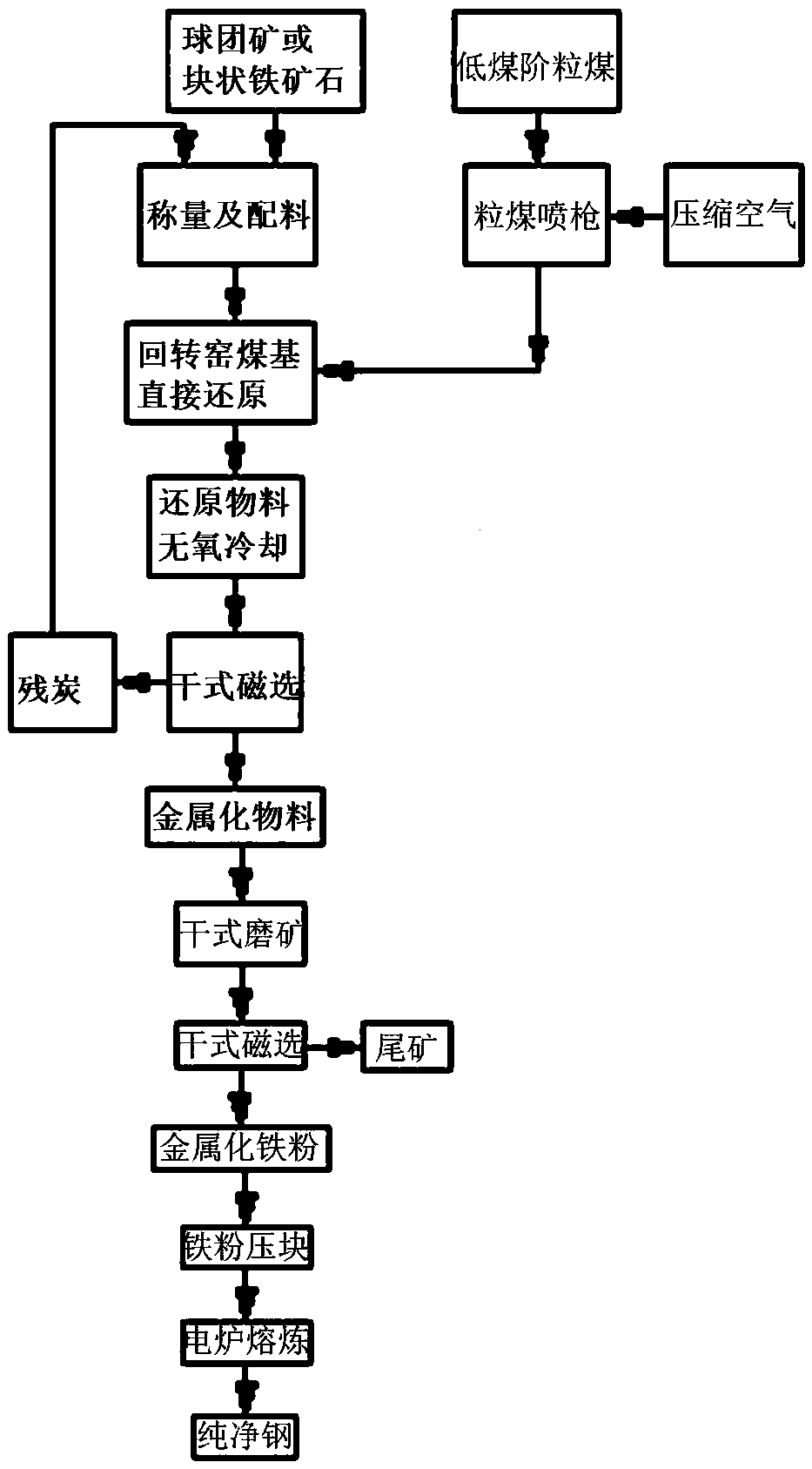

Iron ore low-temperature reduction-normal-temperature slag-iron separation-electric furnace steel making process

A technology for separation of slag and iron, iron ore, applied in electric furnace, process efficiency improvement, furnace and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) After batching and mixing pellets with a particle size of 8-16mm or massive iron ore with a particle size of 10-30mm and residual carbon of 5-10mm at a ratio of 100:15, add them from the kiln inlet end of the rotary kiln. Under the action of high temperature in the rotary kiln, the temperature of the material gradually rises. When the temperature reaches 400-450°C, the iron ore begins to undergo reduction reaction with carbon, and when the temperature reaches 1000-1100°C, the reduction reaction proceeds violently.

[0033] (2) When the reduction reaction of iron ore in the high-temperature section of the rotary kiln progresses to the middle and late stages, the reduction reaction speed decreases. After the kiln is in contact with high-temperature materials, the coal can be pyrolyzed when the temperature reaches 500-900°C during the heating process at 600-800°C / min, and spongy residual carbon and by-product pyrolysis gas and tar can be obtained. It can be used as fue...

Embodiment 2

[0041] (1) After batching and mixing pellets with a particle size of 8-16mm or massive iron ore with a particle size of 10-30mm and residual carbon of 5-10mm at a ratio of 100:12, add them from the kiln inlet end of the rotary kiln. Under the action of high temperature in the rotary kiln, the temperature of the material gradually rises. When the temperature reaches 400-450°C, the iron ore begins to undergo reduction reaction with carbon, and when the temperature reaches 1000-1100°C, the reduction reaction proceeds violently.

[0042] (2) When the reduction reaction of iron ore in the high-temperature section of the rotary kiln progresses to the middle and late stages, the reduction reaction speed decreases. After the kiln is in contact with high-temperature materials, the coal can be pyrolyzed when the temperature reaches 500-900°C during the heating process at 600-800°C / min, and spongy residual carbon and by-product pyrolysis gas and tar can be obtained. It can be used as fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com