Dry-wet comprehensive flame arrester for hydrogen-oxygen mixed gas

A technology of mixed gas and flame arrester, applied in fire rescue and other directions, can solve the problems of reducing flame temperature, unable to prevent hydrogen-oxygen mixed gas tempering and flashing, etc., and achieve the effect of reducing flame temperature, safe and reliable use, and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

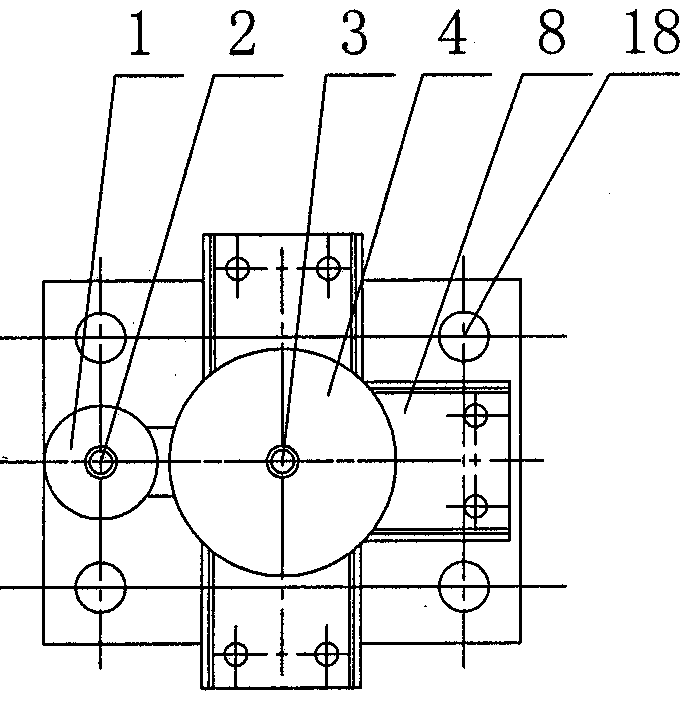

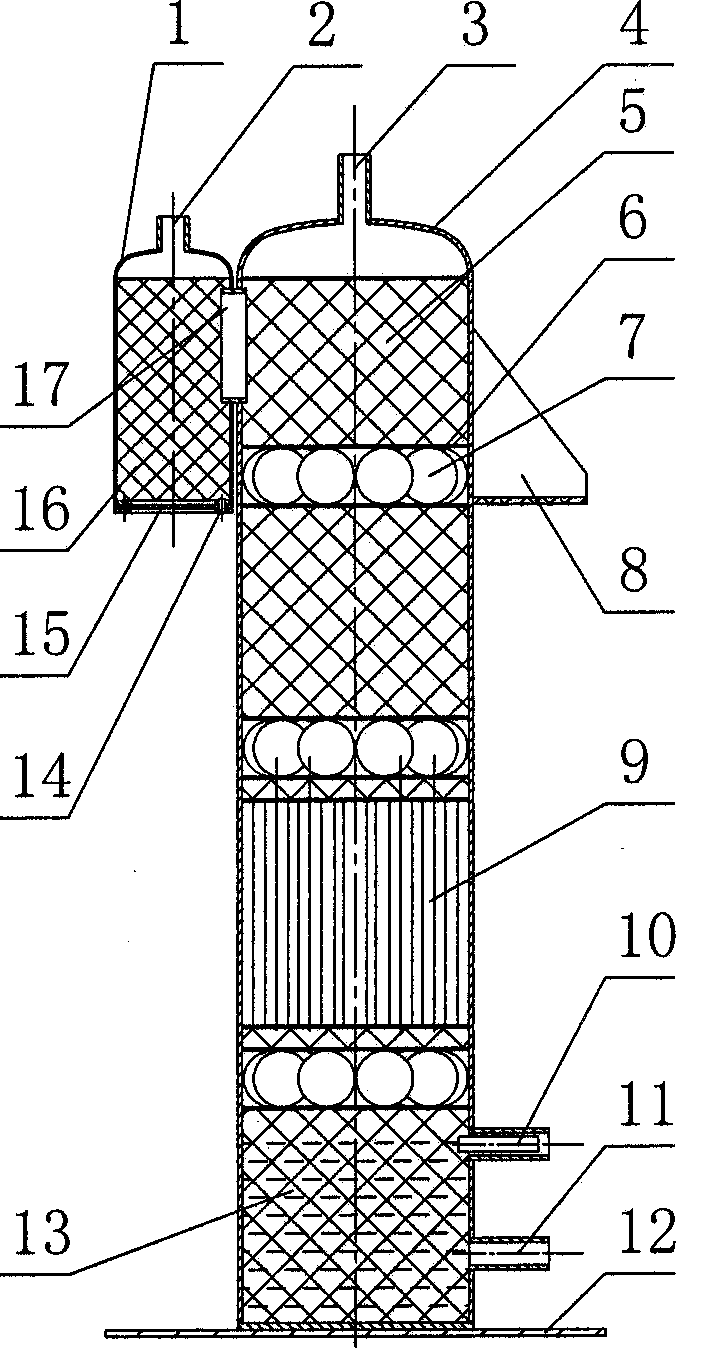

[0016] according to Figure 1~2 The specific structure of the present invention will be described in detail. The hydrogen-oxygen mixed gas dry-wet comprehensive flame arrester includes the sub-flame arrester shell 1 and the mother fire arrester shell 4 connected to each other by the connecting pipe 17, the fire arrester packing arranged in each shell, and the control circuit and other components. Utilize the fixing holes 18 on the bracket 8 and the base 12 to fix the sub-flame arrester housing 1 and the female flame arrester housing 4 to prevent tilting and falling sideways during use.

[0017] In this embodiment, asbestos and foam fire-retardant filler layer 16 are filled in the sub-fire-arresting tank shell 1, the hydrogen-oxygen mixture gas outlet pipe 2 is arranged on the top of the sub-fire-arresting tank shell 1, and the explosion-proof membrane 15 is arranged at the bottom of the sub-fire-arresting tank shell 1 And the pressure sensor (using a pressure of 0.2MPa) 14 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com