Method for quickly measuring coal seam gas content based on diffusivity curve subtraction

A technology for rapid measurement of coal seam gas, applied in measuring devices, diffusion analysis, fuel oil testing, etc., can solve the problems of long measurement period, poor adaptability of coal seam, low success rate, etc., to avoid errors in gas content measurement, strong adaptability, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

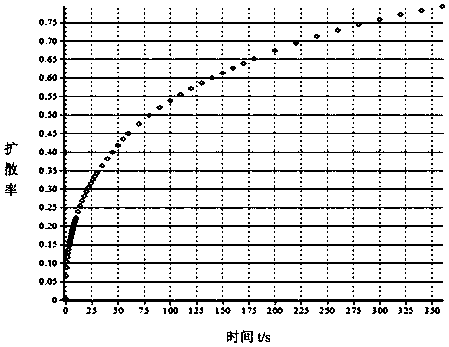

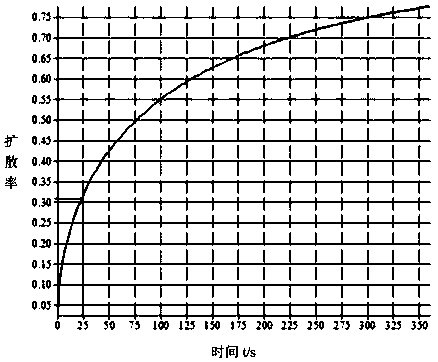

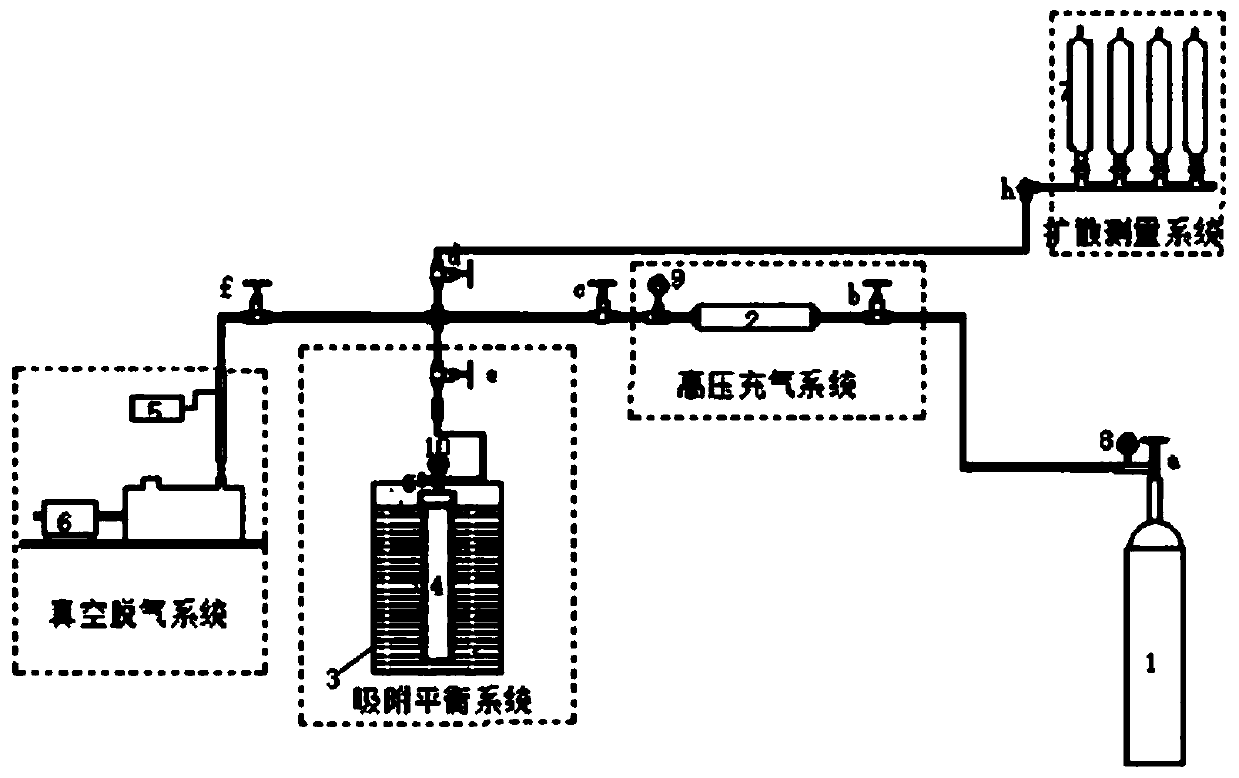

Image

Examples

Embodiment Construction

[0032] In order to make those skilled in the art understand the production process and technical effect of the present invention in detail, the application and technical effect of the present invention will be further introduced below with specific production examples.

[0033] Step 1: On-Site Sampling

[0034] Borehole sampling was carried out at the location where the gas content of the coal seam was to be determined. The coal samples collected were required to be free of gangue and mainly lump coal. The experimental coal samples were taken from the Jiulishan Mine of Henan Coking Coal Group, sealed and transported to the laboratory.

[0035] Step 2: Industrial analysis of laboratory coal samples

[0036] Strictly follow the "Industrial Analysis Methods of Coal" GB / T212-2008 to conduct industrial analysis on coal samples, and measure the important characteristic parameters of coal samples, as shown in the table below

[0037] Table 1 Coal sample characteristic parameters

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com