Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Coal rank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of gas recovery by water drainage for high-coal-rank coal-bed methane well

ActiveCN102493788AAchieving area reductionExpand the desorption rangeSurveyFluid removalUltrasound attenuationWorking fluid

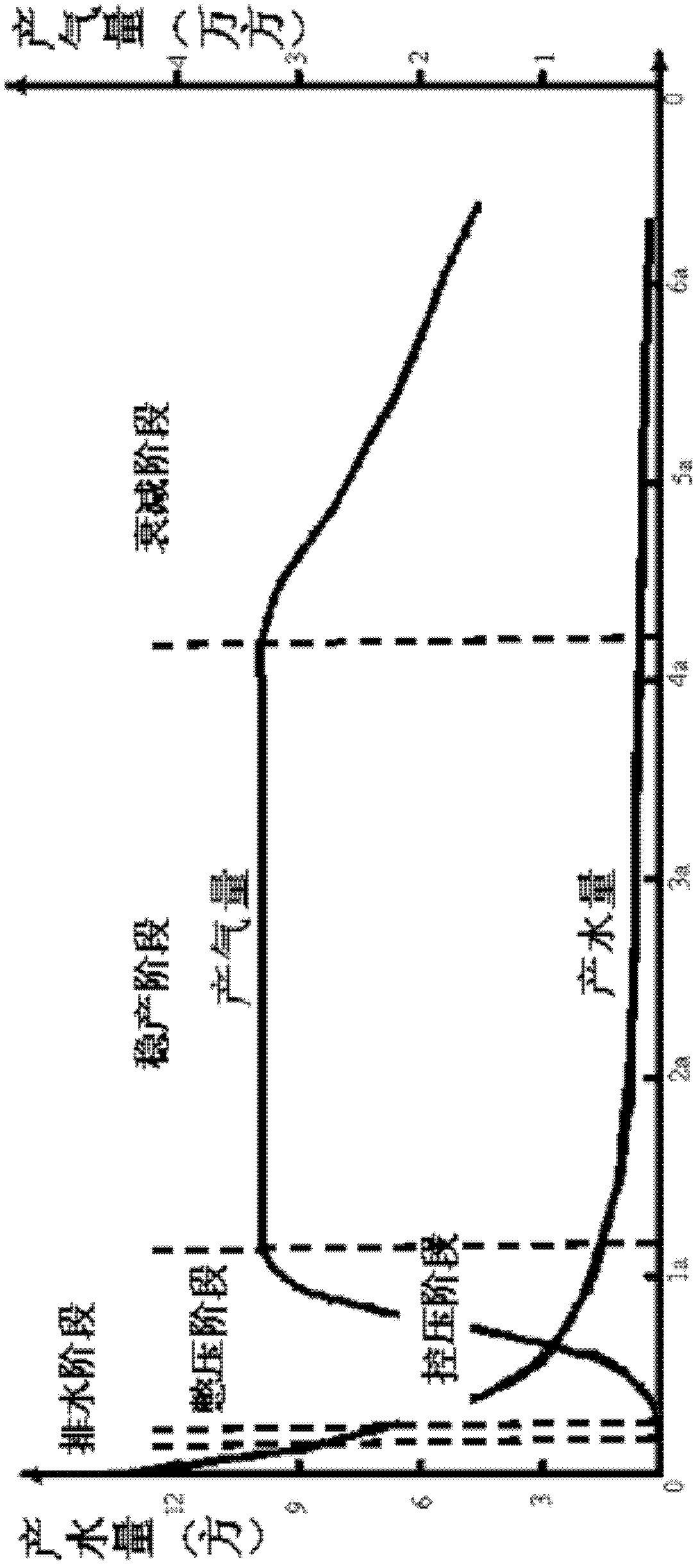

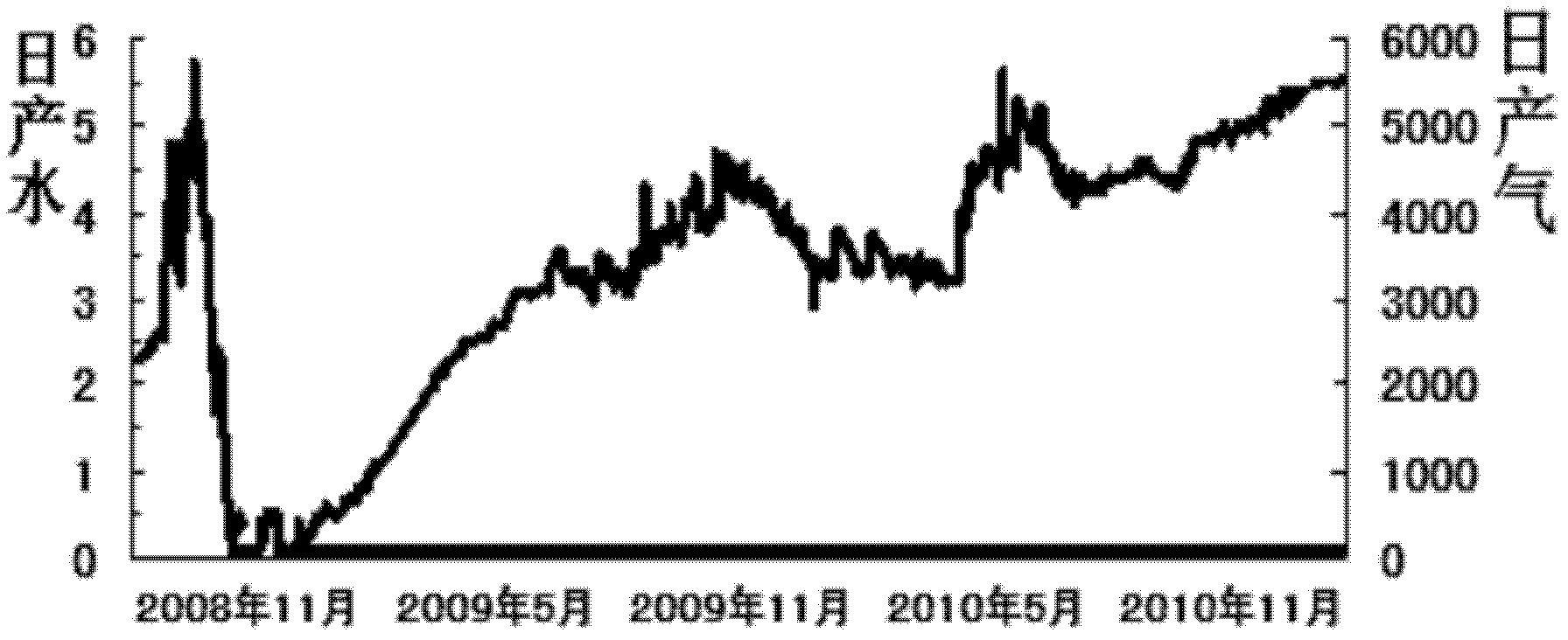

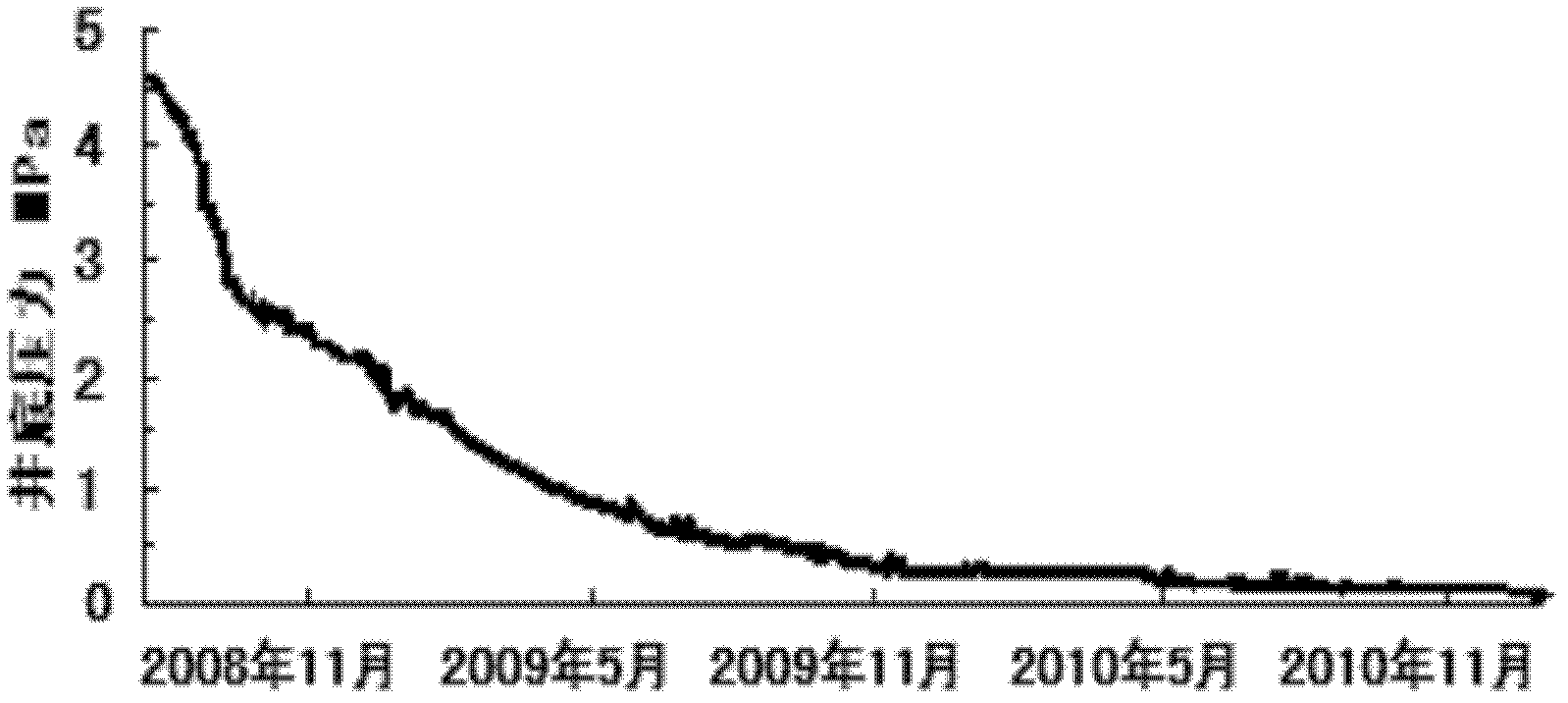

This invention discloses a method of gas recovery by water drainage for high-coal-rank coal-bed methane well, which is applied in the technical field of gas recovery of coal-bed methane well; the method disclosed by this invention comprises a water draining stage, a pressure building stage, a pressure controlling stage, a stable yield and high yield stage and an attenuation stage, wherein different stages have different pressure controlling demands; the dropping speed of a working fluid level of the coal-bed methane well is controlled within 5-7m / d at the water draining stage; underground flow pressure is stabilized at the pressure building stage; the working fluid level is dropped by 0-3m / d in each day; fluctuation of the underground flow pressure is controlled within 0-0.3MPa; air discharging quantity is increased to 200-300m<3> at the pressure controlling stage; the height of the underground working fluid level is kept 15-30m above a coal layer roof board at the stable yield stage; the pressure values of surface casing pressure and the underground flow pressure are within 0.101-0.11MPa at the attenuation stage; and at the attenuation stage, all sleeve pipe gates are opened or an intermittent draw-off type gas recovery procedure is performed by a downward draw-off pump. The method disclosed by this invention has the advantages that underground pressure is controlled so as to realize stable dropping of stratum pressure and the matching of the stratum pressure and desorption pressure, desorption range is enlarged effectively, and area depressurization is realized.

Owner:PETROCHINA CO LTD

Quantitative calculation method for coal and rock adsorbed gas content

InactiveCN103592687AImprove calculation accuracyImprove applicabilitySeismology for water-loggingCalculation methodsCoal rank

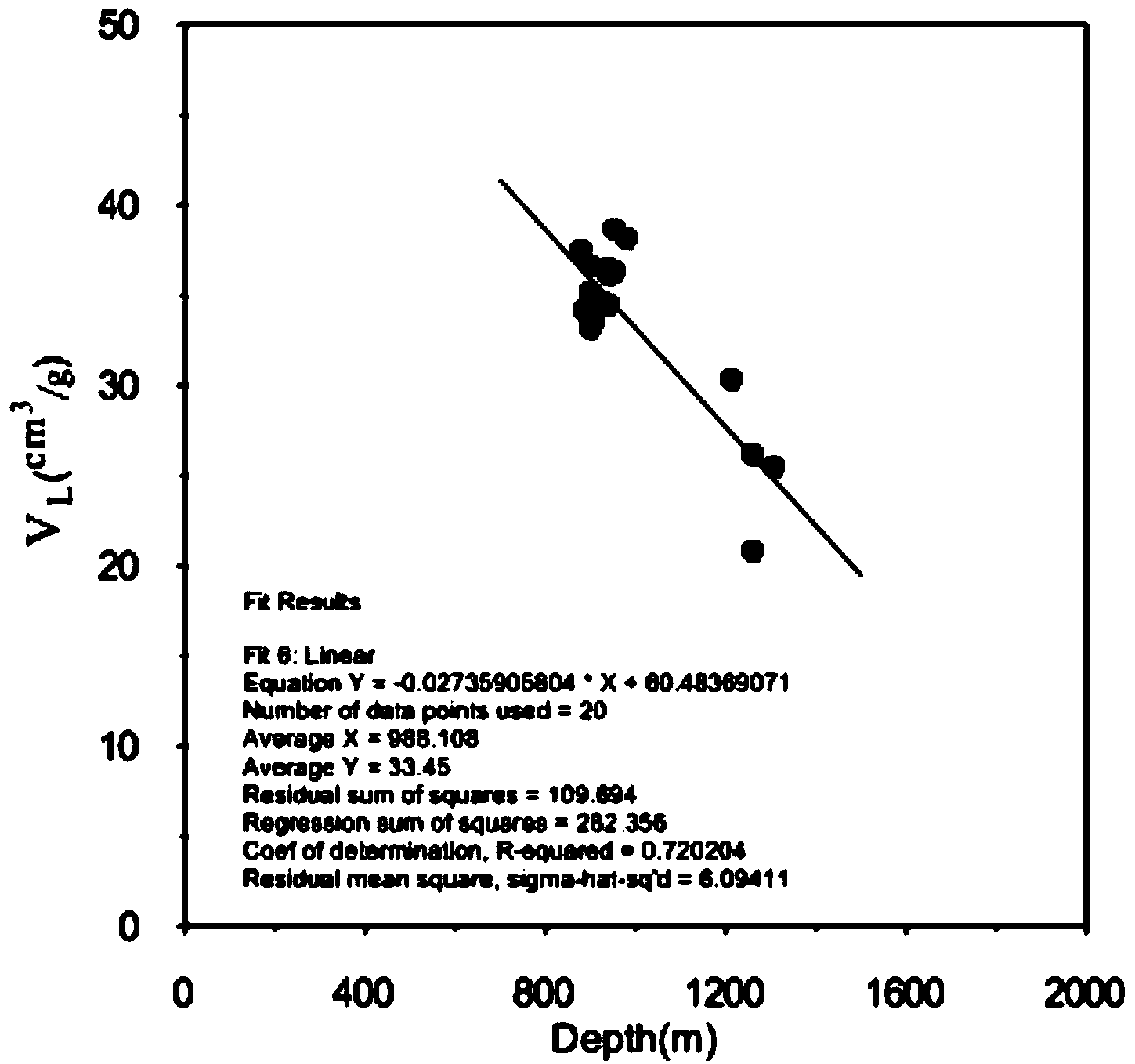

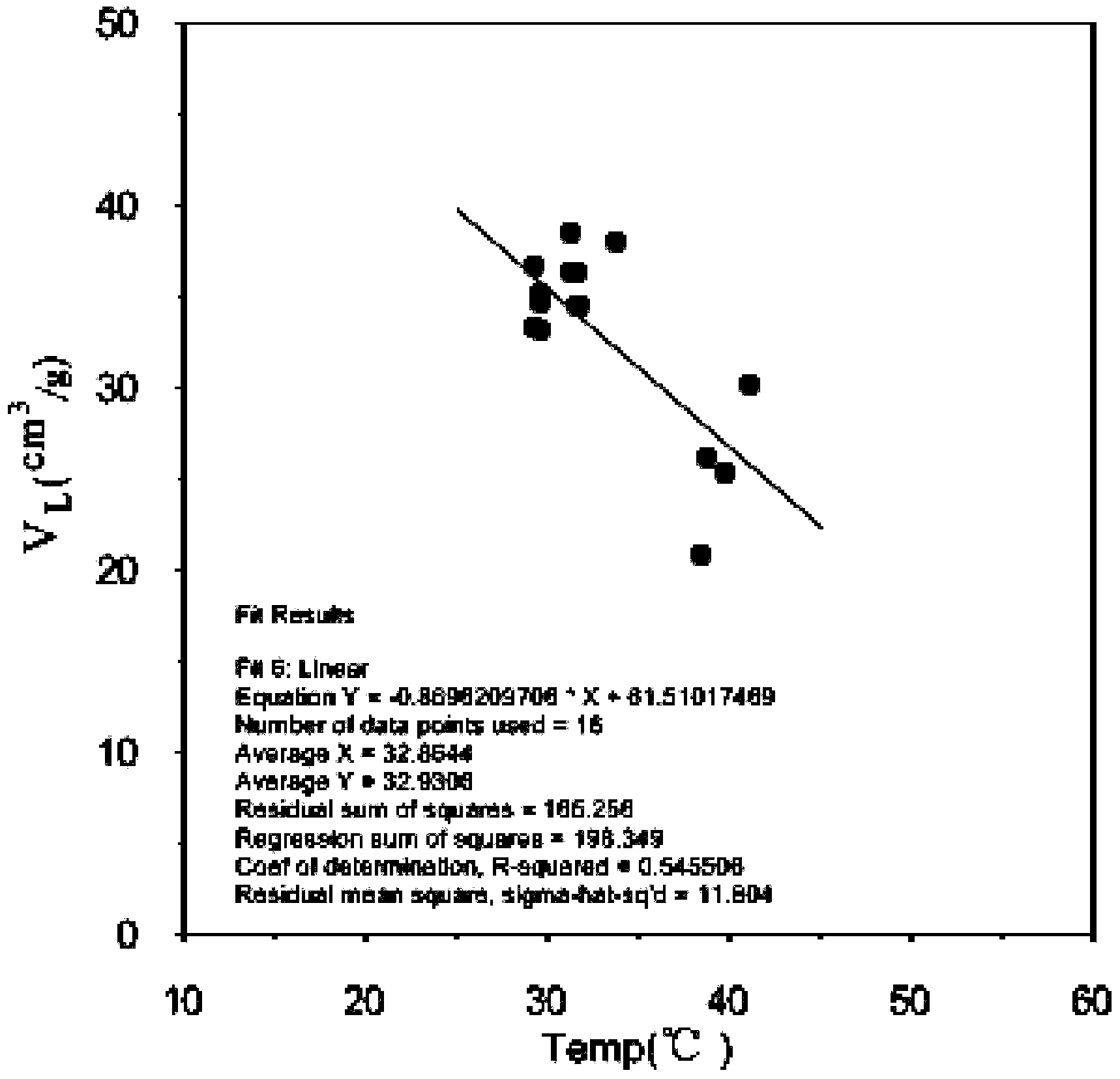

The invention discloses a quantitative calculation method for coal and rock adsorbed gas content. First, logging information is preprocessed; then, fixed carbon content and formation pressure are calculated, a quantitative relation drawing board between the coal and rock adsorbed gas content and a coal rank, a burial depth, temperature and pressure is established, and a vitrinite reflectance function and a regression coefficient between impact factors and Langmuir pressure are obtained; lastly, a dynamic adsorption calculation model of the coal and rock adsorbed gas content is established based on a Langmuir equation, and logging data and parameters are introduced into the dynamic adsorption calculation model for calculation to obtain the coal and rock adsorbed gas content; coal and rock gas characteristics are evaluated according to the coal and rock adsorbed gas content obtained through calculation. According to the quantitative calculation method, quantitative influence on the coal and rock adsorbed gas content by multiple factors under the formation condition is studied sufficiently, experimental data are utilized for scaling to the logging information under the shaft, the dynamic adsorption calculation model of the coal and rock adsorbed gas content based on the logging information is established, and the calculation accuracy of the adsorbed gas content is improved.

Owner:CHINA PETROCHEMICAL CORP +1

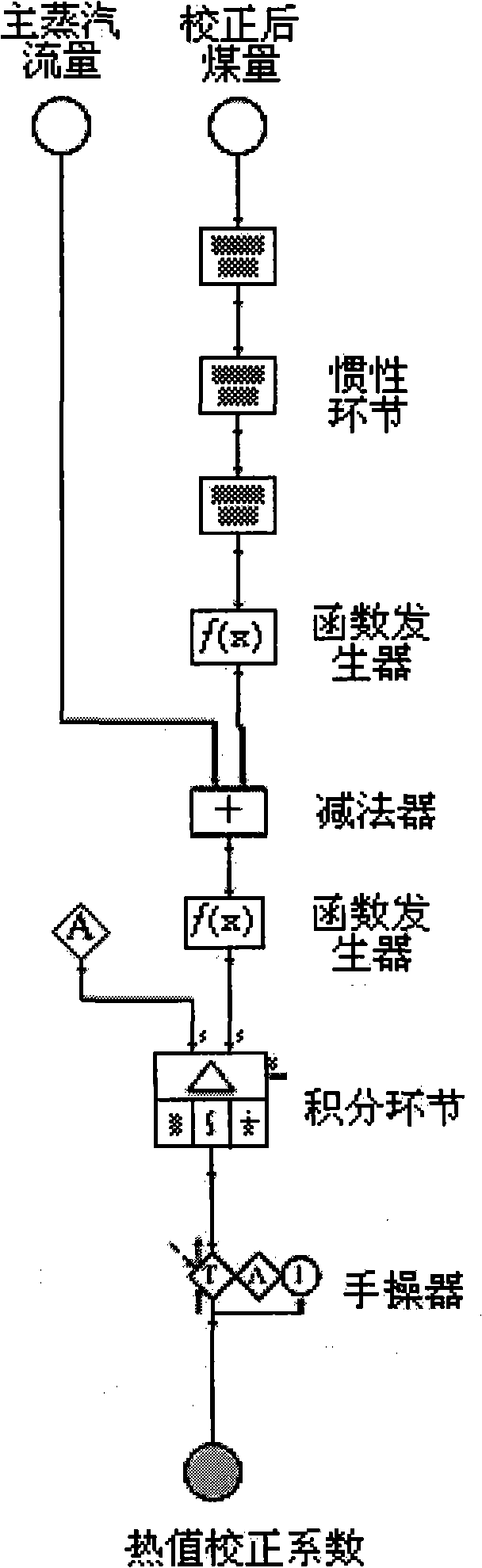

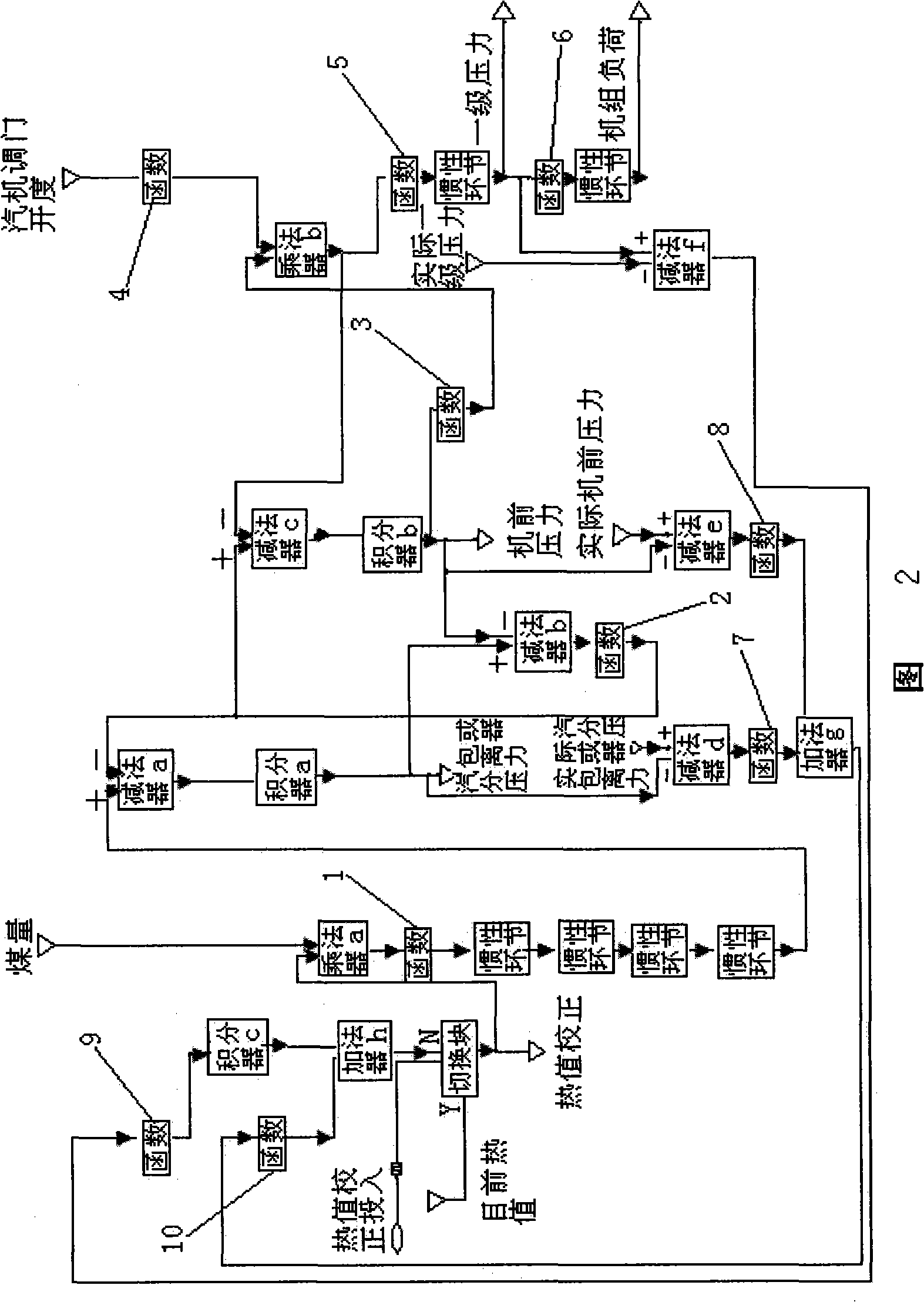

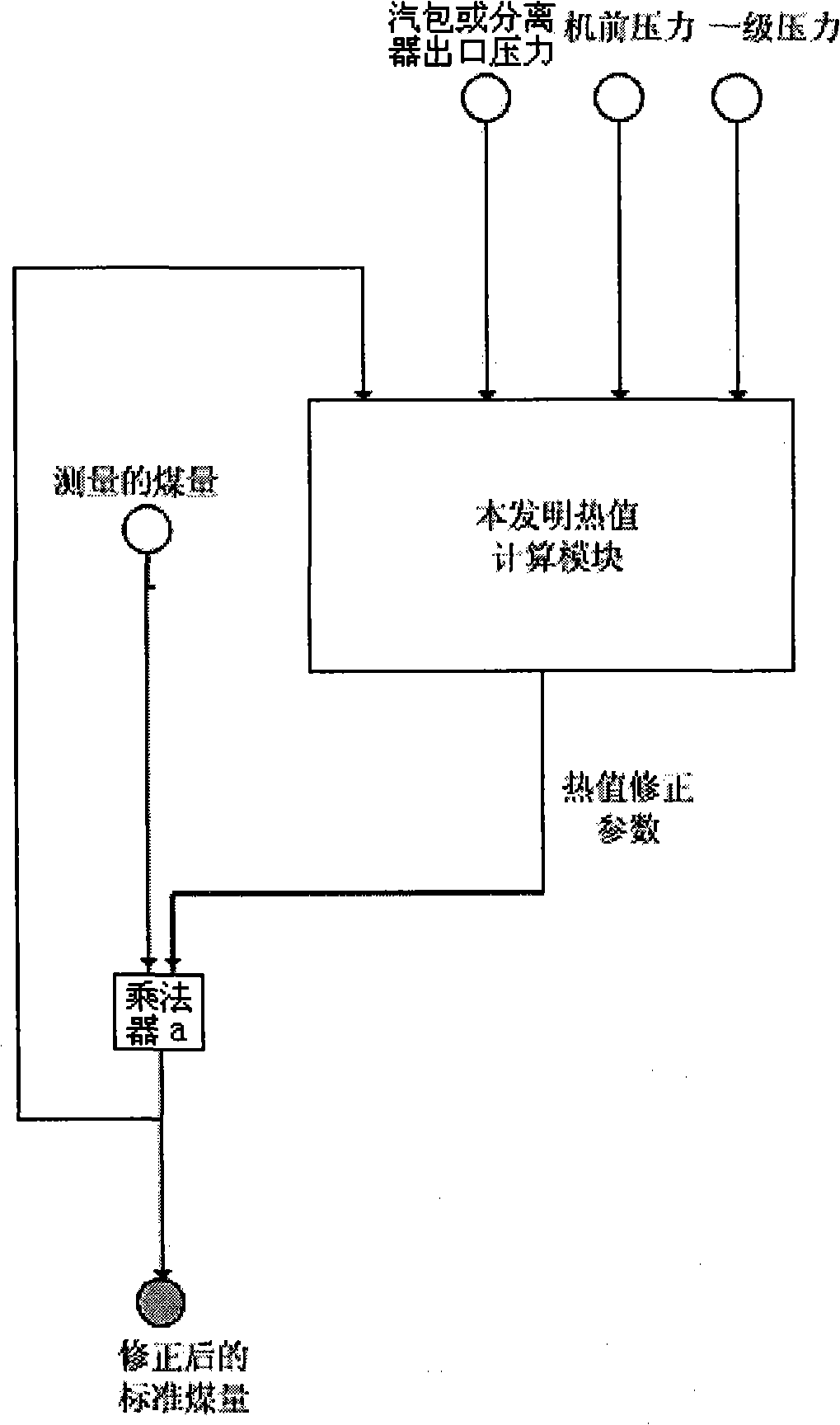

Thermal power unit coal-burning thermal value real time monitoring method and thermal value observer

ActiveCN101320255ASafe and stable operationPrevent overheating and overpressureProgramme controlComputer controlCombustionControl system

The invention relates to a thermal power unit coal heat value real-time monitoring method and a heat value observer thereof. The invention comprises the following steps: 1) based on the dynamic characteristics of the thermal power unit, the heat value observer is established by the energy conservation law; 2) during the stable operation of an actual operating unit under the conditions of the designed coal rank and various loads, the corresponding relation among all the operation parameters of the actual operating unit can be searched in a DCS control system; 3) according to the probability statistics on the operation parameters of the actual operating unit, the static configuration and the dynamic configuration of the parameters of the unit model are carried out, and thus the unit model can be perfectly matched with the actual operating unit; 4) according to the coal consumption signal which is measured in site and the current operation parameters of the unit, the heat value observer can get a heat-value modified parameter through calculation, and the modified parameter can modifies the coal consumption signal in site to obtain the standard coal consumption signal. The application in site shows that the monitoring method and the observer can perfectly make the online real-time monitoring of the changes of the coal heat value, and thus the control system can perfectly overcome the interference on the boiler combustion due to the coal quality variation.

Owner:CHINA ELECTRIC POWER RES INST +2

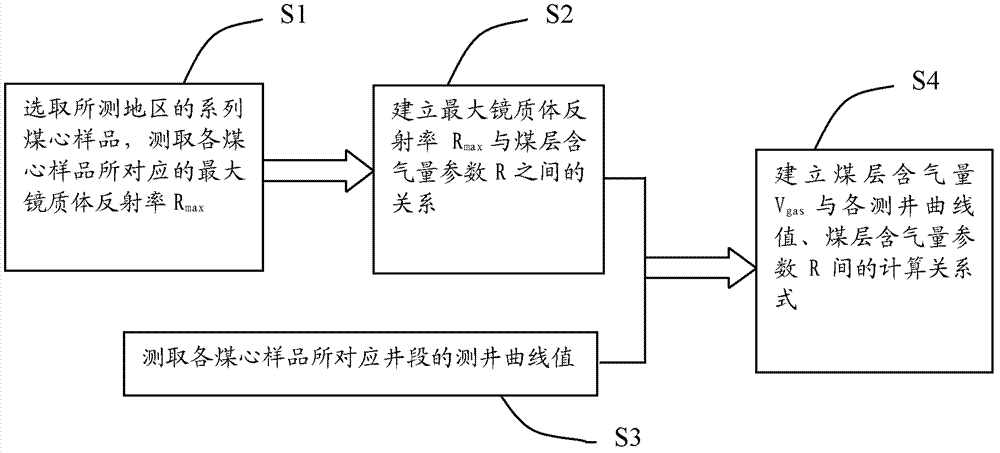

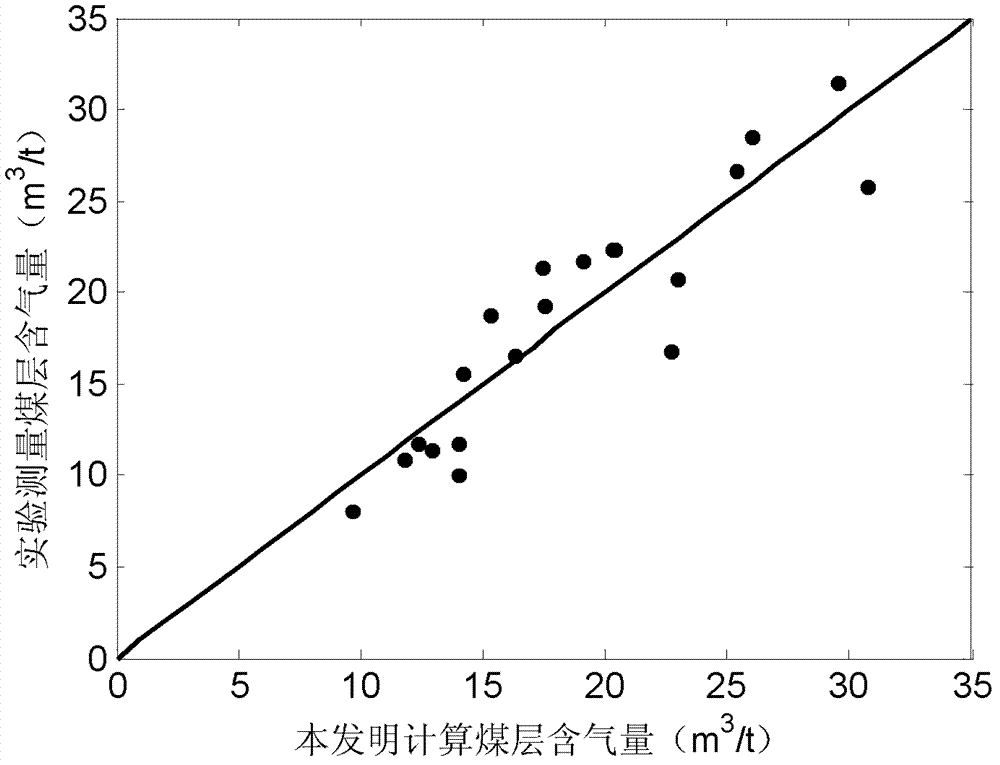

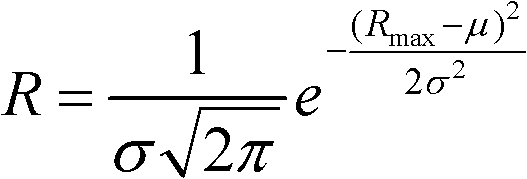

Coal-bed gas-content calculation method

ActiveCN103364844ASignificant impactIn line with the actual geological conditionsGeological measurementsWell loggingCoal rank

The invention discloses a coal-bed gas-content calculation method including: selecting a series of coal-core samples of a tested area; measuring a corresponding maximum vitrinite reflectivity Rmax of each coal-core sample and a well log value of each of corresponding well sections of the coal-core samples; establishing a relationship between the maximum vitrinite reflectivities Rmax and coal-bed gas-content parameters R; and establishing a calculation formula of the coal-bed gas content Vgas according to the well log values and the coal-bed gas-content parameters R. Through introduction of the vitrinite reflectivity, the coal-bed gas-content calculation method takes an effect of coal rank on the coal-bed gas content into full consideration so that the calculated coal-bed gas content complies with an actual geological condition in a better way. And at the same time, the coal-bed gas content is convenient to obtain and low in cost because of being capable of being obtained only based on the well logging information and the vitrinite reflectivity. Moreover, coal-bed gas content of continuous well sections can be obtained so that application effect is good.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Biological permeability-increasing method for coal reservoir

ActiveCN102900411AIncrease the number of cracksIncrease widthFluid removalWell drillingResource development

The invention discloses a biological permeability-increasing method for a coal reservoir, which comprises the following steps in turn: (1) selecting a middle / low-class coal reservoir; (2) forming a channel for injecting liquid into the coal reservoir in a drilling mode or other mode; (3) selecting and culturing microorganism strains suitable for an anaerobic environment and capable of effectively utilizing coal; (4) injecting the nutrient liquid containing the microorganism strains into the coal reservoir in a hydraulic fracturing mode or other mode; (5) confirming shutdown time of a well according to the difference of the coal rank; (6) organizing the subsequent production according to the conventional coal-bed gas well draining extraction or gas extraction process; and (7) checking an effect. A permeability-increasing technology for the coal reservoir is a key point for the coal bed gas resource development and the coal mine gas treatment. The invention provides the permeability-increasing technology utilizing the biotechnology for the middle / low-class coal reservoir; the coal is degraded by the microorganisms, so that the purpose of increasing the permeability of the coal reservoir is achieved; and the biological permeability-increasing method for the coal reservoir has a significance in promoting the coal bed gas resource development and the coal mine gas extraction.

Owner:山西蓝焰煤层气集团有限责任公司 +1

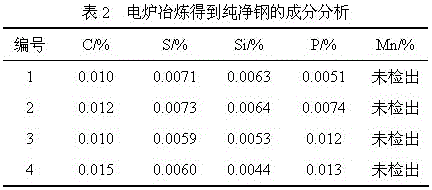

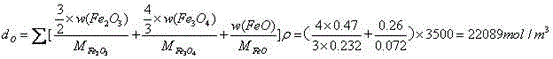

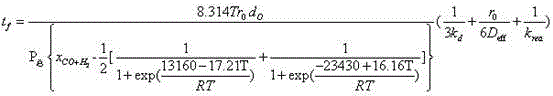

Method for preparing clean steel by coal gas direct reduction one-step method

The invention discloses a method for preparing clean steel by a coal gas direct reduction one-step method. Low-coal-rank coal is pyrolyzed to tar, pyrolyzed coal gas and sponge-shaped fixed carbon at a medium temperature; the sponge-shaped fixed carbon and water vapor are reacted to prepare reducing gas; the reducing gas is introduced in iron pellets or lump ores; iron therein is selectively reduced to obtain pure sponge iron; the pure sponge iron is filled in an electric furnace for smelting to obtain pure liquid-state steel; and meanwhile, the pyrolyzed coal gas is used as heating energy for pyrolysis of the low-coal-rank coal, gasifying reaction of the sponge-shaped fixed carbon and selective gas base direct reduction of the iron pellets or lump ores. The method extracts the tar and the pyrolyzed coal gas in the low-coal-rank coal to a greater extent, and prepares the reducing gas by the sponge-shaped fixed carbon to serve as by-products in the whole process; the energy cost in the whole smelting process is almost zero; and in the selective reducing process, only iron is reduced, and other elements are not reduced, so that the foundation is laid for preparation of clean steel, the oxidation period and the reducing period in the smelting procedure of a traditional electric furnace are synchronously disappeared, and the clean steel is obtained by a simpler flow.

Owner:太原依创瑞诚科技有限公司

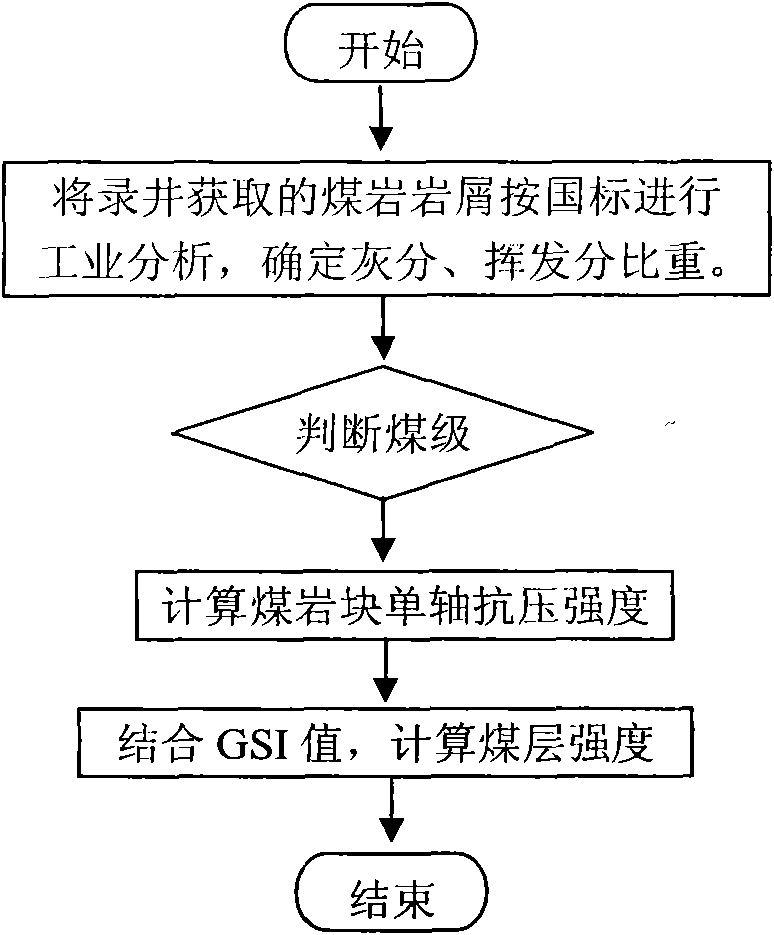

Technology for determining coal bed intensity by using coal ash

InactiveCN102102514AGood application effectBorehole/well accessoriesWell drillingGeological Strength Index

The invention relates to a technology for determining coal bed intensity by using coal ash, which is suitable for the technical field of well wall stabilization in well drilling for coal bed methane. The method comprises the following steps of: classifying, cleaning, baking and crushing coal rock debris obtained by logging, performing proximate analysis of coal according to the national standard, and determining the ratio of ash to volatile; judging the coal grade of the coal rock according to the volatile value; selecting the corresponding empirical formula of the relationship between the ash and the intensity according to the coal grade and calculating the intensity of coal rock blocks; and solving the coal reservoir intensity by combining a geological strength index (GSI) value and applying a Hoek-Brown rock mass strength empirical formula. The method is provided by combining the field on the basis of the Hoek-Brown rock mass strength empirical formula, and is suitable for the requirement for acquiring the parameters of the coal bed intensity in the well wall stabilization prediction of well drilling for the coal bed methane, and the prediction method is simple and has a good effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Coal reservoir water locking damage control method

The invention relates to a coal reservoir water locking damage control method, which comprises the following steps that:1, a ground coal-bed gas well subjected to fracturing transformation is selected; 2, reservoir coal samples are collected on sites, and the contact angle of water on the coal sample surface is tested in an indoor position; 3, quickly penetrating agents T and chlorine dioxides are added into fracturing fluid, the concentration of the quickly penetrating agents T is selected according to the contact angle of the water on the coal sample surface, and the concentration of the chlorine dioxide is selected according to the coal rank of the coal samples (the metamorphism degree of the coal samples); 4, after the quickly penetrating agents T and the chlorine dioxides are added, the uniformly stirred fracturing fluid can be used as ahead fluid, or is used as sand-carrying fluid to be subjected to joint hydraulic fracturing with non-active water fracturing fluid, and 20 to 30 cubic meters of active water fracturing fluid needs to be pumped between the ahead fluid and the sand-carrying fluid for isolation; and 5, the fracturing fluid return and discharging can start only after at least 3 hours from the hydraulic fracturing completion. The coal reservoir water locking damage control method has the advantages that the capillary resistance and the surface tension of a coal-bed gas reservoir layer are reduced; the reservoir layer water locking damage is reduced; the coal-bed gas reservoir layer is favorably protected; and the coal-bed gas recovery rate is favorably improved.

Owner:HENAN POLYTECHNIC UNIV

A method for chemical plugging removal of coalbed methane near wellbore

The invention discloses a coalbed methane near-wellbore area chemical block removing method. The method sequentially includes (1) selecting a coalbed methane well which has serious-polluted coal reservoir near-wellbore area, obvious-decreased gas production or no gas production; (2) injecting proper ethanol to the coalbed segment of the coal reservoir near-wellbore area; (3) selecting soaking period and times according to coal rank difference of the coalbed segment, and then discharging the ethanol; (4) testing effect, namely comparing daily gas production and operating cost of the coalbed methane well before and after operation. According to the method, near-wellbore organic pollution and coal dust blocking are removed, coal is extracted, porosity and permeability of the coal reservoir are increased, a crack system of the coal reservoir is allowed to communicate with the wellbore, a blocking problem of the coalbed methane near-wellbore area is solved, economical investment is low, and gas production of the coalbed methane well can be increased.

Owner:HENAN POLYTECHNIC UNIV

Coalbed methane near-wellbore area chemical block removing method

The invention discloses a coalbed methane near-wellbore area chemical block removing method. The method sequentially includes (1) selecting a coalbed methane well which has serious-polluted coal reservoir near-wellbore area, obvious-decreased gas production or no gas production; (2) injecting proper ethanol to the coalbed segment of the coal reservoir near-wellbore area; (3) selecting soaking period and times according to coal rank difference of the coalbed segment, and then discharging the ethanol; (4) testing effect, namely comparing daily gas production and operating cost of the coalbed methane well before and after operation. According to the method, near-wellbore organic pollution and coal dust blocking are removed, coal is extracted, porosity and permeability of the coal reservoir are increased, a crack system of the coal reservoir is allowed to communicate with the wellbore, a blocking problem of the coalbed methane near-wellbore area is solved, economical investment is low, and gas production of the coalbed methane well can be increased.

Owner:HENAN POLYTECHNIC UNIV

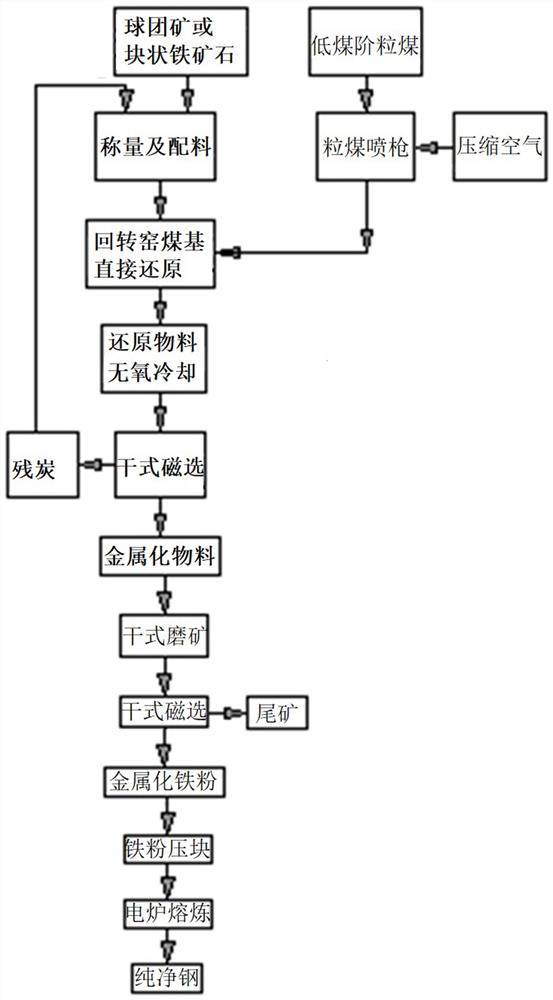

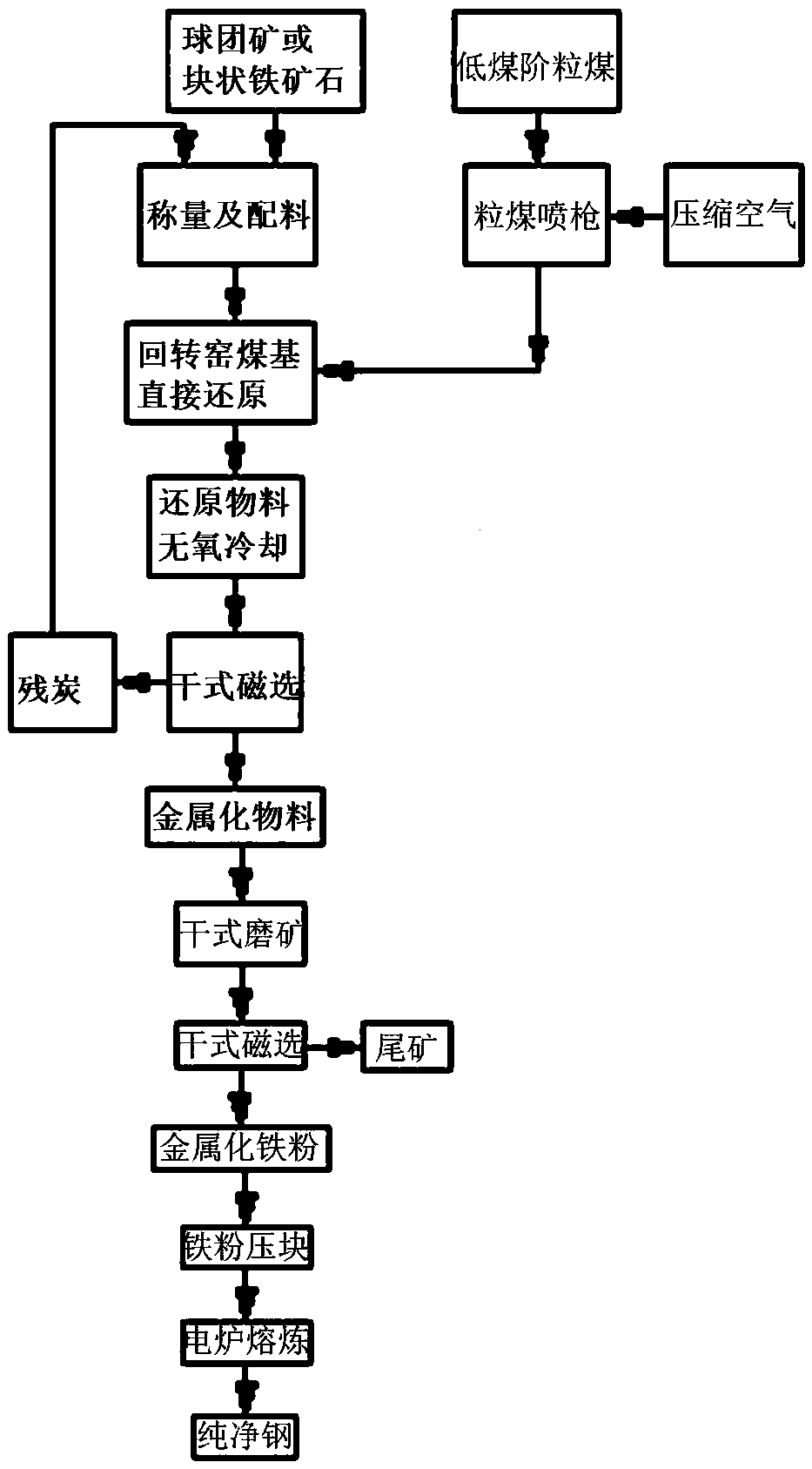

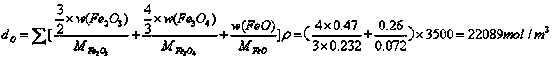

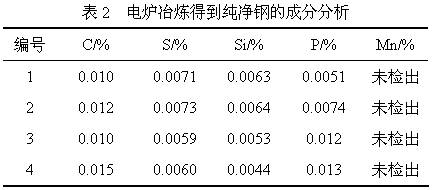

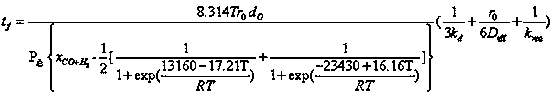

A low-temperature reduction of iron ore-separation of slag and iron at normal temperature-electric furnace steelmaking process

ActiveCN110195139BSimple processReduce environmental discharge pressureRotary drum furnacesElectric furnaceSteelmakingIron powder

The invention relates to an iron ore low-temperature reduction-normal temperature slag-iron separation-electric furnace steelmaking process. During the reduction process of pellet or massive iron ore rotary kiln, low-rank coal is sprayed into the rotary kiln through compressed air. In the middle and late stage, coal is pyrolyzed into tar, pyrolysis gas and residual carbon during the rapid temperature rise process in the high temperature section. After selective reduction of the iron in the massive iron ore, the mixture of the reduced material and carbon residue is subjected to dry magnetic separation, and the carbon residue obtained is returned to the kiln material for recycling, and the metallized material obtained is recycled. After dry grinding, dry magnetic separation, iron powder briquetting, and electric furnace smelting, pure steel can be obtained. The present invention utilizes the tar, pyrolysis gas and residual carbon in the low-rank coal to the greatest extent, and only iron is reduced in the selective reduction process without reducing other elements, which lays the foundation for producing pure steel.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

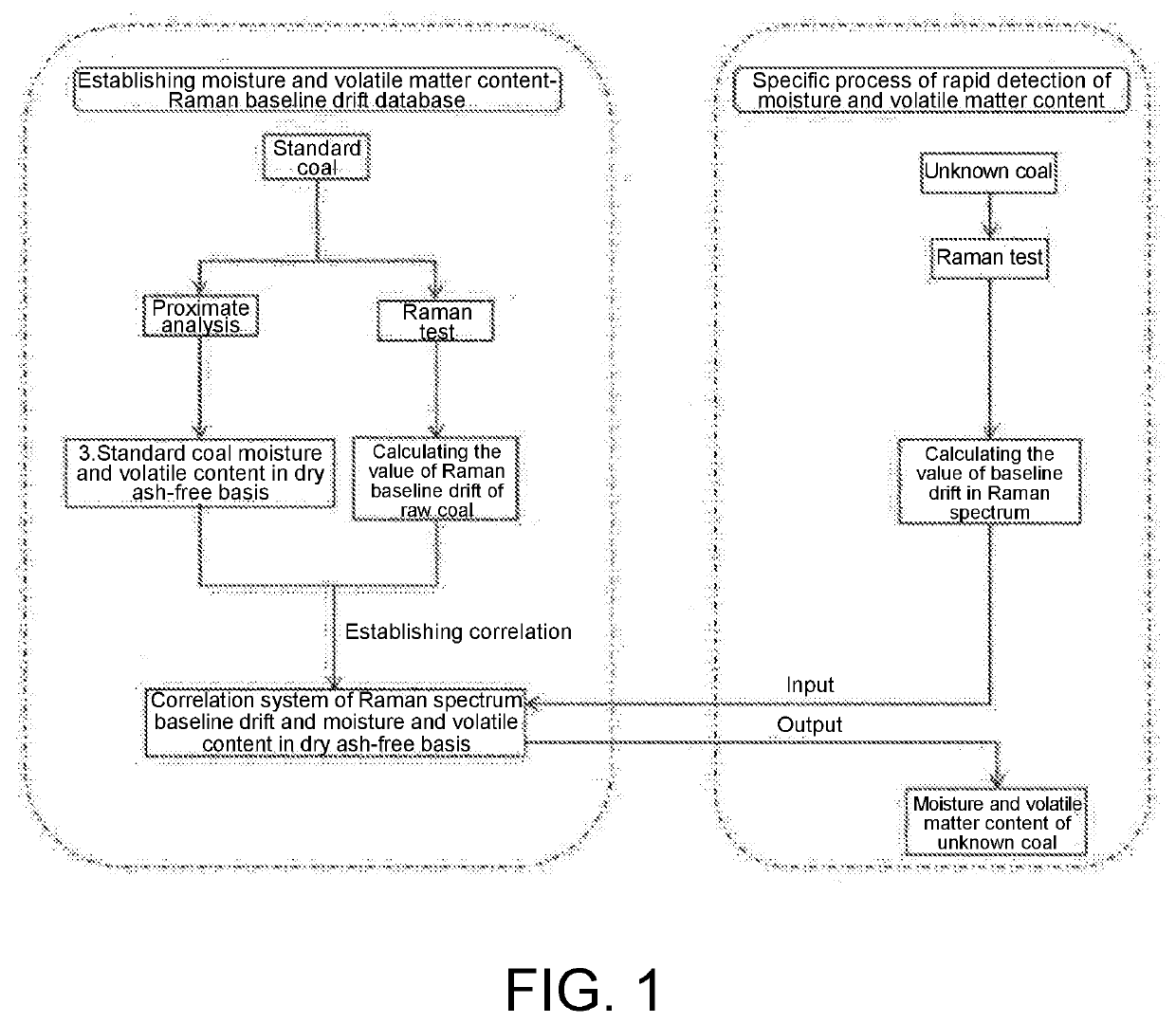

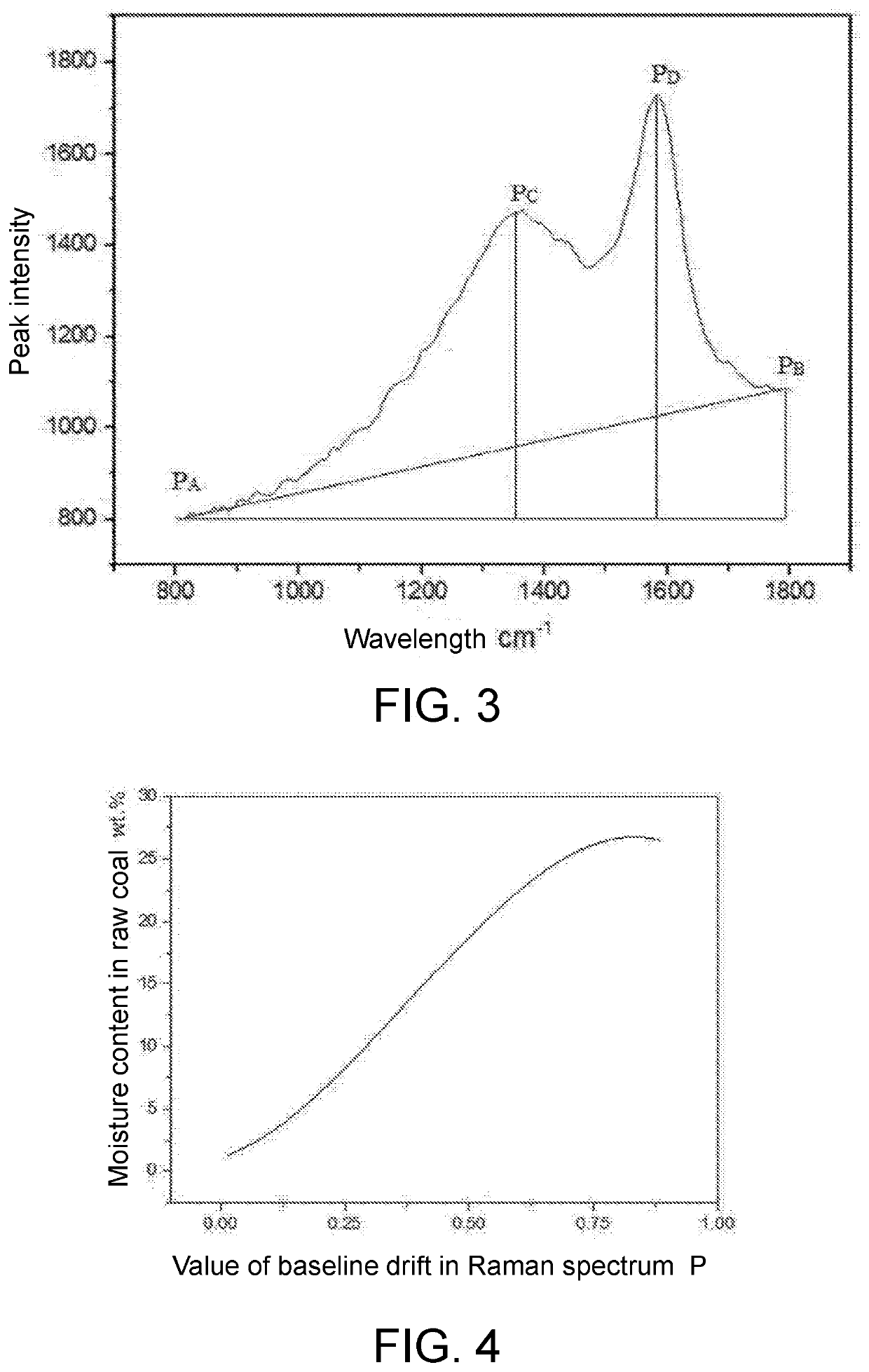

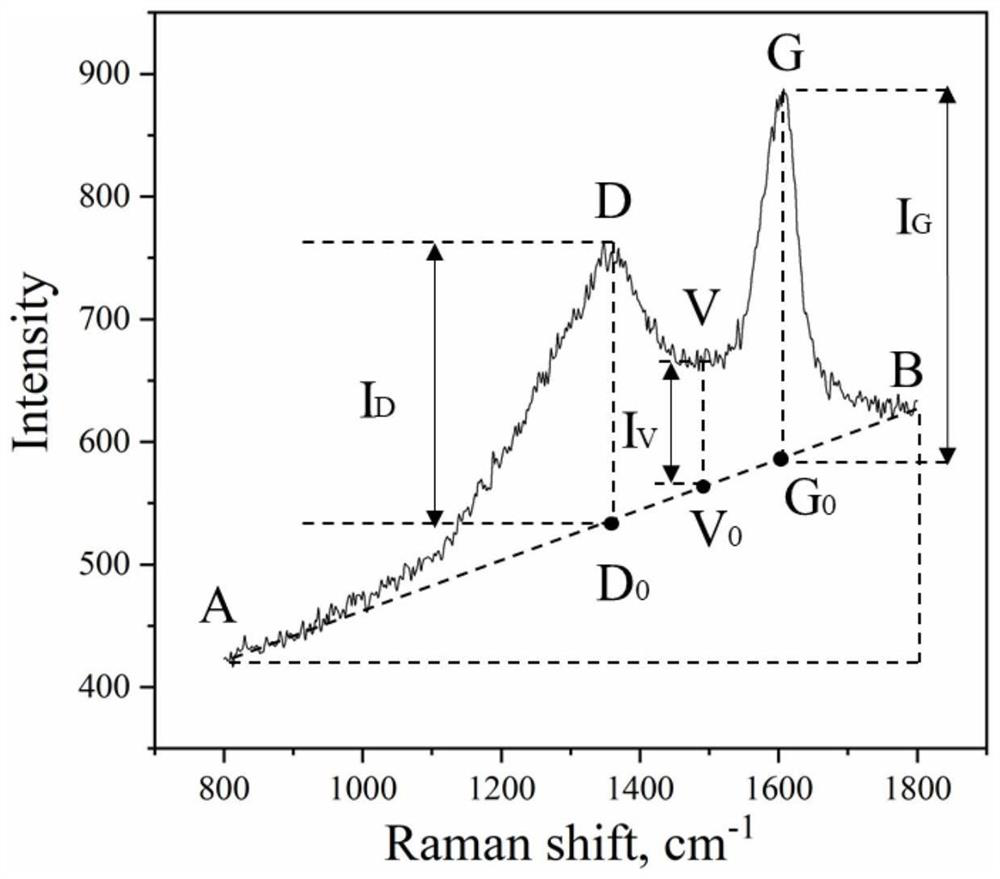

Method for detecting moisture and volatile matter content of raw coal by using value of baseline drift

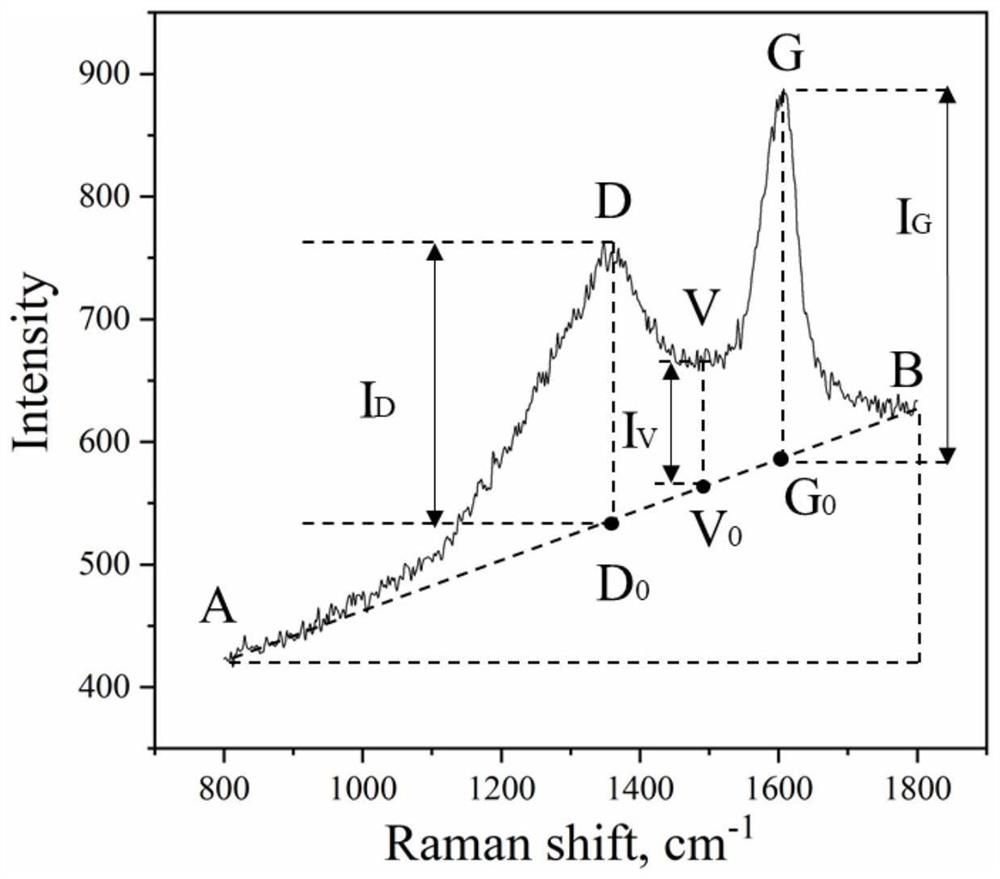

ActiveUS20200264106A1Automatic recognitionAppropriate controlFuel testingRaman scatteringProximate analysisCoal rank

The present invention relates to a method for detecting moisture and volatile matter content in raw coal using the value of baseline drift, comprising the following steps: selecting a plurality of types of standard coal having different coal ranks and different ash contents, performing a Raman spectroscopy test and a proximate analysis on each type of standard coal, calculating the value of baseline drift in the Raman spectrum, and setting up the mapping relationship between the value of baseline drift in the Raman spectrum and the characteristic parameters of the moisture and the volatile matter content. The same method and reference are used to perform a Raman spectroscopy test on raw coal to be tested, so as to calculate the value of baseline drift in a Raman spectrum of the raw coal to be tested, and obtain the moisture and volatile matter content of the raw coal to be tested.

Owner:HUAZHONG UNIV OF SCI & TECH

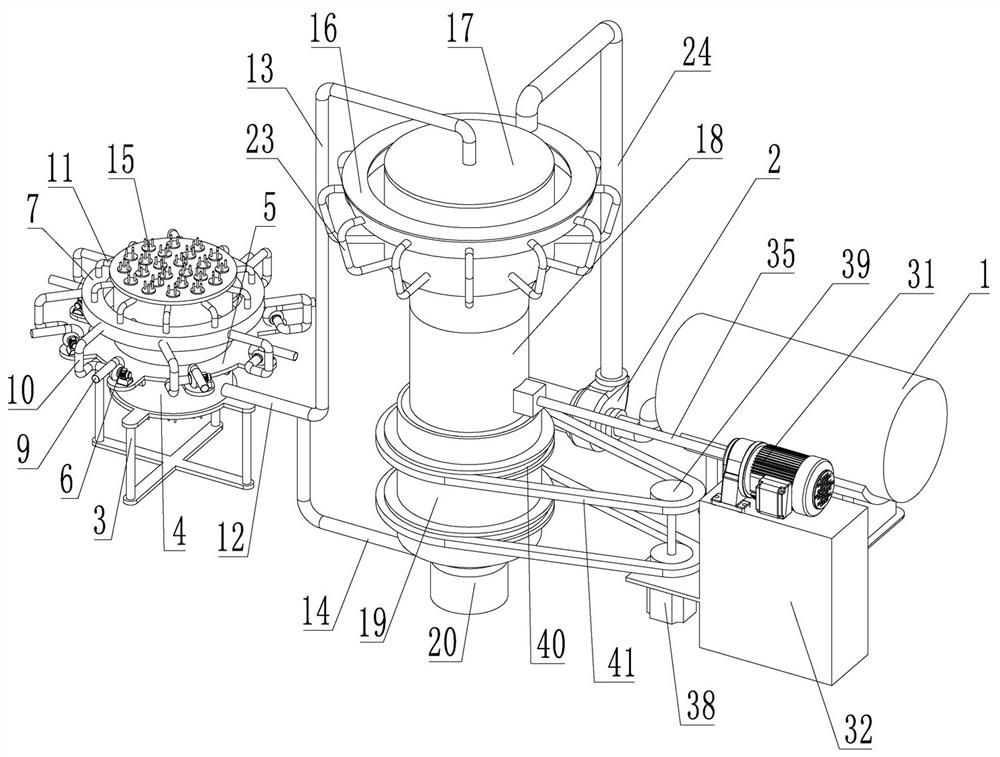

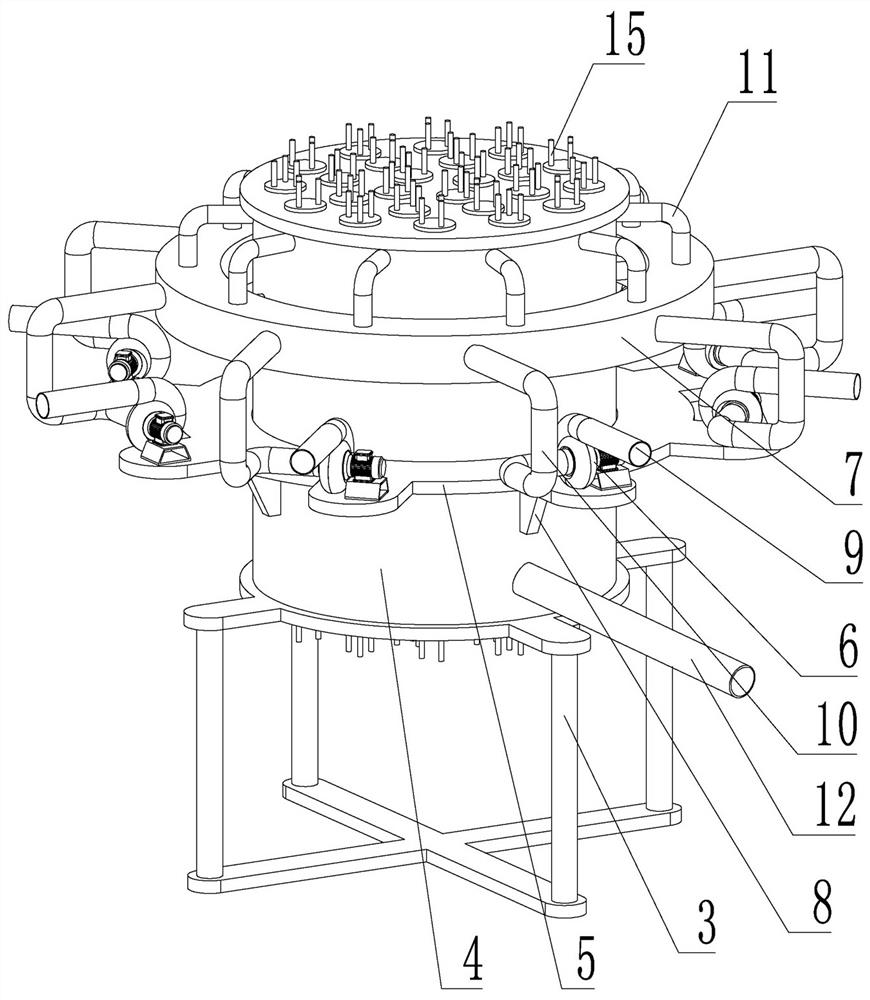

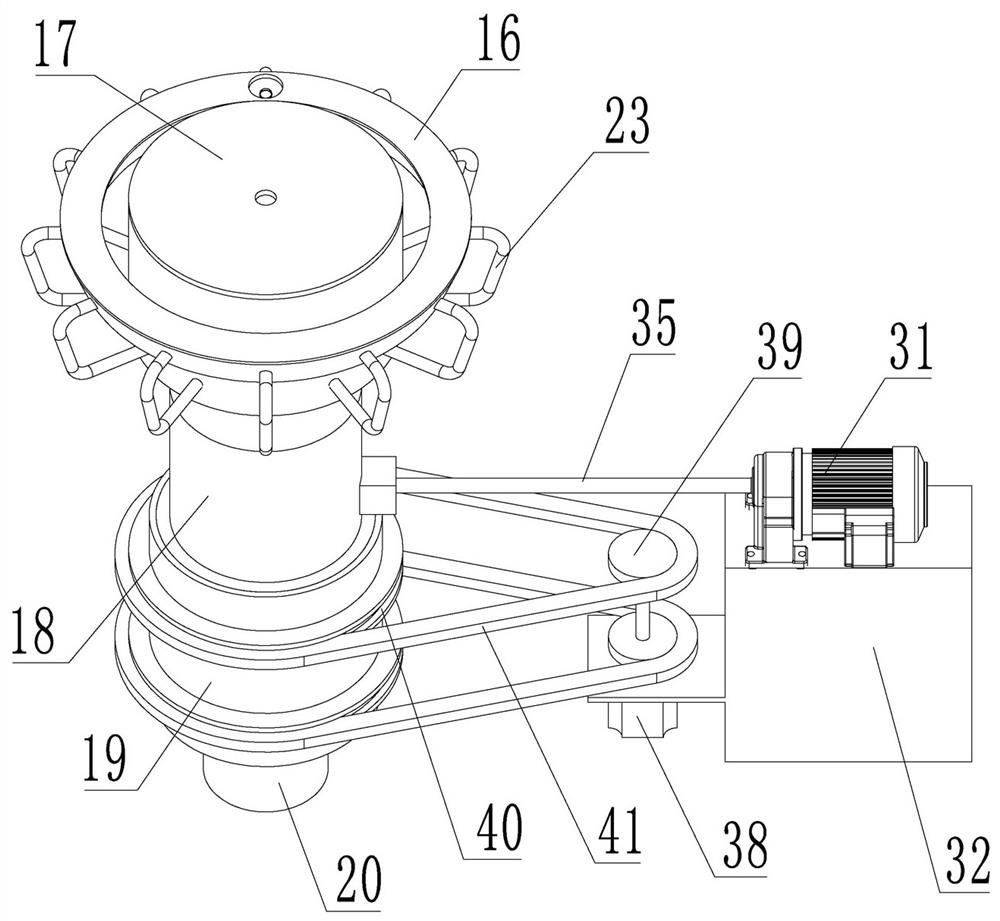

System of increasing yield of coal seam gas by mixing with hot air proppant, and its working method

InactiveCN111706312AImprove resolution rateImprove diversion capacityTransportation and packagingMixersHolding tankHot blast

The invention discloses a system of increasing yield of coal seam gas by mixing with a hot air proppant. The system comprises a high temperature and high pressure hot air generating device, a proppantstorage tank, a proppant delivery pump and a multi-stage mixing device, wherein the air outlet end of the high temperature and high pressure hot air generating device is connected to the air inlet end of the multi-stage mixing device, the discharge end of the proppant storage tank is connected to the feed end of the proppant delivery pump, the discharge end of the proppant delivery pump is connected to the feed end of the multi-stage mixing device, and the mixture discharge end of the multi-stage mixing device is connected to the upper end of a coal seam well opened in a low-coal rank reservoir. The system provided by the invention mixes the hot air with high temperature and high pressure and proppant uniformly three times and then injects the mixture into the coal seam well in the low-coal rank reservoir to heat the coal seam to generate a large number of artificial cracks, which can increase the resolution rate of coal seam gas. At the same time, the filling of the proppant into cracks can prevent the cracks from being closed due to stress release and increase the production of coal seam gas.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Iron ore low-temperature reduction-normal-temperature slag-iron separation-electric furnace steel making process

ActiveCN110195139AQuick restoreSimple processRotary drum furnacesProcess efficiency improvementSlagReducing agent

The invention relates to a iron ore low-temperature reduction-normal-temperature slag-iron separation-electric furnace steel making process. The process is characterized in that in a reduction processof a pellet ore or a lump iron ore in a rotary kiln, a low-coal-rank coal is sprayed into a middle rear section of the rotary kiln through compressed air, the coal is pyrolyzed into tar, pyrolysis gas and residual carbon in a rapid heating process of a high-temperature section, the pyrolysis gas is utilized as a reducing agent of a to-be-reduced material, the tar is used as a fuel for the rotarykiln, the pellet ore or the lump iron ore are subjected to selective reduction of iron in the pellet ore or lump iron ore, the reduced material and a residual carbon mixture are subjected to dry magnetic separation, the obtained residual carbon is returned and distributed to a kiln material for cyclic utilization, the obtained metalized materials are subjected to dry grinding, dry magnetic separation, iron powder briquetting and electric furnace smelting, so that pure steel can be obtained. According to the process, the tar, the pyrolysis coal gas and the residual carbon in the low-coal-rank coal are utilized to the maximum extent, only iron is reduced in the selective reduction process without reducing other elements, and a foundation is laid for preparing pure steel.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

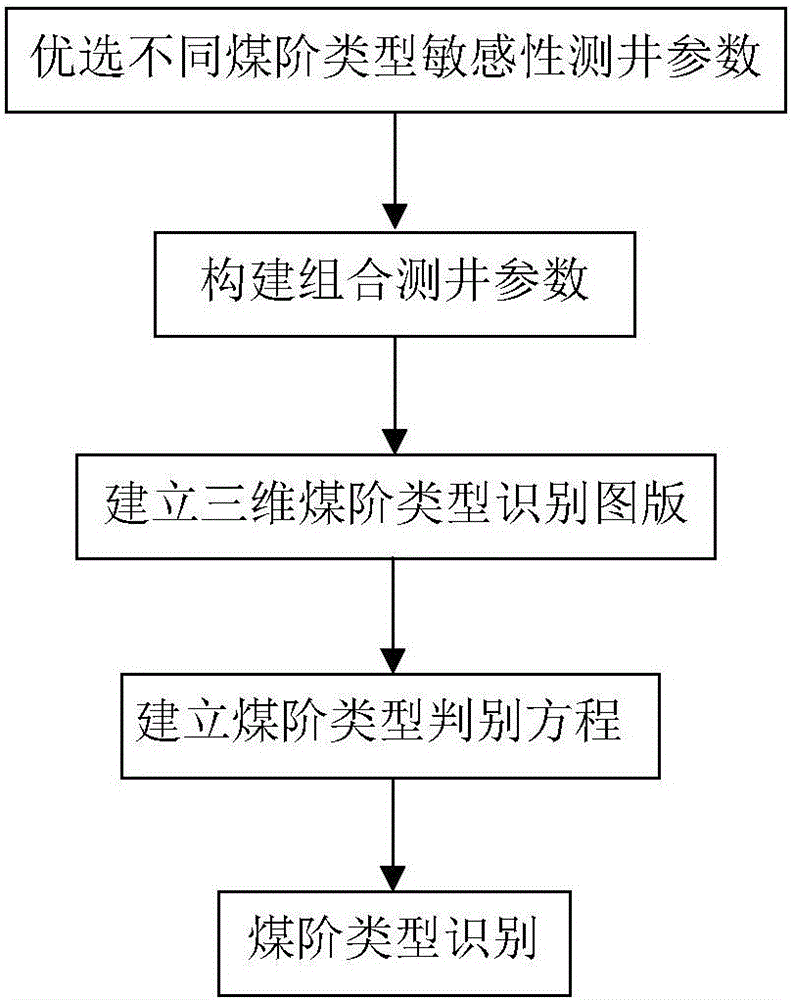

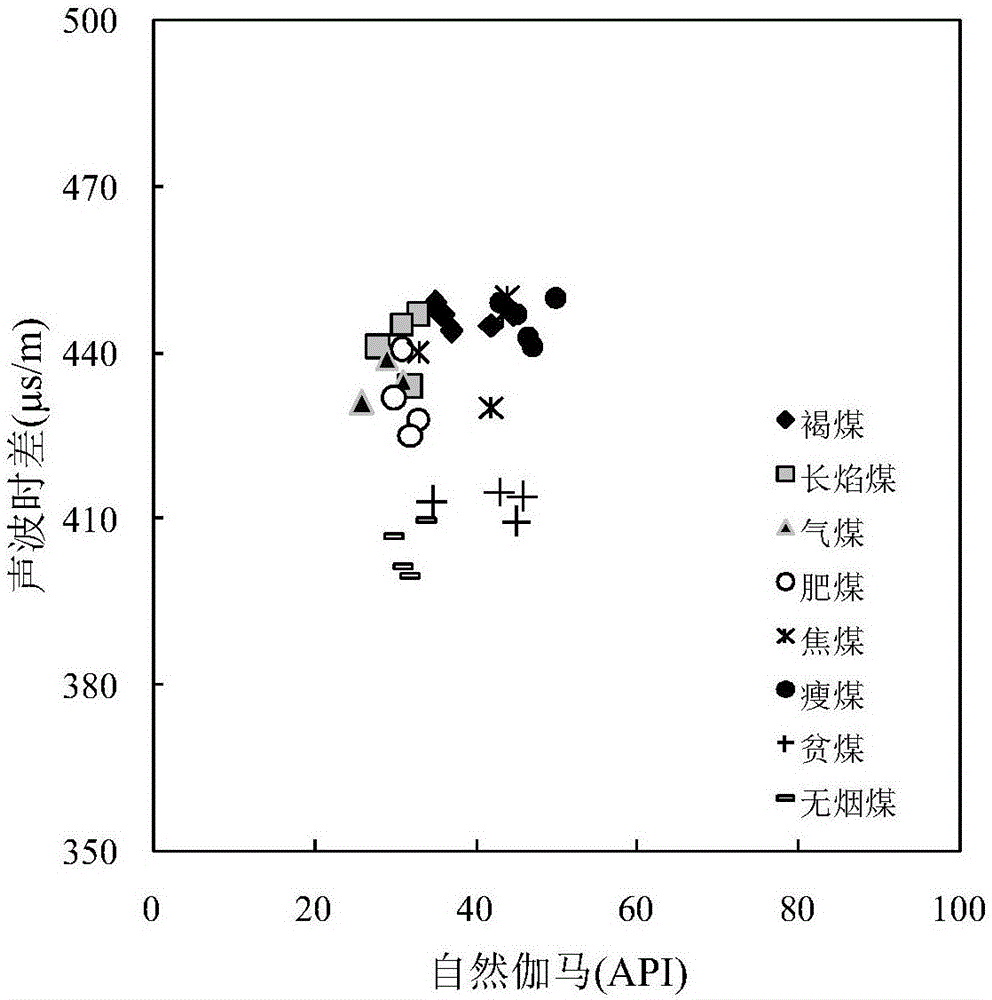

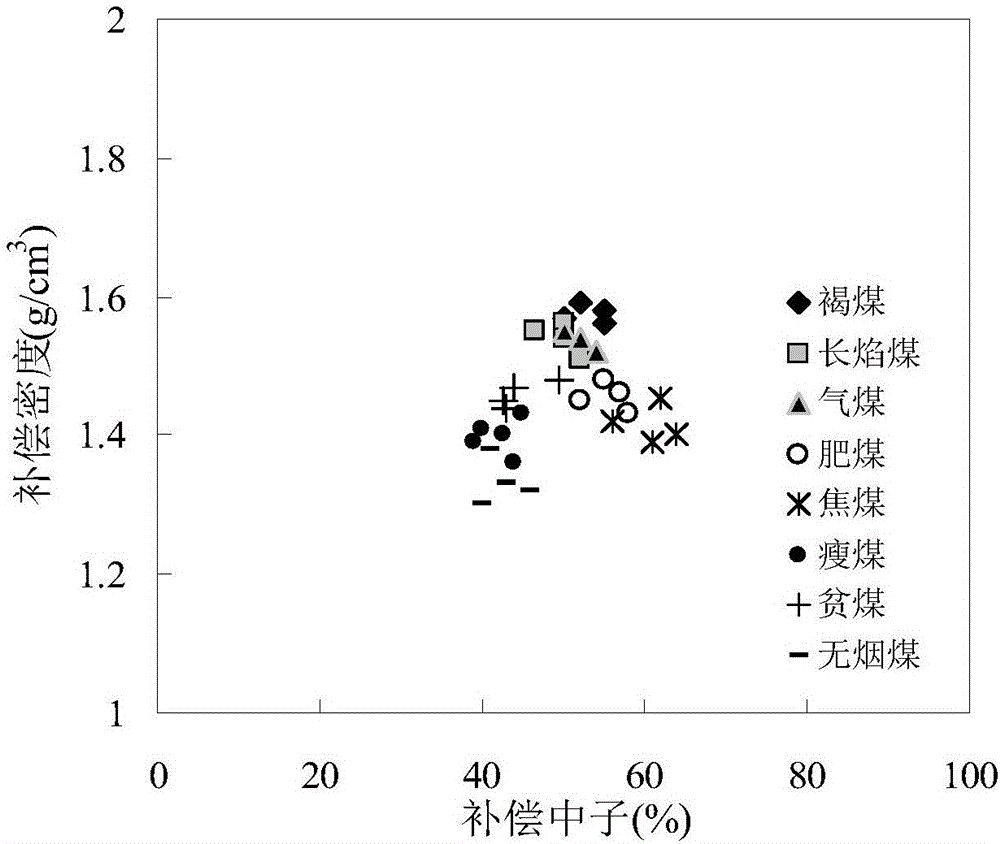

Method for automatically and rapidly partitioning coal rank types by utilizing logging information computer

InactiveCN106484989AAccurate divisionData processing applicationsDesign optimisation/simulationAcoustic waveNeutron

The invention relates to a method for automatically and rapidly partitioning coal rank types by utilizing a logging information computer. The method comprises the steps of: firstly, selecting different coal rank types of sensitive logging parameters; then constructing four combined logging parameters of an apparent wave impedance, a compensation neutron increment coefficient and an electrical resistivity difference index by sufficiently utilizing interval transit time, a compensation density, a compensation neutron and an electrical resistivity; then establishing a three-dimensional coal rank type identification plate; then establishing a coal rank type discriminatory equation; and finally, identifying the coal rank types. According to the method disclosed by the invention, based on logging information of coal rocks, such as natural gamma, a natural potential, the electrical resistivity, the interval transit time, the compensation density, the compensation neutron and the like and on the basis of analyzing different coal rank types of sensitive logging parameters, the combined logging parameters of the coal rocks, such as the apparent wave impedance, the compensation neutron increment coefficient, the electrical resistivity difference index and the like, are established, and by the combined logging parameters, the three-dimensional coal rank type identification plate is constructed, and the plate is programmed so as to partition the coal rank types and provide drilling logging technical support for safety mining of a coal mine and development of a coal bed gas.

Owner:XIAN UNIV OF SCI & TECH

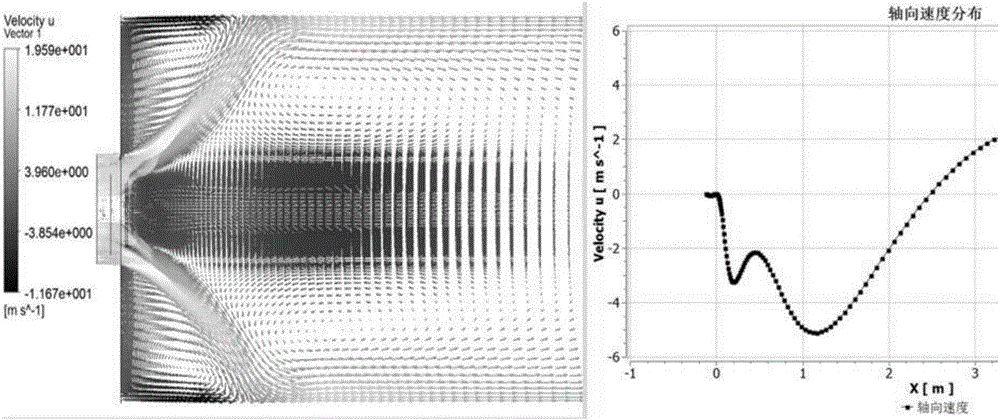

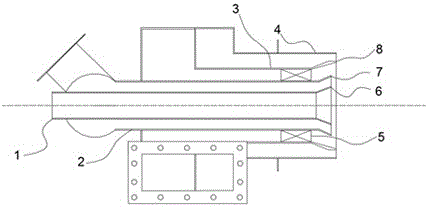

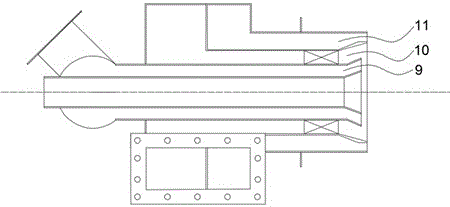

Rotational flow coal powder combustor having multiple coal rank adaptability

InactiveCN106765075ALower flame temperatureIncreased recirculation zoneBurner safety arrangementsPulverulent fuel combustion burnersCombustorEngineering

The invention discloses a rotational flow coal powder combustor having multi-coal rank adaptability. The combustor mainly consists of a central wind pipe, a secondary wind pipe, a tertiary wind pipe, a secondary wind rotational flow blade, a central wind pipe flaring, a primary wind pipe flaring, a secondary wind pipe flaring, and the like. According to the rotational flow coal powder combustor disclosed by the invention, the reasonable design of the flaring of the combustor is matched with the reasonable design of wind distribution pipelines, and staged combustion is formed, so that a large and stable central reflowing region is formed at an outlet of the combustor, and more coal powder can be gathered at the borders of the reflowing region; besides, the coal powder of which the particle diameters are high can rotate and reflow at the outlet of the combustor, so that the staying time of the large-particle-diameter coal powder in a high-temperature region at the outlet of the combustor is prolonged, and the purposes that the coal powder is on fire in time and is stably combusted are guaranteed; the designed rotational flow coal powder combustor disclosed by the invention is simple in structure and convenient to reform; through adjusting air distribution, all kinds of bituminous coal and anthracite coal can be efficiently fueled; and the designed rotational flow coal powder combustor disclosed by the invention is suitable for combusting mixed coal, and can be widely applied to various kinds of coal powder fueled by an industrial boiler, and the multi-coal rank adaptability of the industrial boiler is improved.

Owner:JIMEI UNIV +1

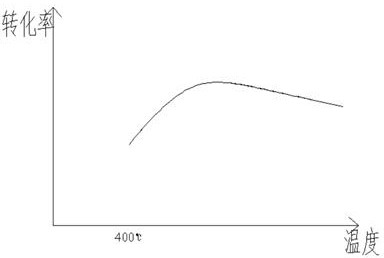

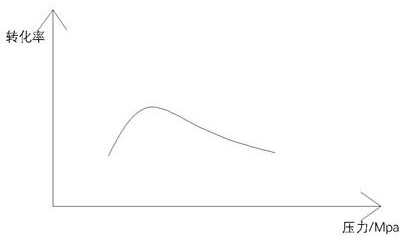

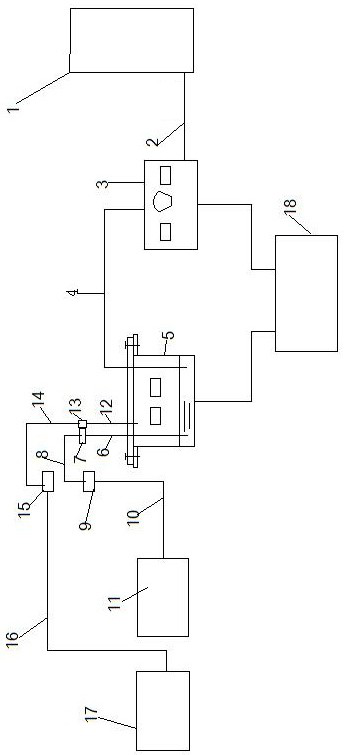

Device and method for gas-liquid fluidization exploitation of old goaf slime water

The invention discloses a device and method for gas-liquid fluidization exploitation of old goaf slime water. The device comprises a superheated steam device, a slime water gasification-liquidation converting device, a gasification-liquidation product collecting device and a control device. The control device comprises a temperature control device, a pressure control device, a pressure and temperature coordinating device and a computer. The superheated steam device is composed of a water tank, a water supply pipeline, a heater and a steam pipeline. The slime water gasification-liquidation converting device comprises a slime water gasification-liquidation converting box. The gasification-liquidation product collecting device comprises an oil collecting device and a mixed gas collecting device. The temperature control device is located inside the heater. The pressure control device is located in the slime water gasification-liquidation converting box. The temperature and pressure coordinating device comprises a gas pump. The computer is connected with the slime water gasification-liquidation converting box and the heater. With the old goaf slime water as the research object, the device and method achieve a slime water gas-liquid fluidization exploitation experiment under the conditions of a given temperature, a given pressure and a given coal grade.

Owner:TAIYUAN UNIV OF TECH

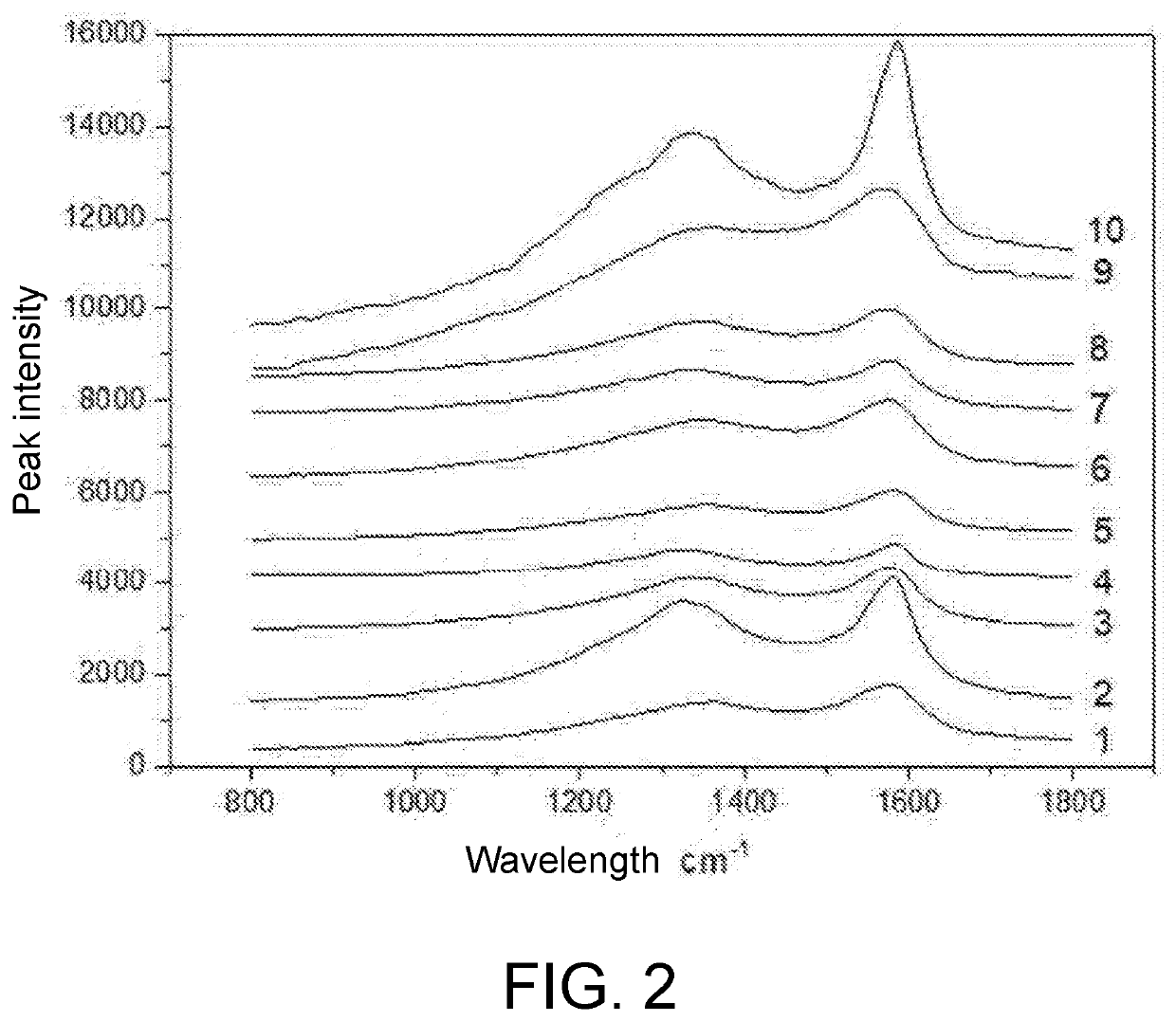

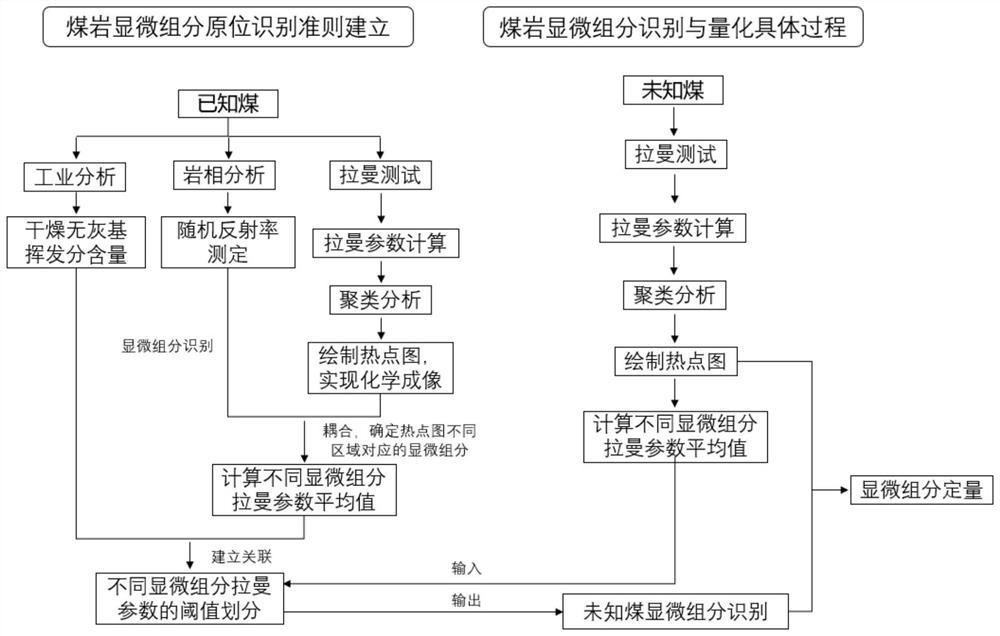

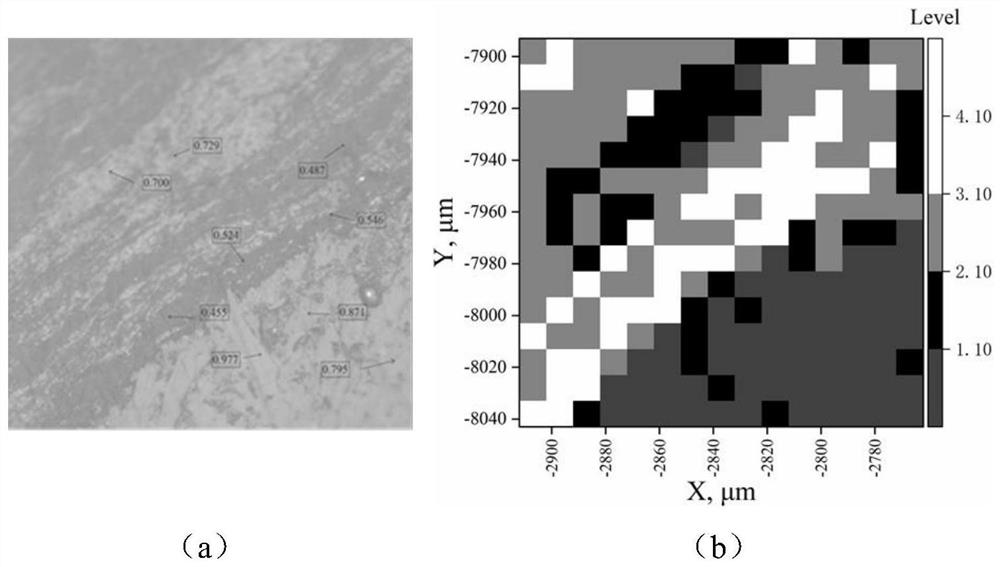

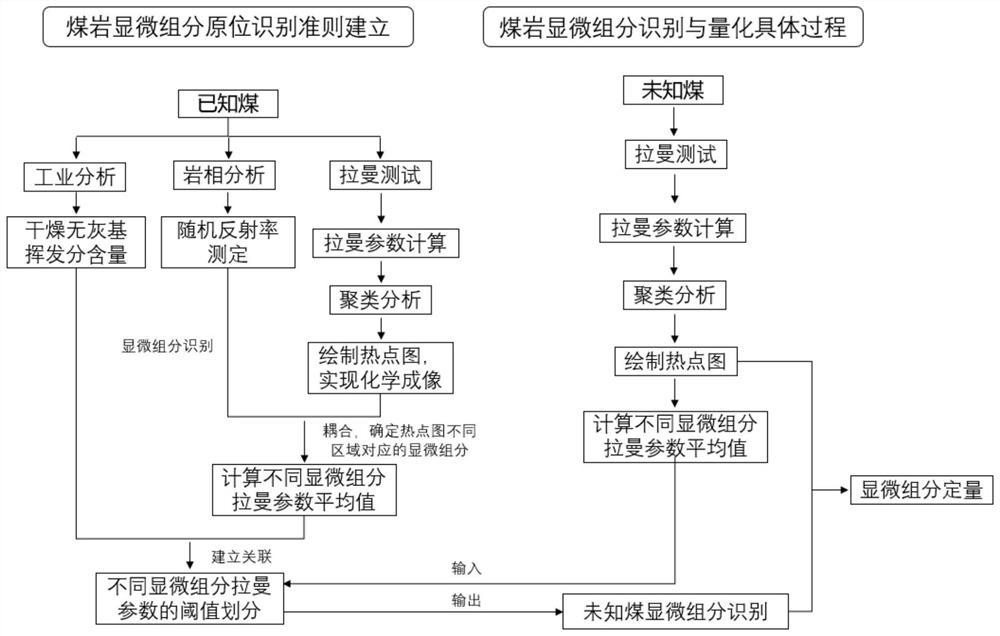

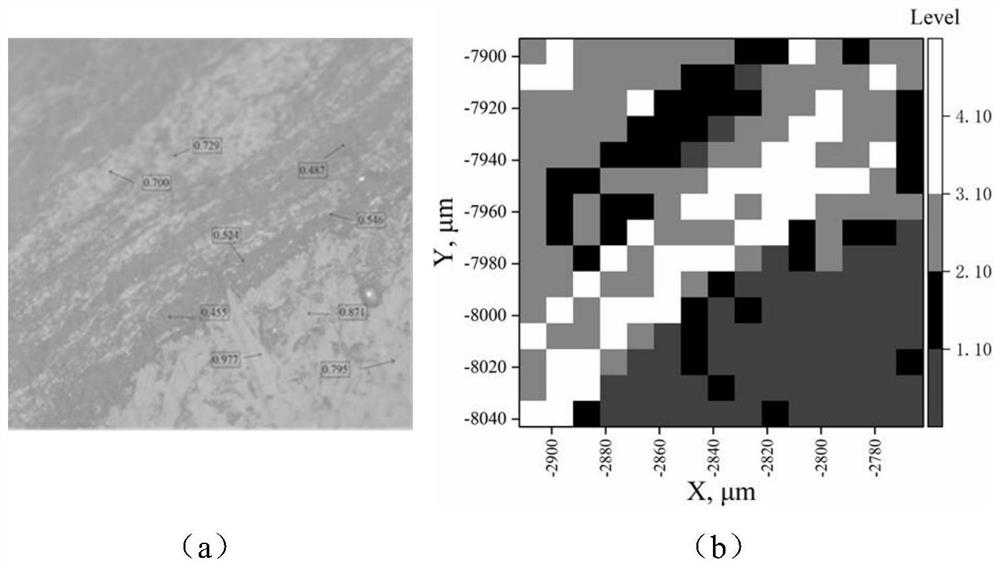

In-situ identification and rapid quantification method for coal rock macerals

The invention discloses an in-situ identification and rapid quantification method for coal rock macerals. The method comprises the following steps: firstly, selecting a plurality of different coal rank standard coals to carry out industrial analysis, lithofacies analysis and Raman spectrum surface scanning to obtain dry ash-free base volatile component content Vdaf, macerate type determination results and Raman characteristic parameters; selecting a plurality of Raman characteristic parameters for clustering analysis, drawing a hot spot map according to a clustering result, comparing the hot spot map with a lithofacies analysis result, and determining microcomponent types corresponding to different colors of the hot spot map; establishing a corresponding relationship between the Raman characteristic parameters and Vdaf, determining a threshold interval where the Raman characteristic parameters of different microscopic components of each coal rank are located, and establishing a microscopic component in-situ identification criterion according to the interval; during detection, performing industrial analysis and Raman test on coal to be detected, identifying the macerals by utilizingthe criterion, and determining the content of the corresponding macerals according to the proportion of each color point in the hot spot map. The experiment and data processing method is simple, andthe detection is rapid and accurate.

Owner:HUAZHONG UNIV OF SCI & TECH

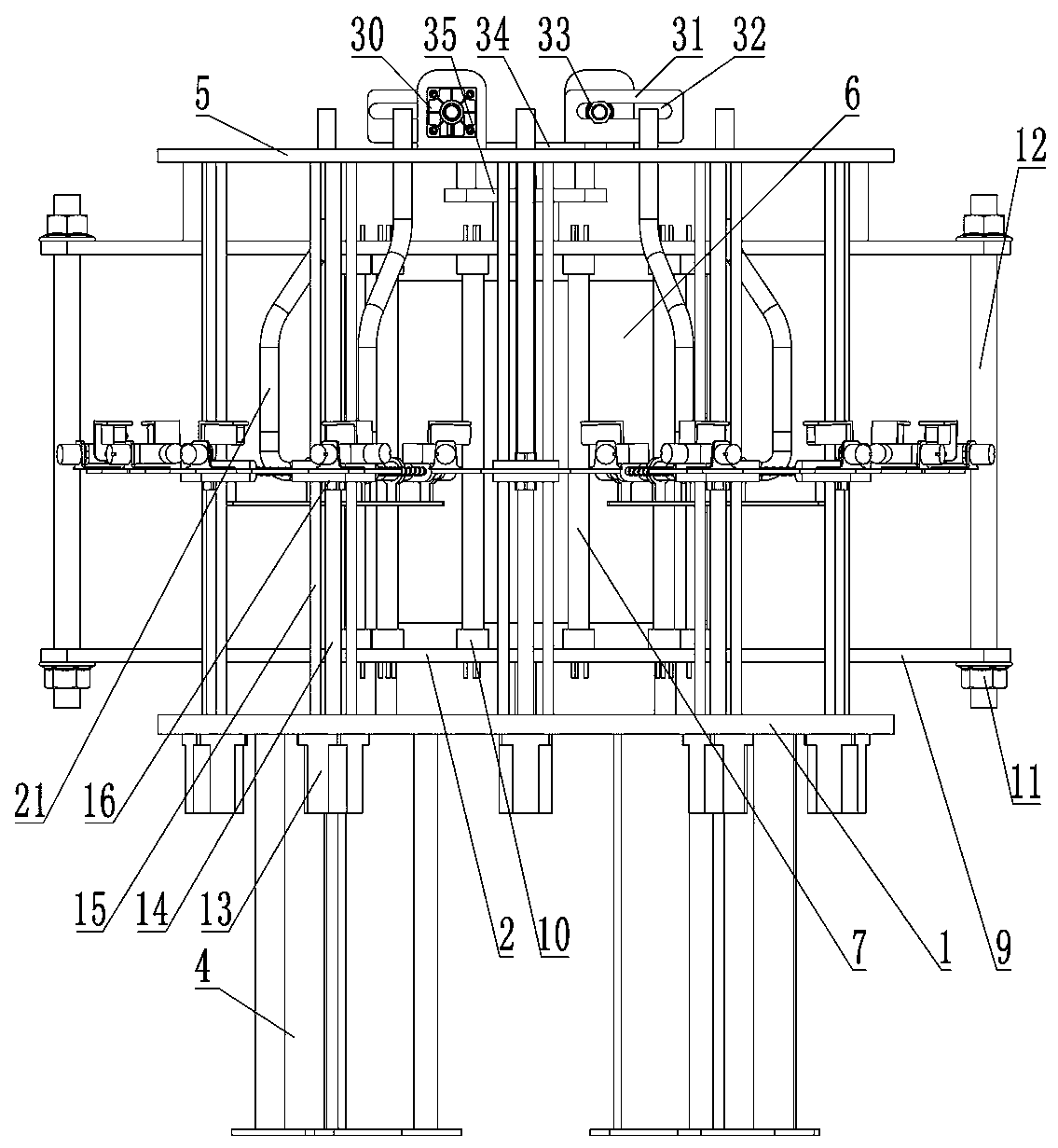

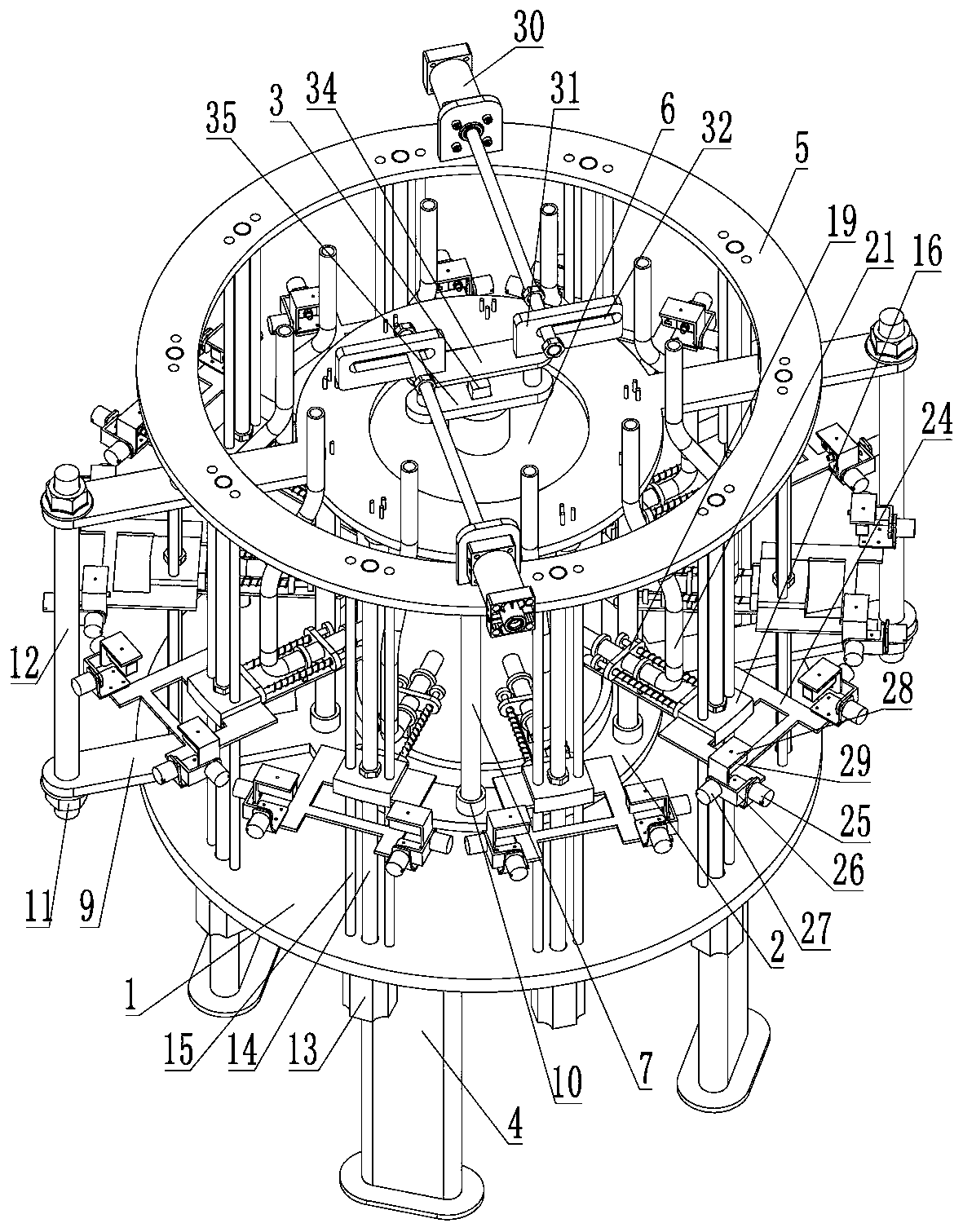

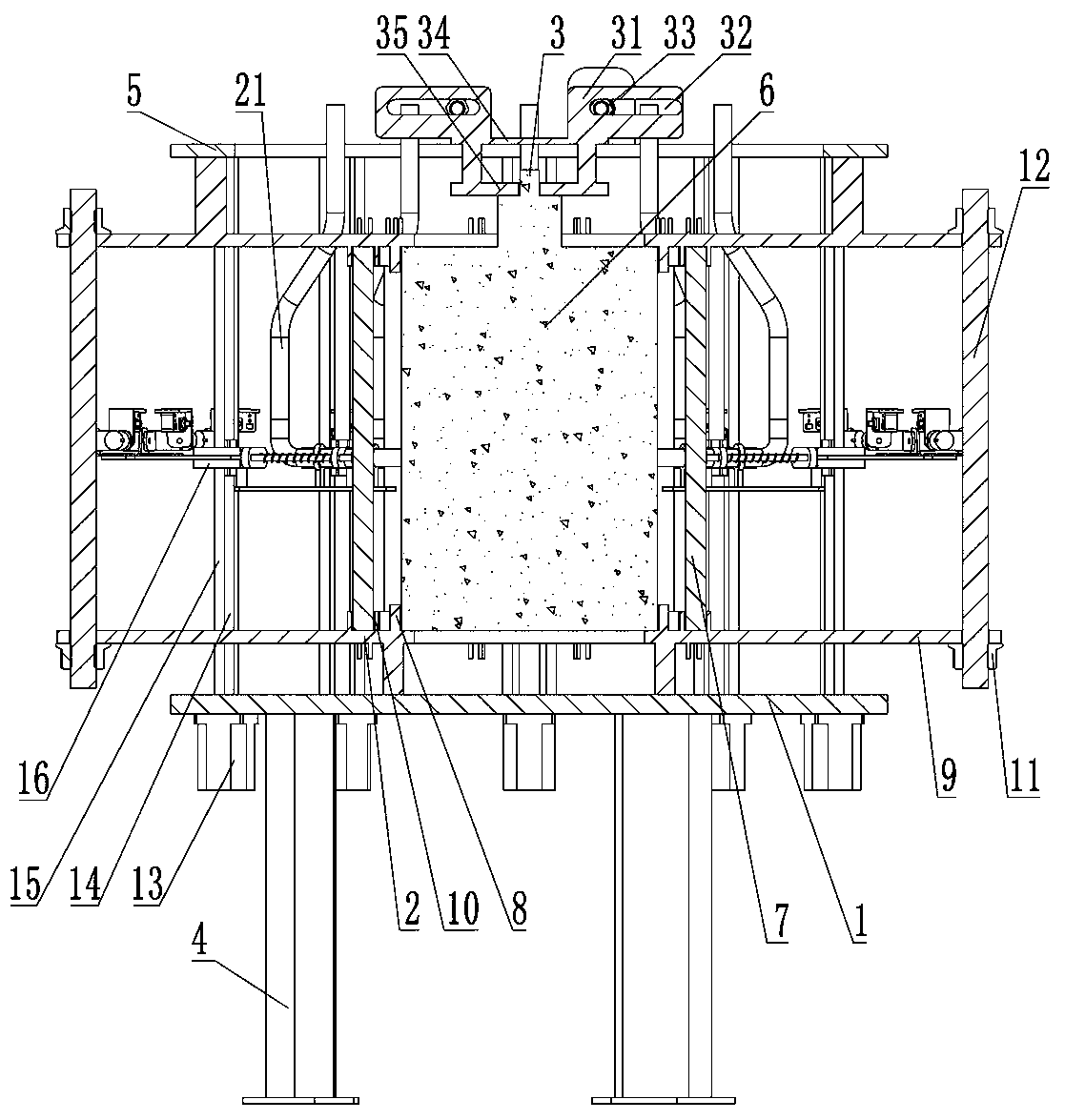

Coal sample crack penetration testing device and testing method thereof

ActiveCN110441214AEffectively explore the law of crack variationExploring the law of crack changePreparing sample for investigationFuel testingHeat resistanceEngineering

The invention discloses a coal sample crack penetration testing device. The coal sample crack penetration testing device comprises a circular fixed plate, a lower positioning mounting assembly and anupper positioning mounting assembly; the lower positioning mounting assembly is fixedly connected with the upper positioning mounting assembly; a coal sample column is arranged between the lower positioning mounting assembly and the upper positioning mounting assembly; the lower positioning mounting assembly is mounted on the upper surface of the circular fixed plate; the upper side of the upper positioning mounting assembly is fixedly provided with a first annular fixed plate; a plurality of lifting assemblies are arranged between the circular fixed plate and the first annular fixed plate ina circular array mode; each lifting assembly is provided with a penetrating mechanism and a crack observation mechanism; a plurality of heating resistance rods are arranged between the lower positioning mounting assembly and the upper positioning mounting assembly in a circular array mode; and a rotary adjusting mechanism is mounted on the first annular fixed plate. The coal sample crack penetration testing device is scientific in design and reasonable in structure, can be used for economically and effectively exploring crack change rules of coal reservoirs of different coal ranks at differenttemperatures, and provides a visual and quantitative research method for coal reservoir reform.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for establishing metallurgical coke pore feature parameter prediction model

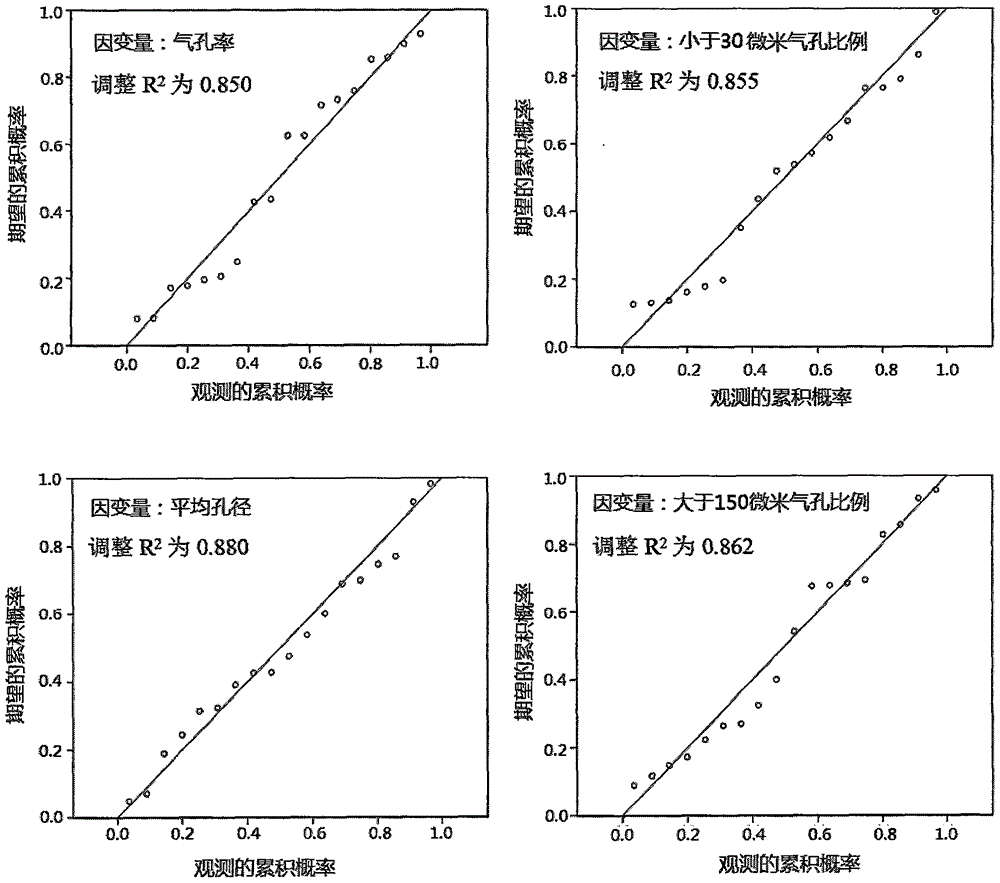

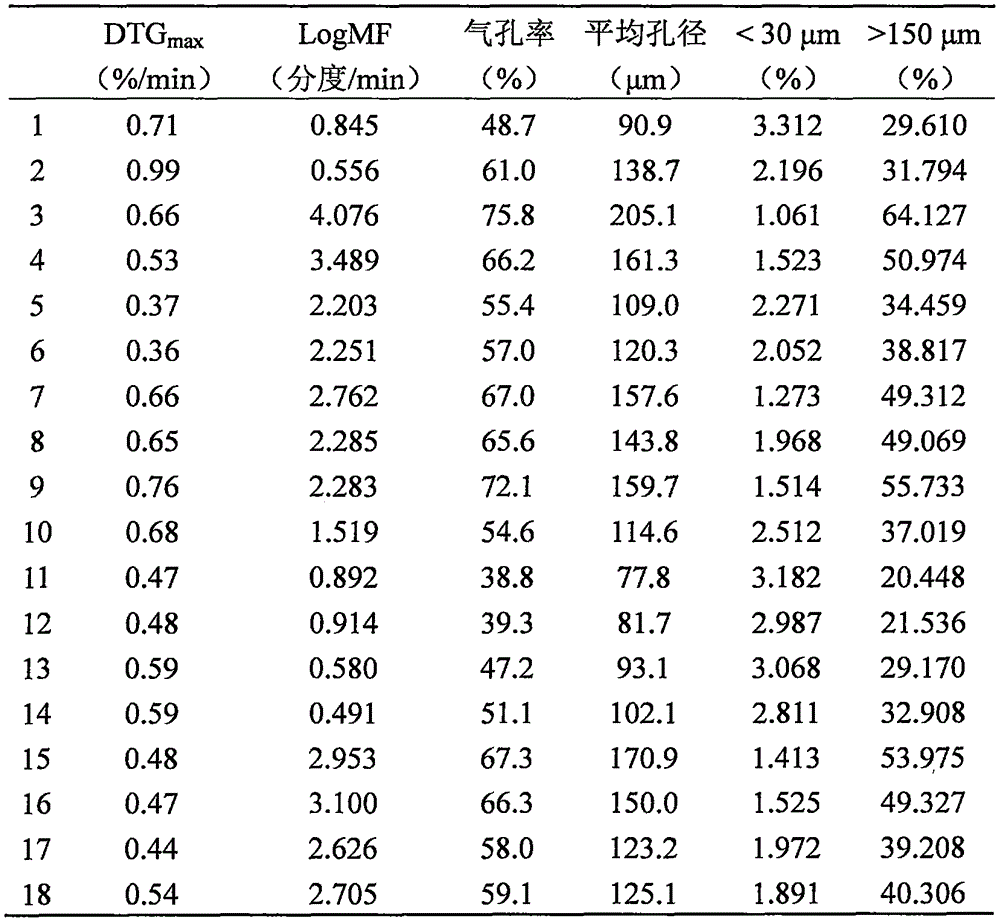

ActiveCN106547935AEasy to testImprove accuracySpecial data processing applicationsImaging analysisPredictive methods

The invention discloses a method for establishing a metallurgical coke pore feature parameter prediction model. The method is characterized by comprising the steps of: 1) performing thermo-gravimetric analysis test on a single coal of more than 15 different coal ranks and a matching coal thereof to obtain a maximum volatile de-volatilization rate DTGmax (% / min) of each sample; 2) performing Gieseler fluidity test on a coking coal to obtain a maximum Gieseler fluidity MF (graduation / min) of each sample; 3) performing coking test on the coking coal samples, and obtaining the average pore size, porosity, proportion of pores smaller than 30 microns and proportion of pores greater than 150 microns of coke via an image analysis method; and 4) performing binary linear regression on the average pore size, porosity, proportion of pores smaller than 30 microns and proportion of pores greater than 150 microns of the coke respectively by using DTGmax and LgMF as independent variables to obtain a relation between the pore structure parameters and the DTGmax and LgMF. The prediction method is simple and convenient in test and high in prediction accuracy.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for underground coal mine dust removal by aqueous alkali

InactiveCN103470296AReduce dust production capacityLower contact angleDust removalFire preventionMental healthCoal dust

The invention relates to a method for underground coal mine dust removal by aqueous alkali. The method sequentially includes the following steps: selecting appropriate alkaline chemicals according to spraying and injection coal seam situations; selecting compounding concentration of corresponding aqueous alkali according to coal rank and laboratory test; selecting low-rank and medium-rank coal, drilling in a coal seam, plugging orifices of drilled holes, preparing the corresponding aqueous alkali, and pumping the prepared aqueous alkali into the drilled holes; soaking for a period of time to enable the coal and the aqueous alkali to be fully reacted, and soaking repeatedly to ensure coal in a drilling control area to be fully reacted with the aqueous alkali; preparing aqueous alkali suitable for spraying, and spraying the aqueous alkali to remove dust during coal mining. Alkali is utilized to react with organic matters in the coal, so that dust production capability of the coal can be lowered greatly; meanwhile, the contact angle of reacted coal dust with water is decreased sharply, an excellent dust removal effect is achieved, physical and mental health of workers is protected, safety in production of coal mines is guaranteed, and the method is high in practicality and has promotion and application values.

Owner:HENAN POLYTECHNIC UNIV

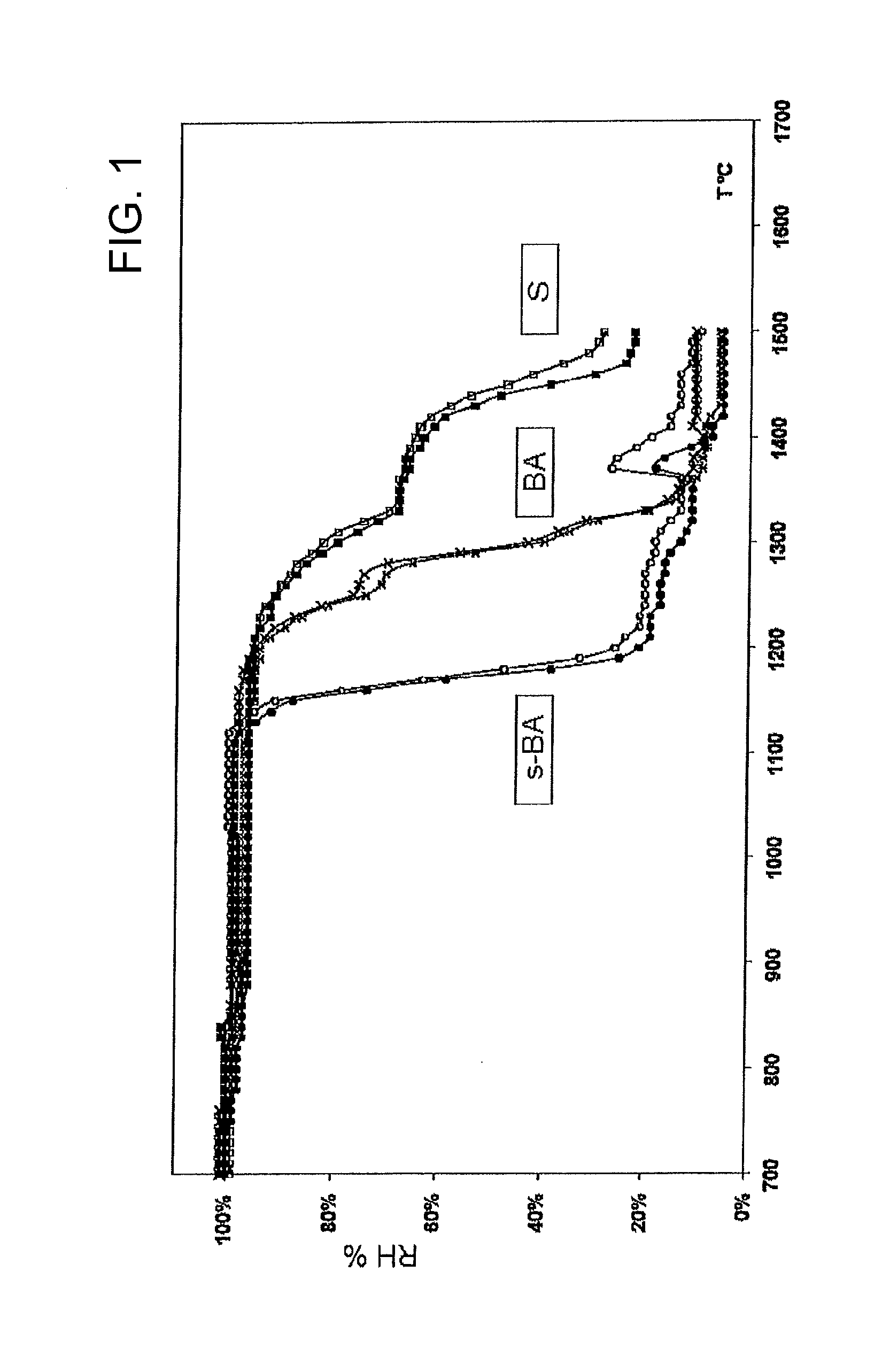

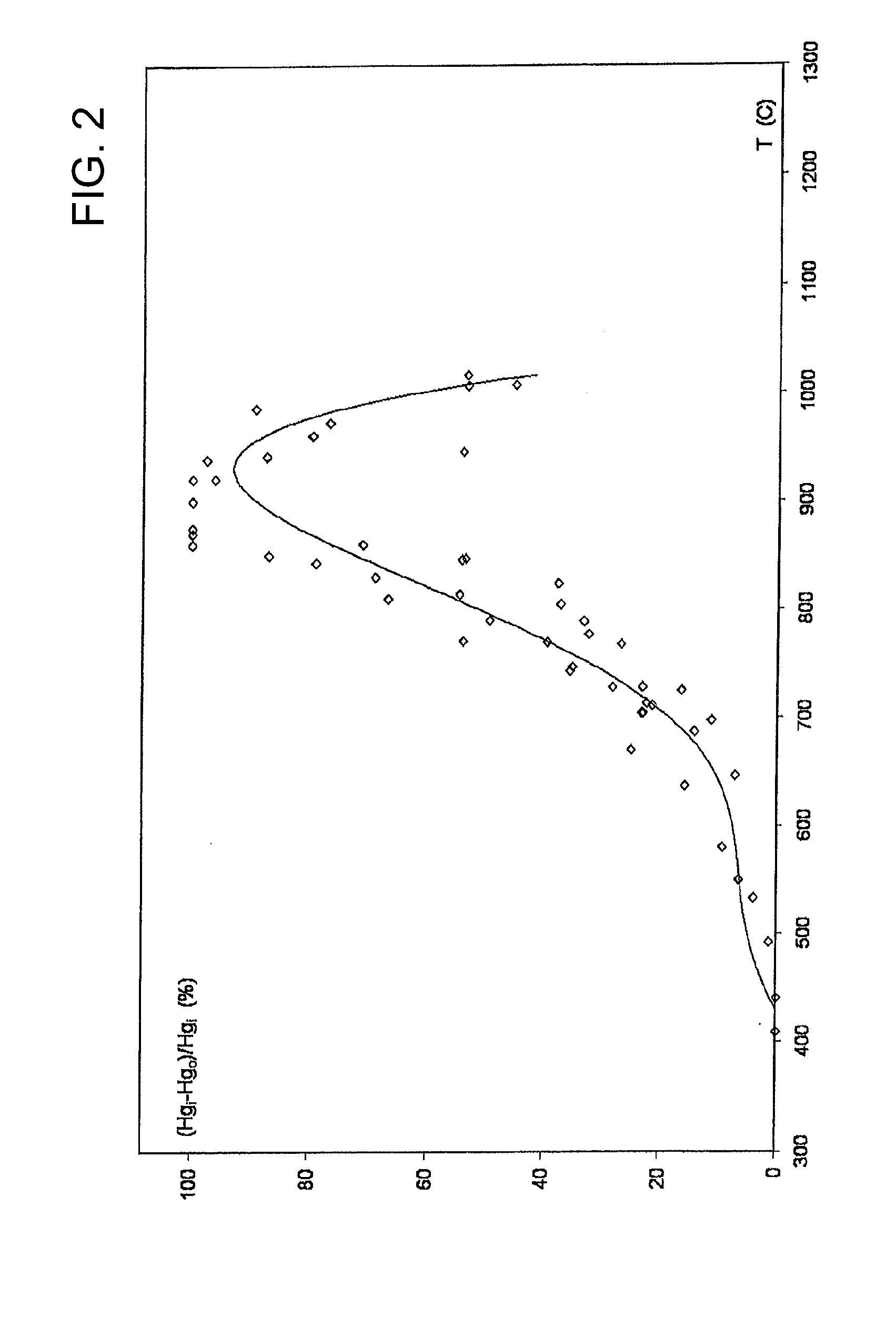

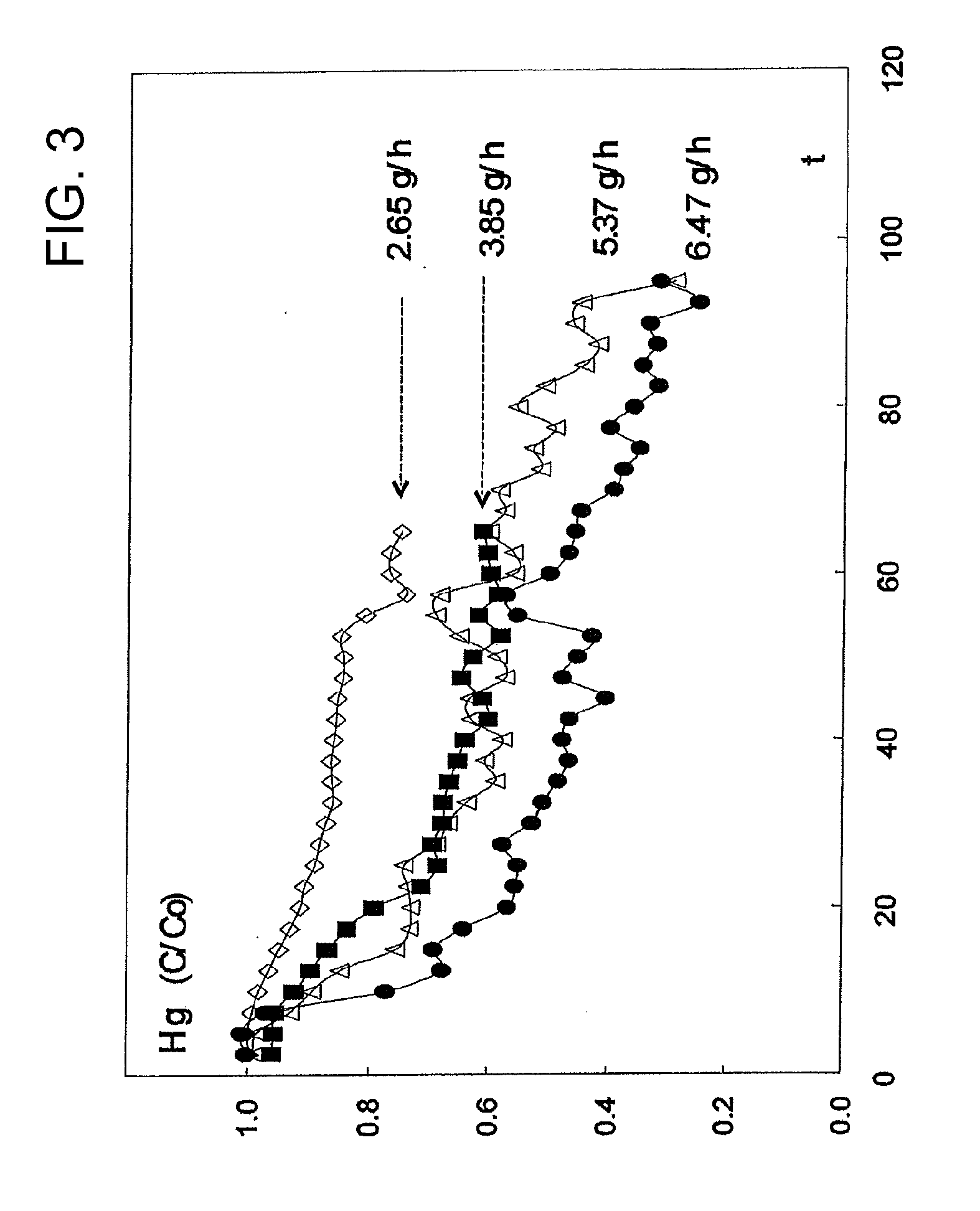

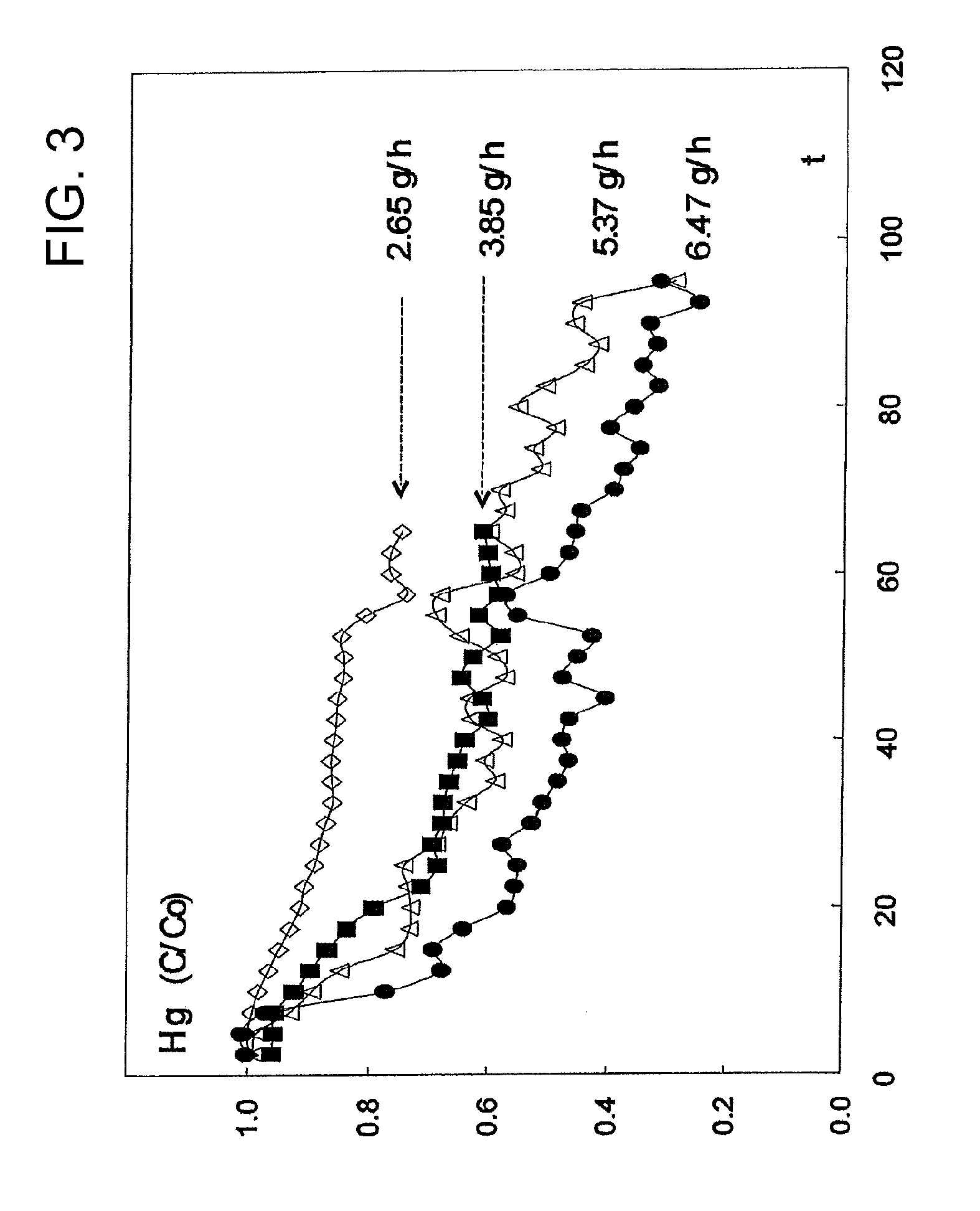

Method for the removal of mercury from a stream of flue gas obtained from the combustion of coal

InactiveUS20120266751A1Improve mercury removalGuaranteed mixGas treatmentUsing liquid separation agentCombustionFlue gas

A method for the removal of mercury from a stream of flue gas obtained from the combustion of at least one coal type having an ASTM D388 coal rank of <3 includes the steps of introducing a kaolin or metakaolin-containing sorbent into the stream of flue gas and contacting the mercury with the kaolin or metakaolin-containing sorbent at a point where both the kaolin or metakaolin-containing sorbent and active free silica are present in the stream. The temperature of the flue gas is at least 900° C. The active free silica content of the flue gas resulting from the combustion of the coal is supplemented by the introduction of added active free silica such that the weight percentage of the total amount of active free silica relative to the weight of kaolin or metakaolin is at least 10%, the weight of any kaolin being expressed as the weight of metakaolin.

Owner:MINPLUS

A method for producing pure steel by one-step direct reduction of coal-to-gas

The invention discloses a method for preparing clean steel by a coal gas direct reduction one-step method. Low-coal-rank coal is pyrolyzed to tar, pyrolyzed coal gas and sponge-shaped fixed carbon at a medium temperature; the sponge-shaped fixed carbon and water vapor are reacted to prepare reducing gas; the reducing gas is introduced in iron pellets or lump ores; iron therein is selectively reduced to obtain pure sponge iron; the pure sponge iron is filled in an electric furnace for smelting to obtain pure liquid-state steel; and meanwhile, the pyrolyzed coal gas is used as heating energy for pyrolysis of the low-coal-rank coal, gasifying reaction of the sponge-shaped fixed carbon and selective gas base direct reduction of the iron pellets or lump ores. The method extracts the tar and the pyrolyzed coal gas in the low-coal-rank coal to a greater extent, and prepares the reducing gas by the sponge-shaped fixed carbon to serve as by-products in the whole process; the energy cost in the whole smelting process is almost zero; and in the selective reducing process, only iron is reduced, and other elements are not reduced, so that the foundation is laid for preparation of clean steel, the oxidation period and the reducing period in the smelting procedure of a traditional electric furnace are synchronously disappeared, and the clean steel is obtained by a simpler flow.

Owner:太原依创瑞诚科技有限公司

A method for in-situ identification and rapid quantification of coal rock microcomponents

Owner:HUAZHONG UNIV OF SCI & TECH

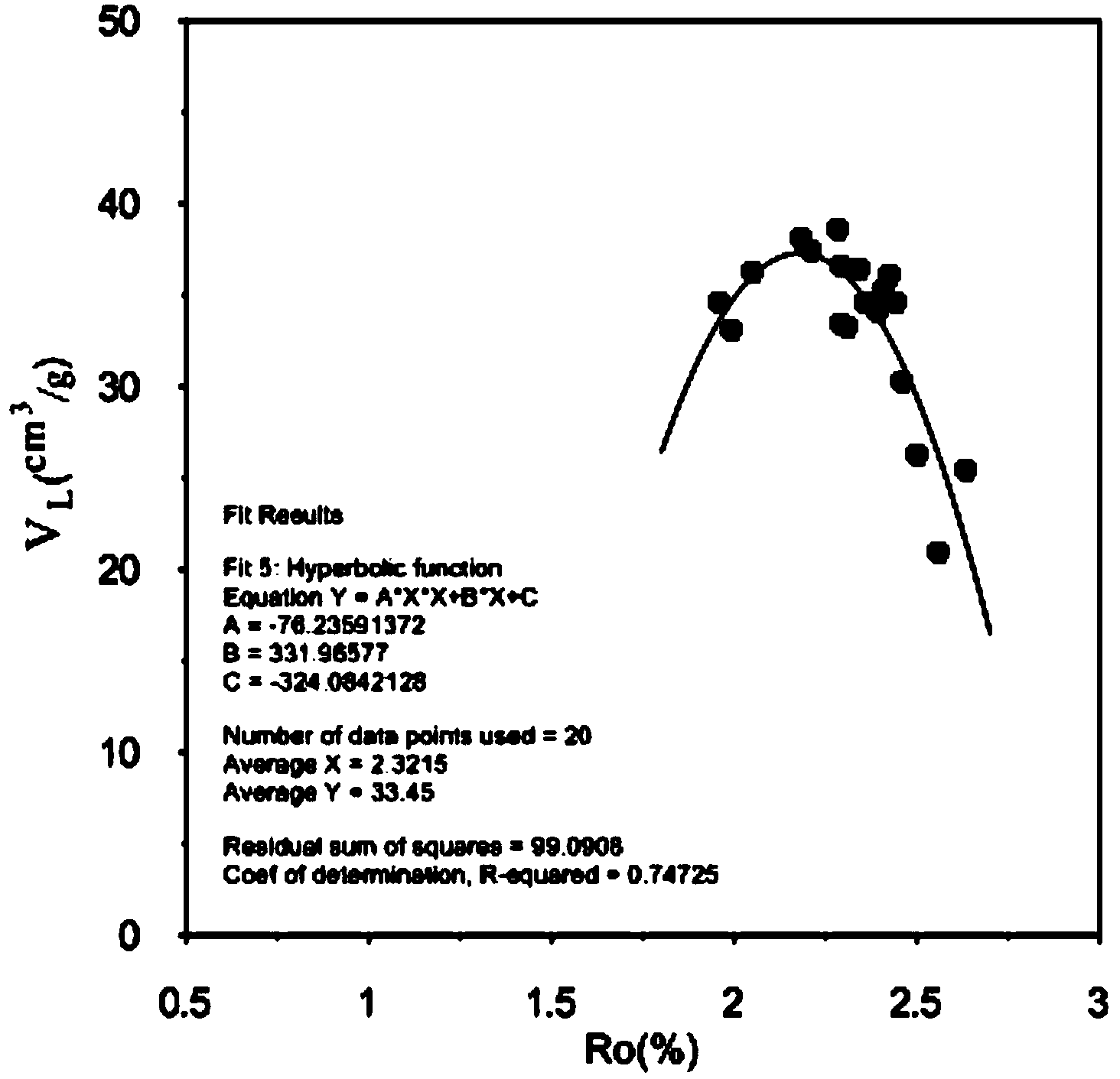

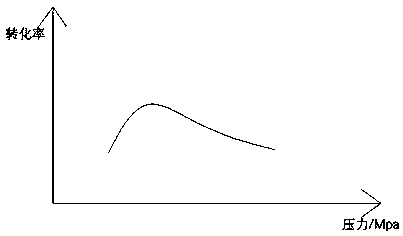

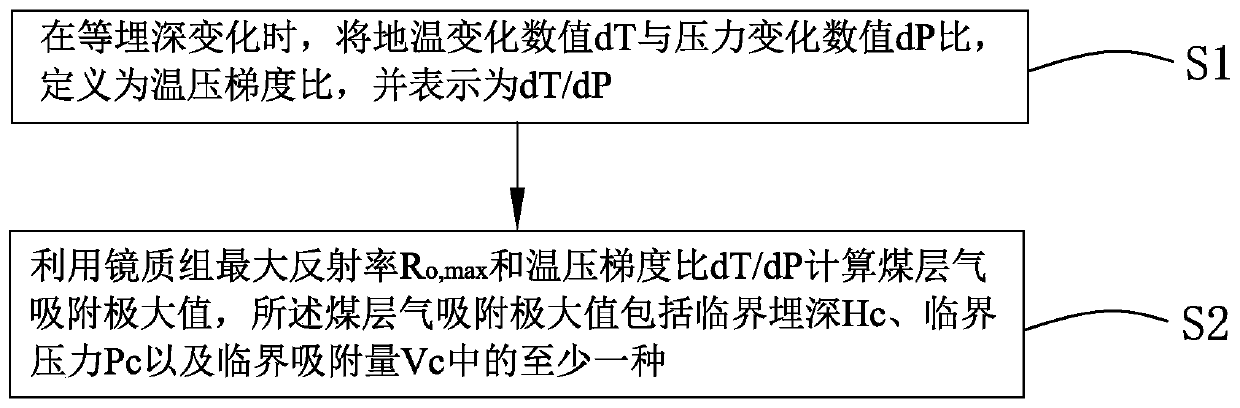

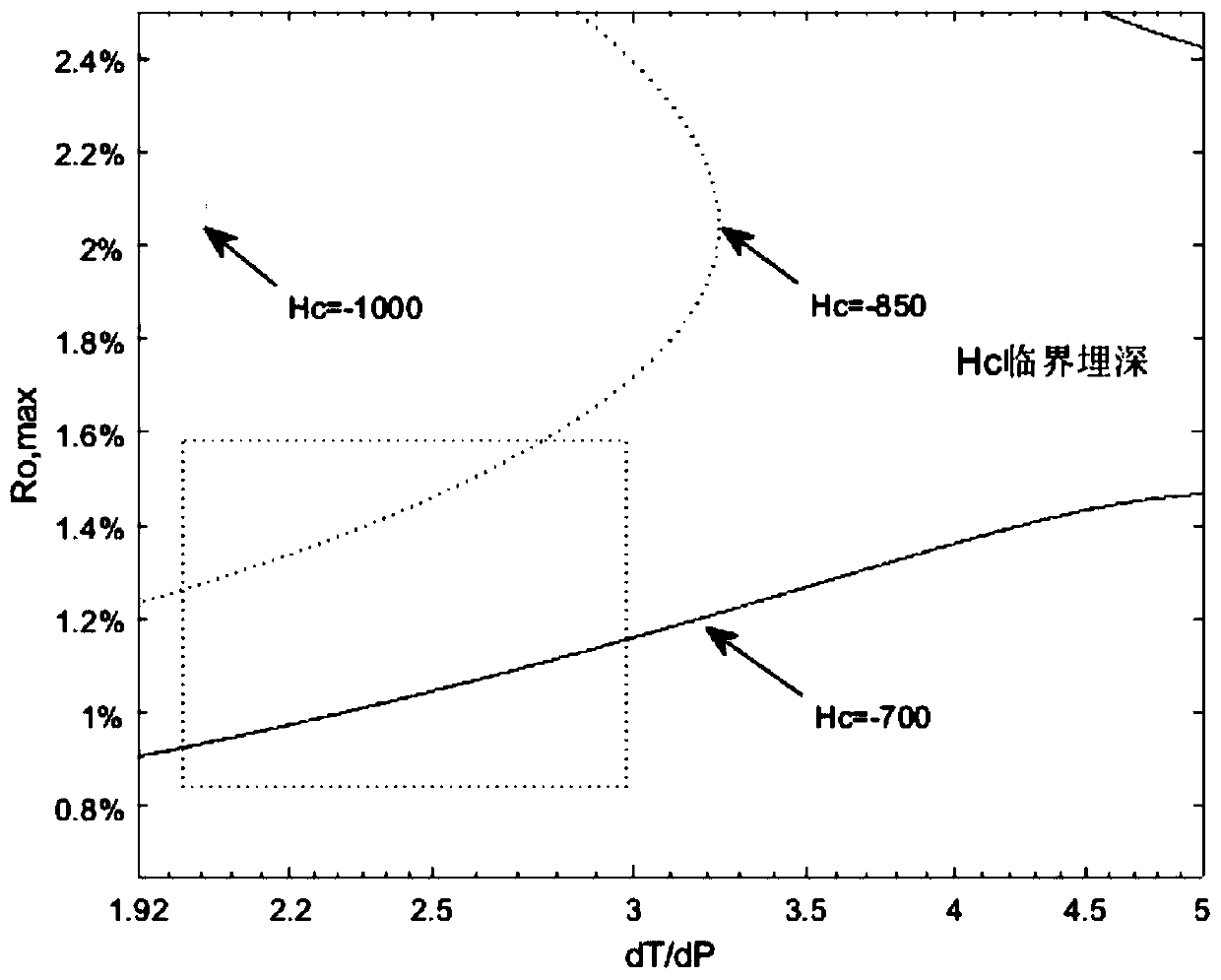

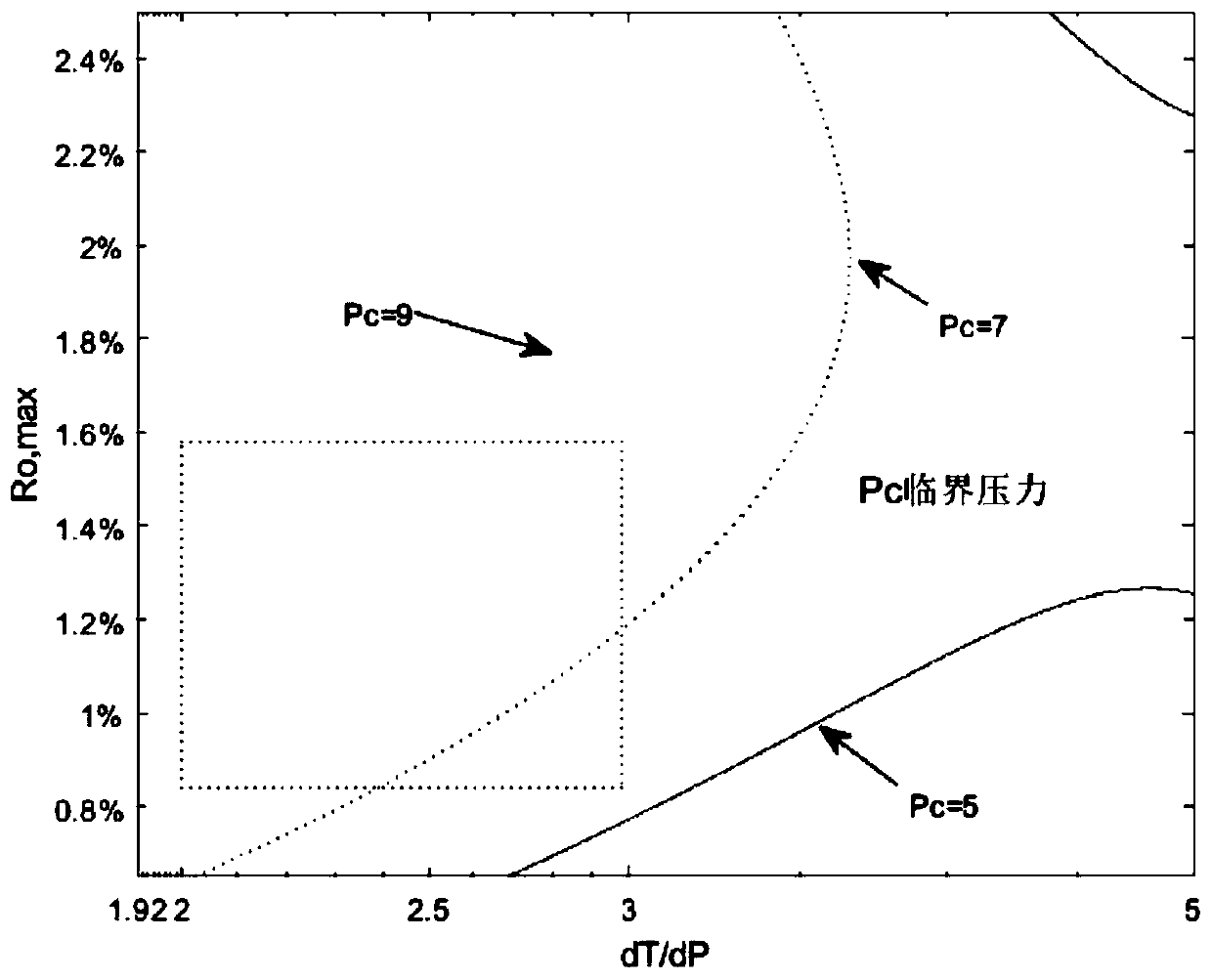

Method for calculating maximum coal-bed gas adsorption value based on coal rank and temperature-pressure gradient ratio

ActiveCN110018245AAccurate prediction of adsorption maximaSimple methodComponent separationGround temperatureCoal rank

The invention provides a method for calculating the maximum coal-bed gas adsorption value based on the coal rank and the temperature-pressure gradient ratio. The method comprises the following steps that when the equal buried depth is changed, the ratio of the ground temperature change numerical value dT to the pressure change numerical value dP is defined as the temperature-pressure gradient ratio, it is represented that the maximum reflectivity R<o, max> of a vitrinite and the temperature-pressure gradient ratio are utilized to calculate the maximum coal-bed gas adsorption value, and the maximum coal-bed gas adsorption value includes at least one of the critical buried depth H<c>, the critical pressure P<c> and the critical adsorption quantity V<c>, wherein the maximum reflectivity R<o,max> of the vitrinite is within the range of 0.65% to 2.50%, the temperature-pressure gradient ratio is within the range of 1.92 to 5.0, the ground temperature change numerical value dT is within therange of 2.5 DEG C / hm to 3.5 DEG C / hm, and the pressure change numerical value dP is within the range of 0.70 MPa / hm to 1.30 MPa / hm. Compared with related technologies, the method for calculating themaximum coal-bed gas adsorption value based on the coal rank and the temperature-pressure gradient ratio is easy and convenient to use and high in precision.

Owner:XIAN SIYUAN UNIV

Method for the removal of mercury from a stream of flue gas obtained from the combustion of coal

InactiveUS8574349B2Good removal effectEfficient removalGas treatmentUsing liquid separation agentCombustionFlue gas

A method for the removal of mercury from a stream of flue gas obtained from the combustion of at least one coal type having an ASTM D388 coal rank of <3 includes the steps of introducing a kaolin or metakaolin-containing sorbent into the stream of flue gas and contacting the mercury with the kaolin or metakaolin-containing sorbent at a point where both the kaolin or metakaolin-containing sorbent and active free silica are present in the stream. The temperature of the flue gas is at least 900° C. The active free silica content of the flue gas resulting from the combustion of the coal is supplemented by the introduction of added active free silica such that the weight percentage of the total amount of active free silica relative to the weight of kaolin or metakaolin is at least 10%, the weight of any kaolin being expressed as the weight of metakaolin.

Owner:MINPLUS

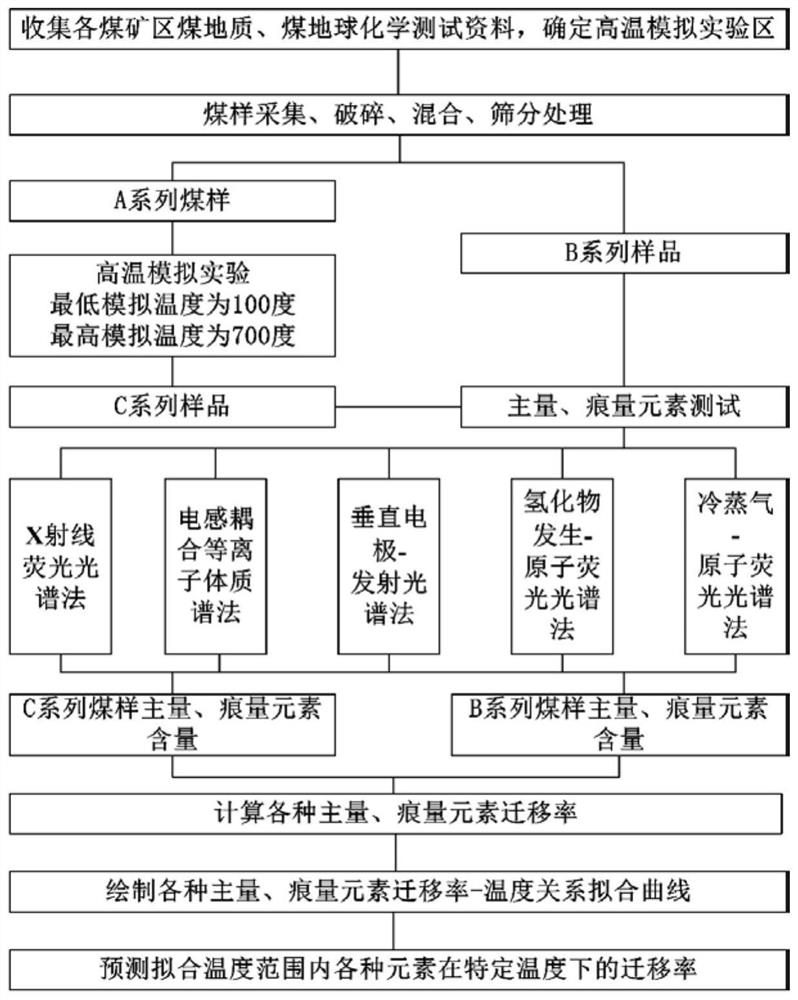

Method for quantitatively evaluating migration rate of elements in coal in high-temperature simulation process

PendingCN114527255AIncrease the scope of applicationWeighing by removing componentPreparing sample for investigationEvaluation resultThermodynamics

Owner:CHINA UNIV OF MINING & TECH

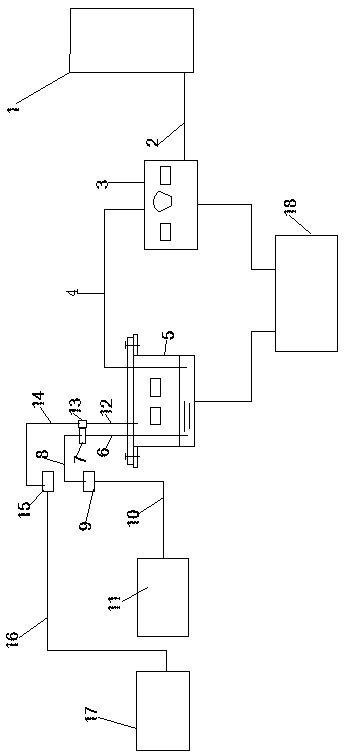

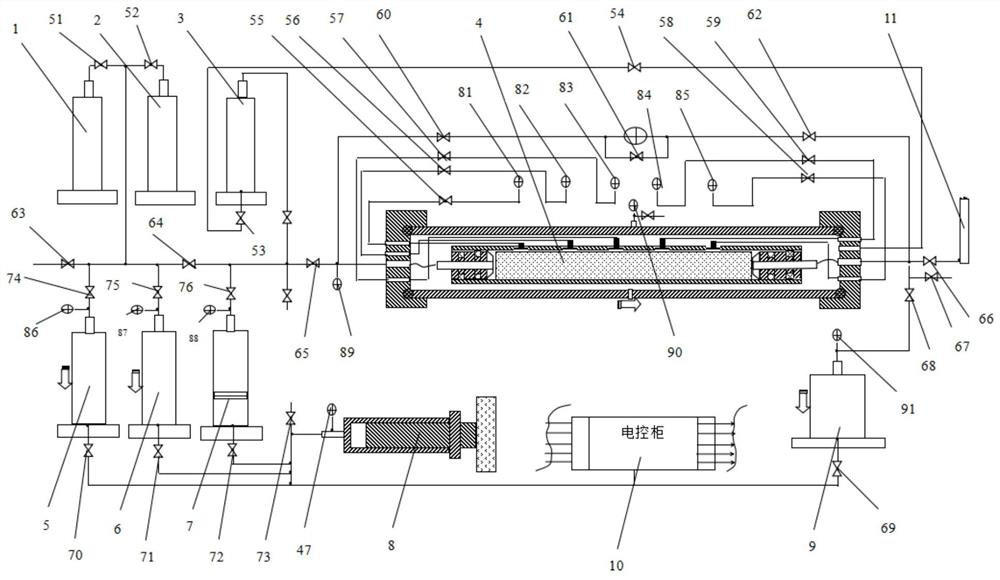

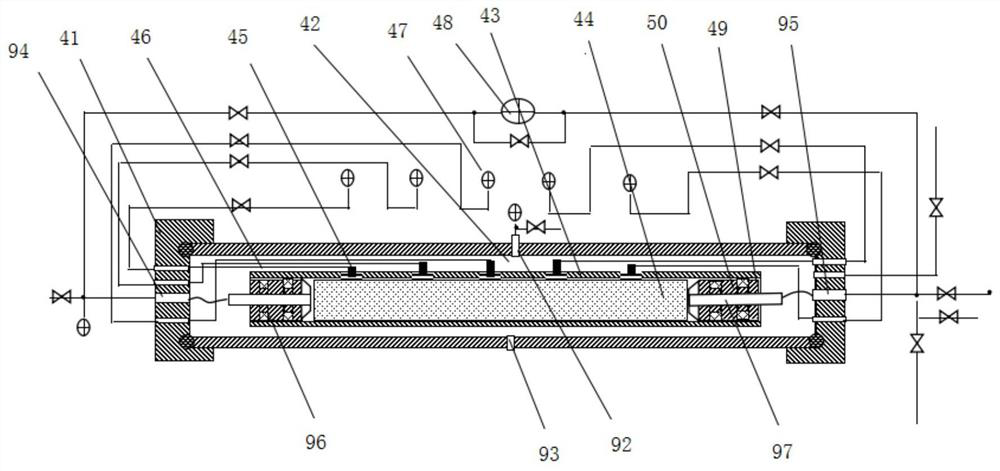

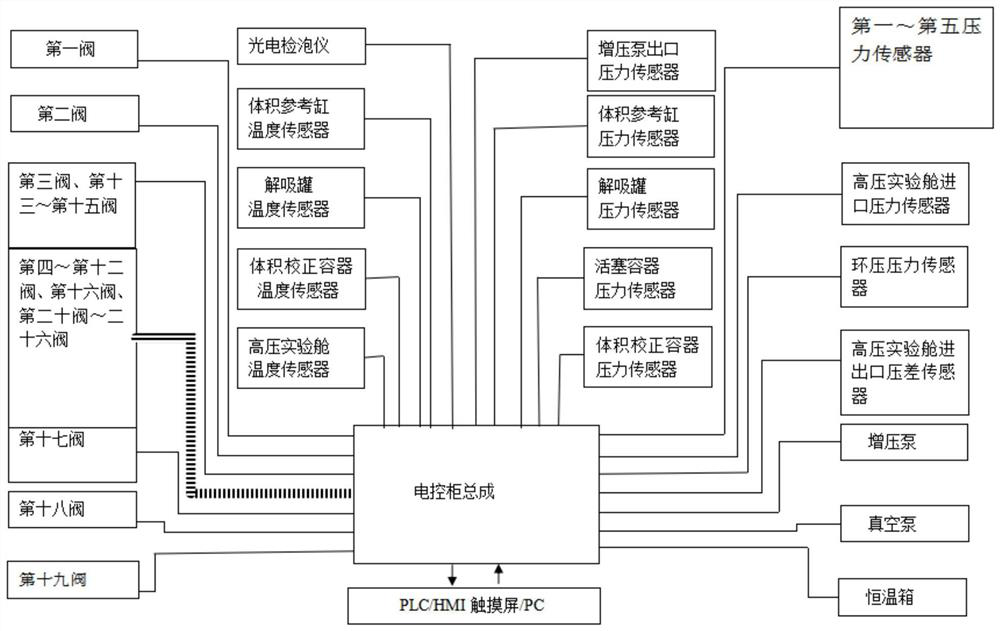

Device for measuring pore pressure conduction rate of medium-high coal rank coal core matrix

The invention provides a device for measuring the pore pressure conduction rate of a medium-high coal rank coal core matrix. The device comprises a helium gas cylinder, a methane gas cylinder, an annular pressure container and a high-pressure experiment bin, the helium gas cylinder and the methane gas cylinder are connected with one end of a volume reference cylinder, an analysis tank or a pistoncontainer, the other ends of the volume reference cylinder, the analysis tank and the piston container are connected with a booster pump, one end of the annular pressure container is connected with the helium cylinder, the methane cylinder and the input end of the high-pressure experiment bin, the other end of the annular pressure container is connected with the output end of the high-pressure experiment bin, the helium cylinder and the methane cylinder are connected with the input port of the high-pressure experiment bin, the output port of the high-pressure experiment bin is connected with the input port of a volume correction container, and the output port of the volume correction container is connected with the volume reference cylinder, the analysis tank and the piston container; andthe high-pressure experiment bin comprises sealing end covers at the two ends and a high-pressure experiment bin chamber arranged between the sealing end covers, a sleeve is arranged in the high-pressure experiment bin chamber, and a rock core is arranged in the sleeve. The conduction rate measuring device provided by the invention provides a theoretical basis for formulating a medium-high coal-rank coal bed gas scheme.

Owner:中洁环淼(江苏)环境科技有限公司

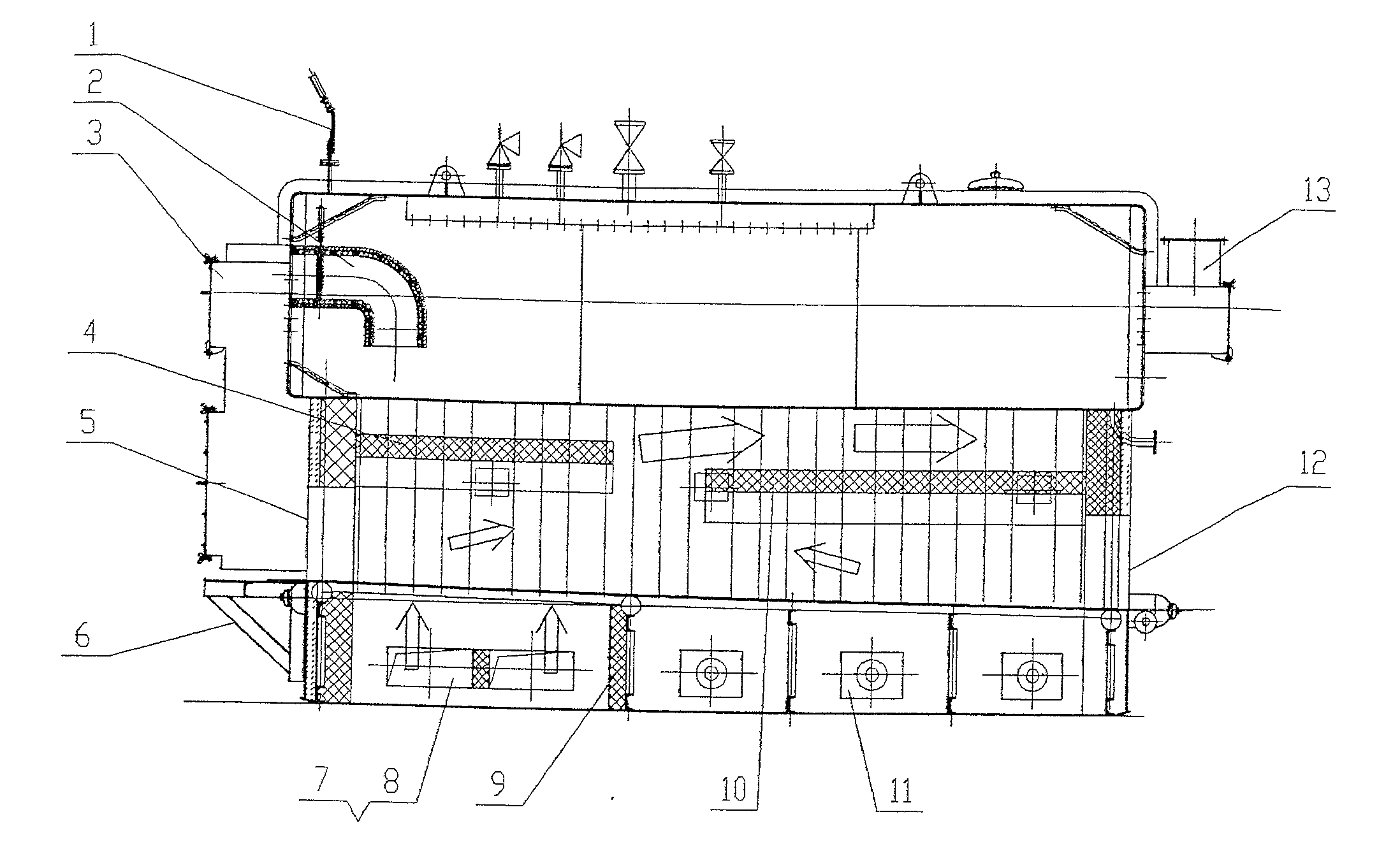

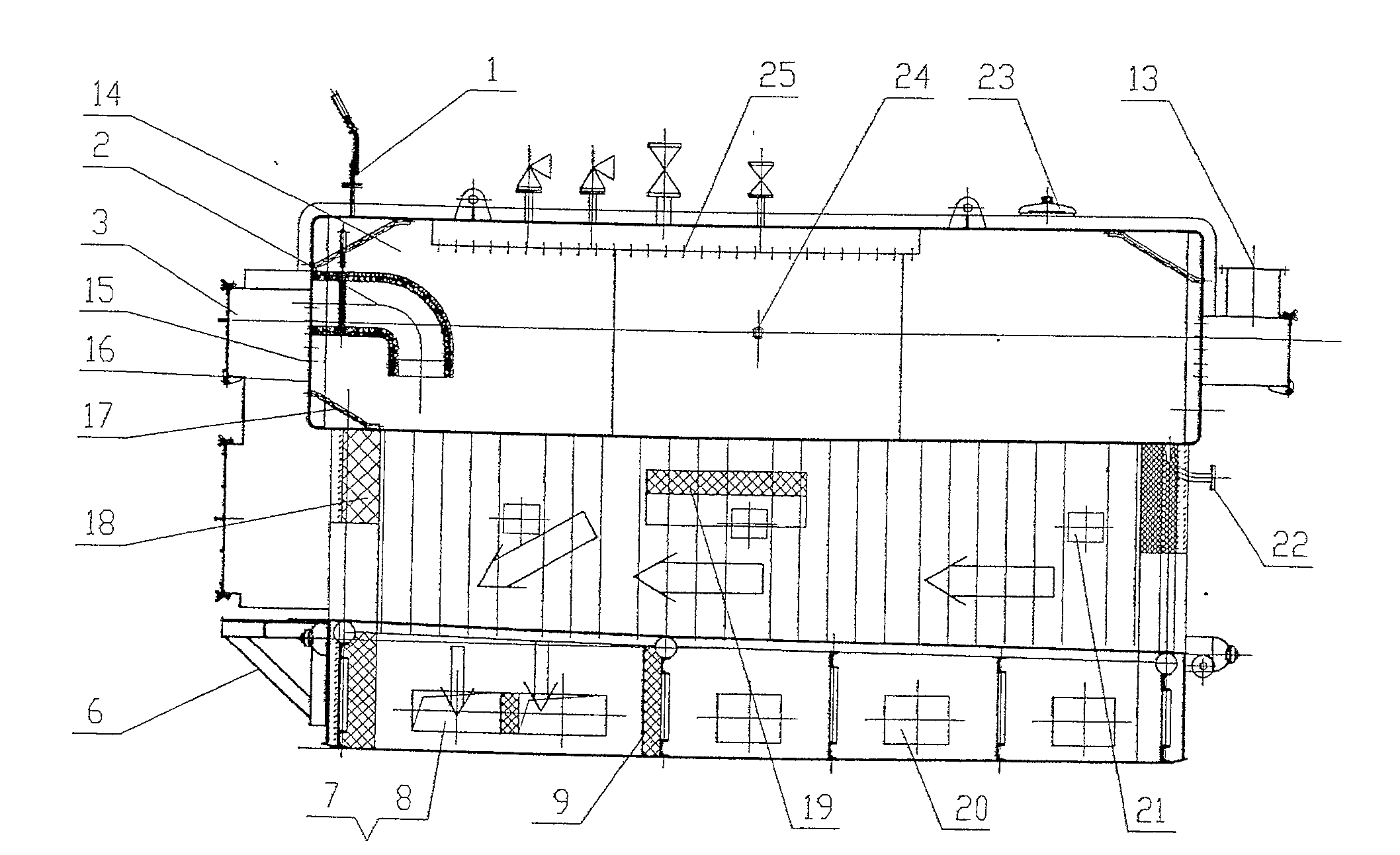

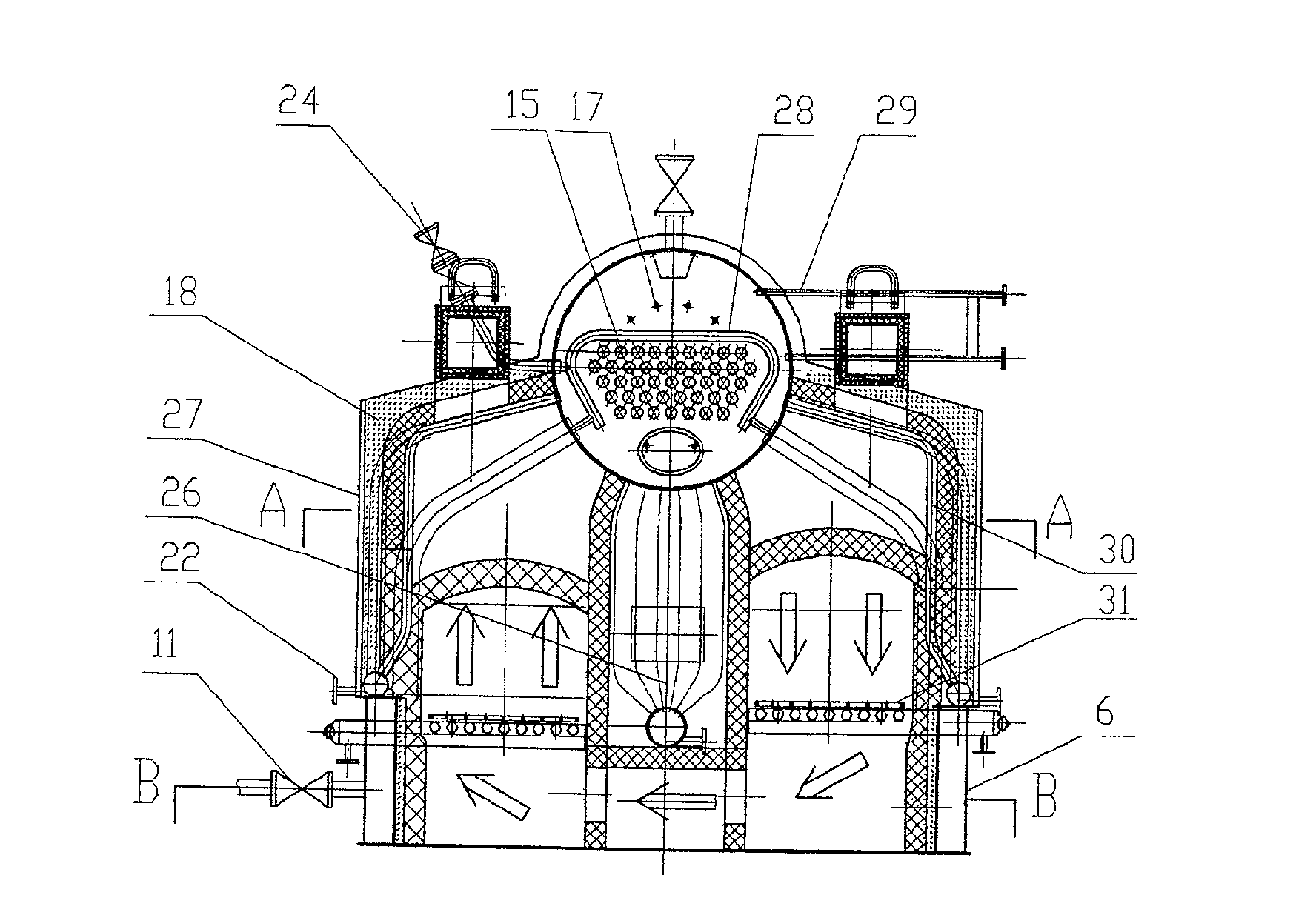

Hot flue gas bidirectional firing, high anthrax adaptability and variable load honeycomb type coal boiler

InactiveCN100565030CCoal tar condensation does not occurImprove environmental performanceWater-tube boilersWater heatersFlue gasHoneycomb

A honeycomb type coal boiler with hot flue gas bidirectional ignition, high-rank coal adaptability and variable load belongs to the boiler technical field, in particular relates to stream for burning honeycomb type coal and a hot-water boiler. A right hearth of the invention is provided with a right side hearth hogging; the left hearth is provided with a left side hearth face arch and a left side hearth rear arch; the structures of the left hearth and the right hearth are asymmetrical; the flue gas channels of the left hearth and the right hearth are also asymmetrical; the invention adopts the mode that the hot flue gas downwards the right hearth and upwards the left hearth ignites bituminous coal in the boiler; the invention solves the following problems that: 1. After the whole hot flue gas is downward to ignite the bituminous coal in the boiler, the flue gas directly enters to the subordinate heating surface for cooling and causes the problems that black smoke is emitted from the boiler, coal tar is condensed from the tube wall of the tail heating surface condenses and causes the block, the shut down of the boiler and the decrease of the thermal efficiency; 2. The desulphurization degree in the coal boiler is low; 3. The coal boiler has poor load adjusting performance; 4. The coal has slow burning speed, high manufacturing cost and large occupied area; 5. The coal boiler is uneasy to be large-sized. The invention has the advantages of higher burning efficiency, stronger coal-rank adaptability, better environmental protection and more reliable operation.

Owner:袁福林

A device and method for fluidized mining of coal slime water gas-liquid in old empty area

The invention discloses a device and method for coal slime water-gas-liquid fluidized mining in an old empty area. The device includes a superheated steam device, a coal slime water gas liquefaction conversion device, a gas liquefaction product collection device, and a control device. The control device includes a temperature control device, a pressure control device, a pressure and temperature coordination device and a computer; , water supply pipeline, heater and steam pipeline; the coal slime water gas-liquid conversion device includes a coal slime water gas liquefaction conversion box, the gas liquefaction product collection device includes an oil collection device and a mixed gas collection device, the temperature control device is located inside the heater, and the pressure control The device is located in the coal slime water-gas liquefaction conversion box, the temperature and pressure coordination device includes an air pump; the computer is connected with the coal slime water-gas liquefaction conversion box and a heater. The invention takes the coal slime water in the old empty area as the research object, and realizes the coal slime water gas-liquid fluidized mining test under the conditions of given temperature, given pressure, and given coal rank.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com