Thermal power unit coal-burning thermal value real time monitoring method and thermal value observer

A technology of thermal power unit and coal-fired calorific value, applied in instruments, simulators, computer control, etc., can solve problems such as difficult and difficult boiler combustion dynamic characteristics, without considering boiler animal heat energy, etc., to avoid over-temperature and over-pressure, The effect of fast response and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

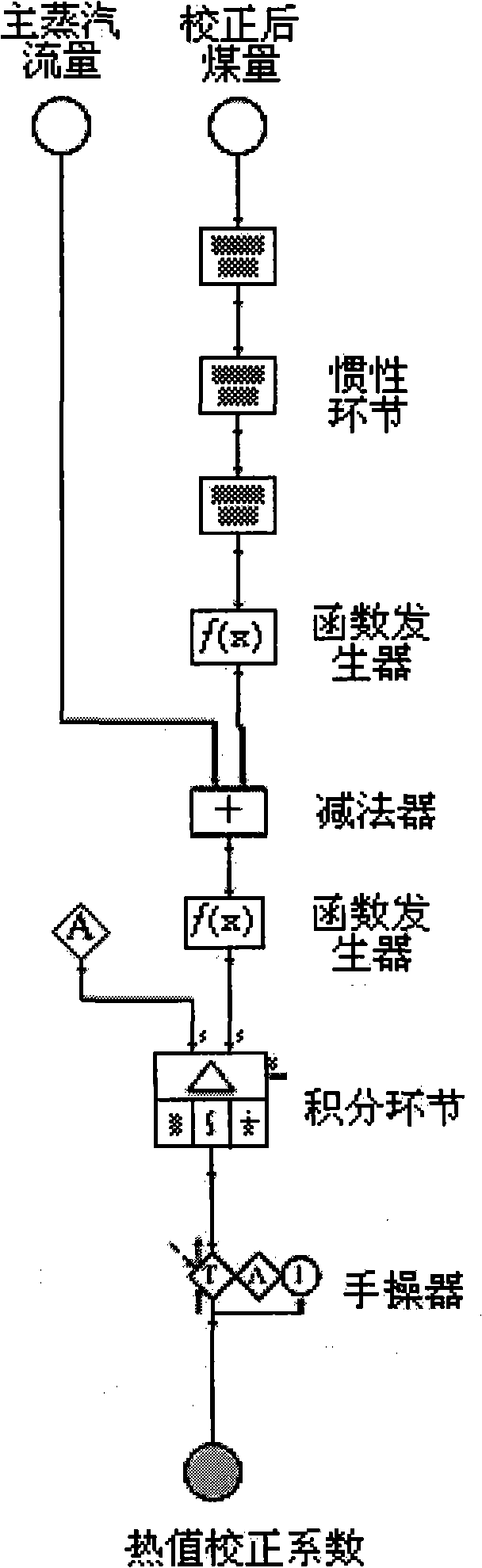

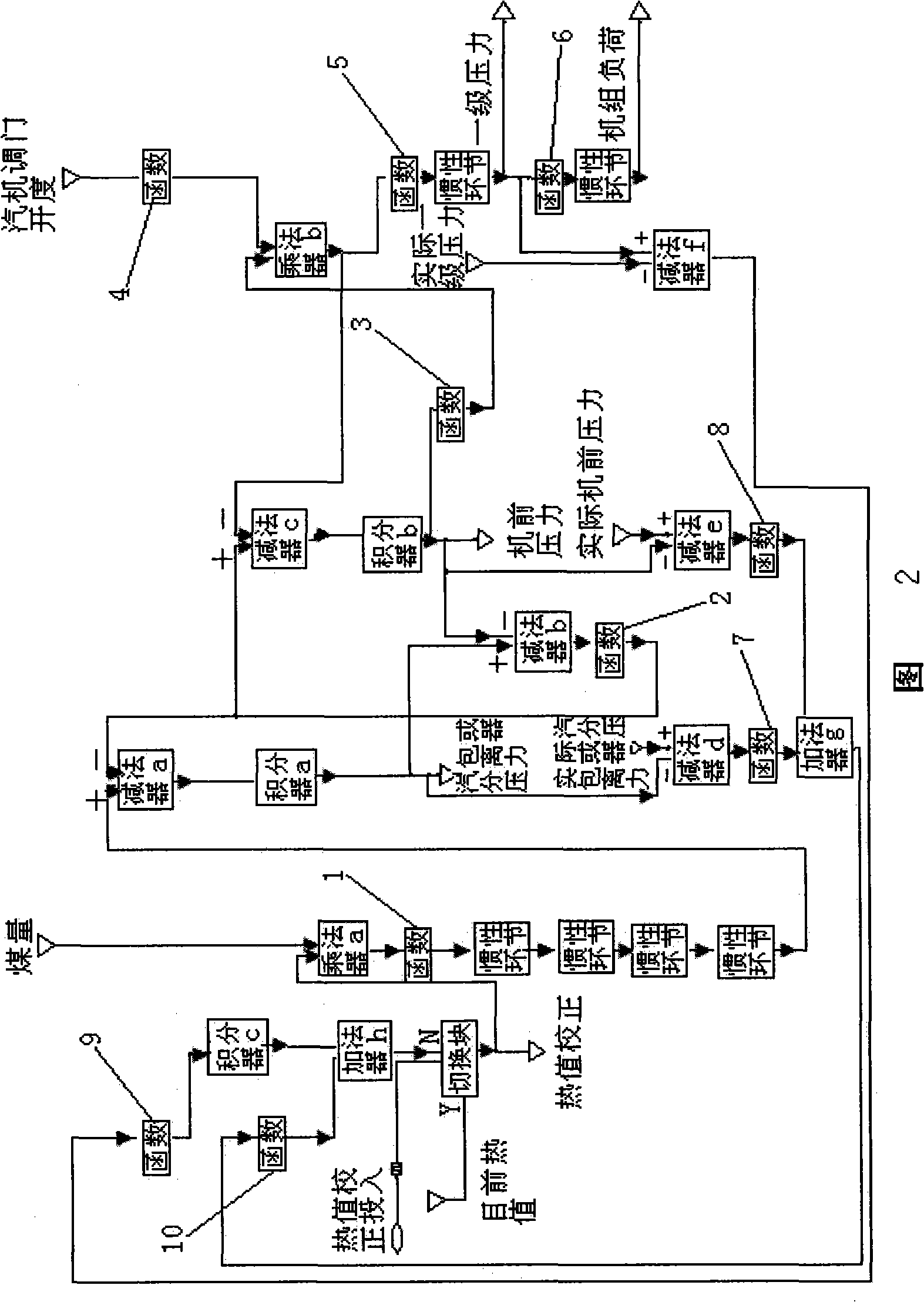

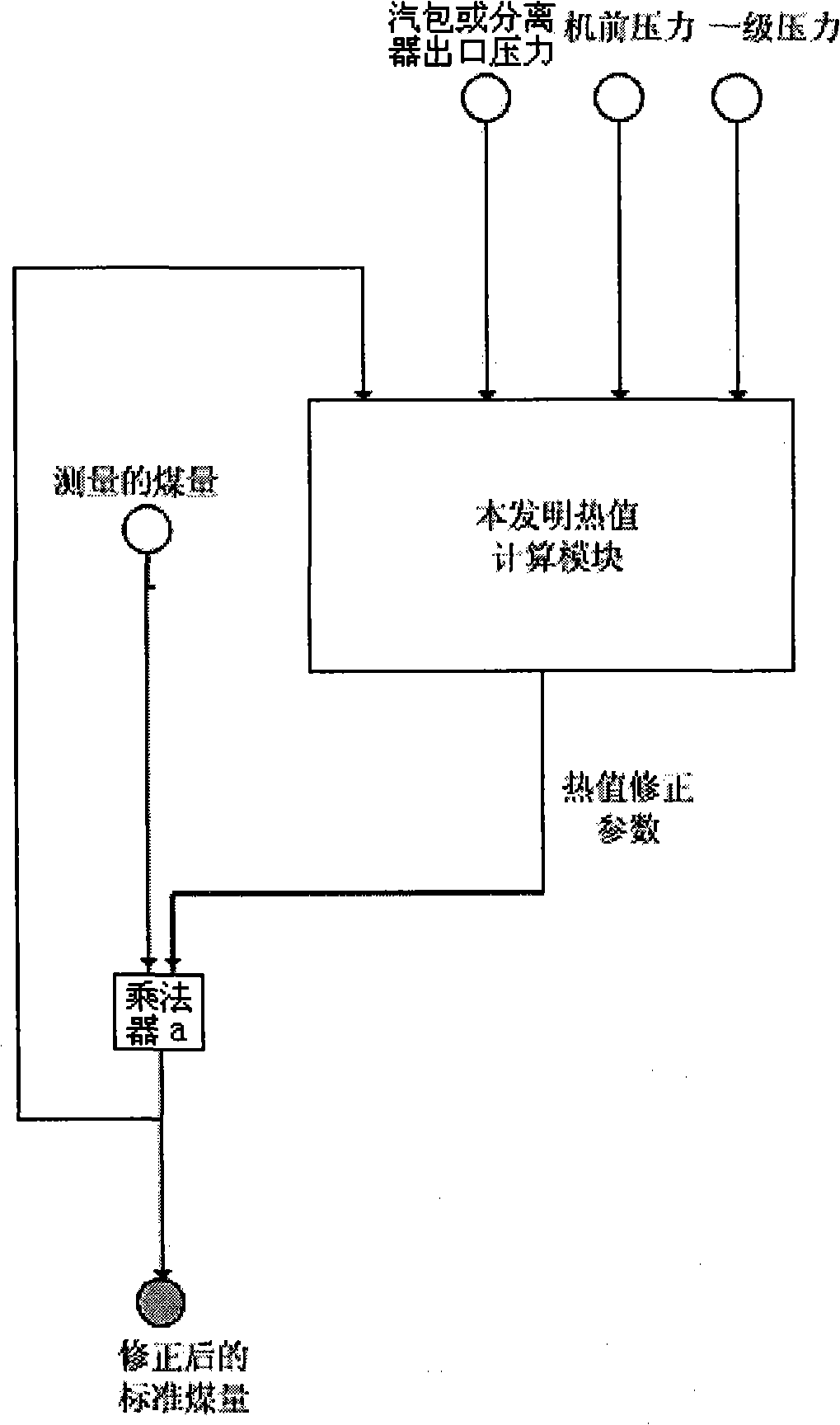

[0017] As shown in Figure 2, the calorific value observer of the present invention is established based on the dynamic characteristics of thermal power units and using the law of energy conservation. It includes two parts: the unit model and the calorific value correction loop. The unit model includes a group of function generators 1 to 6. The input terminal of function generator 1 is connected to a multiplier a, and its output terminal is input to the + input terminal of subtractor a after passing through four inertia links. One input of the multiplier a is connected to the calorific value correction circuit, and the other input is the amount of coal. The input variable of the function generator 1 is the coal volume corrected by the calorific value, and its output is the intermediate reference variable - the main steam flow rate. Its function is to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com