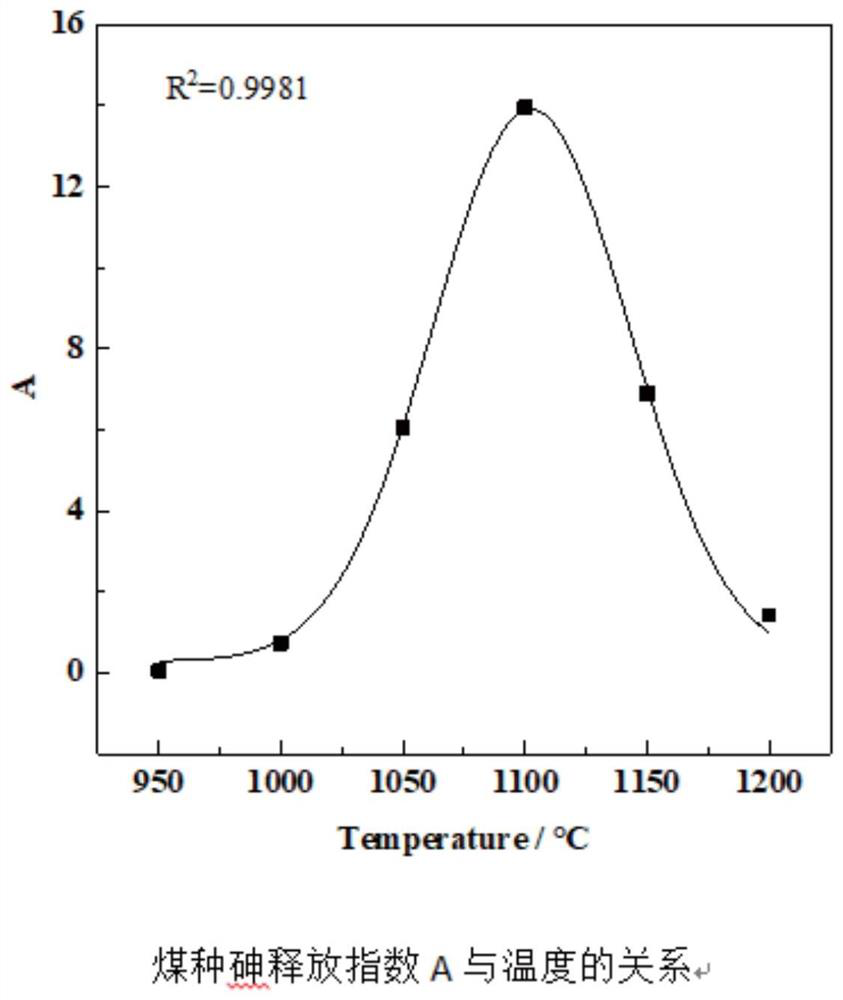

A measurement method and application of arsenic solidification rate based on combustion temperature and ash melting point temperature

ActiveCN112820357BReduce dosageReduce data volumeChemical property predictionMaterial heat developmentThermodynamicsCombustion

The invention discloses a method for measuring arsenic solidification rate based on combustion temperature and ash melting point temperature, collecting basic data of coal type used for calculation, including coal type name, initial content data of arsenic in coal sample, and composition analysis of coal ash Data, coal sample ash melting point temperature, industrial analysis data of coal types; according to the industrial analysis of coal types, the volatile content calculation of coal types under a dry base is completed, and the coal quality category is judged; according to the coal sample combustion temperature and coal sample ash melting point temperature and Composition analysis of coal ash, calculate the volatile amount of arsenic in the coal sample at this temperature; at the same time, correct the difference of different coal quality according to the industrial analysis of coal types; curing rate. The present invention also provides the application of adjusting the spray volume of the arsenic-removing spray liquid based on the measurement method of the arsenic solidification rate. The method collects less data and is convenient for calculation; when predicting coal types with differences, the result can be made more accurate by using the method Accurate and reasonable.

Owner:WUHAN UNIV OF SCI & TECH

A method for in-situ identification and rapid quantification of coal rock microcomponents

Owner:HUAZHONG UNIV OF SCI & TECH

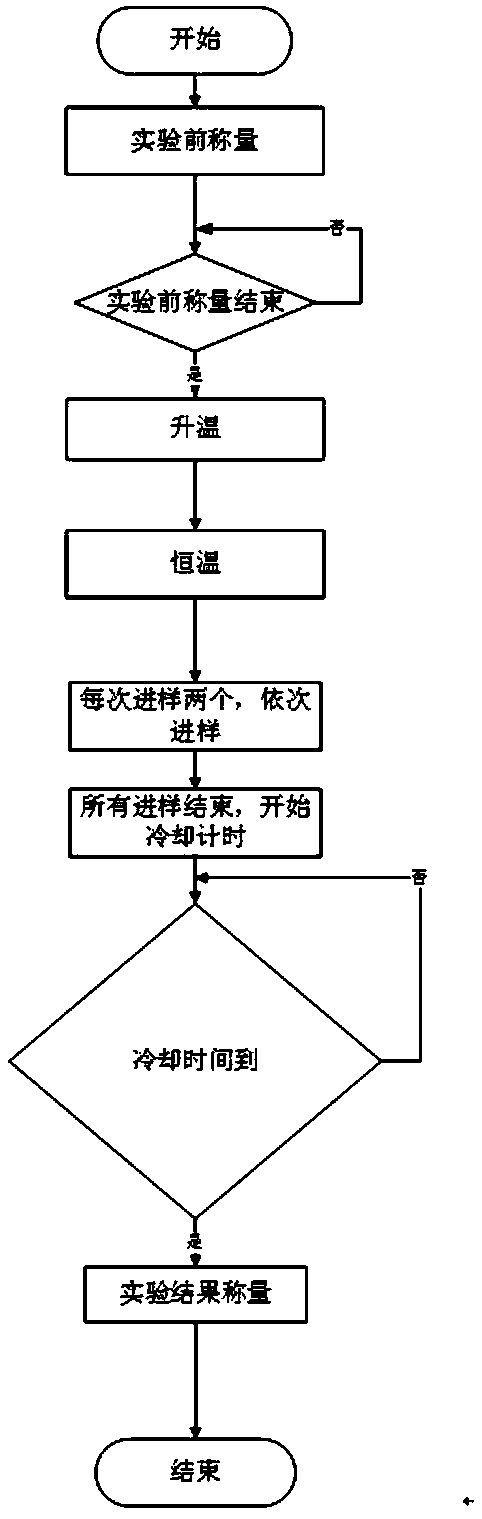

Sample adding method for industrial analysis instrument

ActiveCN110988376AReduce waiting timeReduce labor intensityMaterial analysisProcess engineeringProximate analysis

The invention discloses a sample adding method for an industrial analysis instrument, which comprises the steps of S1, when the instrument enters a heating or constant temperature stage, judging whether there is a sample to be detected in a sample storage area or not, if so, judging whether thesample needs to be added or not, if so the sample adding operation needs to be performed, entering the next step, otherwise, turning to the step S3; S2, adding thesample into a sample container, and weighing the sample by using a sample weighing balance; and S3, starting an experiment as soon as the sample enters a furnace body. The method has the advantages of immediate measurement when a sample is supplied and high working efficiency.

Owner:HUNAN SUNDY SCI & TECH DEV

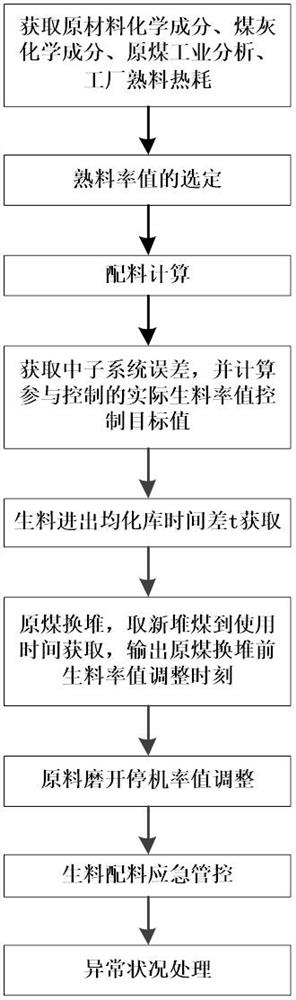

A closed-loop control method and system for cement raw meal batching

ActiveCN112255988BImprove counterpart problemsRealize closed-loop controlTotal factory controlProgramme total factory controlLoop controlAsh chemistry

Owner:中才邦业(杭州)智能技术有限公司

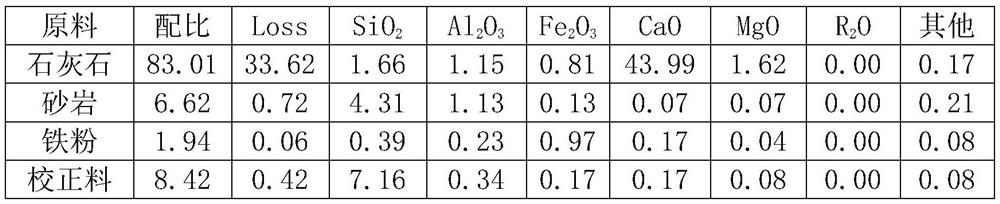

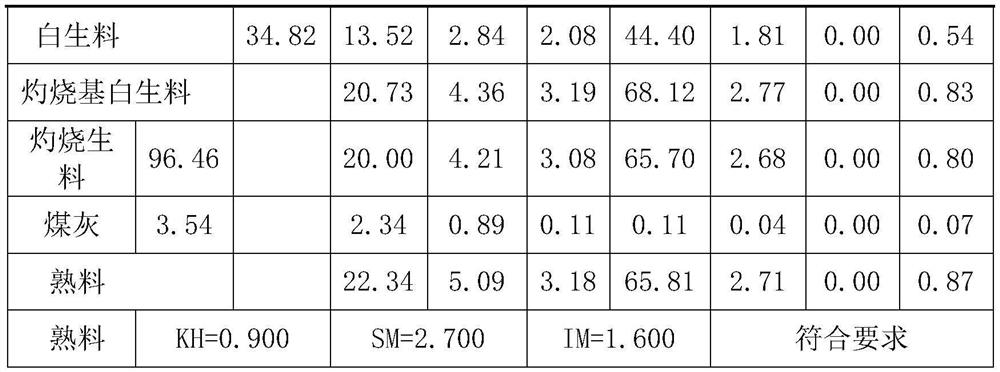

Matching method of fire coal for cement calcination

ActiveCN111592248ATo achieve the purpose of saving energy and reducing consumptionImprove product qualityChemical compositionPhysical chemistry

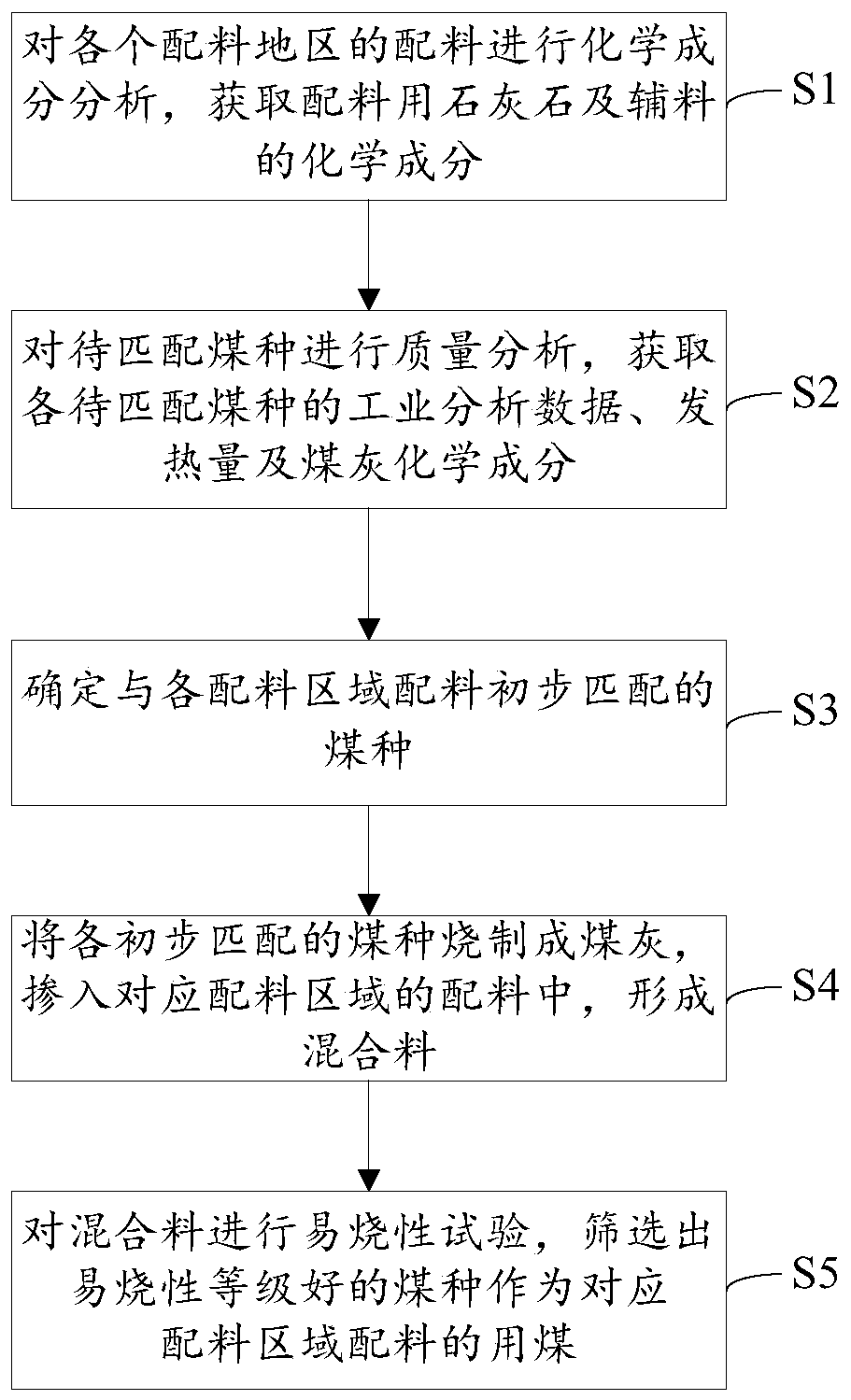

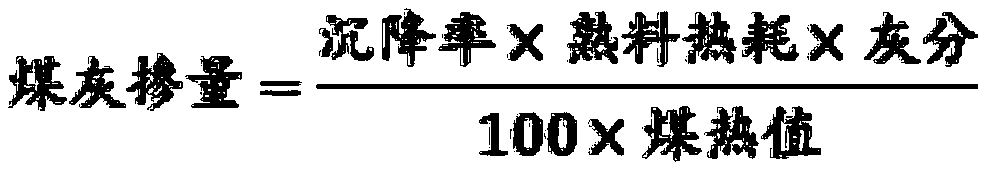

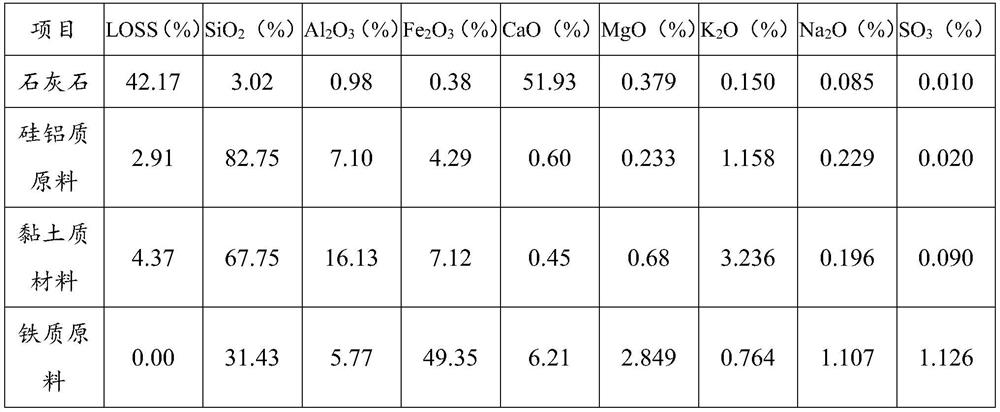

The invention discloses a matching method of fire coal for cement calcination. The method comprises the following steps: S1, carrying out chemical component analysis on ingredients in each ingredientarea to obtain chemical components of limestone for the ingredients and auxiliary materials; S2, performing quality analysis on the to-be-matched coal types to obtain industrial analysis data, heat productivity and coal ash chemical analysis of each to-be-matched coal type; S3, determining coal types preliminarily matched with ingredients in each ingredient area; S4, firing the preliminarily matched coal types into coal ash, and doping the coal ash into ingredients of the corresponding ingredient areas to form a mixture; S5, performing a burnability test on the mixture, and screening out a coal type with a good burnability grade as coal for burdening in a corresponding burdening area; a production line is guided to select a proper coal type, indexes of the production line are optimized, selection and use of different fuels are guided, and theoretical and data support is provided; therefore, the purposes of saving energy and reducing consumption are achieved, and product quality is improved.

Owner:安徽精公检测检验中心有限公司

A method of matching coal for cement calcination

ActiveCN111592248BTo achieve the purpose of saving energy and reducing consumptionImprove product qualityChemical compositionPhysical chemistry

The invention discloses a coal-fired matching method for cement calcination. The method comprises the following steps: S1, analyzing the chemical composition of ingredients in each batching area, and obtaining the chemical composition of limestone and auxiliary materials for batching; S2, the type of coal to be matched Carry out quality analysis to obtain industrial analysis data, calorific value and coal ash chemical analysis of each coal type to be matched; S3, determine the coal type that initially matches the batching area; S4, burn each initially matched coal type into coal Ash is mixed into the ingredients in the corresponding ingredient area to form a mixture; S5. Carry out a flammability test on the mixture, and select a coal with a good flammability grade as the coal used in the ingredients in the corresponding ingredient area; guide the production line to select the appropriate Coal types, optimize the indicators of the production line, guide the selection and use of different fuels, and provide theoretical and data support; in order to achieve the purpose of saving energy and reducing consumption, and improving product quality.

Owner:安徽精公检测检验中心有限公司

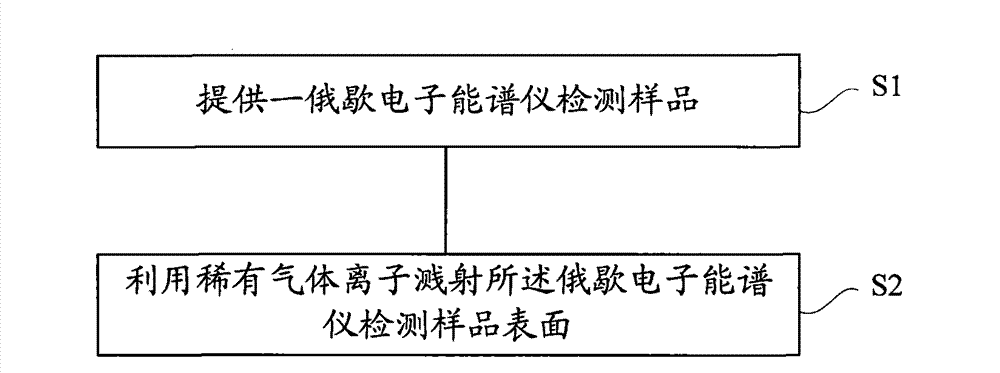

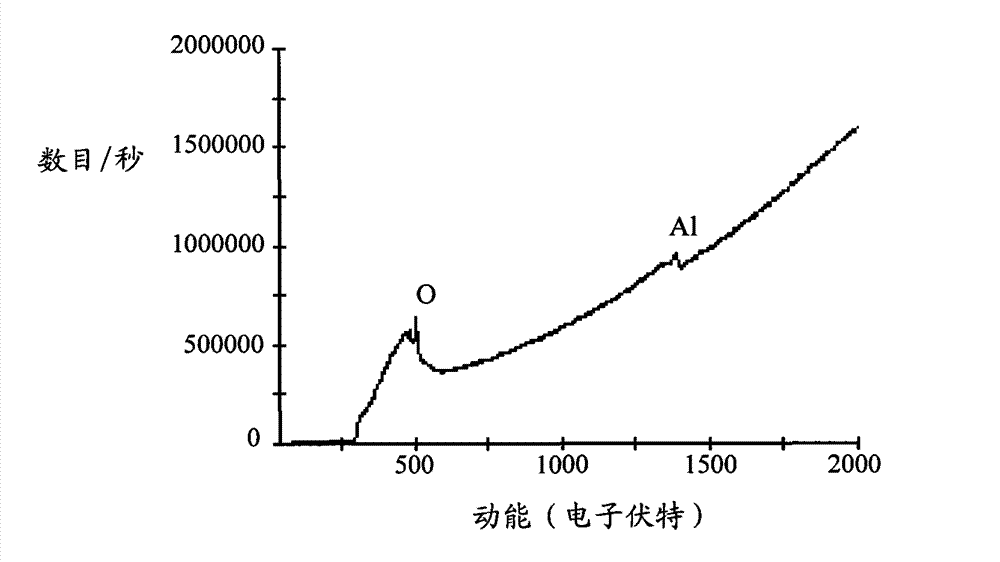

Surface processing method of Auger electron spectrometer detecting sample

InactiveCN101988911BImprove signal-to-noise ratioQuickly and effectively neutralizes buildupMaterial analysis using wave/particle radiationPreparing sample for investigationNoble gasProximate analysis

The invention discloses a surface processing method of an Auger electron spectrometer detecting sample, which comprises the following steps of providing the Auger electron spectrometer detecting sample; and utilizing rare gas ions to sputter the surface of the Auger electron spectrometer detecting sample. The method is simple and practical, has low cost, can rapidly and effectively reduce the charge effect and has no damage to the surface of the detecting sample requiring to be proximately analyzed so as to ensure obtaining the accurate proximate analysis result of the surface of the detecting sample and enhance the yield of the product.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Diagnosis and prevention system and method of high temperature corrosion state of boiler water cooled wall

ActiveCN101858591BWeather/light/corrosion resistanceBoiler indication operationsEngineeringHigh-temperature corrosion

The invention relates to diagnosis and prevention system and method of a high temperature corrosion state of a boiler water cooled wall. The system comprises a plurality of temperature sensors, a coal fired quality sampling module, a coal fineness sampling module, a flue gas sampling module, a data layer module, a characteristic layer data processing module and a decision layer module, wherein the temperature sensors collect the temperature of the water cooled wall through a multi-channel A / D conversion collection module; the coal fired quality sampling module sends coal quality information into a coal quality analysis module, and the coal quality analysis module carries out proximate analysis; the coal fineness sampling module sends collected coal fineness information into a fineness analysis module; the flue gas sampling module sends collected flue gas information into a component analysis module; the data layer module carries out wave filtering treatment on the temperature information, the coal quality information, the fineness information and the flue gas information and rejects abnormal data; the characteristic layer data processing module extracts the characteristic quantityfrom the data after processing of the data layer module; and the decision layer module comprehensively analyzes and judges the data extracted by the characteristic layer data processing module by an expert system to obtain a reasonable and accurate result, and the result is output and participate into operation regulation.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

An intelligent monitoring method for coal quality components of coal mills in thermal power plants

ActiveCN106405044BGuided Combustion OptimizationImprove accuracyFuel testingAnalysis dataElemental analysis

The invention discloses an intelligent monitoring method for the coal components of a heat-engine plant coal pulverizer. The method comprises the steps of 1) continuously collecting the operation data of each coal pulverizer, the coal amount of the coal pulverizer and the power generation load of a generator set; 2) respectively calculating the raw coal moisture MNJ and the equivalent electrical load QNJ of each coal pulverizer according to obtained data; 3) subjecting all coal components to proximate analysis, elemental analysis, calorific value analysis, ash fusion point analysis and combustion characteristic analysis, and establishing a coal component characteristic analysis database with the raw coal moisture MNJ and the equivalent electrical load QNJ as an index; 4) outputting the inquired characteristics of raw coal components with a raw coal moisture Mi and an equivalent electrical load Qi monitored during the operation of the coal pulverizer in real time as an index. On the condition that no inquired characteristic is obtained, the raw coal component of the coal pulverizer is deemed as a new coal component or a mixed coal component. After that, the new coal component or the mixed coal component is manually sampled to be subjected to coal component analysis and characteristic analysis, and then the obtained data of the new coal component or the mixed coal component are added into the coal component characteristic analysis database. According to the technical scheme of the invention, the coal characteristics of each coal pulverizer can be inquired in the online manner, and the advantages of high accuracy and complete analysis data are realized. Meanwhile, the boiler combustion is instructed to be optimized.

Owner:NANJING INST OF TECH

Method for detecting moisture and volatile matter content of raw coal by using value of baseline drift

ActiveUS10900904B2Appropriate controlHigh speedRadiation pyrometryFuel testingProximate analysisCoal rank

The present invention relates to a method for detecting moisture and volatile matter content in raw coal using the value of baseline drift, comprising the following steps: selecting a plurality of types of standard coal having different coal ranks and different ash contents, performing a Raman spectroscopy test and a proximate analysis on each type of standard coal, calculating the value of baseline drift in the Raman spectrum, and setting up the mapping relationship between the value of baseline drift in the Raman spectrum and the characteristic parameters of the moisture and the volatile matter content. The same method and reference are used to perform a Raman spectroscopy test on raw coal to be tested, so as to calculate the value of baseline drift in a Raman spectrum of the raw coal to be tested, and obtain the moisture and volatile matter content of the raw coal to be tested.

Owner:HUAZHONG UNIV OF SCI & TECH

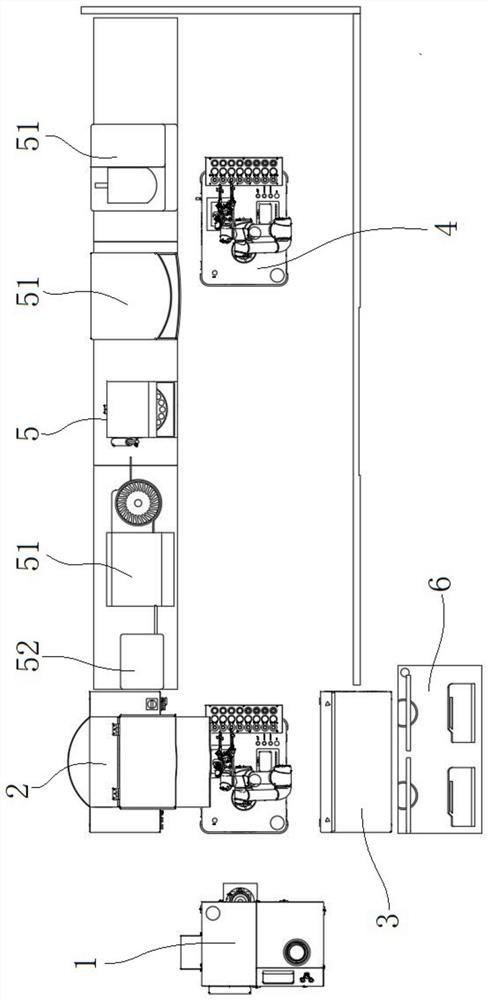

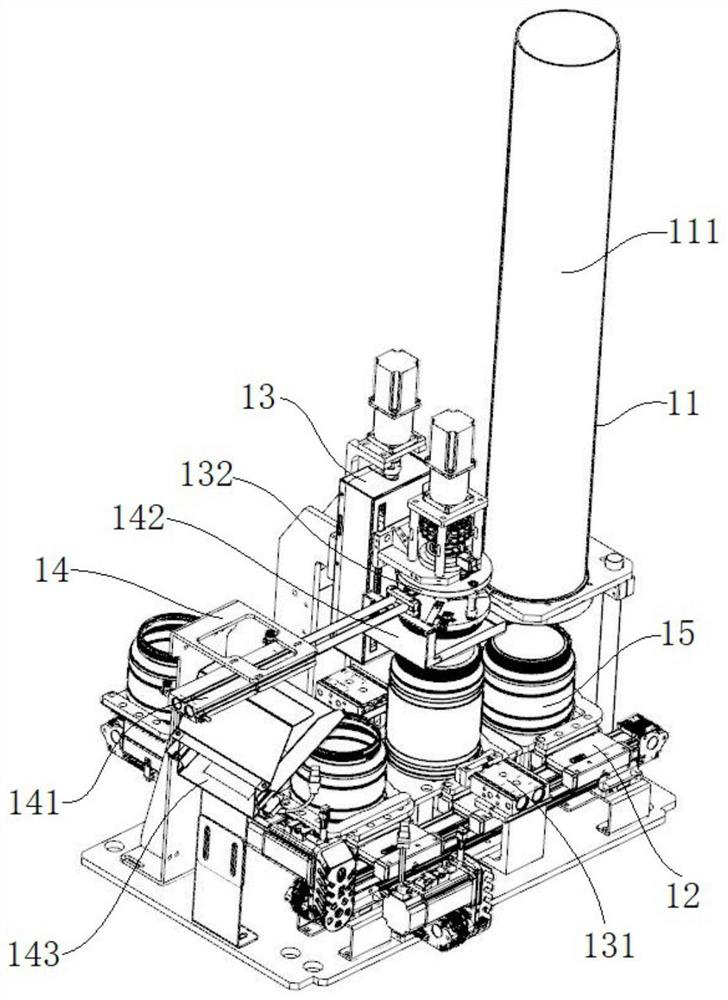

A laboratory material automatic analysis system

ActiveCN113063955BReduce settingsReduce labor intensityMaterial analysisExperimental laboratoryElectric control

The invention discloses a laboratory material automatic analysis system, which comprises a material sample barrel automatic receiving and opening output unit, a material accurate weighing unit, a crucible bench unit, a grabbing and stacking robot unit, a material analysis unit and a centralized electric control unit. The present invention is an intelligent digital control system, through the coordinated operation of each unit, it can automatically receive and output the material sample barrel with a lid, and quantitatively and accurately scoop the material sample in the opened material sample barrel to A series of automatic operations, such as accurate weighing in the crucible, automatic industrial analyzers for different types of automatic experimental analysis of material samples, and automatic storage and output of experimental results, can achieve improvement on the premise of reducing the personnel settings and labor intensity of experimental operators. The experimental efficiency of the material composition analysis experiment and the accuracy of the experimental data can greatly reduce the interference of human factors on the experimental process, and it is especially suitable for the laboratory material composition analysis.

Owner:SAIMO ELECTRIC

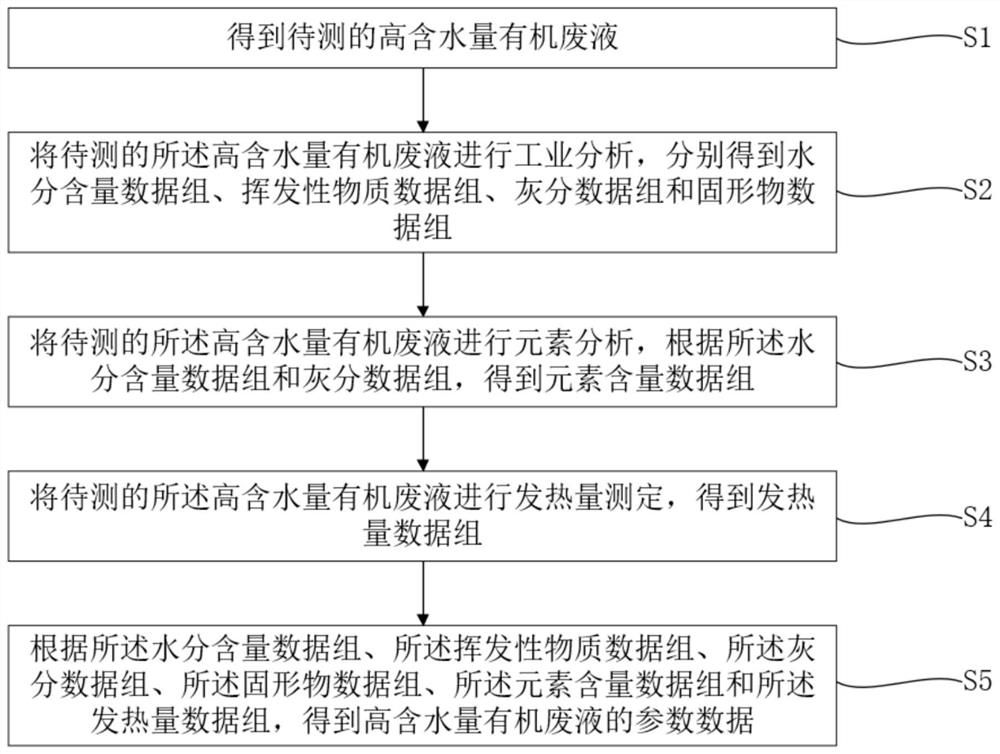

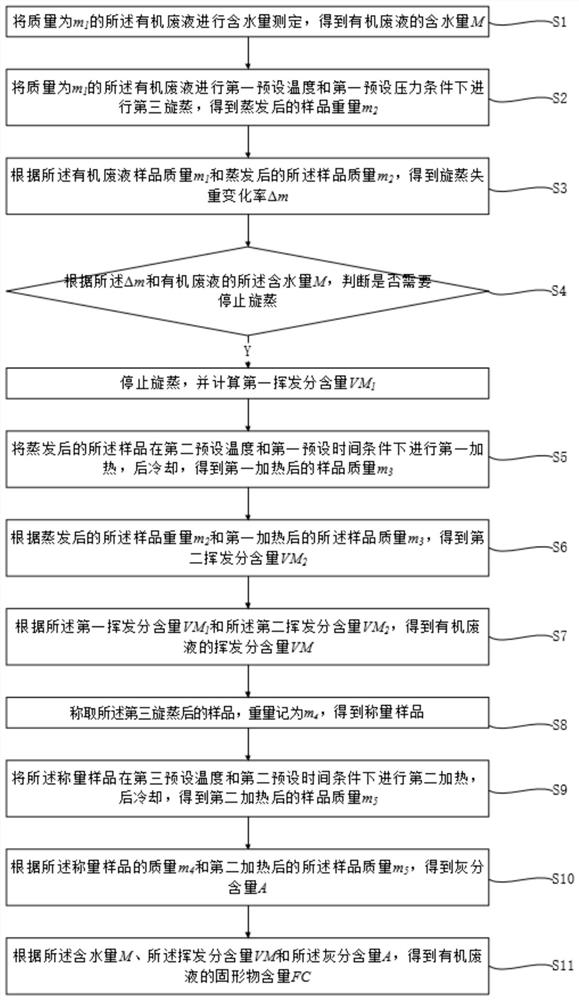

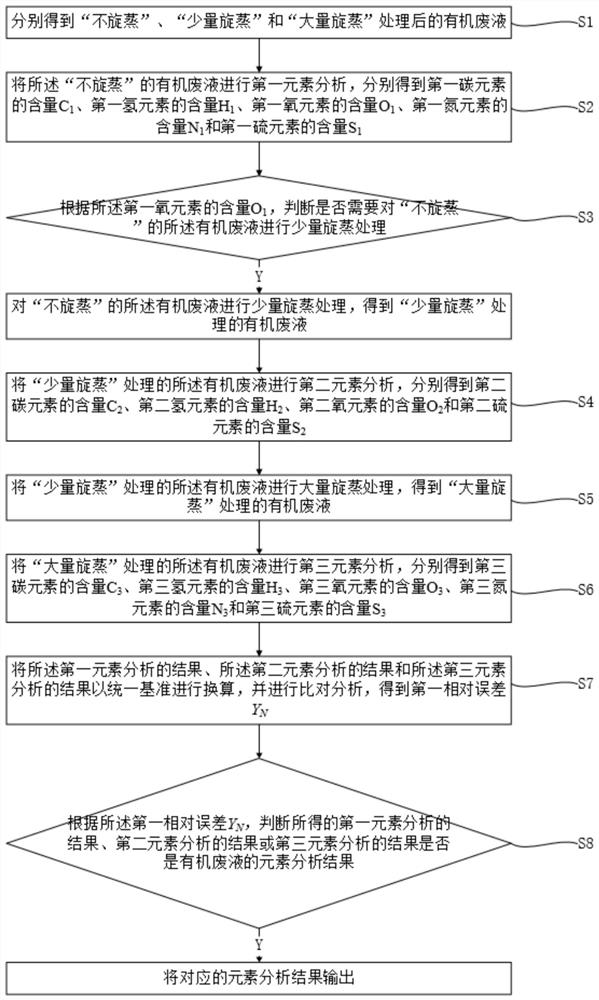

Method for analyzing and testing organic waste liquid with high water content

PendingCN114324469AAccurate analysisWeighing by removing componentMaterial moisture contentData setElemental analysis

The invention relates to the field of detection and analysis, in particular to an analysis and test method for high-water-content organic waste liquid. The method comprises the following steps: obtaining to-be-detected high-water-content organic waste liquid; industrially analyzing the to-be-detected high-water-content organic waste liquid to respectively obtain a water content data set, a volatile substance data set, an ash content data set and a solid matter data set; performing elemental analysis on the to-be-detected high-water-content organic waste liquid, and obtaining an element content data set according to the water content data set and the ash content data set; measuring the calorific value of the to-be-measured high-water-content organic waste liquid to obtain a calorific value data set; obtaining parameter data according to the moisture content data set, the volatile substance data set, the ash content data set, the solid content data set, the element content data set and the calorific value data set; the comprehensive and accurate analysis of the organic waste liquid is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Efficiency Improvement Method for Staged Combustion of W-type Flame Boiler

InactiveCN107355804BBurn fullyImprove efficiencyAir supply regulationIndirect carbon-dioxide mitigationAnthraciteEngineering

The invention relates to an efficiency-improving method for W-type flame boiler grading combustion. The efficiency-improving method comprises steps of analyzing coaly element and proximate analysis to selected coal, presetting a boiler combustion strategy, simulating boiler fuel combustion according to the preset combustion strategy to acquire a boiler work condition, and conducting comparison analysis to boiler work conditions according to different combustion strategies to acquire an optimal boiler grading combustion coal proportion and a coal injection way of a coal grinding machine. Burning coal and anthracite proportion during the boiler grading combustion process can be well determined.

Owner:中国大唐集团科学技术研究总院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com