Method for preparing clean steel by coal gas direct reduction one-step method

A pure steel and coal-to-gas technology, applied in the field of smelting reduction ironmaking, can solve the problems of slow reduction speed, long smelting cycle, low efficiency, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] Example 1: Annual production of 100,000 tons of pure steel using iron oxide pellets.

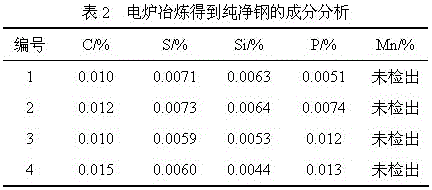

[0105] Raw materials: 1) 73,000 tons of long-flame coal, including 6% ash, 33% volatile matter, 60% fixed carbon, 0.28% sulfur, and a particle size of 40-60mm; 2) 160,000 tons of iron oxide pellets, whose composition See the table below.

[0106]

[0107] Heat long-flame coal at a heating rate of 70°C / min to 650°C for pyrolysis, process 9 tons per hour, and accumulatively obtain 5,800 tons of light tar and 29.2 million Nm of 73,000 tons of long-flame coal 3 Pyrolysis gas, 43,000 tons of spongy fixed carbon. Light tar of which is sold as a commercial product.

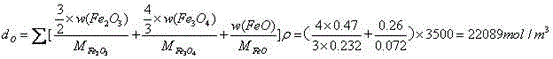

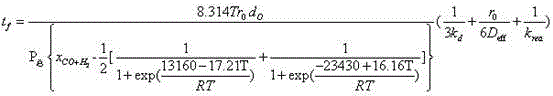

[0108] 60% of the total pyrolysis gas (17.52 million Nm 3 ) as an energy source, heat 68% (29,240 tons) of spongy fixed carbon obtained by pyrolysis to 850-1100°C at a rate of 3.65 tons per hour, and pass 5.18×10 water vapor with a pressure of 0.1MPa and a temperature of 450K 7 N m 3 , the reaction system obtained reduci...

Embodiment 2

[0117] Example 2: 100,000 tons of pure steel is produced annually by using Indonesian sea sand ilmenite.

[0118] Raw materials: 1) 78,000 tons of non-caking coal, including 6% ash, 35% volatile, 62% fixed carbon, 0.26% sulfur, particle size 40~60mm; 2) pellets made of Indonesian sea sand ilmenite The ore is 18,500 tons, and its composition is as follows.

[0119]

[0120] Heat the non-caking coal at a heating rate of 75℃ / min to 680℃ for pyrolysis, process 9 tons per hour, and accumulatively obtain 6197 tons of light tar and 31.2 million Nm of 78,000 tons of non-caking coal 3 Pyrolysis gas and 45,900 tons of spongy fixed carbon.

[0121] 60% of the total pyrolysis gas (1.87 million Nm 3 ) as an energy source, heat 65% (31,200 tons) of the spongy fixed carbon obtained by pyrolysis to 850-1100°C at a rate of 3.9 tons per hour, and feed 5.53×10 water vapor with a pressure of 0.1MPa and a temperature of 450K 7 N m 3 , the reaction system obtains reducing gas, where (CO+H 2 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com