A laboratory material automatic analysis system

An automatic analysis system and laboratory technology, applied in the field of material composition analysis, can solve problems such as cumbersome work, inability to install multiple robots, and high intensity, and achieve the effect of reducing interference, personnel settings and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings.

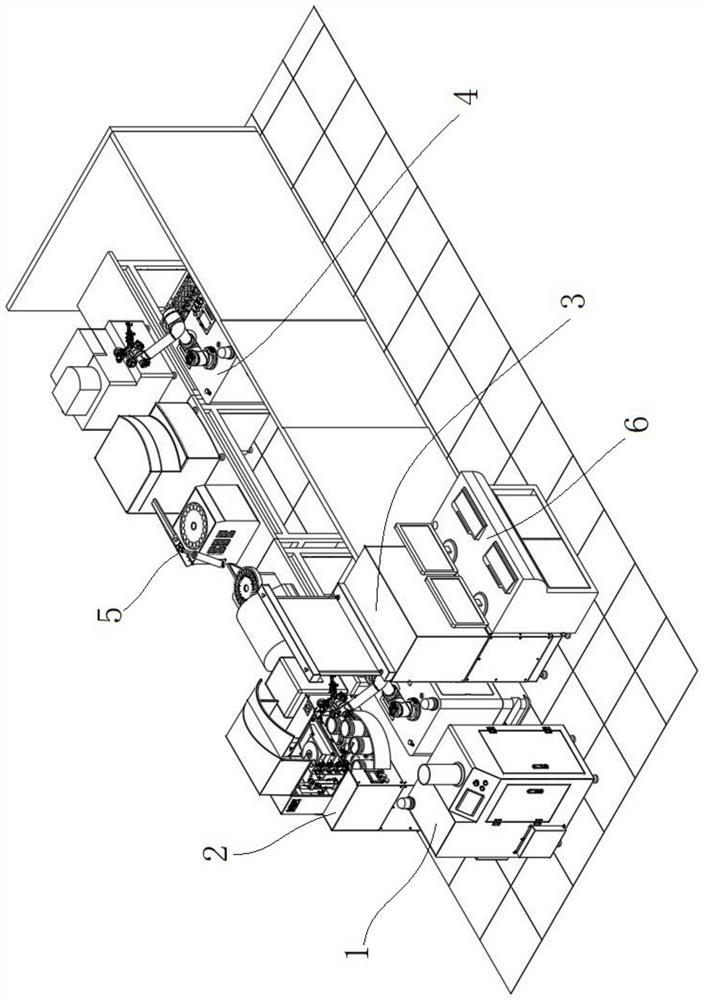

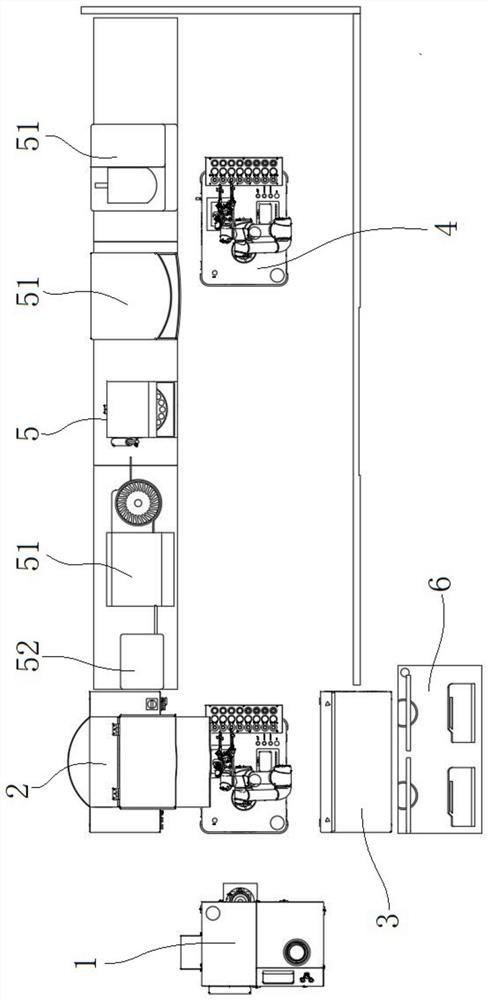

[0061] like figure 1 , figure 2 As shown, the laboratory material automatic analysis system includes the material sample barrel automatic receiving and opening output unit 1, the material accurate weighing unit 2, the crucible bench unit 3, the grabbing robot unit 4, the material analysis unit 5 and the centralized electric control unit Unit 6.

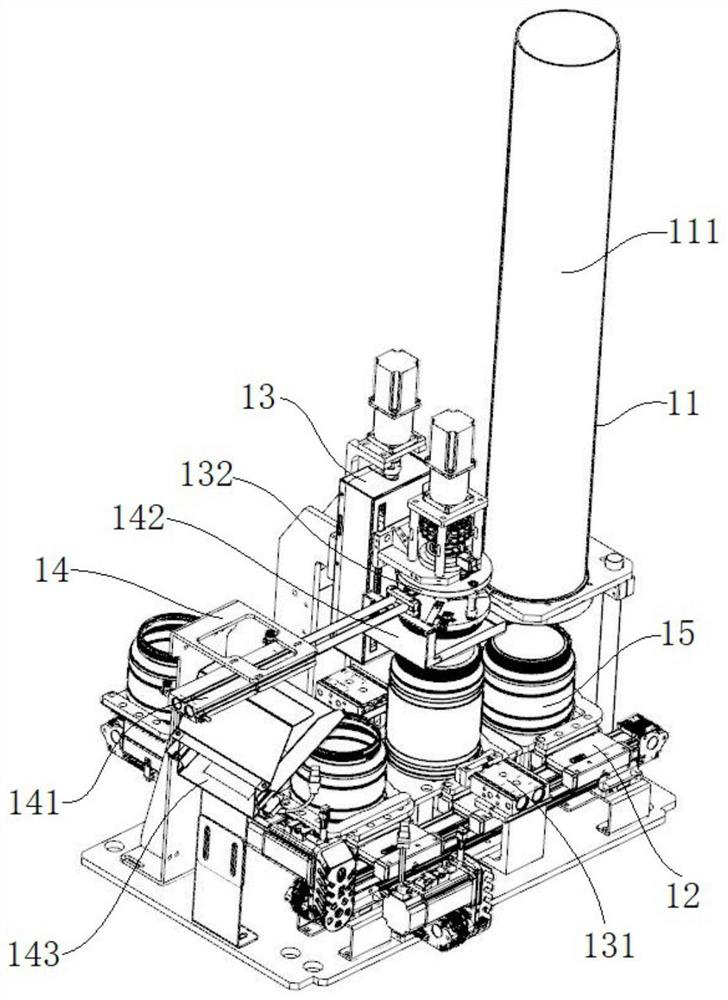

[0062] The automatic receiving and uncapping output unit 1 of the material sample bucket is used for automatically receiving and uncapping the material sample bucket 15 covered with a bung, and then positioning and outputting the material sample bucket 15 after uncapping, such as image 3 As shown, the material sample barrel automatic receiving and opening output unit 1 includes a sample barrel automatic receiving device 11 installed on the frame I, a sample barrel translational conveying device 12, a sample barrel clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com