Hydrogen-oxygen mixed gas dry and wet integrated flame arrester

A technology of mixed gas and flame arrester, which is applied in fire rescue and other fields, can solve the problems of unable to prevent the hydrogen-oxygen mixed gas from flashing back and reducing the flame temperature, and achieve the effects of safe and reliable use, lower flame temperature, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

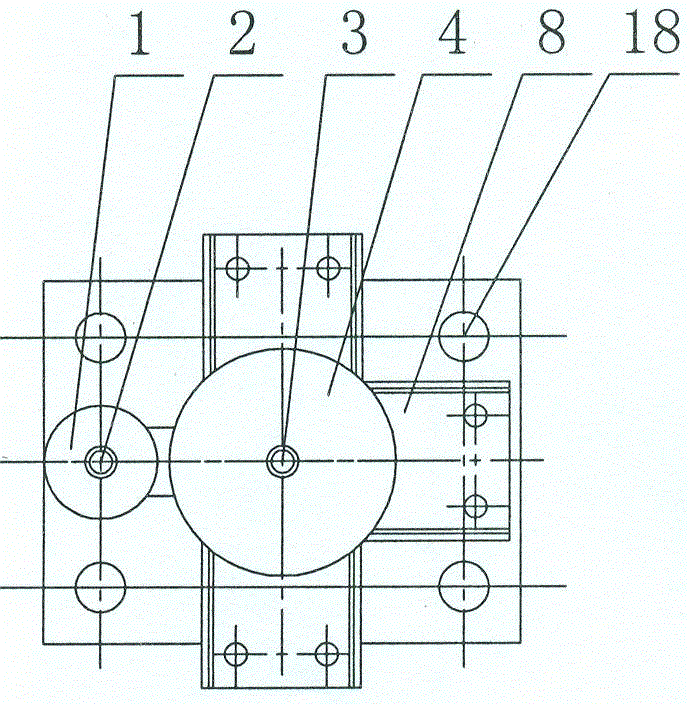

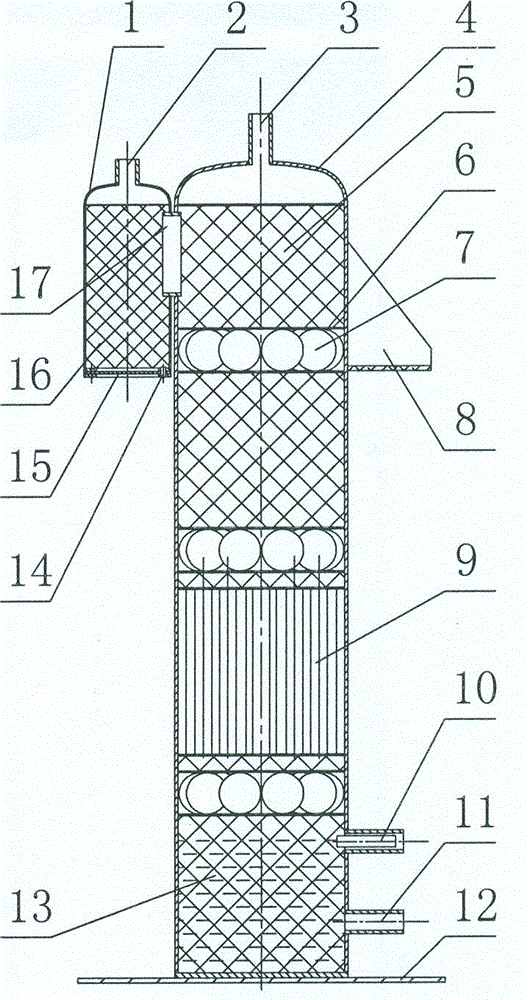

[0016] according to Figure 1~2 The specific structure of the present invention will be described in detail. The hydrogen-oxygen mixed gas dry-wet integrated flame arrestor includes a sub-fire arrestor shell 1, a mother flame arrestor shell 4 connected to each other by a communicating pipe 17, a fire-resisting filler arranged in each shell, and a control circuit and other components. The bracket 8 and the fixing holes 18 on the base 12 are used to fix the child flame arrestor shell 1 and the female flame arrestor shell 4 to prevent tilting and falling sideways during use.

[0017] In this embodiment, the asbestos plus foam fire retardant filler layer 16 is filled in the sub-flame retarder shell 1, the hydrogen-oxygen mixed gas outlet pipe 2 is provided on the top of the sub-flame retarder shell 1, and the explosion-proof film 15 is set on the bottom of the sub-flame retarder shell 1 And the pressure sensor connected to the control circuit (using a pressure of 0.2MPa)14. The mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com