Method for establishing metallurgical coke pore feature parameter prediction model

A technology of characteristic parameters and prediction model, applied in the field of coking, can solve the problem of unpredictable pore structure parameters, and achieve the effect of simple test and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

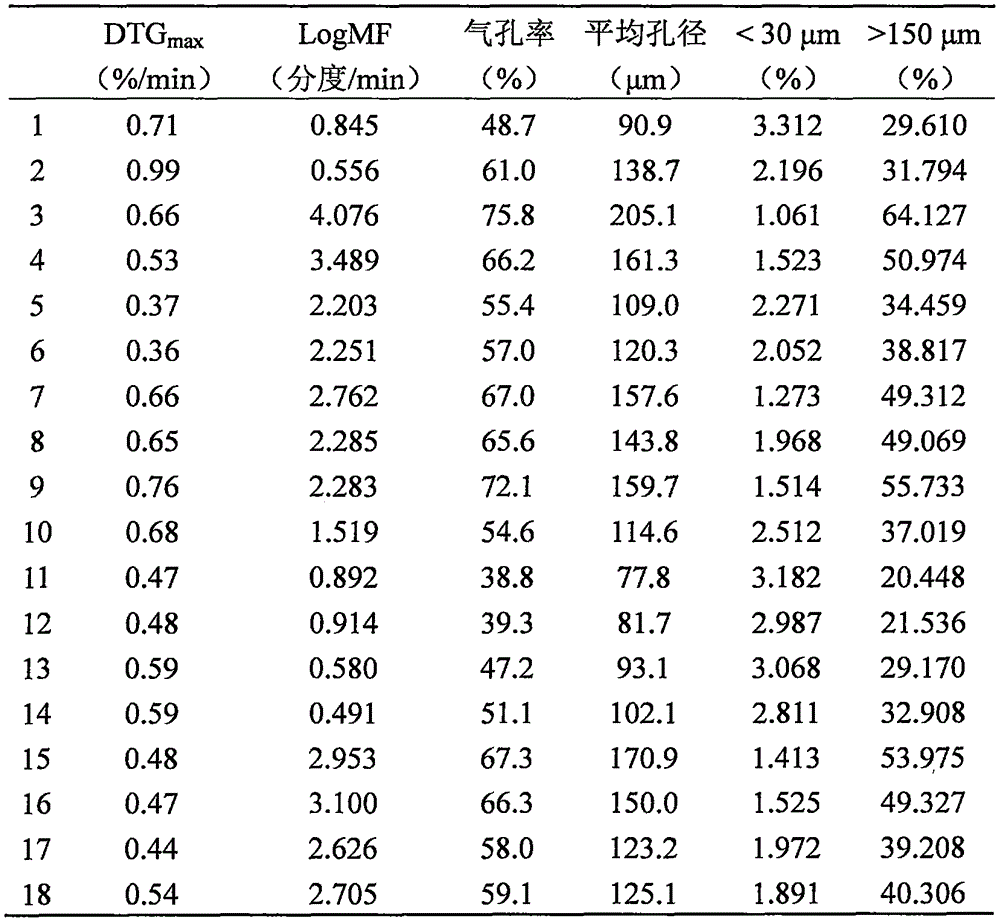

[0017] (1) A total of 18 samples of single coal and its blending coals of different coal ranks were selected, and the samples were subjected to thermogravimetric analysis with a thermal analyzer. The sample size (air-dried coal sample) was 10.0 mg, from 30°C. The temperature is increased to 950°C at a temperature rise rate of 3°C / min, and the argon flow rate is 60ml / min. According to the thermogravimetric test curve, the volatilization of each sample is analyzed to obtain the maximum rate DTG max (% / minute);

[0018] (2) Using a Gee's fluidity tester, measure the Gee's fluidity of 18 samples in accordance with GB / T 25213-2010, and obtain the Gee's maximum fluidity MF (division / min) of each sample;

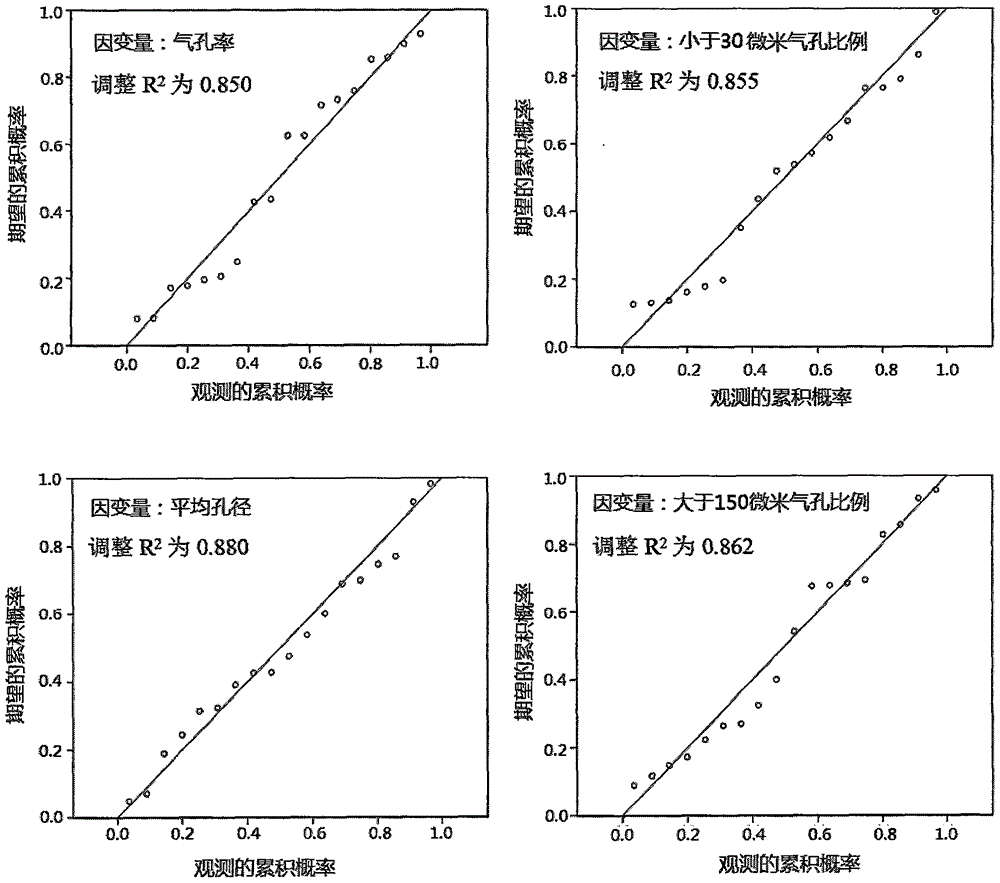

[0019] (3) The coking coal sample is subjected to a coking experiment to obtain a coke sample, and the pore parameters of the coke are detected by image analysis, including the average pore size, porosity, ratio of pores less than 30 microns and ratio of pores greater than 150 microns. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com