Rotational flow coal powder combustor having multiple coal rank adaptability

A pulverized coal burner, an adaptable technology, applied in burners, burners, burners burning powder fuel, etc., can solve the problems of reduced thermal efficiency, slagging in the furnace, long time consumption, etc., to promote ignition and burnout , The effect of enhancing heat and mass exchange and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

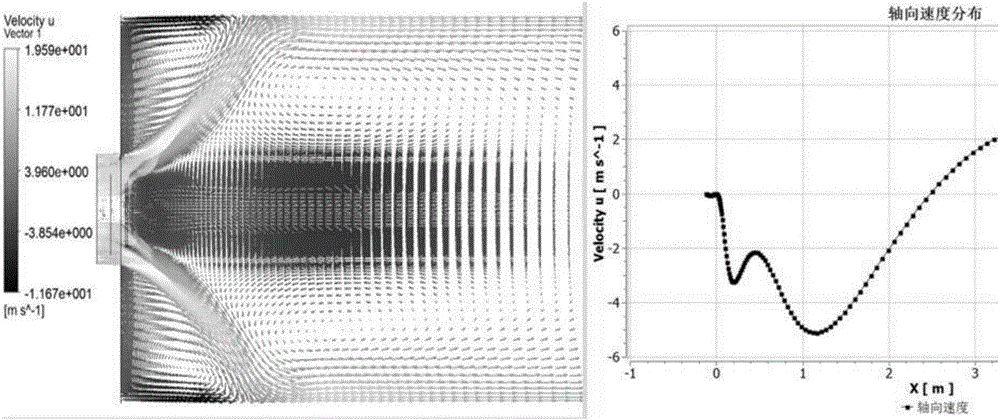

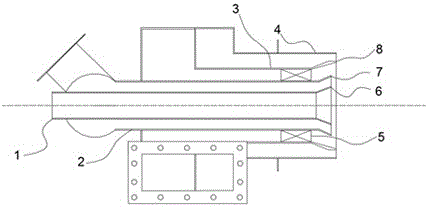

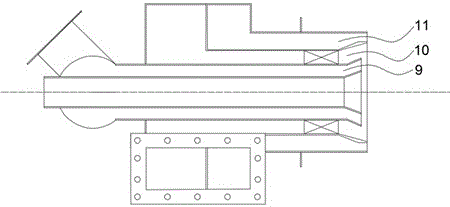

[0034] Embodiment: a kind of multi-coal adaptive swirl pulverized coal burner, such as figure 1 with figure 2 As shown, it includes central air duct 1, primary air duct 2, secondary air duct 3, tertiary air duct 4, secondary air swirl blade 5, central air duct flare 6, primary air duct flare 7 and secondary air Tube flaring 8. The primary air duct 2 is set outside the central air duct 1, the secondary air duct 3 is set outside the primary air duct 2, the tertiary air duct 4 is set outside the secondary air duct 3, and the swirl vanes 5 are set between the primary air duct 2 and the secondary air duct 2. Between the secondary air pipes 3, it is located at the outlet of the secondary air passage 10. The central air duct flaring 6 is installed at the exit of the central air duct 1, the primary air duct flaring 7 is installed at the primary air duct 2 exit, and the secondary air duct flaring 8 is installed at the secondary air duct 3 exit. Between the central air duct 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com