Thickness measuring device and measuring method of optical distance adjusting ring

A technology for optical distance and thickness measurement, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of inaccurate measurement, inability to measure the thickness of large-scale optical distance adjustment rings, demanding measurement objects and measurement environments, etc., to achieve accurate and convenient measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

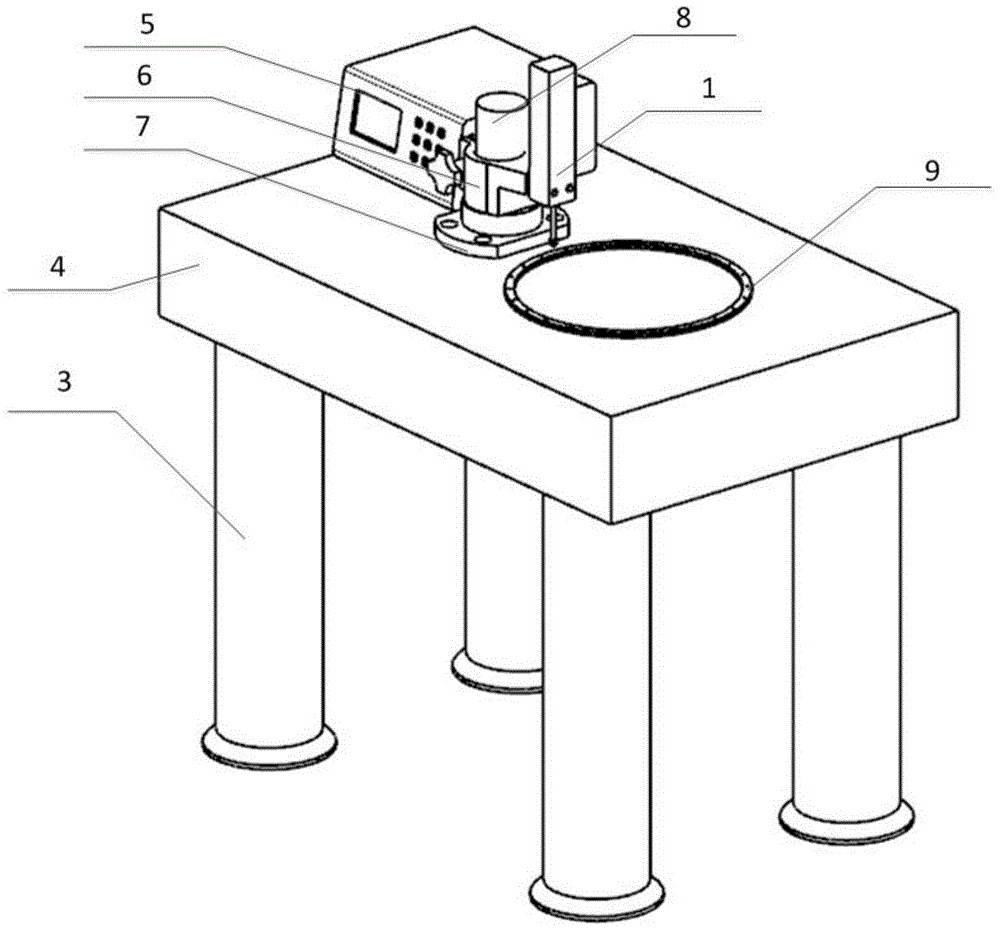

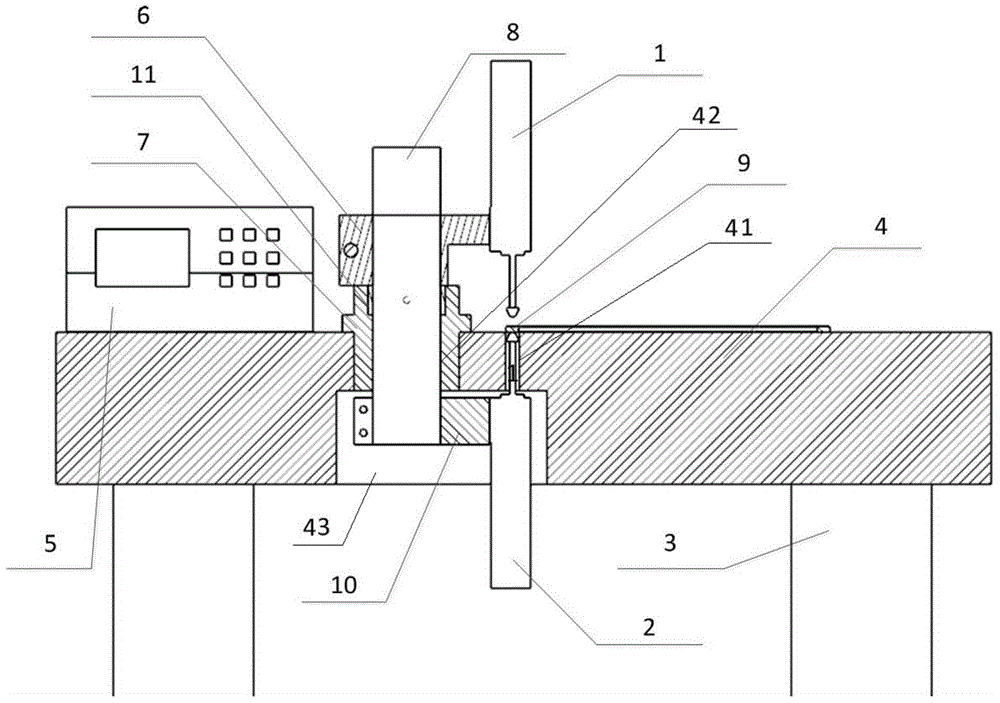

[0053] First, see figure 1 , figure 2 with Figure 5 Connect the connecting flange 7 for connecting the marble platform to the measuring platform 4 made of high-precision marble through hexagon socket screws, insert the single-slit opening clamping sleeve 11 into the connecting flange 7 for connecting the marble platform, and install the length gauge on the column 8 is installed in the single-slit opening clamping sleeve 11, and the length meter installation column 8 is fixed on the connecting flange 7 by installing a set screw in the set screw hole 17, and the connecting flange 7 is processed by adopting a reasonable processing technology. Seam opening clamping cover 11, length gauge install column 8 to guarantee the perpendicularity of length gauge column 8 and marble system measuring platform 4 upper surfaces after installation.

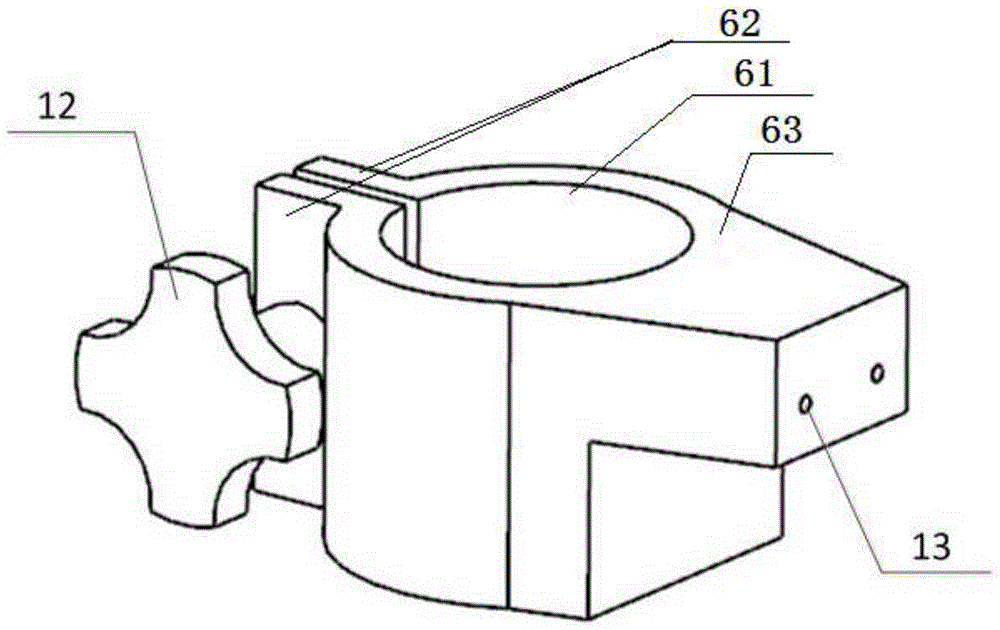

[0054] see figure 1 , figure 2 , image 3 , Figure 4 , the upper length gauge 1 passes through the first threaded hole 13 on the adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com