Tobacco rapid industrial analysis method

A technology of industrial analysis and analysis method, applied in the field of analysis and tobacco analysis, can solve the problems of inability to adapt to rapid online analysis in industrial sites, low work efficiency, long time, etc., to meet the requirements of rapid online analysis, improve measurement efficiency, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

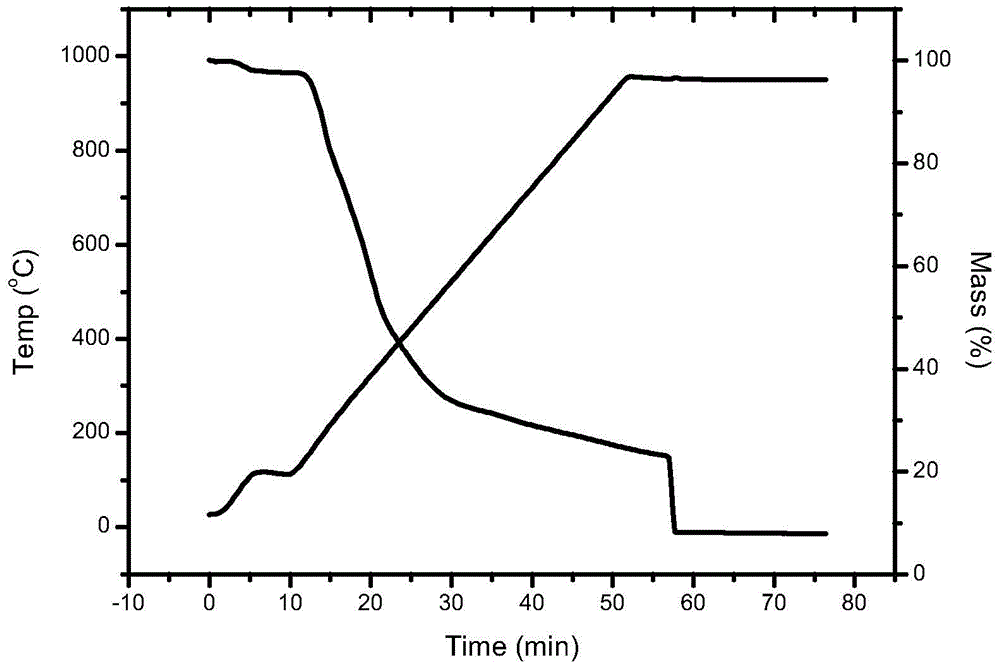

[0024] Such as figure 1 As shown, a rapid industrial analysis method for tobacco of the present invention directly uses thermogravimetric analysis (TGA), the instrument generates a complete TG curve, and simultaneously obtains the moisture value, ash value, and volatile content value in the tobacco through the TG curve And fixed carbon value.

[0025] The specific operation includes the following steps:

[0026] (1) Tobacco samples are crushed and sieved to obtain tobacco dust. Weigh 10 mg of tobacco dust and place it in the sample crucible of the thermogravimetric analyzer. In an inert gas atmosphere (flow rate 100mL / min), the temperature is raised to 105 at 20℃ / min. ℃, and keep it for 8min. At this time, the weight loss percentage of the sample in the TG curve is the moisture value of the tobacco sample.

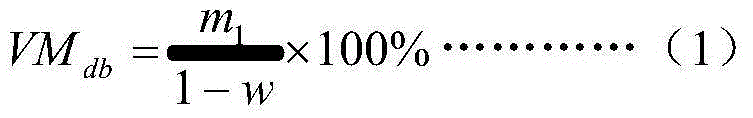

[0027] (2) Continue to program the temperature from 105°C to 950°C at 20°C / min under an inert gas atmosphere (flow rate 100mL / min) and keep it for 5 minutes. At this time, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com