Device for measuring pore pressure conduction rate of medium-high coal rank coal core matrix

A technology of pore pressure and conduction rate, applied in the direction of analyzing materials and instruments, which can solve the problems of substandard output, investment in water, and no gas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

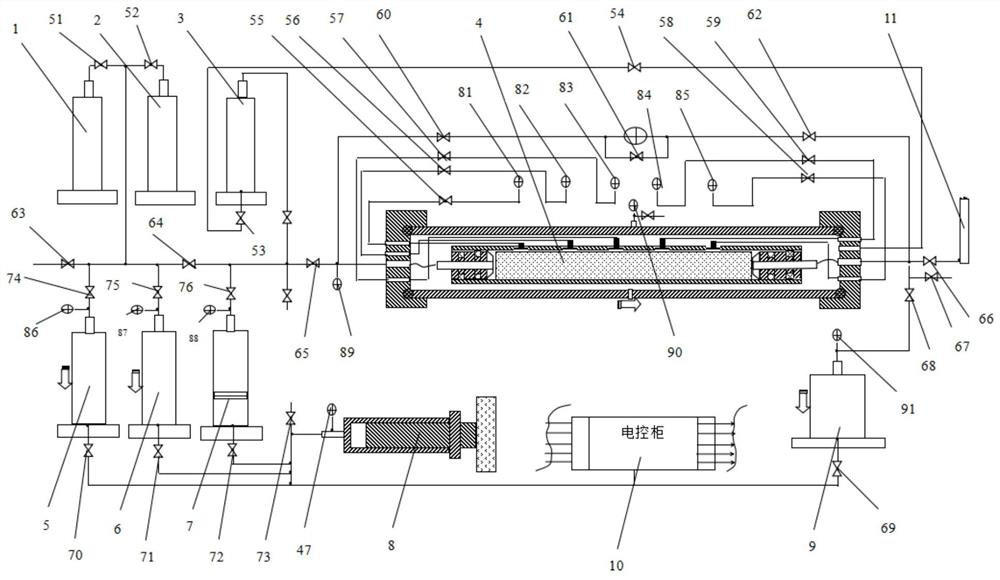

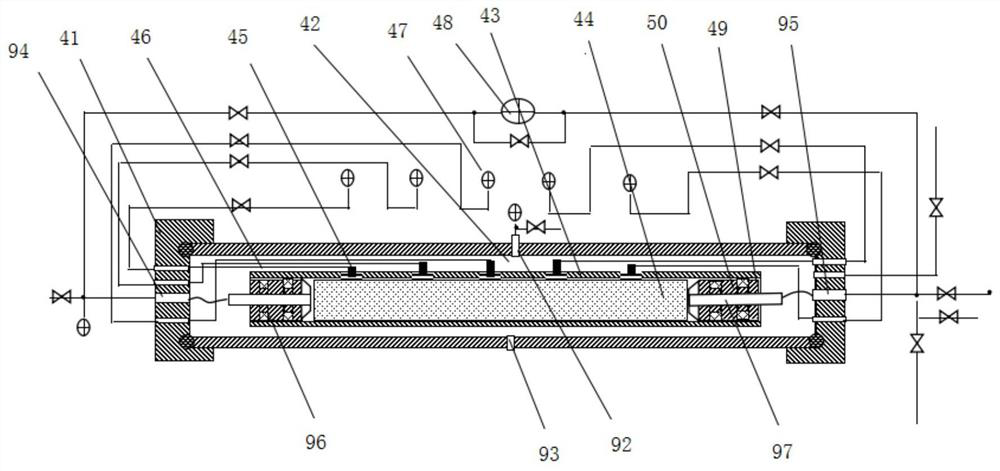

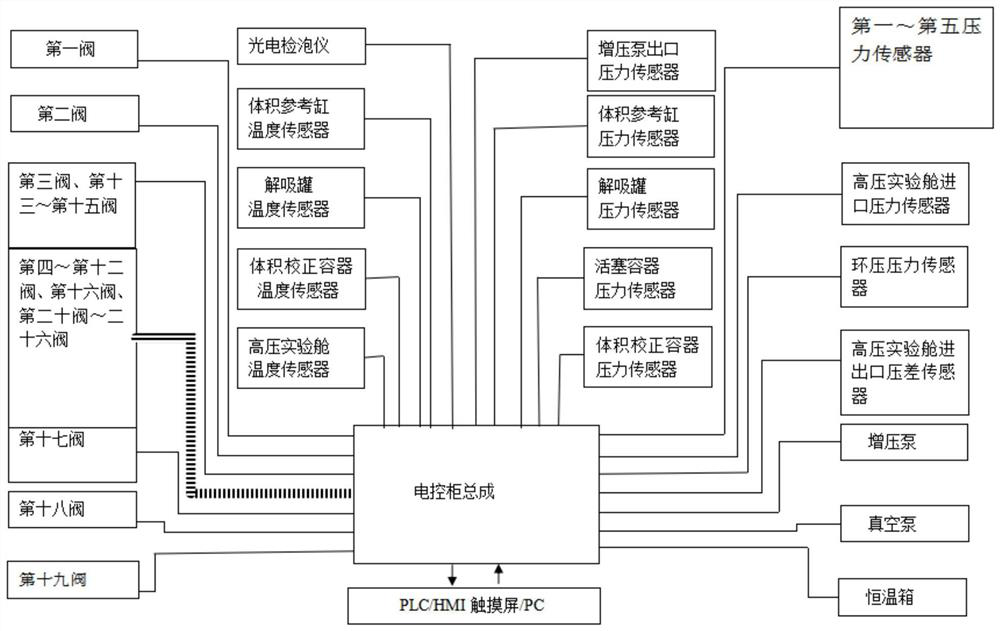

[0023] Such as Figure 1~2 As shown: the present invention provides a medium-high rank coal core matrix pore pressure conduction rate measuring device, which is characterized in that it includes a helium cylinder 1, a methane cylinder 2, an annular pressure vessel 3 and a high-pressure experimental chamber 4, the helium Bottle 1 and methane gas cylinder 2 are all connected to one end of volume reference cylinder 5, analysis tank 6 or piston container 7, and the other ends of the volume reference cylinder 5, analysis tank 6 and piston container 7 are all connected to booster pump 8, and the ring pressure One end of the container 3 is respectively connected to the input end of the helium gas cylinder 1, the methane gas cylinder 2 and the high-pressure experimental chamber 4, and the other end of the ring pressure container 3 is connected to the output end of the high-pressure experimental chamber 4, and the helium gas cylinder 1 and the methane gas cylinder 2 are both Connect th...

Embodiment 2

[0093] Example 2: Helium pressure conductivity test

[0094] In the device process of the present invention, the static pressure triaxial segmental precision pressure measurement sample experiment high pressure experimental chamber, the triaxial stress environment segmental pressure collection fluorine rubber sleeve, the experimental device outlet volume measurement and the bubble photoelectric detection unit are composed of a process The main unit, and other auxiliary units include helium cylinders, coalbed methane (CH 4 ) container, pressure transmission container, piston pressurized pump, constant temperature box, vacuum pump, microcomputer, etc. constitute a complete experimental system to carry out related physical simulation tests such as the pressure transmission rate of medium and high coal rank coalbed methane. Experiments have determined that it is generally 8 MPa, the closing pressure of cleat fractures in coal rocks, at this time only the matrix pores are used as g...

Embodiment 3

[0098] Embodiment 3: Methane pressure conductivity test

[0099] Methane gas equilibrium conduction rate experiment: close the first valve of helium and the third valve of the annular pressure container pipeline → close the fifteenth valve at the inlet of the core → open the reference cylinder to vent, and evacuate to -0.1MPa, close the sample in the high-pressure experimental chamber Intake the fifteenth valve of the internal pressure in the experiment, open the outlet and evacuate the seventeenth valve, and start to evacuate the core and volume correction container in the end cover of the core sleeve of the high-pressure experimental cabin for 24 hours, and close the eighteenth valve and the seventeenth valve after the evacuation is completed. Valve; open the twenty-fourth valve between the methane gas and the volume reference cylinder to fill the volume reference cylinder with methane gas, open the booster pump connected to the reference cylinder to maintain a pressure of 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com