Oxy-hydrogen mixed gas integrated generating device

A technology of mixing gas and generating device, which is applied in the fields of climate sustainability, chemical industry, cells, etc., can solve the problems of imperfect safety settings, low gas production, and high cost, and achieves safe and reliable use, high electrolysis efficiency, and thermal power. less loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

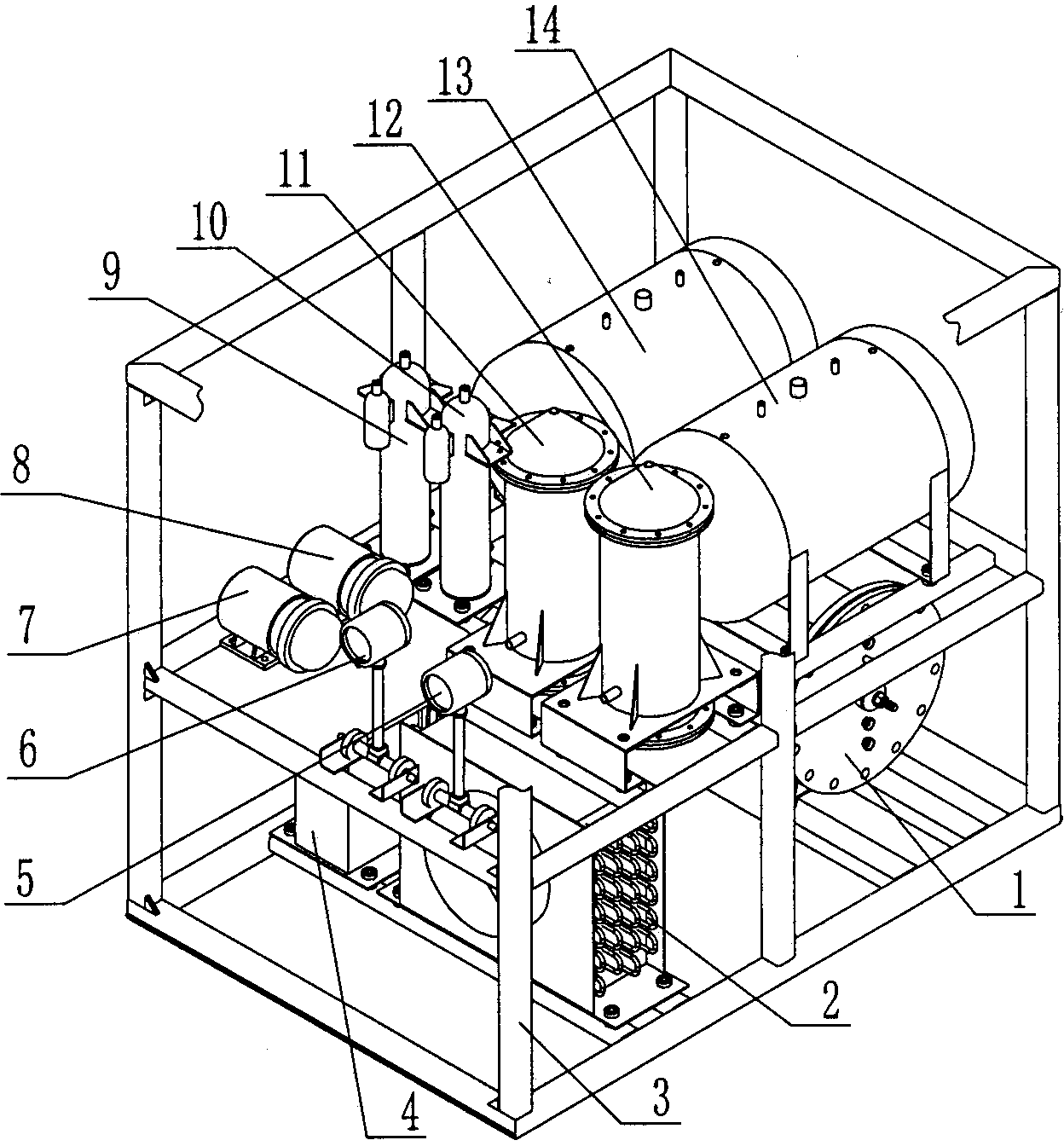

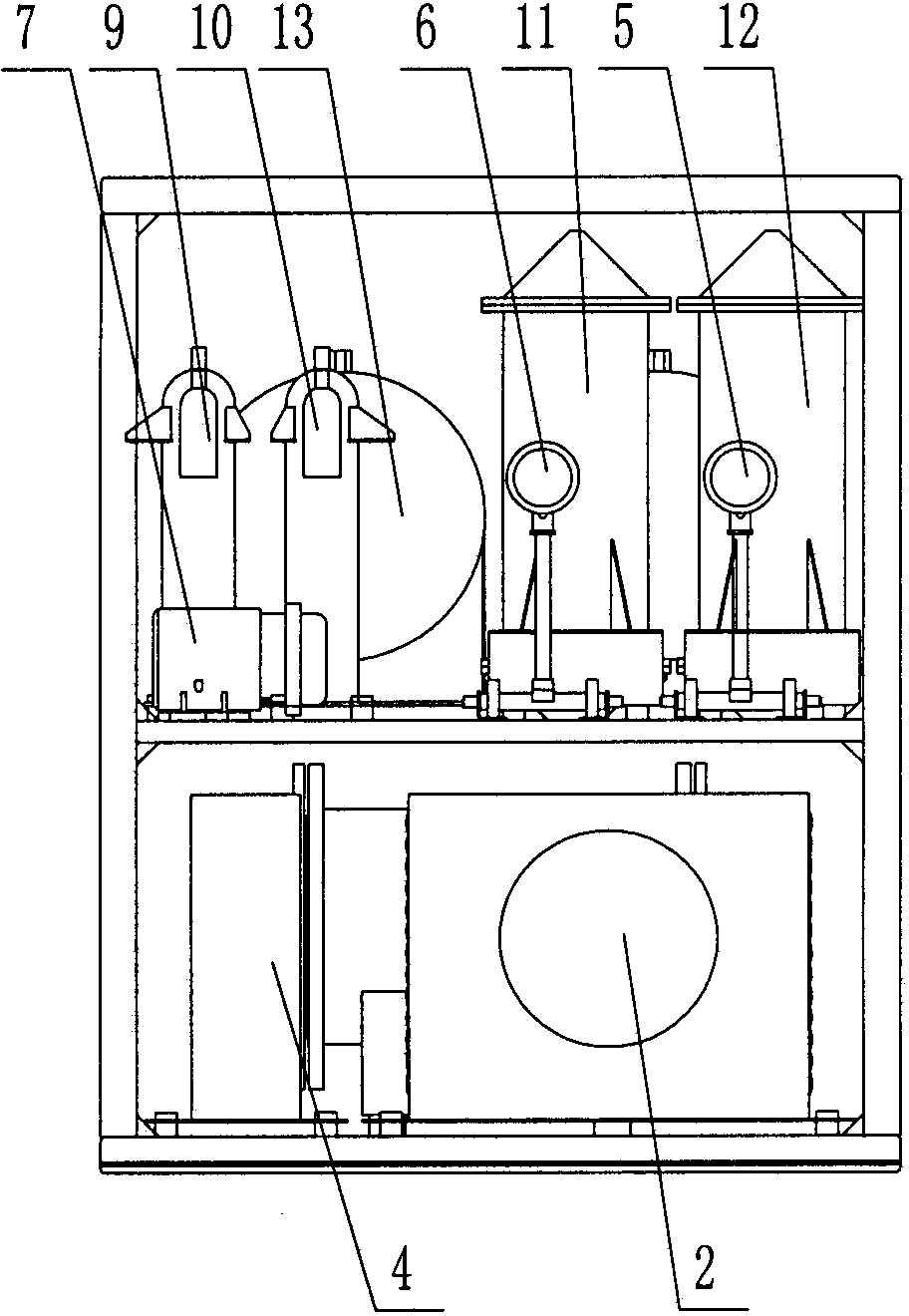

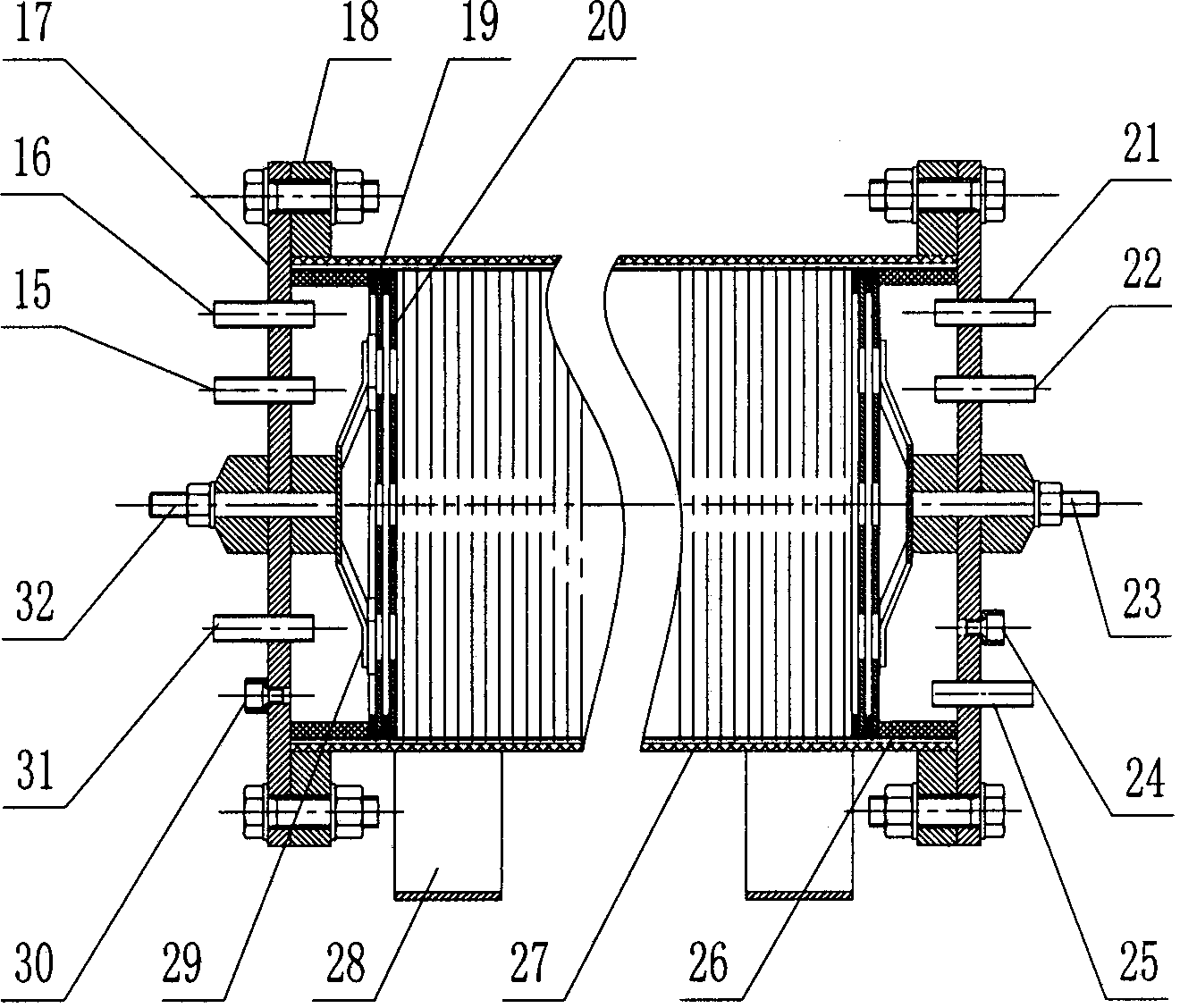

[0041] according to Figure 1-20 The specific structure of the present invention will be described in detail. The hydrogen-oxygen mixed gas integrated generator includes an insulating frame 3, a hydrogen-oxygen mixed gas generator assembled on the insulating frame 3, hydrogen and oxygen flame arresters, hydrogen and oxygen liquid storage filter tanks 14, 13, hydrogen and oxygen Gas storage and water separator 12, 11, heat exchanger 4, radiator 2, temperature sensor 31, liquid level sensor 5, pressure sensor 6, and electrolyte circulation circuit and control circuit and other components. Among them, the hydrogen-oxygen mixed gas generator adopts at least one closed electrolytic water generator 1. When the amount of hydrogen-oxygen mixed gas is small, a closed electrolytic water generator 1 is used, which is an integrated hydrogen-oxygen mixed gas generator of type I structure (such as Figure 1-5 shown), when the amount of hydrogen-oxygen mixed gas is large, two closed electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com